engine coolant SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 291 of 1082

15-150000-00

5. Pilot Flow Control

The pilot flow represents the amount of fuel injected into the cylinder during the pilot injection. This

amount is determined according to the engine speed and the total flow.

A first correction is made according to the air and water temperature.

This correction allows the pilot flow to be adapted to the operating temperature of the engine. When

the engine is warm, the ignition time decreases because the end-of-compression temperature is

higher. The pilot flow can therefore be reduced because there is obviously less combustion noise

when the engine is warm.

A second correction is made according to the atmospheric pressure. -

-

During starting, the pilot flow is determined on the basis of the engine speed and the coolant

temperature.

6. Cylinder Balancing Strategy

Balancing of the point to point flows ▶

The pulse of each injector is corrected according to the difference in instantaneous speed measured

between 2 successive injectors.

The instantaneous speeds on two successive injections are first calculated.

The difference between these two instantaneous speeds is then calculated.

Finally, the time to be added to the main injection pulse for the different injectors is determined. For each

injector, this time is calculated according to the initial offset of the injector and the instantaneous speed

difference.

Detection of an injector which has stuck closed ▶

The cylinder balancing strategy also allows the detection of an injector which has stuck closed. The

difference in instantaneous speed between 2 successive injections then exceeds a predefined threshold.

In this case, a fault is signaled by the system.

Page 295 of 1082

15-190000-00

HFM

Accelerator pedalCoolant

temperature

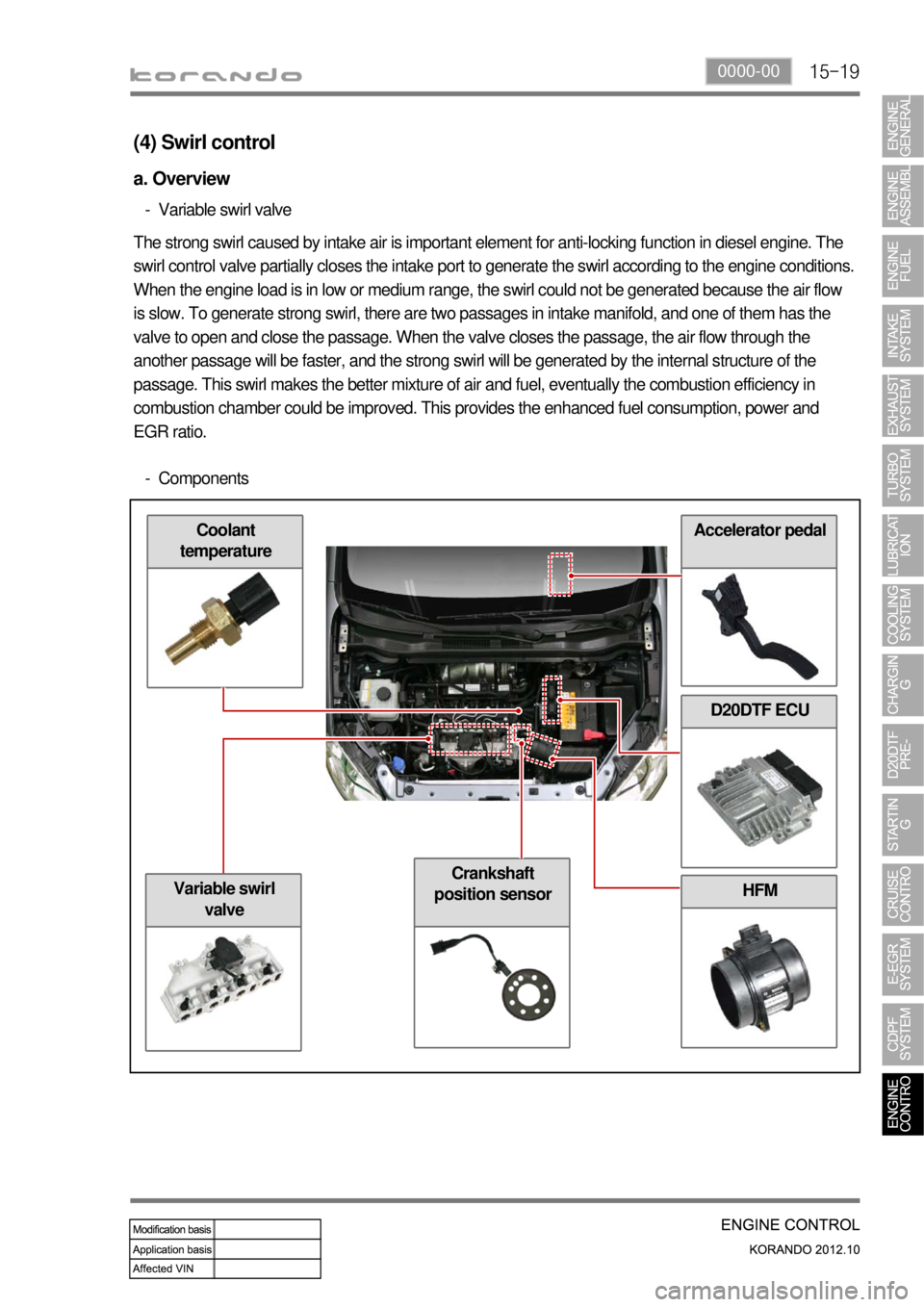

(4) Swirl control

a. Overview

Variable swirl valve -

The strong swirl caused by intake air is important element for anti-locking function in diesel engine. The

swirl control valve partially closes the intake port to generate the swirl according to the engine conditions.

When the engine load is in low or medium range, the swirl could not be generated because the air flow

is slow. To generate strong swirl, there are two passages in intake manifold, and one of them has the

valve to open and close the passage. When the valve closes the passage, the air flow through the

another passage will be faster, and the strong swirl will be generated by the internal structure of the

passage. This swirl makes the better mixture of air and fuel, eventually the combustion efficiency in

combustion chamber could be improved. This provides the enhanced fuel consumption, power and

EGR ratio.

Components -

D20DTF ECU

Crankshaft

position sensor

Variable swirl

valve

Page 300 of 1082

15-24

HFM sensor

(intake air temp.)

Oxygen sensorD20DTF ECU

T-MAP sensor

(5) EGR control

a. Overview

The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating

some of the exhaust gas to the intake system.

The major difference with the previous EURO 4 type, is that the DC motor with improved response rate

according to the EURO 5 regulation. The solenoid type actuator is used in the conventional model, but in

this new model, the DC motor type actuator with improved response rate is adopted. Also the hall senso

r

which provides a more stabilized signal than the potentiometer, and the EGR bypass flap which

improves engine warming up efficiency are also used. The HFM sensor and the position sensor are

used to feedback the amount of EGR for both EURO 4 and EURO 5.

b. Components

Electronic

throttle body

Coolant

temp.sensor

E-EGR valveCrankshaft posi.

sensor

Accelerator

pedalE-EGR cooler

Page 302 of 1082

15-26

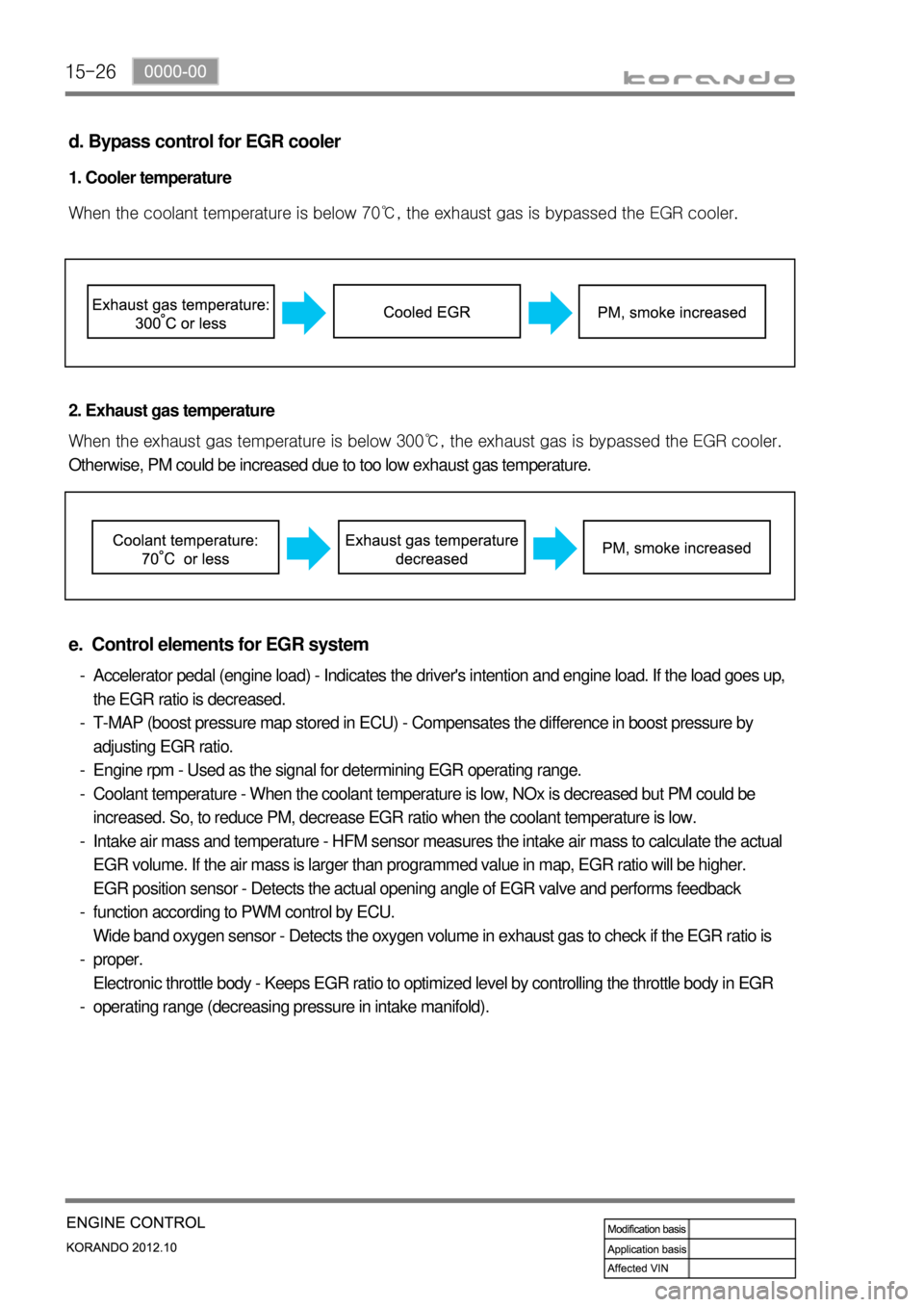

d. Bypass control for EGR cooler

1. Cooler temperature

<007e008f008c00950047009b008f008c0047008a00960096009300880095009b0047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c00930096009e0047005e00570b4500530047009b008f008c0047008c009f008f00

88009c009a009b0047008e0088009a00470090009a00470089>ypassed the EGR cooler.

2. Exhaust gas temperature

<007e008f008c00950047009b008f008c0047008c009f008f0088009c009a009b0047008e0088009a0047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c00930096009e0047005a005700570b4500530047009b008f00

8c0047008c009f008f0088009c009a009b0047008e0088009a> is bypassed the EGR cooler.

Otherwise, PM could be increased due to too low exhaust gas temperature.

e. Control elements for EGR system

Accelerator pedal (engine load) - Indicates the driver's intention and engine load. If the load goes up,

the EGR ratio is decreased.

T-MAP (boost pressure map stored in ECU) - Compensates the difference in boost pressure by

adjusting EGR ratio.

Engine rpm - Used as the signal for determining EGR operating range.

Coolant temperature - When the coolant temperature is low, NOx is decreased but PM could be

increased. So, to reduce PM, decrease EGR ratio when the coolant temperature is low.

Intake air mass and temperature - HFM sensor measures the intake air mass to calculate the actual

EGR volume. If the air mass is larger than programmed value in map, EGR ratio will be higher.

EGR position sensor - Detects the actual opening angle of EGR valve and performs feedback

function according to PWM control by ECU.

Wide band oxygen sensor - Detects the oxygen volume in exhaust gas to check if the EGR ratio is

proper.

Electronic throttle body - Keeps EGR ratio to optimized level by controlling the throttle body in EGR

operating range (decreasing pressure in intake manifold). -

-

-

-

-

-

-

-

Page 304 of 1082

15-28

Accelerator

pedal

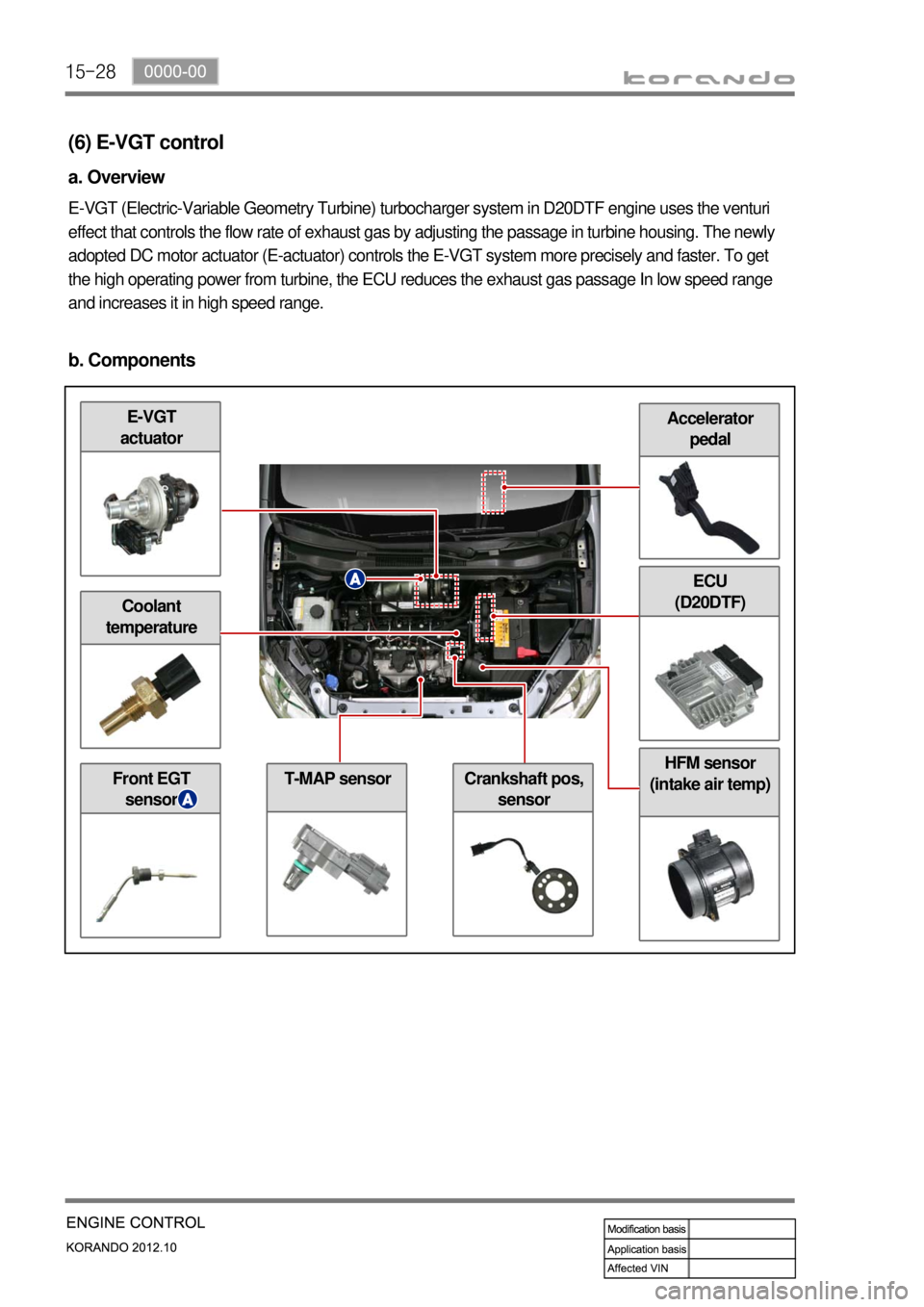

(6) E-VGT control

a. Overview

E-VGT (Electric-Variable Geometry Turbine) turbocharger system in D20DTF engine uses the venturi

effect that controls the flow rate of exhaust gas by adjusting the passage in turbine housing. The newly

adopted DC motor actuator (E-actuator) controls the E-VGT system more precisely and faster. To get

the high operating power from turbine, the ECU reduces the exhaust gas passage In low speed range

and increases it in high speed range.

b. Components

E-VGT

actuator

Coolant

temperature

Front EGT

sensorT-MAP sensorCrankshaft pos,

sensor

HFM sensor

(intake air temp)

ECU

(D20DTF)

Page 306 of 1082

15-30

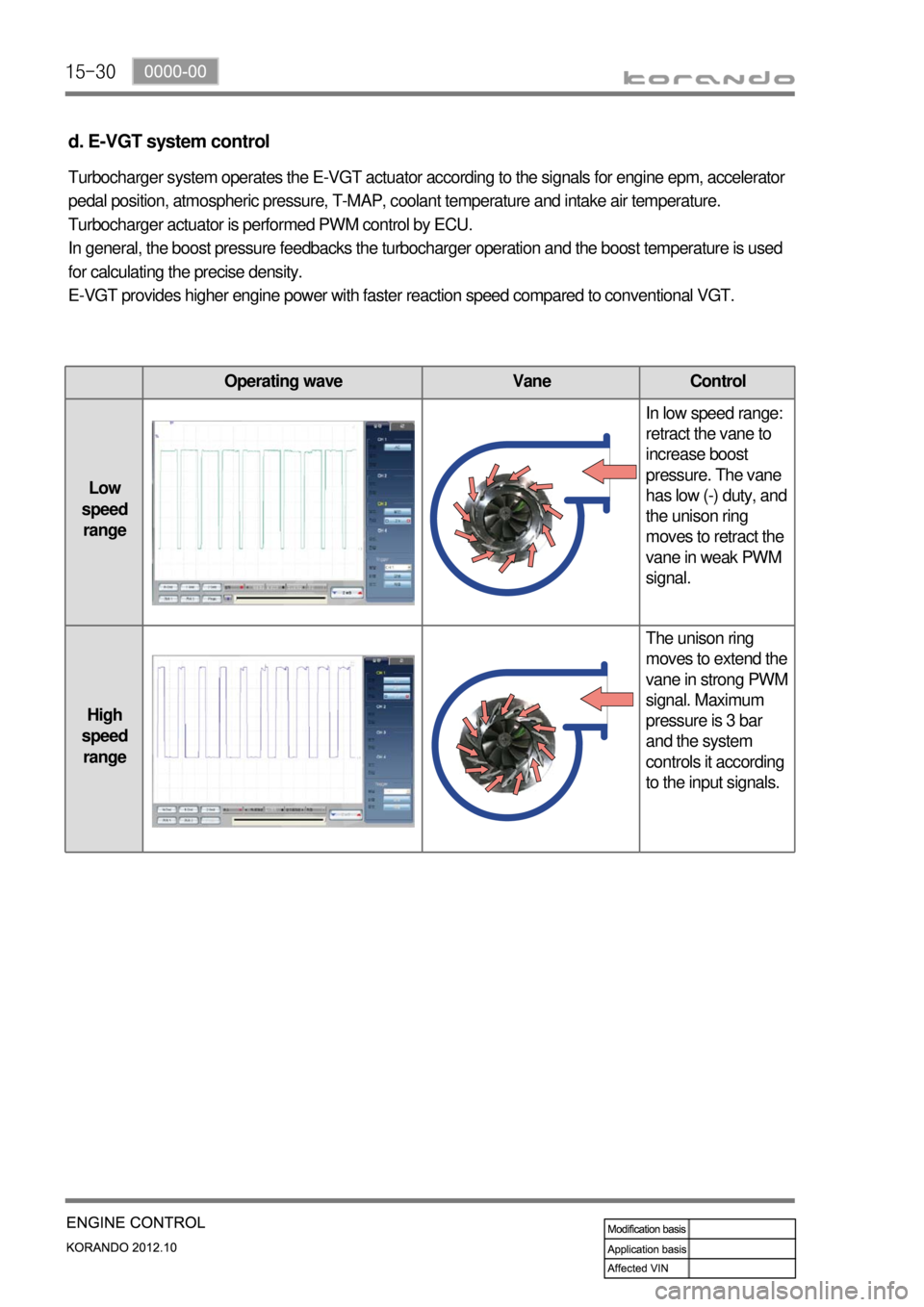

d. E-VGT system control

Turbocharger system operates the E-VGT actuator according to the signals for engine epm, accelerator

pedal position, atmospheric pressure, T-MAP, coolant temperature and intake air temperature.

Turbocharger actuator is performed PWM control by ECU.

In general, the boost pressure feedbacks the turbocharger operation and the boost temperature is used

for calculating the precise density.

E-VGT provides higher engine power with faster reaction speed compared to conventional VGT.

Operating wave Vane Control

Low

speed

rangeIn low speed range:

retract the vane to

increase boost

pressure. The vane

has low (-) duty, and

the unison ring

moves to retract the

vane in weak PWM

signal.

High

speed

rangeThe unison ring

moves to extend the

vane in strong PWM

signal. Maximum

pressure is 3 bar

and the system

controls it according

to the input signals.

Page 307 of 1082

15-310000-00

HFM sensor

(air mass)

CDPF

(7) Wide band oxygen sensor

a. Overview

For diesel engine, combustion is not performed at the optimum (theoretically correct) air-fuel ratio and

the oxygen concentration is thin in most cases. So the wide-band oxygen sensor is used for this kind of

engine, and this sensor is a little different from the one that used for gasoline engine. The combustion in

diesel engine is controlled by fuel injection volume. Therefore, the wide band oxygen sensor should be

used in diesel engine. This sensor measures the air-fuel ratio in very wide range, and is also called full

range oxygen sensor.

The wide band oxygen sensor measures the oxygen density in exhaust gas and sends it to ECU to

control the EGR more precisely. -

b. Components

D20DTF

ECU

EGR valveElectronic

throttle bodyCoolant temp.

sensor

Oxygen

sensorInjector (C3I)

Page 310 of 1082

15-34

Coolant temp.

sensor

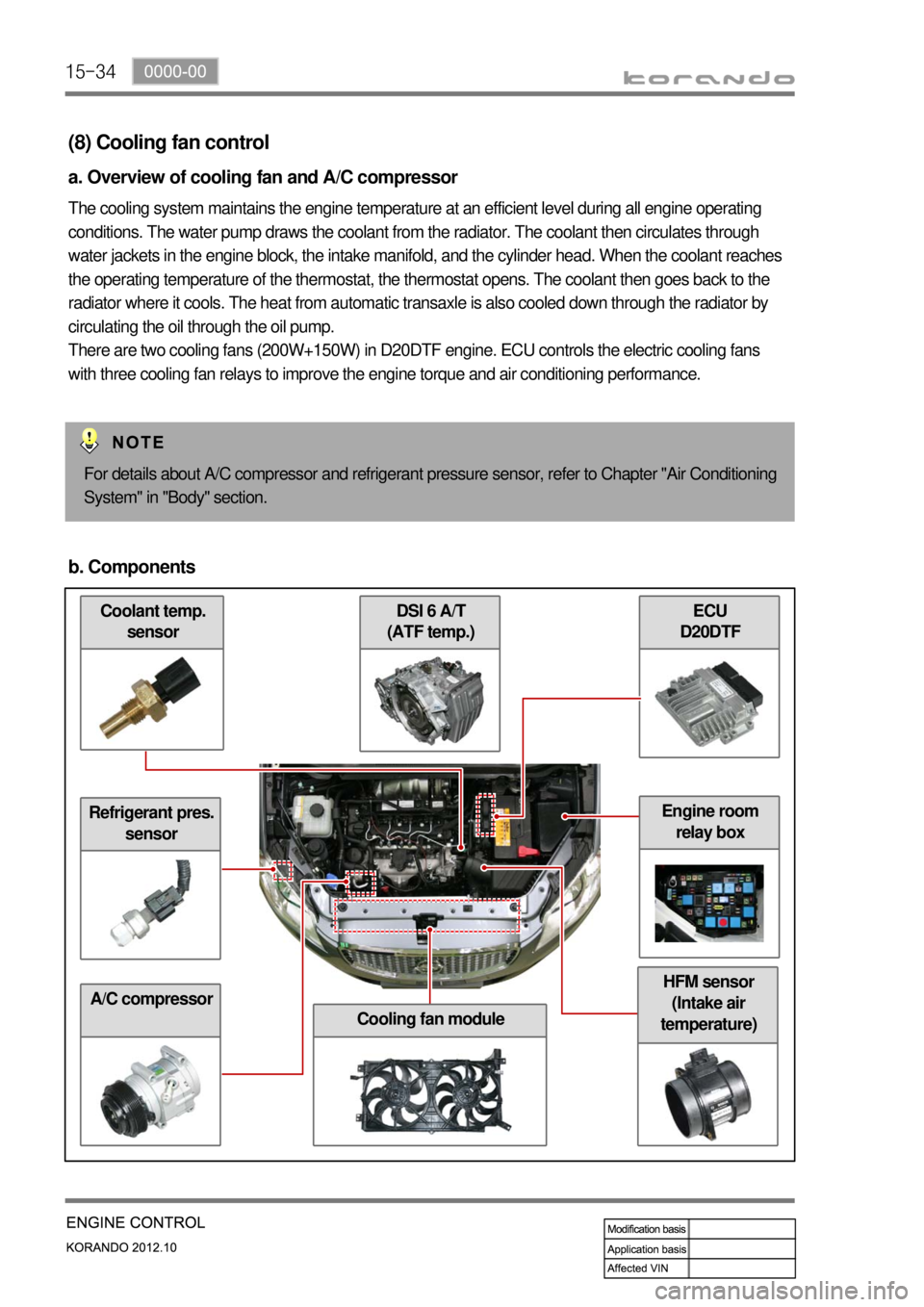

(8) Cooling fan control

a. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump.

There are two cooling fans (200W+150W) in D20DTF engine. ECU controls the electric cooling fans

with three cooling fan relays to improve the engine torque and air conditioning performance.

For details about A/C compressor and refrigerant pressure sensor, refer to Chapter "Air Conditioning

System" in "Body" section.

b. Components

Refrigerant pres.

sensor

A/C compressor

ECU

D20DTF DSI 6 A/T

(ATF temp.)

Cooling fan module

HFM sensor

(Intake air

temperature)

Engine room

relay box

Page 312 of 1082

15-36

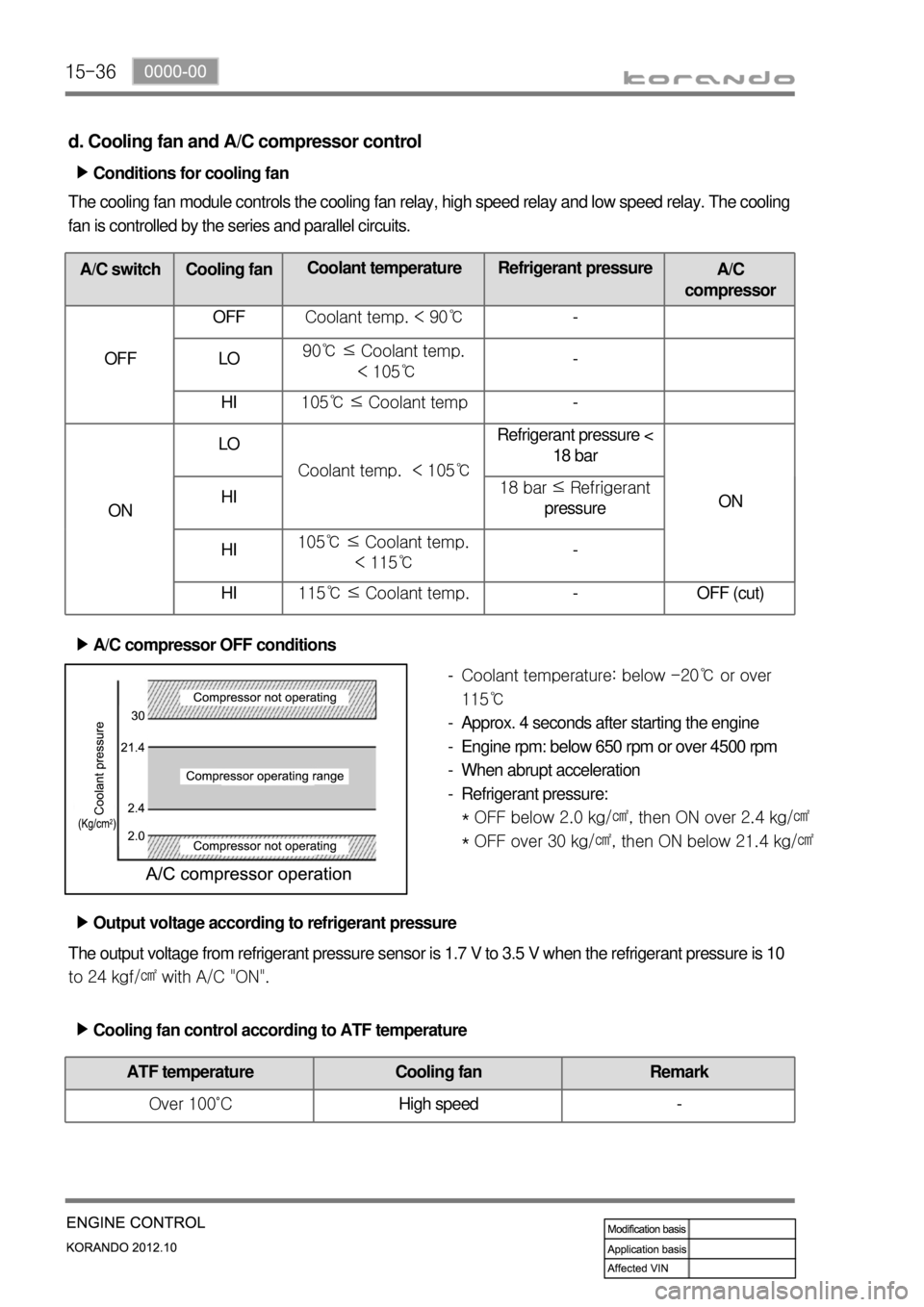

d. Cooling fan and A/C compressor control

Conditions for cooling fan ▶

The cooling fan module controls the cooling fan relay, high speed relay and low speed relay. The cooling

fan is controlled by the series and parallel circuits.

A/C switch Cooling fanCoolant temperature Refrigerant pressure

A/C

compressor

OFF OFF Coolant temp. < 90℃-

LO 90℃ ≤ Coolant temp.

< 105℃-

HI105℃ ≤ Coolant temp-

ONLO

Coolant temp. < 105℃Refrigerant pressure <

18 bar

ON HI18 bar ≤ Refrigerant

pressure

HI105℃ ≤ Coolant temp.

< 115℃-

HI115℃ ≤ Coolant temp. - OFF (cut)

A/C compressor OFF conditions ▶

Coolant temperature: below -20℃ or over

115℃

Approx. 4 seconds after starting the engine

Engine rpm: below 650 rpm or over 4500 rpm

When abrupt acceleration

Refrigerant pressure:

* OFF below 2.0 kg/㎠, then ON over 2.4 kg/㎠

* OFF over 30 kg/㎠, then ON below 21.4 kg/㎠ -

-

-

-

-

The output voltage from refrigerant pressure sensor is 1.7 V to 3.5 V when the refrigerant pressure is 10

to 24 kgf/㎠ with A/C "ON".Output voltage according to refrigerant pressure ▶

Cooling fan control according to ATF temperature ▶

ATF temperature Cooling fan Remark

Over 100˚CHigh speed -

Page 313 of 1082

15-370000-00

HFM

(Intake air temp.)Coolant temp.

sensor

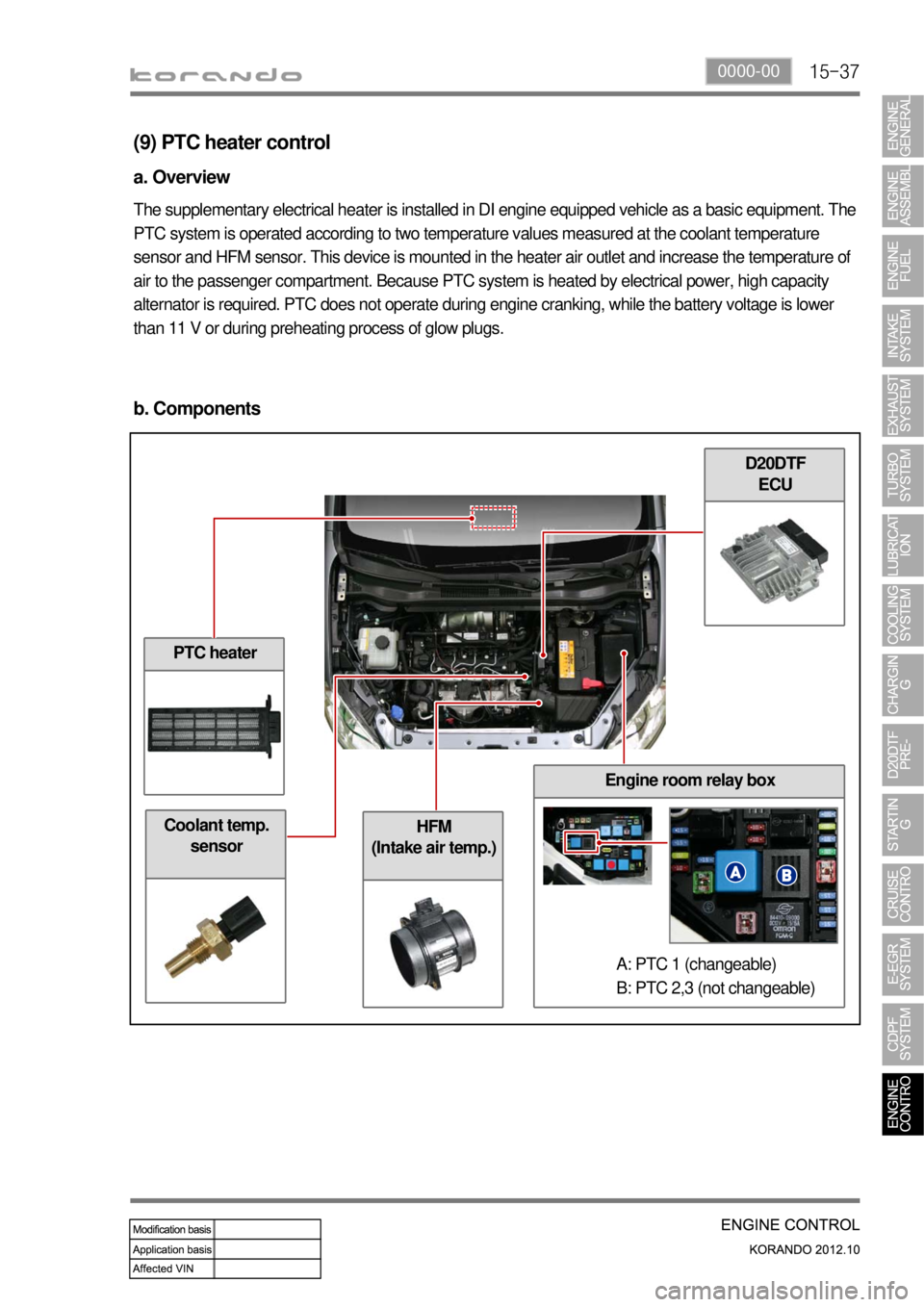

(9) PTC heater control

a. Overview

The supplementary electrical heater is installed in DI engine equipped vehicle as a basic equipment. The

PTC system is operated according to two temperature values measured at the coolant temperature

sensor and HFM sensor. This device is mounted in the heater air outlet and increase the temperature of

air to the passenger compartment. Because PTC system is heated by electrical power, high capacity

alternator is required. PTC does not operate during engine cranking, while the battery voltage is lower

than 11 V or during preheating process of glow plugs.

b. Components

PTC heater

D20DTF

ECU

Engine room relay box

A: PTC 1 (changeable)

B: PTC 2,3 (not changeable)