wheel SSANGYONG KORANDO 2012 Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 911 of 1082

06-54110-01

2. TORQUE STEER

Torque steer is a condition in which a vehicle pulls to either side because of an inequality of traction

between the left and right driving wheels when a large torque is applied to the front wheel of a FWD or

4WD.

Especially for a FWD vehicle, this mechanical condition can cause the steering effect because of the

output torque (rotational force) produced by the gyroscope.

This rotational force is due to the difference in distance between the left/right front wheels and the

transaxle which leads to the change of the shaft bending angle.

To prevent this, the intermediate shaft, called Intermediate shaft, is employed on each side so that the

bending angle and the length are kept constant.

A gyroscope is a device for measuring or maintaining orientation, based on the principles of angular

momentum. In essence, a mechanical gyroscope is a spinning wheel or disk whose axle is free to

take any orientation. Although this orientation does not remain fixed, it changes in response to an

external torque much less and in a different direction than it would without the large angular

momentum associated with the disk's high rate of spin and moment of inertia. Since external torque

is minimized by mounting the device in gimbals, its orientation remains nearly fixed, regardless of

any motion of the platform on which it is mounted.

Page 912 of 1082

06-6

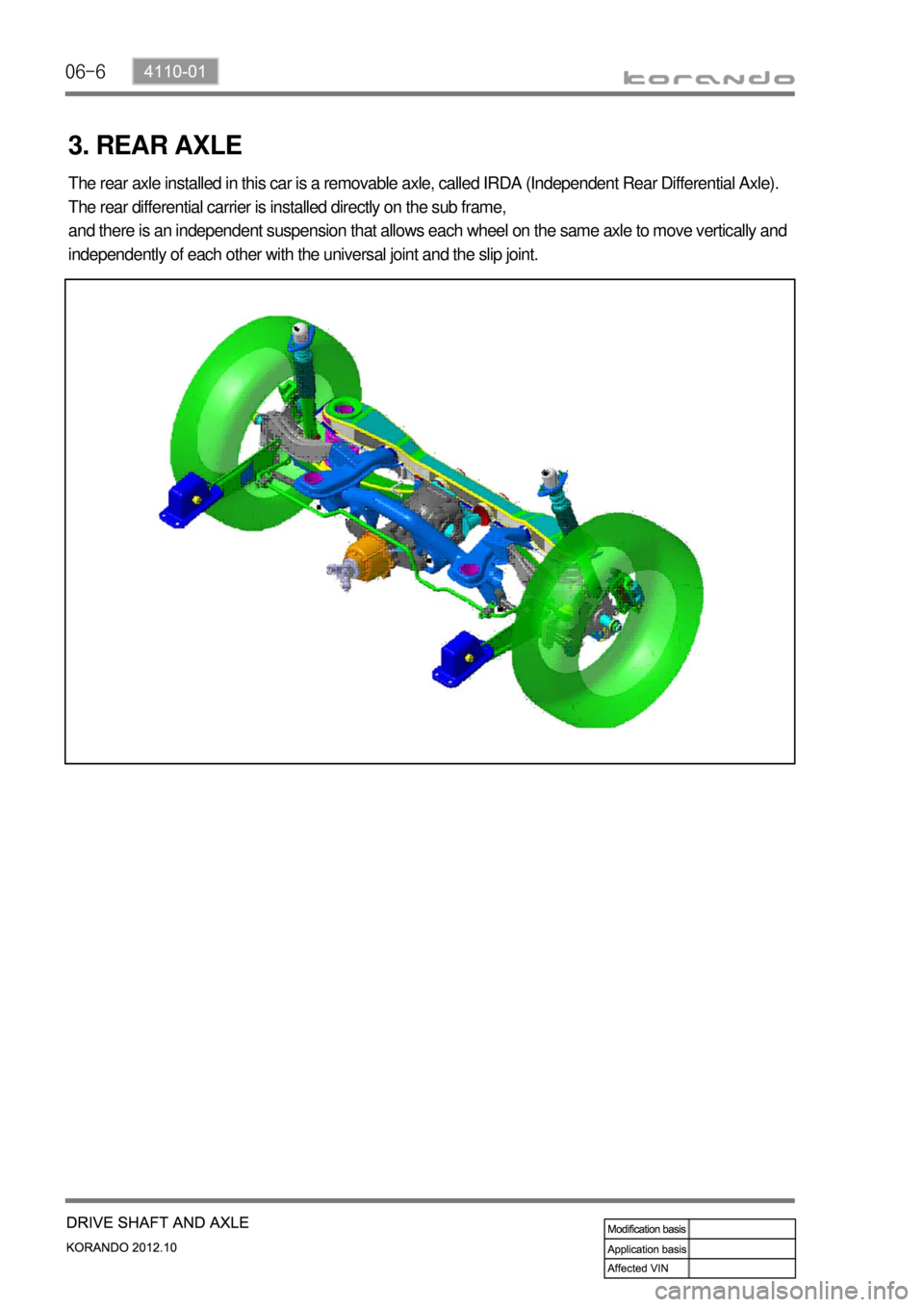

3. REAR AXLE

The rear axle installed in this car is a removable axle, called IRDA (Independent Rear Differential Axle).

The rear differential carrier is installed directly on the sub frame,

and there is an independent suspension that allows each wheel on the same axle to move vertically and

independently of each other with the universal joint and the slip joint.

Page 914 of 1082

07-4

1. OVERVIEW

The AWD system in this vehicle is the electronic 4WD system and controls the traction to rear wheels

according to the driving conditions.

1) Driving Mode

(1) AUTO mode (Normal driving mode)

Normally the vehicle is in 2WD mode.

Automatically change to this mode when the vehicle needs higher traction.

(2) LOCK mode (when pressing 4WD LOCK switch)

This mode provides the highest traction. Use

this mode when driving on unpaved, rugged,

steep, sandy, wet or slippery roads.

In 4WD LOCK mode, if the rear wheel speed

exceeds 40 km/h, 4WD LOCK mode is

canceled and 4WD AUTO mode is activated

(Indicator OFF). If the speed is decreased

below 35 km/h, 4WD LOCK mode is resumed

(Indicator ON again). -

-

Mode table ▶

4WD LOCK switch Vehicle speed Driving mode

Not pressed (4WD AUTO) No conditions 4WD AUTO

Pressed (4WD LOCK) over 40 km/h 4WD AUTO

Pressed (4WD LOCK) below 35 km/h 4WD LOCK

Page 915 of 1082

07-50000-00

2. SYSTEM LAYOUT

1) Components

(1) PTU (Power Transfer Unit)

<007b008f008c004700970096009e008c00990047009b009900880095009a008d008c00990047009c00950090009b0047009000950047009b008f008c0047008d009900960095009b0047009e008f008c008c00930047008b00990090009d008c0047009400

96008b008c00930047008a008f00880095008e008c009a0047>the angle of engine torque to 90°

and transfer it to E-coupling to distribute the torque to rear wheels.

(2) E-Coupling (Electronic Coupling)

E-Coupling transfer the engine torque from PTU to rear axle and controls to distribute it between front

wheels and rear wheels.

(3) E-Coupling Control Unit (ECU)

E-Coupling controls the current (clutch engagement force) of EMCD in E-Coupling according to CAN

signals (wheel speed, engine torque, pedal position, ABS/ESP signals).

* EMCD: Electro-Magnetic Control Device PTU assemblyE-coupling control unit

(located on the floor under driver seat)E-coupling

Page 917 of 1082

08-4

1) Wheel Alignment

System Description Specification

Front Ground clearance (A)76.8 ± 5 mm

Trim height : wheel

center ↔ Wheel

house433 mm

Camber (maintenance

free)-0.15 ± 0.5˚

Caster (maintenance

free)4.8 ± 0.5˚

Total toe-in0.0 ± 0.1˚

(adjust by tie rod)

King pin angle12.85˚

Rear Ground clearance (A)63.3 ± 5 mm

Trim height : wheel

center ↔ Wheel

house437 mm

Camber (maintenance

free)-0.5 ± 0.5˚

[ adjust by cam bolt on

upper arm ]

Total toe-in0.0 ± 0.1˚

[ adjust by cam bolt on

track rod ]

Page 921 of 1082

08-8

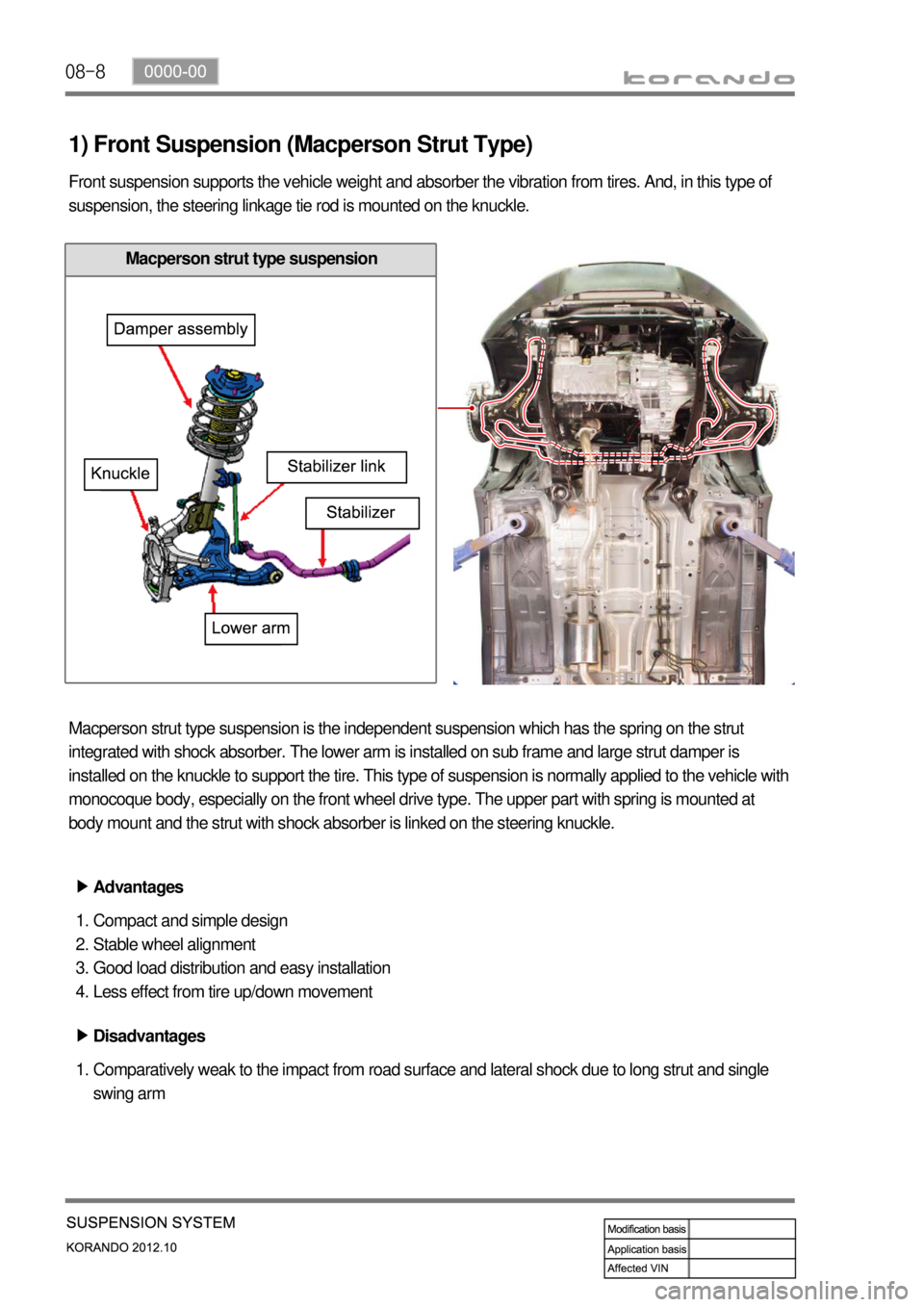

1) Front Suspension (Macperson Strut Type)

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle.

Macperson strut type suspension is the independent suspension which has the spring on the strut

integrated with shock absorber. The lower arm is installed on sub frame and large strut damper is

installed on the knuckle to support the tire. This type of suspension is normally applied to the vehicle with

monocoque body, especially on the front wheel drive type. The upper part with spring is mounted at

body mount and the strut with shock absorber is linked on the steering knuckle.

Advantages ▶

Compact and simple design

Stable wheel alignment

Good load distribution and easy installation

Less effect from tire up/down movement 1.

2.

3.

4.

Disadvantages ▶

Comparatively weak to the impact from road surface and lateral shock due to long strut and single

swing arm 1.

Macperson strut type suspension

Page 924 of 1082

09-4

3) Parts Arrangement

Part nameVehicle with

CBSVehicle with ABS/EBDVehicle with

ESP

HECU

Not appliedAppliedApplied Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator

Longitudinal G sensor 2WD: N/A, 4WD: Applied Not applied

Sensor cluster

(Yaw rate sensor,

lateral/longitudinal G sensor)

Not applied Applied

ESP indicator

ESP OFF switch and warning

lamp

Steering wheel angle sensor

Page 925 of 1082

09-54850-00

F. Front/rear wheel speed sensor

Front/rear-4WD Rear-2WDH. Parking brake

A. Meter cluster-ABS, EBD, ESP

indicator/warning lampB. Master cylinder and

boosterC. HECU

G. Brake pedal

4) Component

ABS warning lamp

ESP indicator

D. Front brake

assembly

E. Rear brake

assembly

Disc

Disc

Parking brake

warning lamp

Caliper

Caliper

Page 927 of 1082

09-74850-00

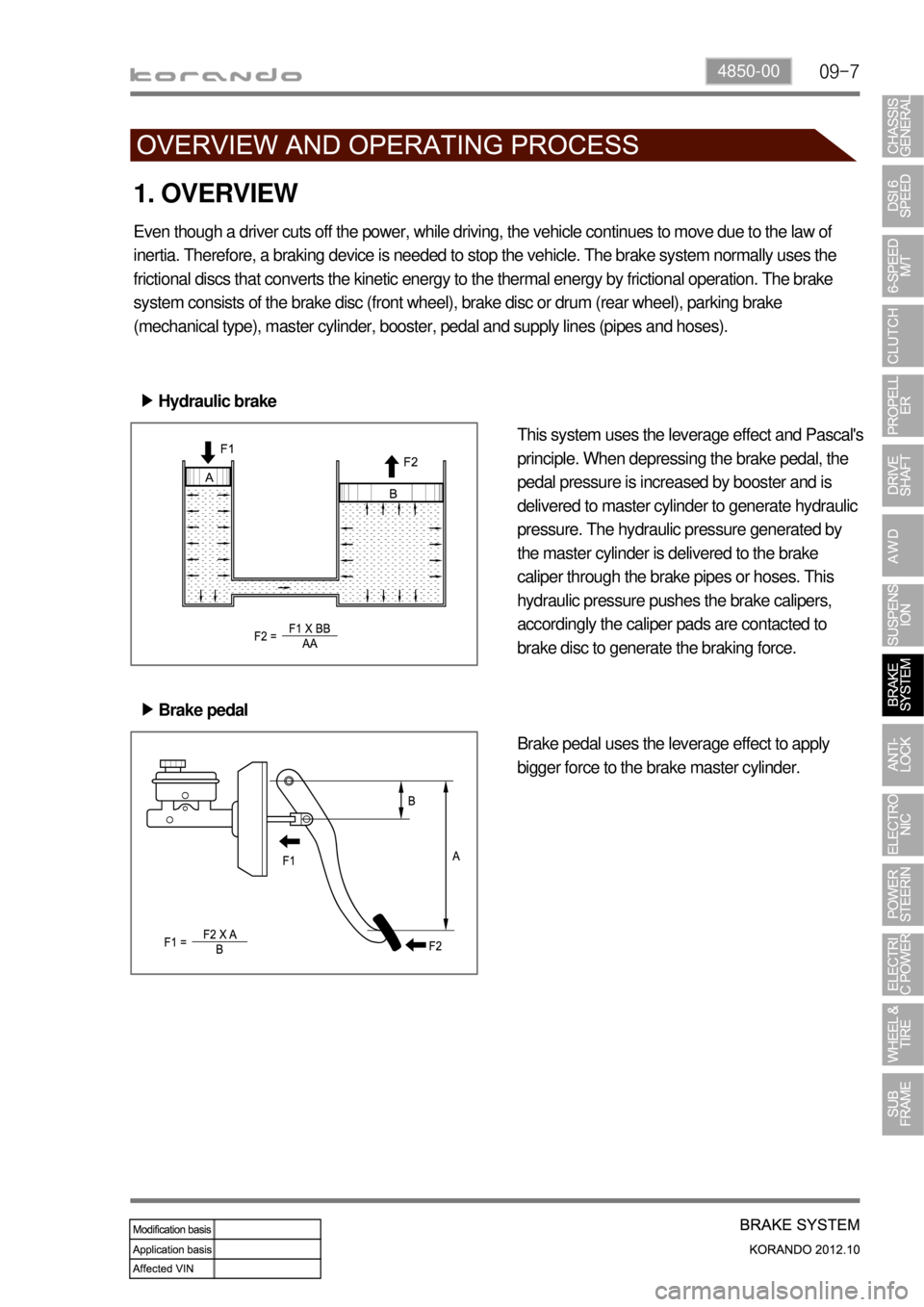

1. OVERVIEW

Even though a driver cuts off the power, while driving, the vehicle continues to move due to the law of

inertia. Therefore, a braking device is needed to stop the vehicle. The brake system normally uses the

frictional discs that converts the kinetic energy to the thermal energy by frictional operation. The brake

system consists of the brake disc (front wheel), brake disc or drum (rear wheel), parking brake

(mechanical type), master cylinder, booster, pedal and supply lines (pipes and hoses).

Hydraulic brake ▶

Brake pedal ▶This system uses the leverage effect and Pascal's

principle. When depressing the brake pedal, the

pedal pressure is increased by booster and is

delivered to master cylinder to generate hydraulic

pressure. The hydraulic pressure generated by

the master cylinder is delivered to the brake

caliper through the brake pipes or hoses. This

hydraulic pressure pushes the brake calipers,

accordingly the caliper pads are contacted to

brake disc to generate the braking force.

Brake pedal uses the leverage effect to apply

bigger force to the brake master cylinder.

Page 928 of 1082

09-8

Pad guide bolt:

25.5~30.4Nm

Brake hose bracket

mounting bolt (12 mm):

9.8 ~ 12.8Nm

Air breather screw: 8.8 ~

10.8Nm

Caliper mounting bolt

(19mm x 2EA):

83.3 ~ 102.9Nm

Brake hose bolt

(12 mm):

19.6 ~ 29.4Nm

Wheel disc

Brake caliper

Brake hub

Brake disc

Knuckle Drive shaft Brake hoseBrake pad

Shock absorber

Brake disc

Back plate

Knuckle

2. SECTIONAL DIAGRAM

Front disc brake ▶