coolant temperature SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 100 of 1082

01-4

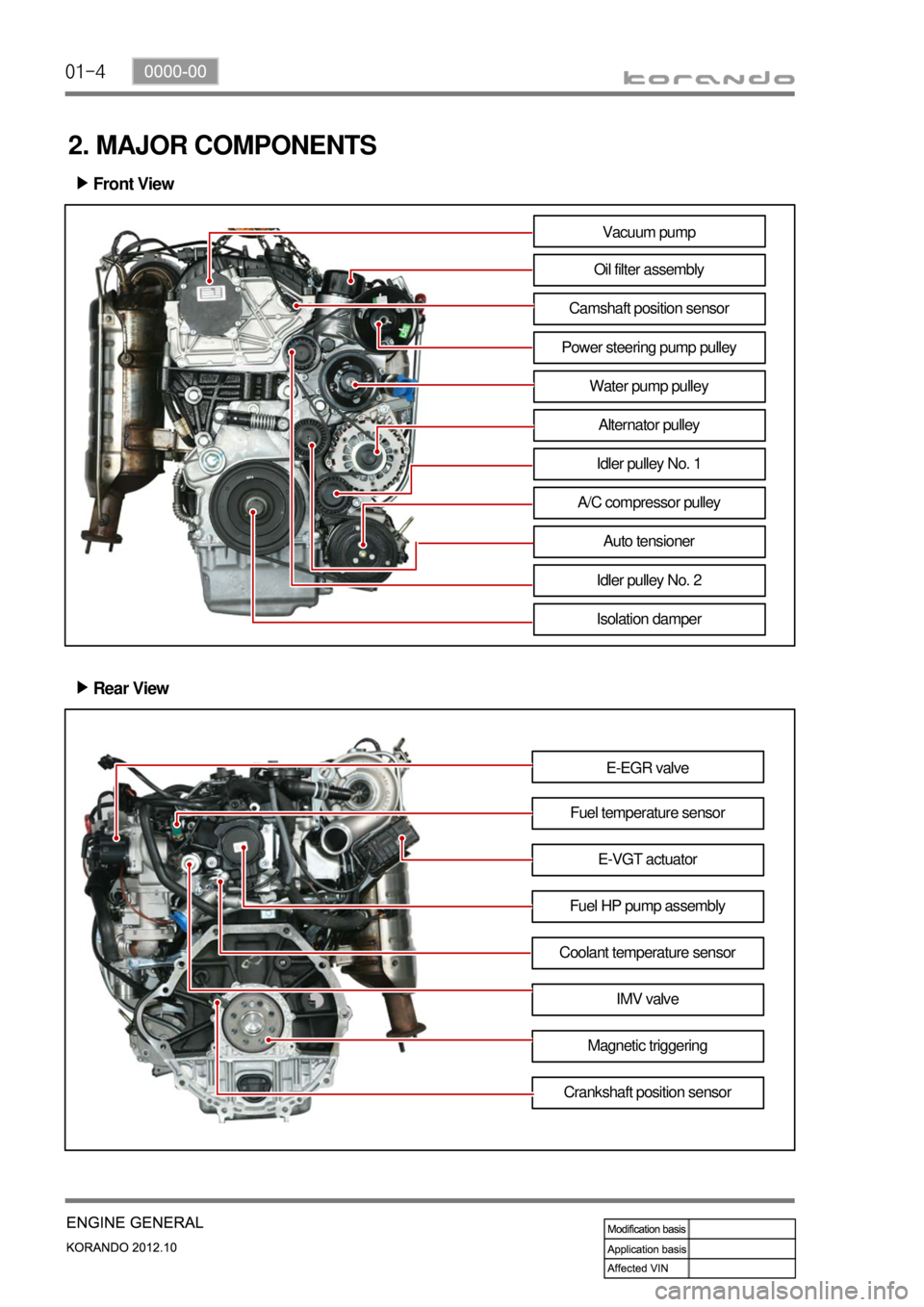

2. MAJOR COMPONENTS

Front View ▶

Vacuum pump

Oil filter assembly

Camshaft position sensor

Power steering pump pulley

Water pump pulley

Alternator pulley

Idler pulley No. 1

A/C compressor pulley

Auto tensioner

Idler pulley No. 2

Isolation damper

Rear View ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assemblyE-VGT actuator

Coolant temperature sensor

IMV valve

Magnetic triggering

Crankshaft position sensor

Page 111 of 1082

02-4

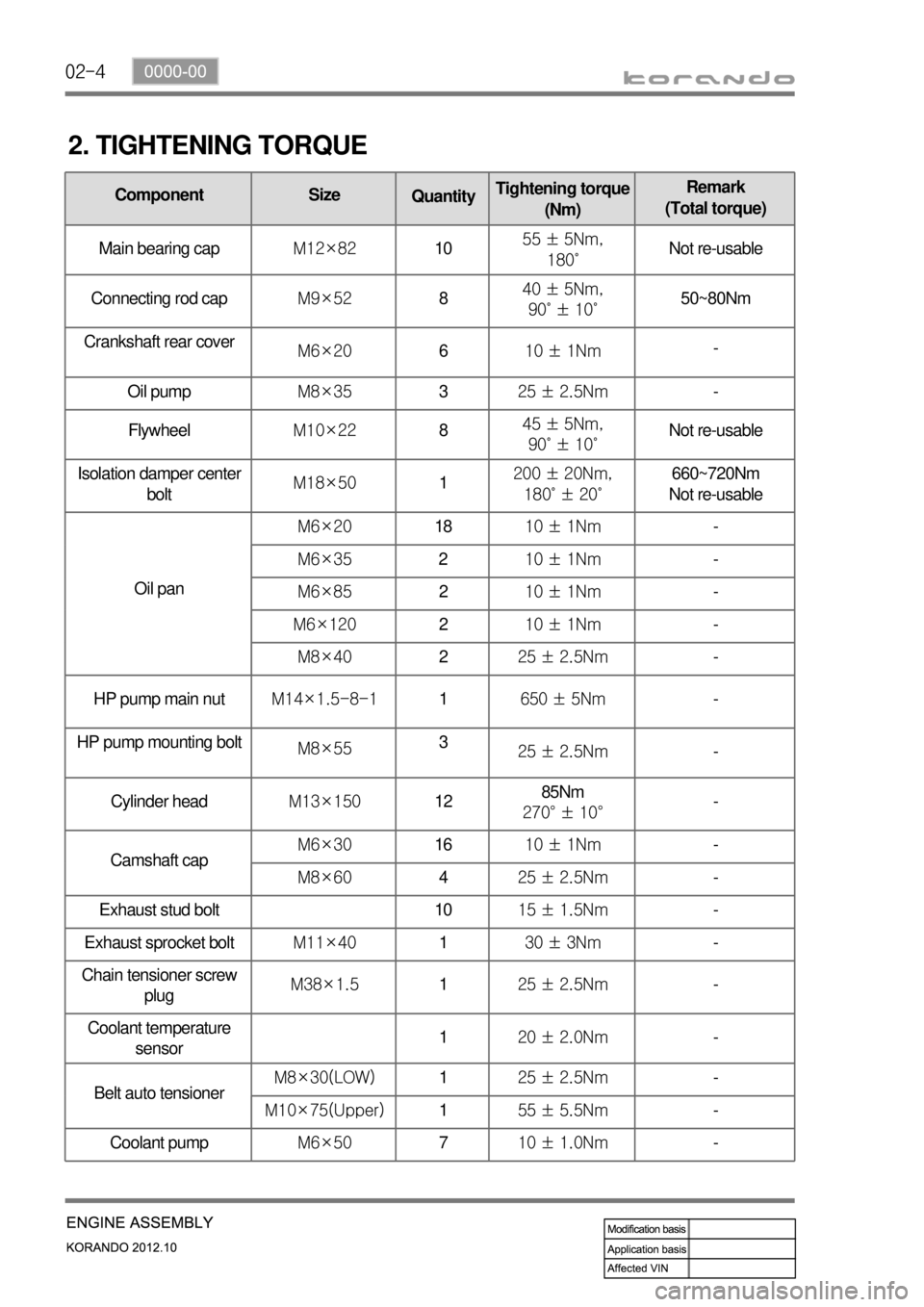

2. TIGHTENING TORQUE

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Main bearing capM12×821055 ± 5Nm,

180˚Not re-usable

Connecting rod capM9×52840 ± 5Nm,

90˚ ± 10˚50~80Nm

Crankshaft rear cover

M6×20610 ± 1Nm-

Oil pumpM8×35325 ± 2.5Nm-

FlywheelM10×22845 ± 5Nm,

90˚ ± 10˚Not re-usable

Isolation damper center

boltM18×501200 ± 20Nm,

180˚ ± 20˚660~720Nm

Not re-usable

Oil panM6×201810 ± 1Nm-

M6×35210 ± 1Nm-

M6×85210 ± 1Nm-

M6×120210 ± 1Nm-

M8×40225 ± 2.5Nm-

HP pump main nutM14×1.5-8-11650 ± 5Nm-

HP pump mounting bolt

M8×553

25 ± 2.5Nm-

Cylinder headM13×1501285Nm

270° ± 10°-

Camshaft capM6×301610 ± 1Nm-

M8×60425 ± 2.5Nm-

Exhaust stud bolt 1015 ± 1.5Nm-

Exhaust sprocket boltM11×40130 ± 3Nm-

Chain tensioner screw

plugM38×1.5125 ± 2.5Nm

-

Coolant temperature

sensor120 ± 2.0Nm-

Belt auto tensionerM8×30(LOW)125 ± 2.5Nm-

M10×75(Upper)155 ± 5.5Nm-

Coolant pumpM6×50710 ± 1.0Nm-

Page 152 of 1082

03-170000-00

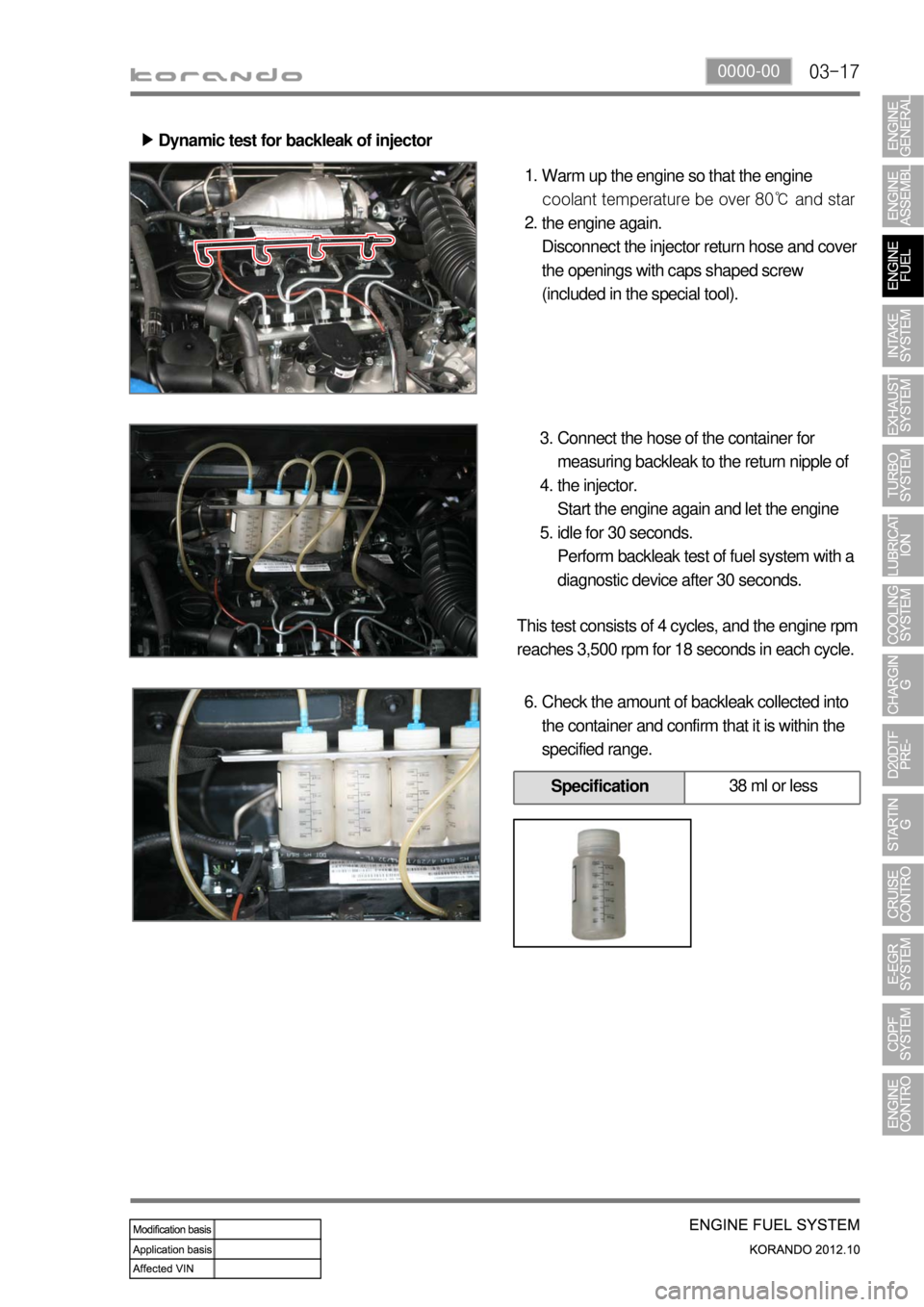

Dynamic test for backleak of injector ▶

Warm up the engine so that the engine

coolant temperature be over 80℃ and star

the engine again.

Disconnect the injector return hose and cover

the openings with caps shaped screw

(included in the special tool). 1.

2.

Connect the hose of the container for

measuring backleak to the return nipple of

the injector.

Start the engine again and let the engine

idle for 30 seconds.

Perform backleak test of fuel system with a

diagnostic device after 30 seconds. 3.

4.

5.

This test consists of 4 cycles, and the engine rpm

reaches 3,500 rpm for 18 seconds in each cycle.

Check the amount of backleak collected into

the container and confirm that it is within the

specified range. 6.

Specification38 ml or less

Page 163 of 1082

03-28

The engine ECU calculates the accelerator pedal based on the input signals from various sensors, and

controls the overall operation of the vehicle.

The ECU receives the signals from various sensor through data line, and performs effective air-fuel ratio

control based on these signals.

The crankshaft speed (position) sensor measures the engine speed, and the camshaft speed (position)

sensor determines the order of injections, and the ECU detects the amount of the accelerator pedal

depressed (driver's will) by receiving the electrical signals from the accelerator pedal sensor.

The mass air flow sensor detects the volume of intake air and sends the value to the ECU.

The major function of the ECU is controlling air-fuel ratio to reduce the emission level (EGR valve control)

by detecting instantaneous air flow change with the signals from the mass air flow sensor.

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster pressure

sensor, atmospheric pressure sensor to: a) determine injection starting point and set value for pilot

injection, and b) deal with various operations and variable conditions.

Page 196 of 1082

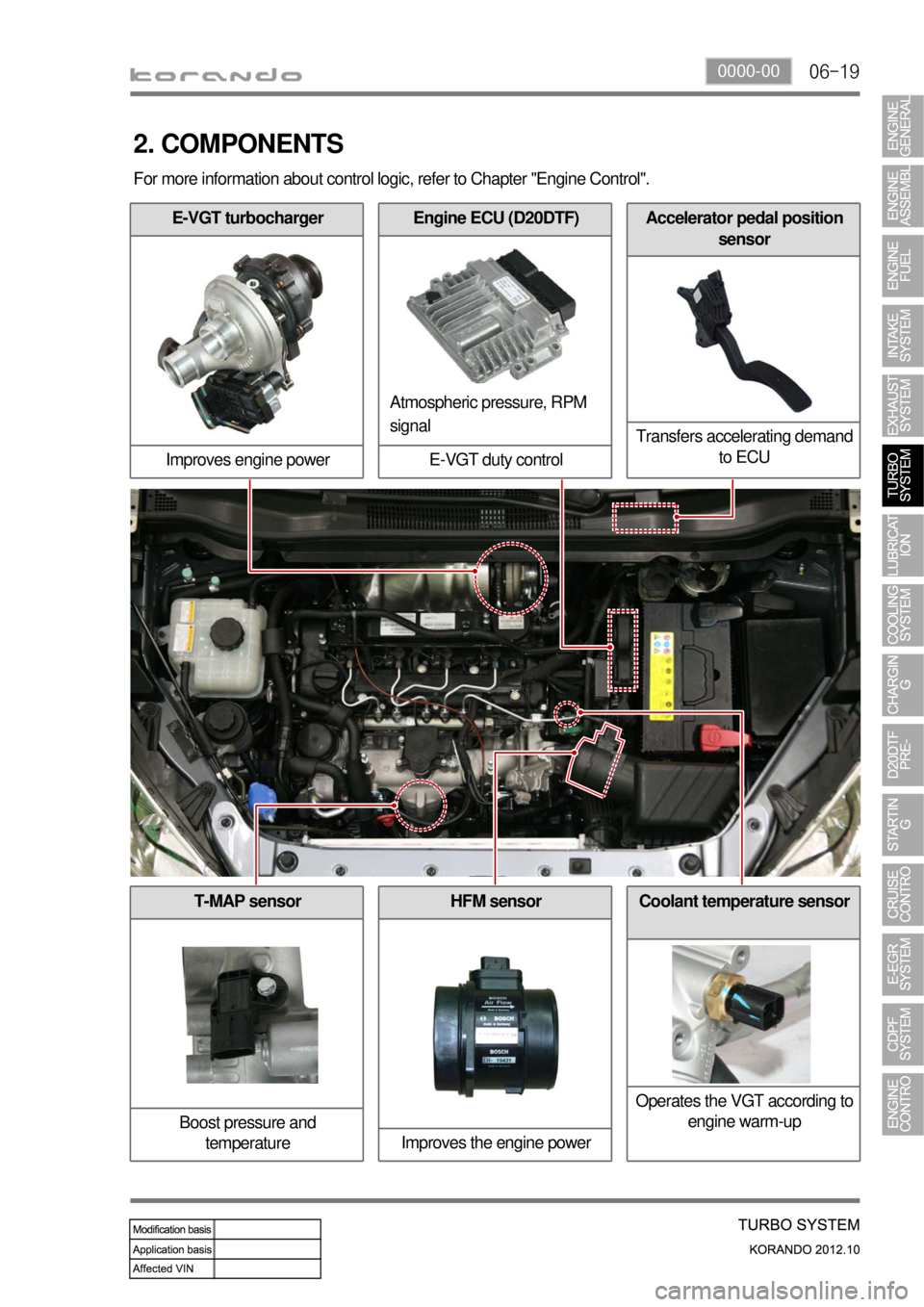

06-190000-00

T-MAP sensor

Boost pressure and

temperature

E-VGT turbocharger

Improves engine power

2. COMPONENTS

Engine ECU (D20DTF)

E-VGT duty controlAccelerator pedal position

sensor

Transfers accelerating demand

to ECU

Atmospheric pressure, RPM

signal

HFM sensor

Improves the engine powerCoolant temperature sensor

Operates the VGT according to

engine warm-up

For more information about control logic, refer to Chapter "Engine Control".

Page 206 of 1082

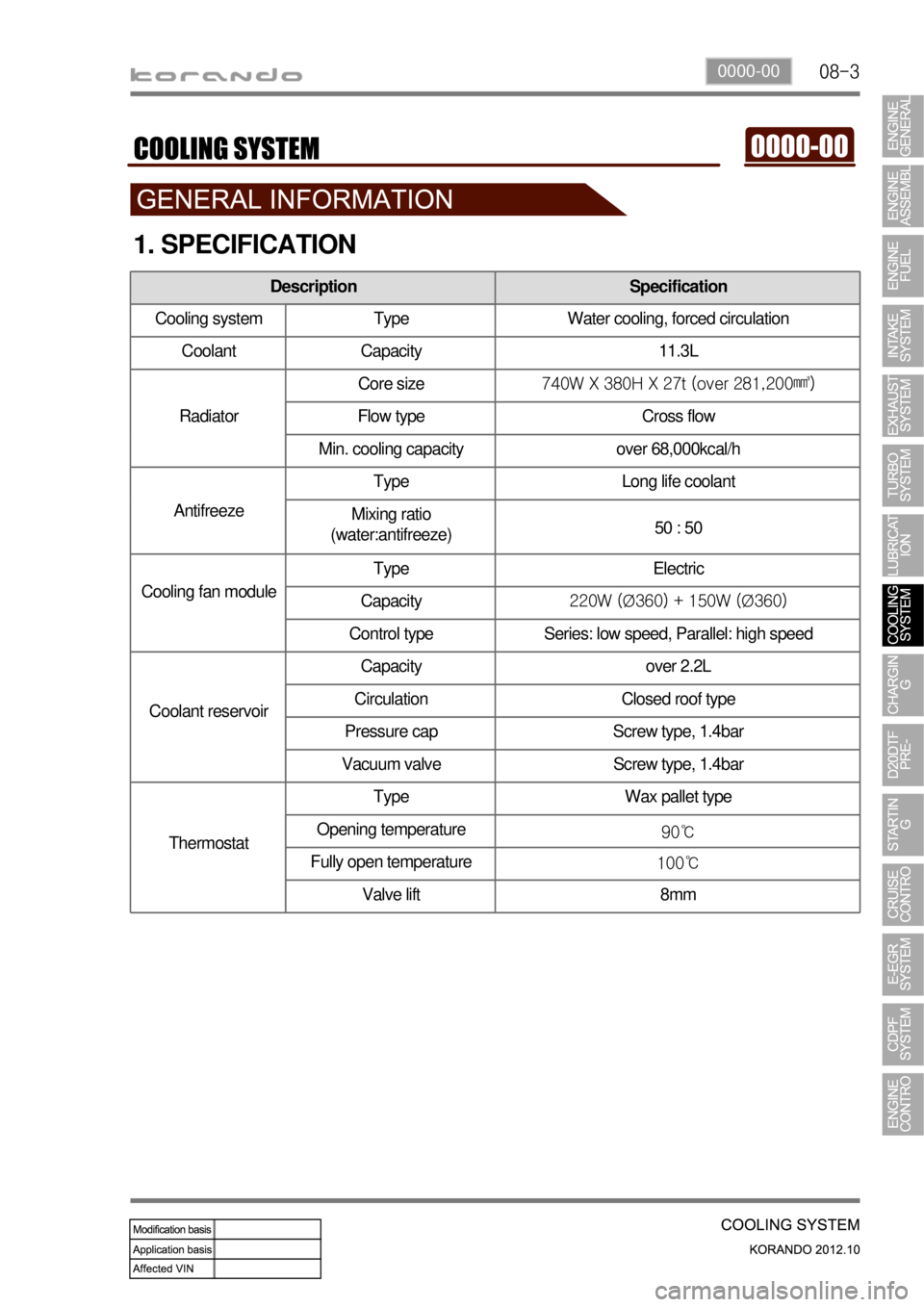

08-30000-00

1. SPECIFICATION

Description Specification

Cooling system Type Water cooling, forced circulation

Coolant Capacity 11.3L

RadiatorCore size740W X 380H X 27t (over 281,200㎣)

Flow type Cross flow

Min. cooling capacity over 68,000kcal/h

AntifreezeType Long life coolant

Mixing ratio

(water:antifreeze)50 : 50

Cooling fan moduleType Electric

Capacity220W (Ø360) + 150W (Ø360)

Control type Series: low speed, Parallel: high speed

Coolant reservoirCapacity over 2.2L

Circulation Closed roof type

Pressure cap Screw type, 1.4bar

Vacuum valve Screw type, 1.4bar

ThermostatType Wax pallet type

Opening temperature

90℃

Fully open temperature

100℃

Valve lift 8mm

Page 207 of 1082

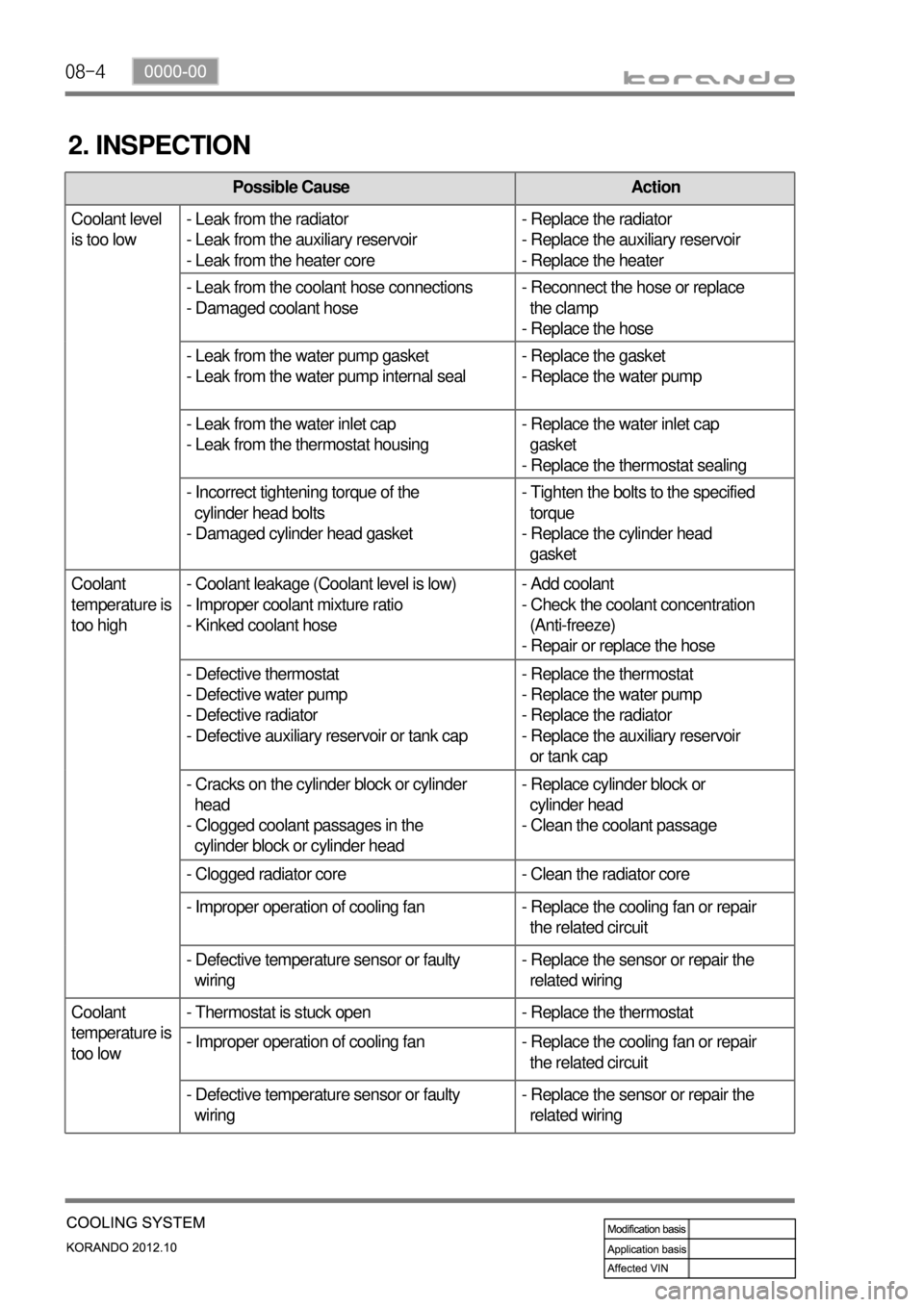

08-4

2. INSPECTION

Possible Cause Action

Coolant level

is too low- Leak from the radiator

- Leak from the auxiliary reservoir

- Leak from the heater core- Replace the radiator

- Replace the auxiliary reservoir

- Replace the heater

- Leak from the coolant hose connections

- Damaged coolant hose- Reconnect the hose or replace

the clamp

- Replace the hose

- Leak from the water pump gasket

- Leak from the water pump internal seal- Replace the gasket

- Replace the water pump

- Leak from the water inlet cap

- Leak from the thermostat housing- Replace the water inlet cap

gasket

- Replace the thermostat sealing

- Incorrect tightening torque of the

cylinder head bolts

- Damaged cylinder head gasket- Tighten the bolts to the specified

torque

- Replace the cylinder head

gasket

Coolant

temperature is

too high- Coolant leakage (Coolant level is low)

- Improper coolant mixture ratio

- Kinked coolant hose- Add coolant

- Check the coolant concentration

(Anti-freeze)

- Repair or replace the hose

- Defective thermostat

- Defective water pump

- Defective radiator

- Defective auxiliary reservoir or tank cap- Replace the thermostat

- Replace the water pump

- Replace the radiator

- Replace the auxiliary reservoir

or tank cap

- Cracks on the cylinder block or cylinder

head

- Clogged coolant passages in the

cylinder block or cylinder head- Replace cylinder block or

cylinder head

- Clean the coolant passage

- Clogged radiator core - Clean the radiator core

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Coolant

temperature is

too low- Thermostat is stuck open - Replace the thermostat

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Page 209 of 1082

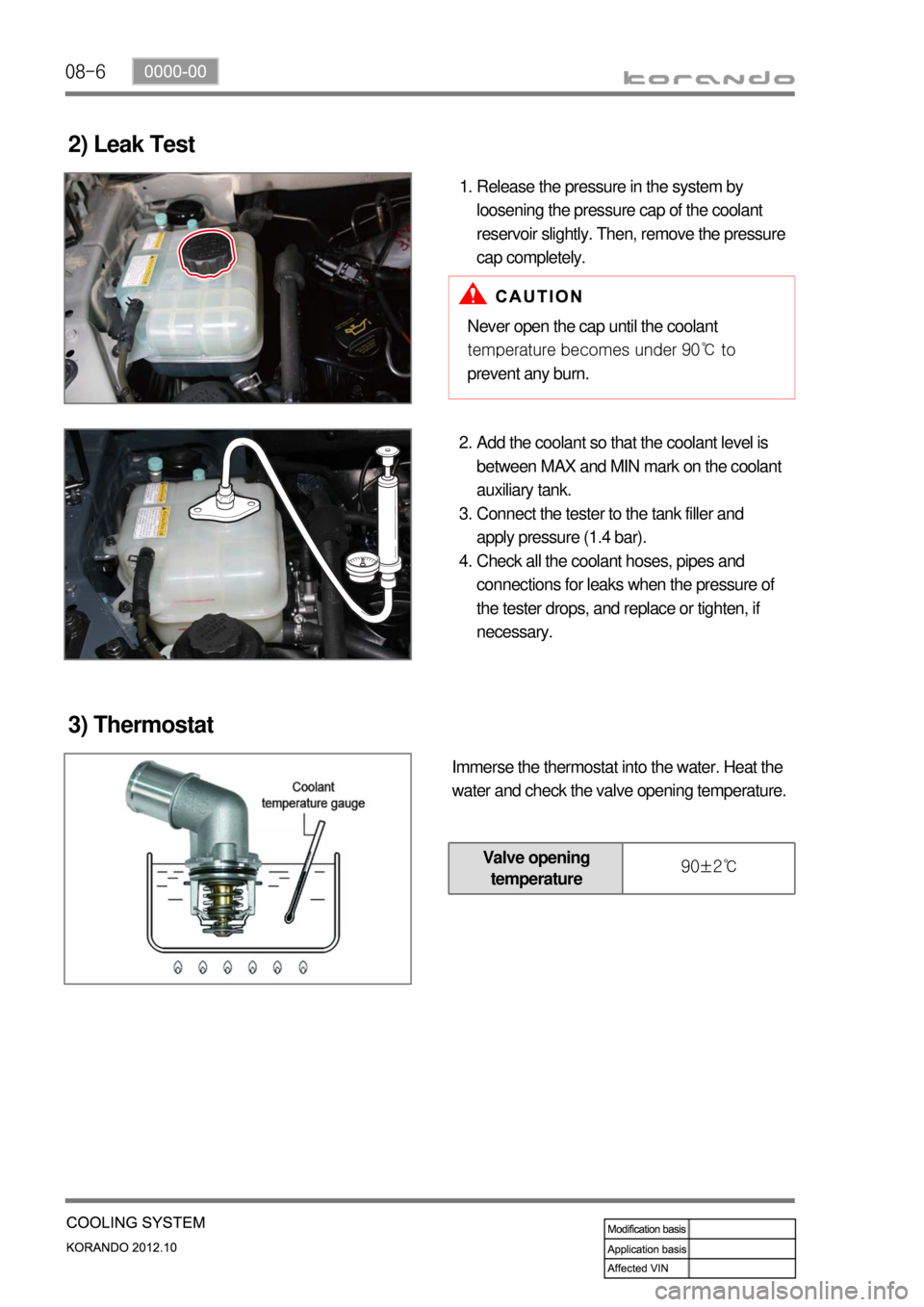

08-6

2) Leak Test

Release the pressure in the system by

loosening the pressure cap of the coolant

reservoir slightly. Then, remove the pressure

cap completely. 1.

Never open the cap until the coolant

temperature becomes under 90℃ to

prevent any burn.

Add the coolant so that the coolant level is

between MAX and MIN mark on the coolant

auxiliary tank.

Connect the tester to the tank filler and

apply pressure (1.4 bar).

Check all the coolant hoses, pipes and

connections for leaks when the pressure of

the tester drops, and replace or tighten, if

necessary. 2.

3.

4.

3) Thermostat

Immerse the thermostat into the water. Heat the

water and check the valve opening temperature.

Valve opening

temperature 90±2℃

Page 211 of 1082

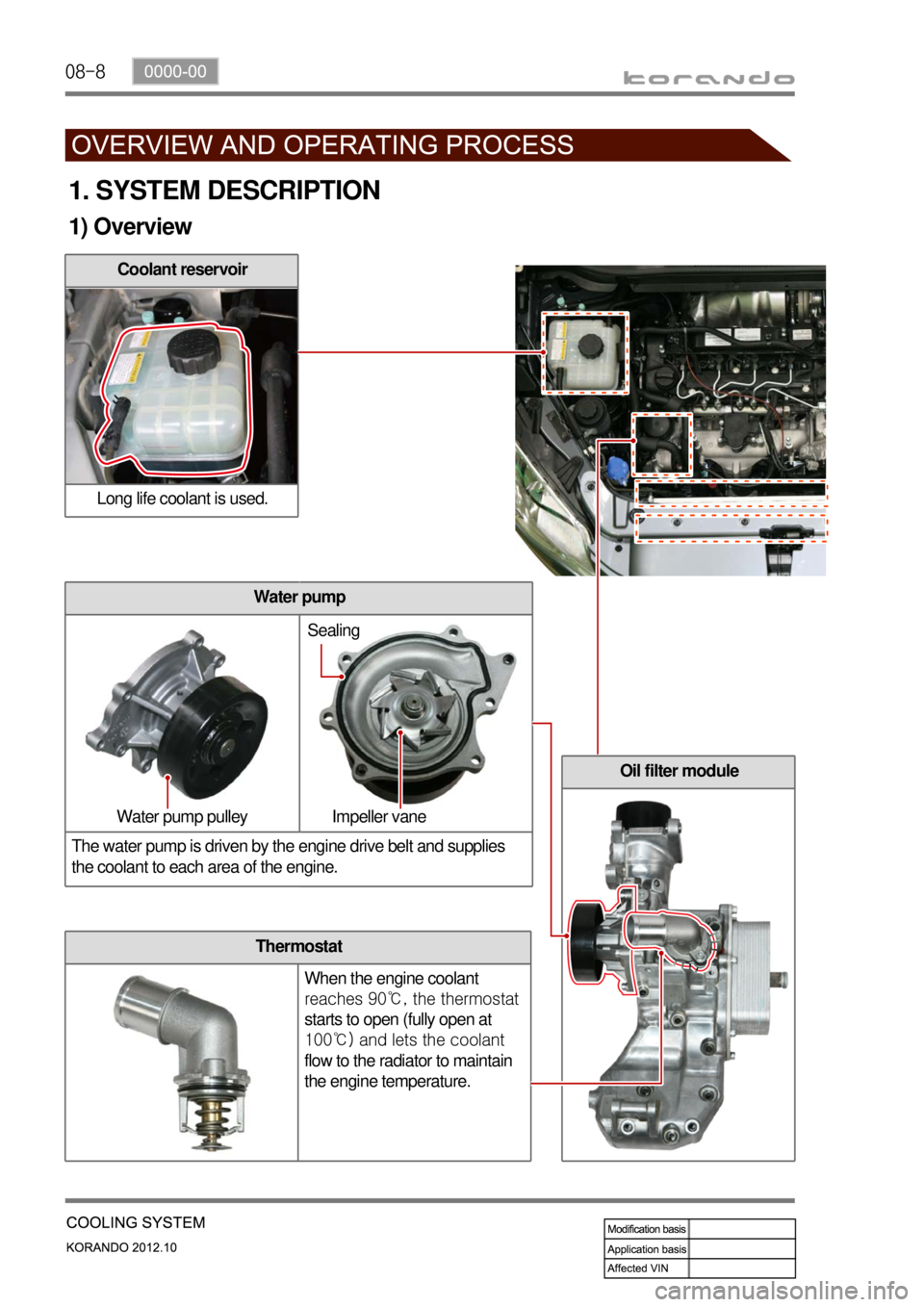

08-8

Thermostat

When the engine coolant

reaches 90℃, the thermostat

starts to open (fully open at

100℃) and lets the coolant

flow to the radiator to maintain

the engine temperature.

1. SYSTEM DESCRIPTION

1) Overview

Coolant reservoir

Long life coolant is used.

Water pump

The water pump is driven by the engine drive belt and supplies

the coolant to each area of the engine.

Oil filter module

Water pump pulley Impeller vaneSealing

Page 212 of 1082

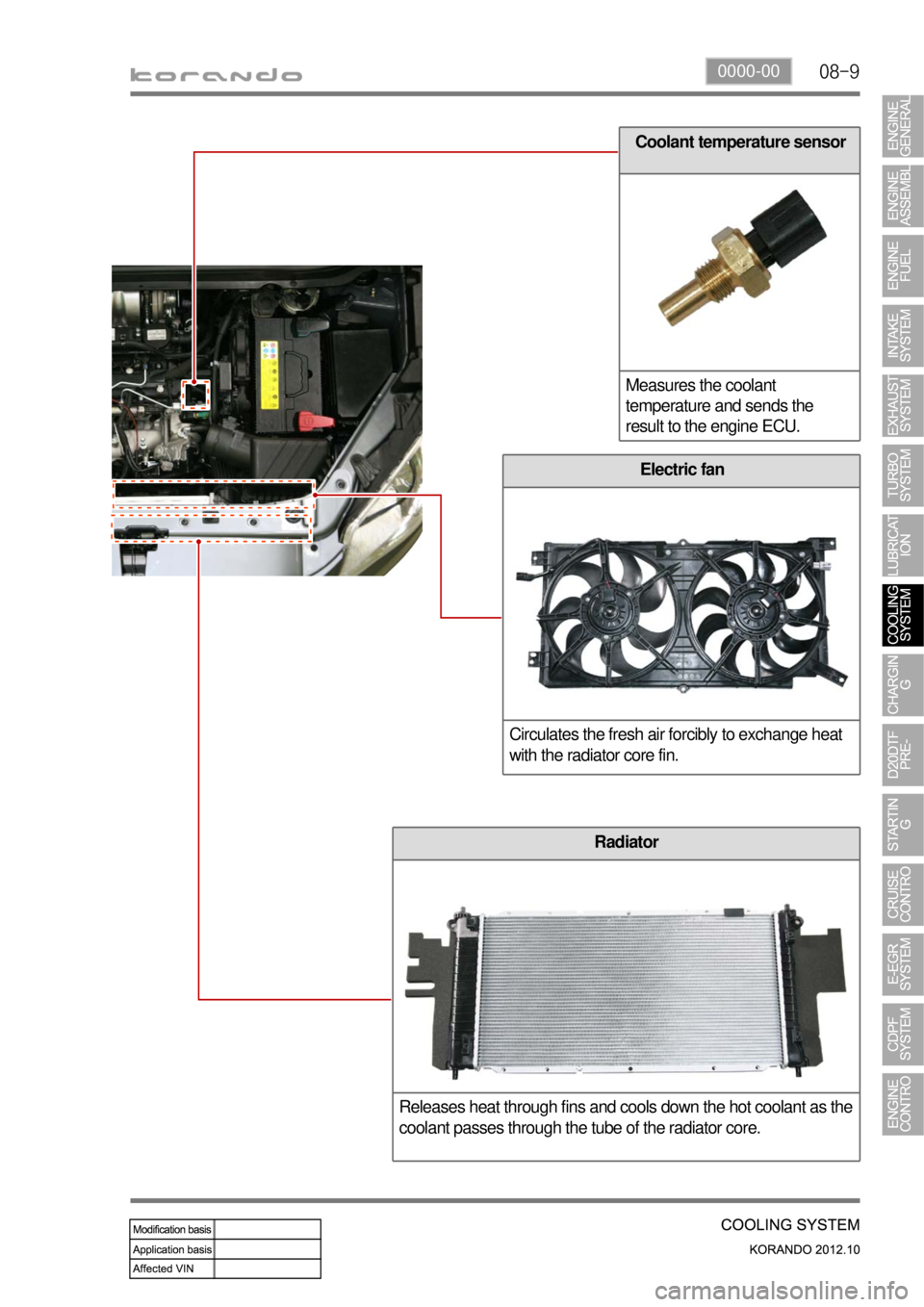

08-90000-00

Coolant temperature sensor

Measures the coolant

temperature and sends the

result to the engine ECU.

Electric fan

Circulates the fresh air forcibly to exchange heat

with the radiator core fin.

Radiator

Releases heat through fins and cools down the hot coolant as the

coolant passes through the tube of the radiator core.