battery SSANGYONG KORANDO 2012 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 710 of 1082

05-478010-01

Pin No.Message

Operating condition

Domestic Export

Smart key

warningThis message comes on for 10 seconds if incorrect

signal on vehicle power control, ignition switch or gear

shift position is received or the signal is not received from

the SKM after the smart key is verified.

This message comes on for approx. 10 seconds if the

low smart key battery is detected when the ignition

switch is pressed or the engine is started.

DoorThis message comes on to inform the driver that any of

the doors is open or closed.

While the door/tailgate is displayed in 4 steps, the hood

displayed in 3 steps.

Parking aid

systemIf any obstacle is detected in the rear of the vehicle when

the shift lever is moved to "R" position with IGN ON,

each sensor shows its position and distance.

If any error is detected during initial diagnosis, it is

displayed as "?". Other than that is operated in the same

way as the PAS distance measurement mode.

Cruise

controlThis message comes on when the cruise control system

is activated.

This message comes on when the cruise control system

is deactivated.

This message comes on when the cruise switch is

moved to the ECO position.Pin No. Message Operating condition

Page 723 of 1082

06-12

Door lock/unlock control by door LOCK switch ▶

When moving the driver or passenger door lock (knob) switch to LOCK from UNLOCK position, BCM

sends the LOCK signal for 0.5 seconds.

When moving the driver or passenger door lock (knob) switch to UNLOCK from LOCK position, BCM

sends the UNLOCK signal for 0.5 seconds.

The LOCK (UNLOCK) operation by the door lock (knob) switch is not available when sending the

LOCK (UNLOCK) signal by any other method such as remote control key.

When reconnecting the battery, the door lock (knob) switch is not operational regardless of the door

lock switch positions.

All doors stay unlocked when receiving the door lock signal in 0.5 seconds after closing the doors. 1.

2.

3.

4.

5.

Page 727 of 1082

06-16

Operation curve ▶

Folding/unfolding control ▶

When pressing the mirror folding/unfolding switch with IGN ON, the mirrors are folded or unfolded

according to the mirror condition. If the outside rearview mirror was folded, the mirror should be

<009c0095008d00960093008b008c008b0053004700880095008b0047009d0090008a008c0047009d008c0099009a008800550047006d00960093008b00900095008e0056009c0095008d00960093008b00900095008e00470096009c009b0097009c009b00

470090009a00470088008a009b0090009d0088009b008c008b> for 16±6 seconds.

This operation time should be completed even when the ignition switch is turned to OFF position

during its operation.

At first time pressing the mirror folding/unfolding switch after reconnecting the battery, the mirror

folding operation is performed.

You can control the mirror position within the first 30 sec. after turning the ignition OFF. In other

words, this control must be available for 30 seconds (time lag period) after turning the ignition switch

to OFF position. Folding/unfolding is completed when time lag of 30 seconds elapse during

operation.

When receiving the folding/unfolding signal during the mirror folding/unfolding operation, the output

should be activated after having time lag of 0.1 second.

The folding/unfolding operation is performed regardless of the vehicle speed.

Manual operation

<005400470074009000990099009600990047009c0095008d00960093008b008c008b004702e700470074009000990099009600990047008d00960093008b00900095008e0056009c0095008d00960093008b00900095008e0047009a0090008e0095008800

930047008d0099009600940047009a009e0090009b008a008f> → Mirror folding

<005400470074009000990099009600990047008d00960093008b008c008b004702e700470074009000990099009600990047008d00960093008b00900095008e0056009c0095008d00960093008b00900095008e0047009a0090008e009500880093004700

8d0099009600940047009a009e0090009b008a008f004702e7> Mirror unfolding 1.

2.

3.

4.

5.

Page 747 of 1082

06-36

4) Horn Switch

Horn switch

Two horns are installed in the radiator grille at the bottom of both sides (one on each side). There is

another horn installed at the bottom of the battery tray side in the engine compartment for theft alarm.

Operating the horn switch on the steering wheel applies the power to the horn relay to operate both

horns (Dual horn).

The theft deterrent horn is controlled by the BCM in armed mode regardless of the horn relay operation.

Page 767 of 1082

07-14

2) Operation

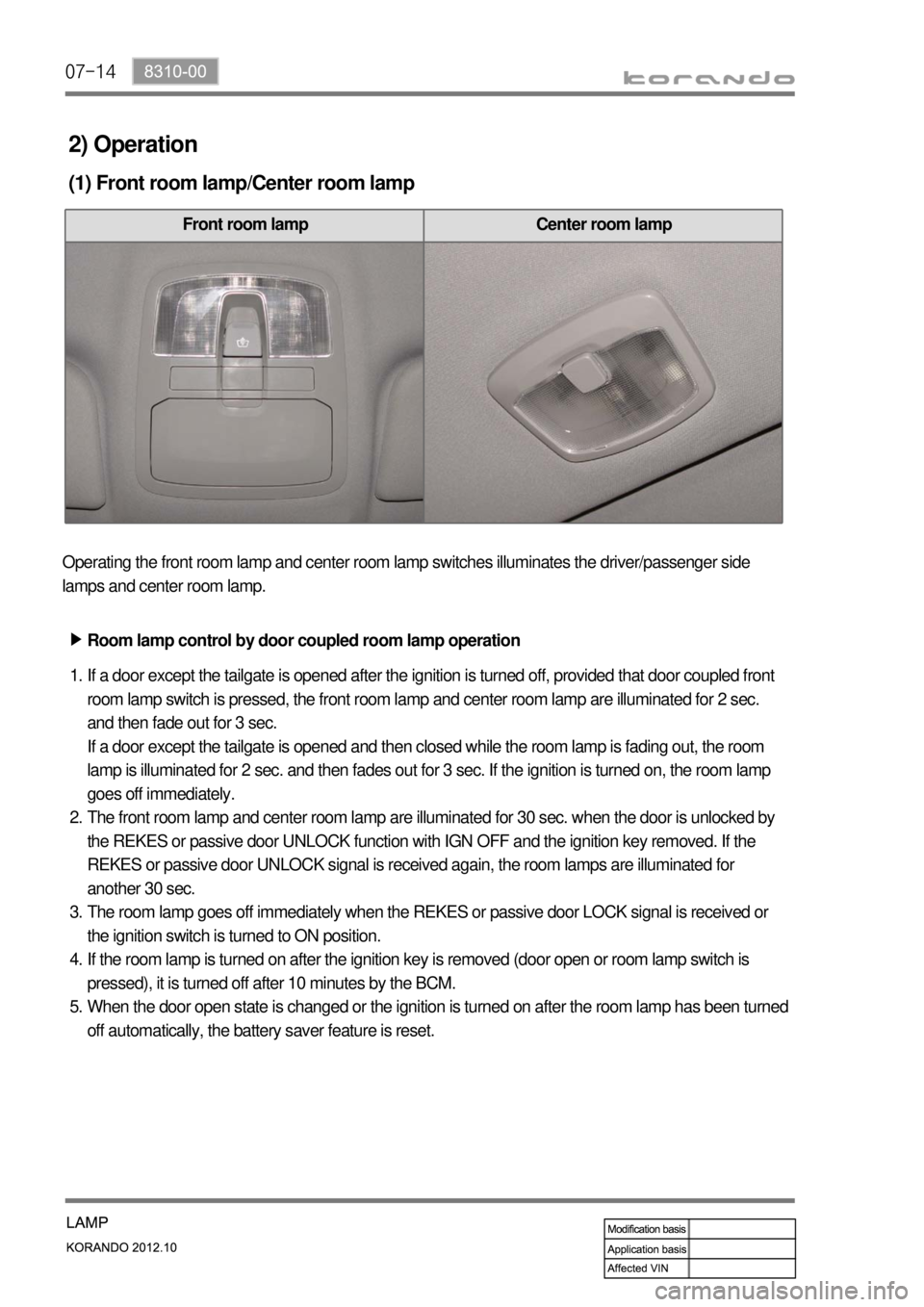

(1) Front room lamp/Center room lamp

Front room lamp Center room lamp

Operating the front room lamp and center room lamp switches illuminates the driver/passenger side

lamps and center room lamp.

Room lamp control by door coupled room lamp operation ▶

If a door except the tailgate is opened after the ignition is turned off, provided that door coupled front

room lamp switch is pressed, the front room lamp and center room lamp are illuminated for 2 sec.

and then fade out for 3 sec.

If a door except the tailgate is opened and then closed while the room lamp is fading out, the room

lamp is illuminated for 2 sec. and then fades out for 3 sec. If the ignition is turned on, the room lamp

goes off immediately.

The front room lamp and center room lamp are illuminated for 30 sec. when the door is unlocked by

the REKES or passive door UNLOCK function with IGN OFF and the ignition key removed. If the

REKES or passive door UNLOCK signal is received again, the room lamps are illuminated for

another 30 sec.

The room lamp goes off immediately when the REKES or passive door LOCK signal is received or

the ignition switch is turned to ON position.

If the room lamp is turned on after the ignition key is removed (door open or room lamp switch is

pressed), it is turned off after 10 minutes by the BCM.

When the door open state is changed or the ignition is turned on after the room lamp has been turned

off automatically, the battery saver feature is reset. 1.

2.

3.

4.

5.

Page 818 of 1082

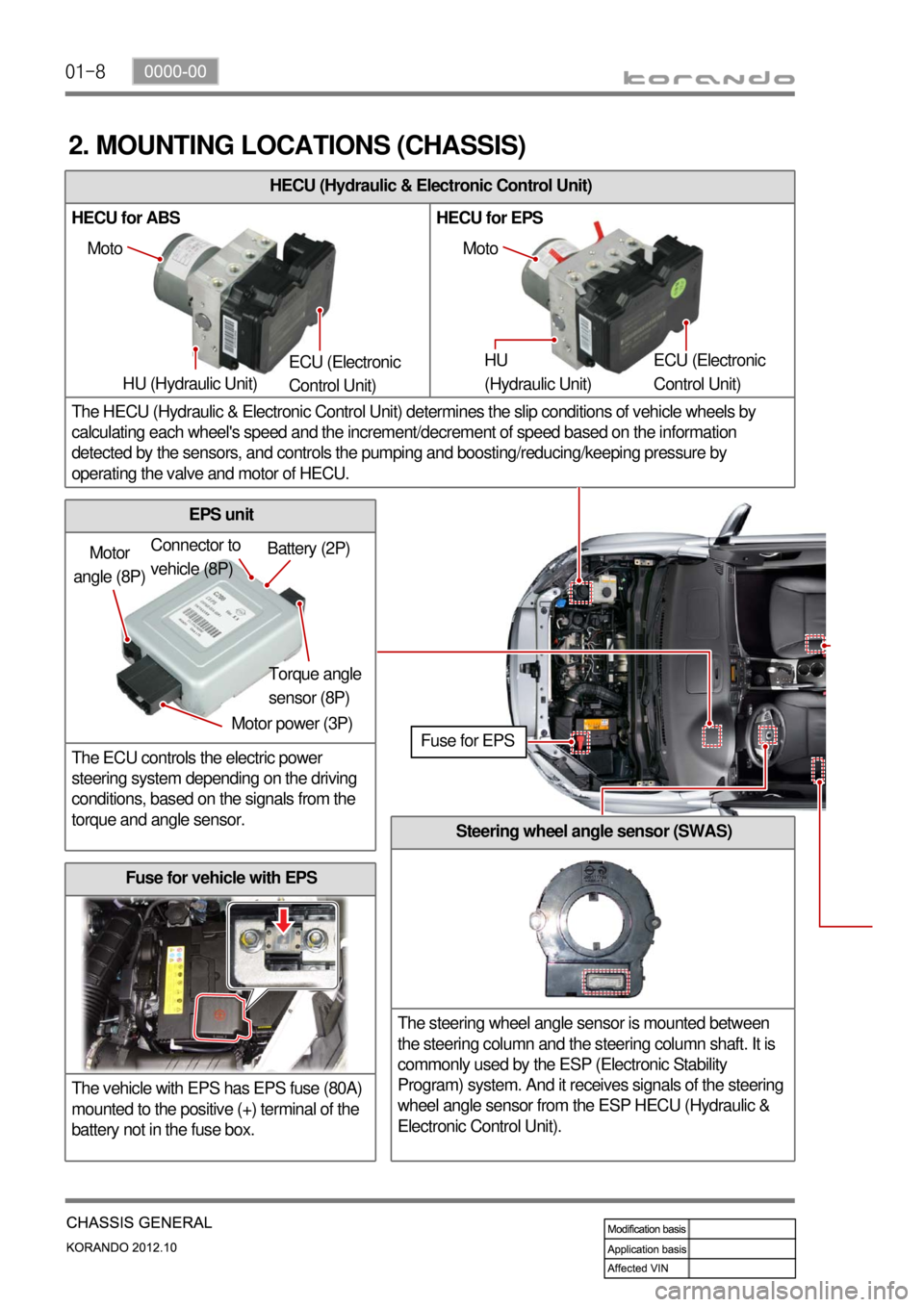

01-8

Fuse for vehicle with EPS

The vehicle with EPS has EPS fuse (80A)

mounted to the positive (+) terminal of the

battery not in the fuse box.

EPS unit

The ECU controls the electric power

steering system depending on the driving

conditions, based on the signals from the

torque and angle sensor.

HECU (Hydraulic & Electronic Control Unit)

HECU for ABS HECU for EPS

The HECU (Hydraulic & Electronic Control Unit) determines the slip conditions of vehicle wheels by

calculating each wheel's speed and the increment/decrement of speed based on the information

detected by the sensors, and controls the pumping and boosting/reducing/keeping pressure by

operating the valve and motor of HECU.

2. MOUNTING LOCATIONS (CHASSIS)

Moto

HU (Hydraulic Unit) ECU (Electronic

Control Unit) Moto

HU

(Hydraulic Unit) ECU (Electronic

Control Unit)

Motor

angle (8P)

Motor power (3P)Torque angle

sensor (8P) Battery (2P) Connector to

vehicle (8P)

Fuse for EPS

Steering wheel angle sensor (SWAS)

The steering wheel angle sensor is mounted between

the steering column and the steering column shaft. It is

commonly used by the ESP (Electronic Stability

Program) system. And it receives signals of the steering

wheel angle sensor from the ESP HECU (Hydraulic &

Electronic Control Unit).

Page 831 of 1082

01-210000-00

ECU

The ECU controls the electric

power steering system

depending on the driving

conditions, based on the

signals from the torque and

angle sensor.

2) EPS (Electric Power Steering)

Fuse

The vehicle with EPS has

EPS fuse (80A) mounted to

the positive (+) terminal of the

battery, and this fuse supplies

power to the EPS unit

directly..

Steering gear box assembly

When the driver turns the steering wheel, a torque is generated and the torque sensor and the steering

angle sensor in the EPS system detect the rotation of the steering column to run the electric motor. At

this time, the worm gear connected to the motor drives the helical gear mounted to the steering column

to generate the assist torque for the steering column. This allows the driver to operate the steering

wheel easier.

ECU

Tie rod end

Tie rod end Gear boxSteering cylinder

Steering wheel assembly

BLAC motor

Lower

shaft Column

shaft

Colum shaft assembly

The column shaft assembly consists

of BLAC motor, ECU, torque and

angle sensors. The electric power

steering (EPS) system uses the

electric motor to assist the steering

force. It functions independently

regardless of whether the engine is

running or not, unlike the existing

hydraulic power steering.

The lower shafts functions in the

same way as the hydraulic type.

Page 833 of 1082

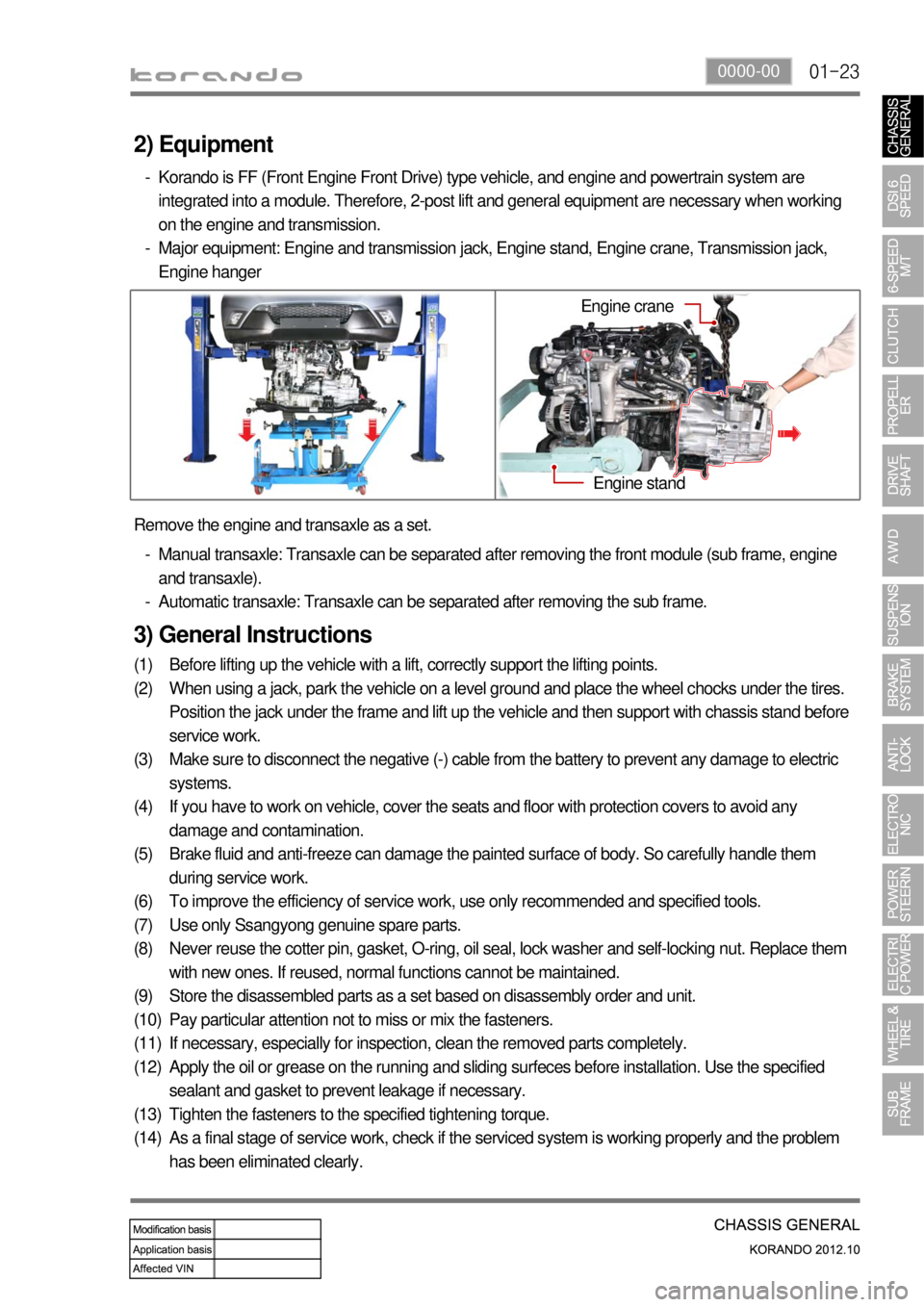

01-230000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 847 of 1082

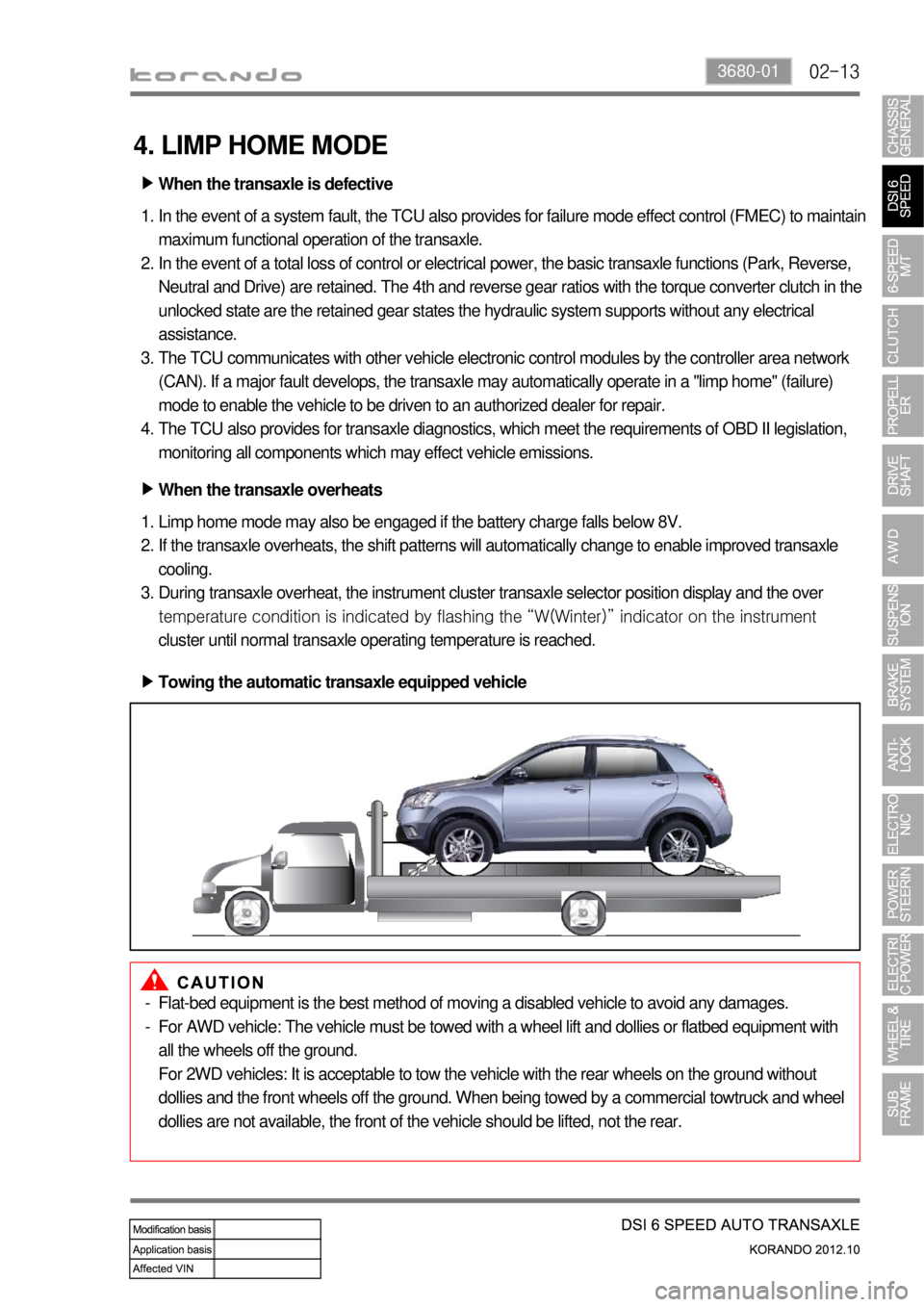

02-133680-01

4. LIMP HOME MODE

When the transaxle is defective ▶

In the event of a system fault, the TCU also provides for failure mode effect control (FMEC) to maintain

maximum functional operation of the transaxle.

In the event of a total loss of control or electrical power, the basic transaxle functions (Park, Reverse,

Neutral and Drive) are retained. The 4th and reverse gear ratios with the torque converter clutch in the

unlocked state are the retained gear states the hydraulic system supports without any electrical

assistance.

The TCU communicates with other vehicle electronic control modules by the controller area network

(CAN). If a major fault develops, the transaxle may automatically operate in a "limp home" (failure)

mode to enable the vehicle to be driven to an authorized dealer for repair.

The TCU also provides for transaxle diagnostics, which meet the requirements of OBD II legislation,

monitoring all components which may effect vehicle emissions. 1.

2.

3.

4.

When the transaxle overheats ▶

Limp home mode may also be engaged if the battery charge falls below 8V.

If the transaxle overheats, the shift patterns will automatically change to enable improved transaxle

cooling.

During transaxle overheat, the instrument cluster transaxle selector position display and the over

<009b008c00940097008c00990088009b009c0099008c0047008a00960095008b0090009b00900096009500470090009a004700900095008b0090008a0088009b008c008b0047008900a00047008d00930088009a008f00900095008e0047009b008f008c00

4702c8007e004f007e00900095009b008c0099005002c90047>indicator on the instrument

cluster until normal transaxle operating temperature is reached. 1.

2.

3.

Towing the automatic transaxle equipped vehicle ▶

Flat-bed equipment is the best method of moving a disabled vehicle to avoid any damages.

For AWD vehicle: The vehicle must be towed with a wheel lift and dollies or flatbed equipment with

all the wheels off the ground.

For 2WD vehicles: It is acceptable to tow the vehicle with the rear wheels on the ground without

dollies and the front wheels off the ground. When being towed by a commercial towtruck and wheel

dollies are not available, the front of the vehicle should be lifted, not the rear. -

-

Page 956 of 1082

11-4

2) Specification of Steering Wheel Angle Sensor

Description Specification

Operating voltage 9 to 16 V

Maximum output current 10 mA

Maximum detection angle speed±100°/Sec

Operating temperature-30 to 75 ℃

Supplying voltage 9 to 16 V (battery voltage)

Output voltage (HI) approx. 3.50 V (3.0 to 4.1 V)

Output voltage (LO) approx. 1.50 V (1.3 to 2.0 V)

Pulses/rev 45 pulses/rev

3) Specification of Sensor Cluster

Description Specification

Supplying voltage approx. 12 V (8 to 16 V)

Current consumption below 250 mA -

Operating range Yaw rate sensor± 75 °/Sec

Lateral/longitudinal sensor± 14.7m/Sec²