SSANGYONG KORANDO 2013 Service Manual

KORANDO 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57503/w960_57503-0.png

SSANGYONG KORANDO 2013 Service Manual

Trending: driver seat adjustment, engine overheat, remove seats, oil, headlamp, cruise control, pairing phone

Page 1031 of 1336

3660-01

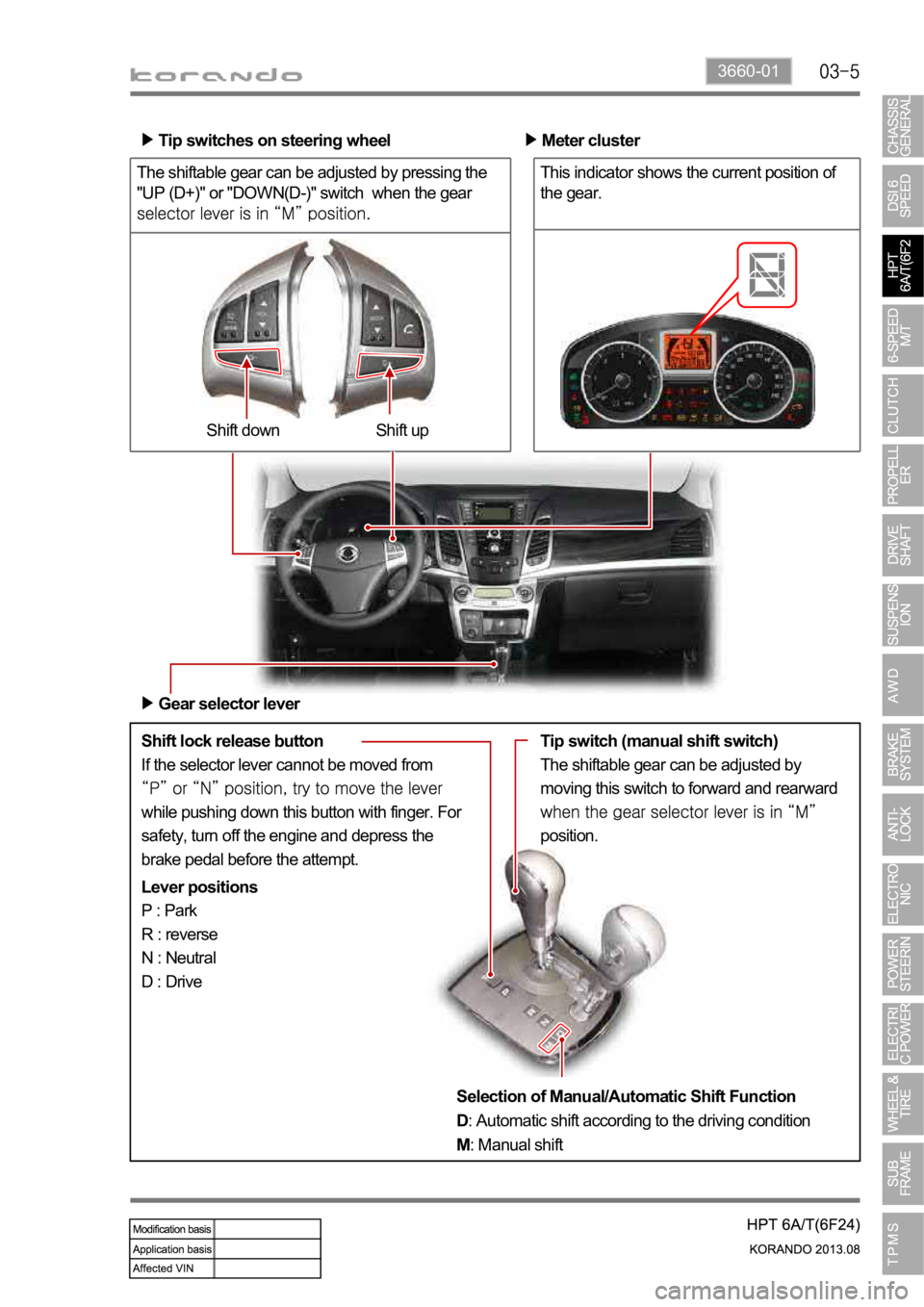

The shiftable gear can be adjusted by pressing the

"UP (D+)" or "DOWN(D-)" switch when the gear

Shift lock release button

If the selector lever cannot be moved from

while pushing down this button with finger. For

safety, turn off the engine and depress the

brake pedal before the attempt.Shift up Shift down Tip switches on steering wheel

Meter cluster

This indicator shows the current position of

the gear.

Gear selector lever

Lever positions

P : Park

R : reverse

N : Neutral

D : DriveTip switch (manual shift switch)

The shiftable gear can be adjusted by

moving this switch to forward and rearward

position.

Selection of Manual/Automatic Shift Function

D: Automatic shift according to the driving condition

M: Manual shift

Page 1032 of 1336

3. SPECIFICATIONS

1) Specifications

Type/Weight 6F24 6-speed automatic transaxle /

approx. 86 kg (including ATF)

TORQUE 230 Nm

Overall length / Center length 373.1 mm / 204 mm

Descriptions Specification

Gear ratio 1st gear 4.212

2nd gear 2.637

3rd gear 1.800

4th gear 1.386

5th gear 1.000

6th gear 0.772

Reverse gear 3.385

Shift pattern Variable

Shift range 4 Range (P-R-N-D) + Manual mode

Shift range valve VFS : 6EA

Planetary gear 3EA (Front, Middle, Rear)

Clutch 2EA

Brake 3EA

O.W.C 1EA

Oil Type ATF SP-IV M

Capacity approx. 7.1 L

Change interval Maintenance free. However, under the severe

conditions or commercially used, change the oil at

every 100,000 km (EU: 90,000 km).

Resistance of oil

temperature sensor-20

0

20

100

Weight 2WD 87.5kg

4WD 88.5kg

Page 1033 of 1336

3660-01

4. COMPONENTS

HPT 6A/T (6F24)

One-way clutchTorque converter

(with slip lockup)

Oil pumpHarness

Valve bodySide gearDriven gear

Page 1034 of 1336

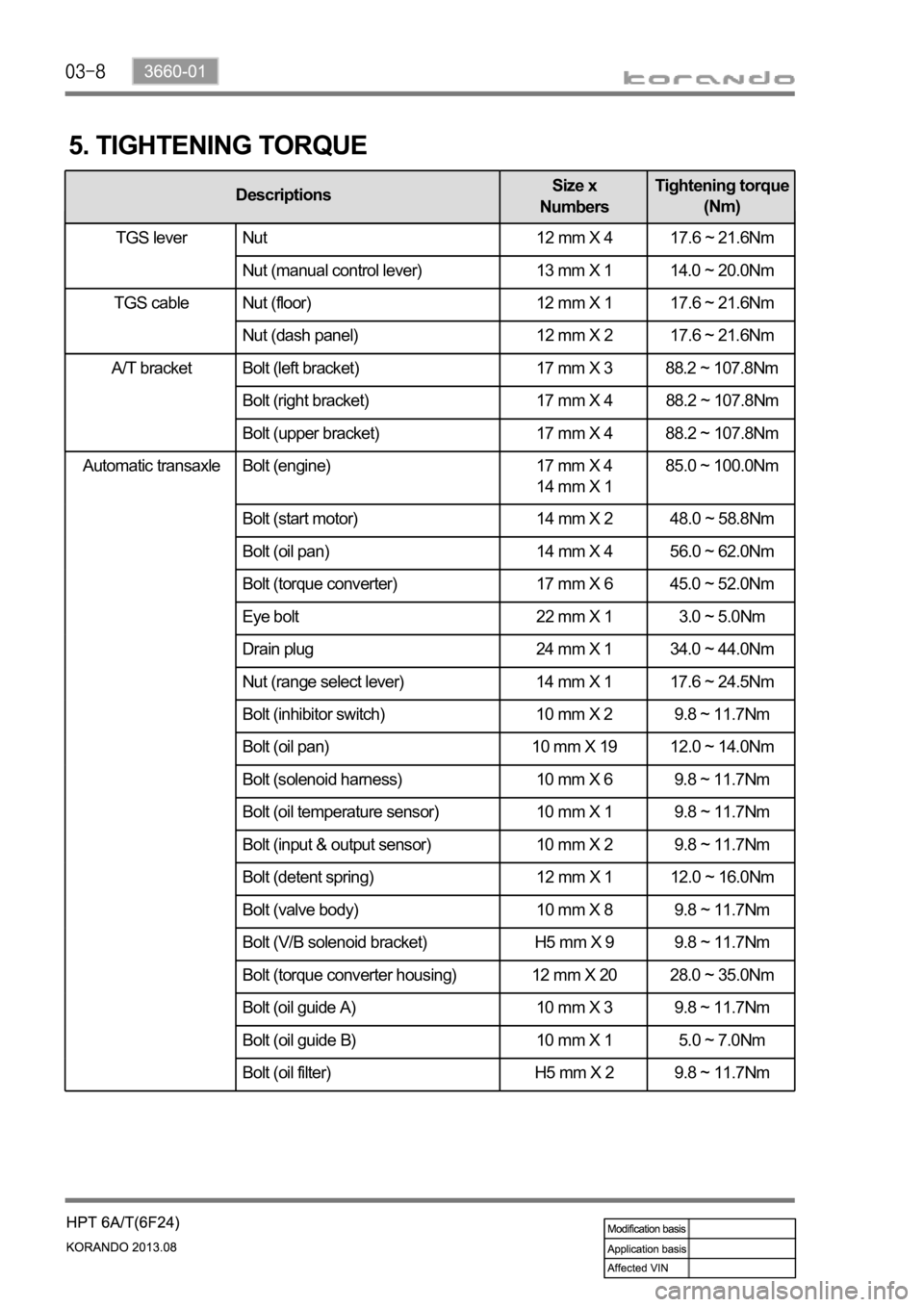

Automatic transaxle Bolt (engine) 17 mm X 4

14 mm X 1 85.0 ~ 100.0Nm

Bolt (start motor) 14 mm X 2 48.0 ~ 58.8Nm

Bolt (oil pan) 14 mm X 4 56.0 ~ 62.0Nm

Bolt (torque converter) 17 mm X 6 45.0 ~ 52.0Nm

Eye bolt 22 mm X 1 3.0 ~ 5.0Nm

Drain plug 24 mm X 1 34.0 ~ 44.0Nm

Nut (range select lever) 14 mm X 1 17.6 ~ 24.5Nm

Bolt (inhibitor switch) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (oil pan) 10 mm X 19 12.0 ~ 14.0Nm

Bolt (solenoid harness) 10 mm X 6 9.8 ~ 11.7Nm

Bolt (oil temperature sensor) 10 mm X 1 9.8 ~ 11.7Nm

Bolt (input & output sensor) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (detent spring) 12 mm X 1 12.0 ~ 16.0Nm

Bolt (valve body) 10 mm X 8 9.8 ~ 11.7Nm

Bolt (V/B solenoid bracket) H5 mm X 9 9.8 ~ 11.7Nm

Bolt (torque converter housing) 12 mm X 20 28.0 ~ 35.0Nm

Bolt (oil guide A) 10 mm X 3 9.8 ~ 11.7Nm

Bolt (oil guide B) 10 mm X 1 5.0 ~ 7.0Nm

Bolt (oil filter) H5 mm X 2 9.8 ~ 11.7Nm

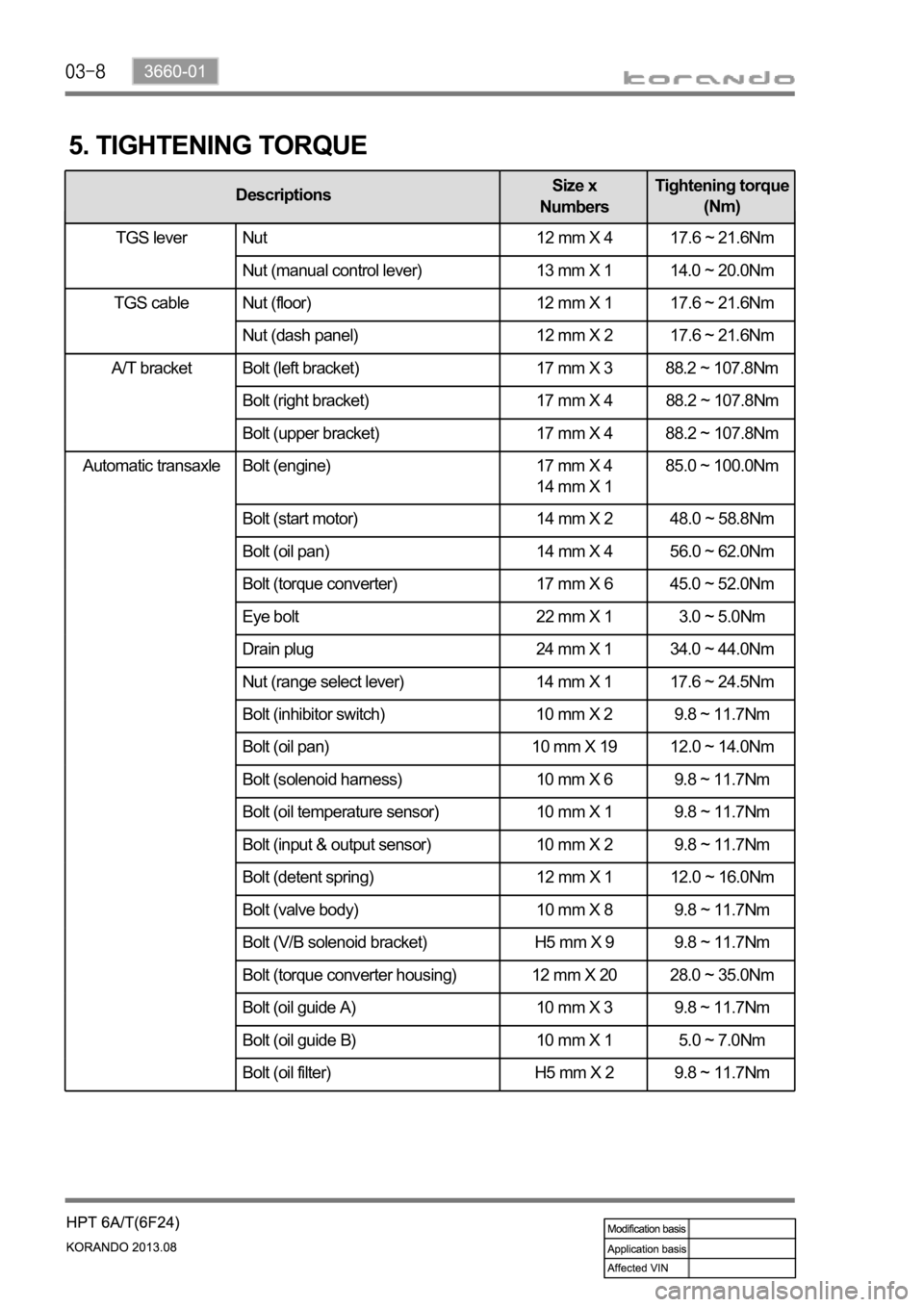

5. TIGHTENING TORQUE

DescriptionsSize x

NumbersTightening torque

(Nm)

TGS lever Nut 12 mm X 4 17.6 ~ 21.6Nm

Nut (manual control lever) 13 mm X 1 14.0 ~ 20.0Nm

Nut (floor) 12 mm X 1 17.6 ~ 21.6Nm

Nut (dash panel) 12 mm X 2 17.6 ~ 21.6Nm

A/T bracket Bolt (left bracket) 17 mm X 3 88.2 ~ 107.8Nm

Bolt (right bracket) 17 mm X 4 88.2 ~ 107.8Nm

Bolt (upper bracket) 17 mm X 4 88.2 ~ 107.8Nm

TGS lever

TGS cable

Page 1035 of 1336

3660-01

DescriptionsSize x

NumbersTightening torque

(Nm)

Automatic

transaxleBolt (oil lubrication pipe) 10 mm X 1 9.8 ~ 11.7Nm

Bolt (oil pump) 12 mm X 7 20.0 ~ 26.0Nm

Bolt (parking rod guide) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (U/D brake retainer) T40 X 6 31.0 ~ 36.0Nm

Bolt (U/D brake chamber) T30 X 2 4.9 ~ 9.8Nm

Bolt (rear cover) 12 mm X 13 28.0 ~ 35.0Nm

Page 1036 of 1336

6. SPECIAL SERVICE TOLLS

Part number Name Tool How to use

00104-001(UD) Remover &

Installer - U/D

brake return sprin

00104-002(OD) Remover&

Installer - O/D

clutch return

spring

00104-003(LR)

(use with 00104-001)Remover&

Installer - L/R

brake return

spring

* Special service tool Supplier: Tool & Tech

Page 1037 of 1336

3660-01

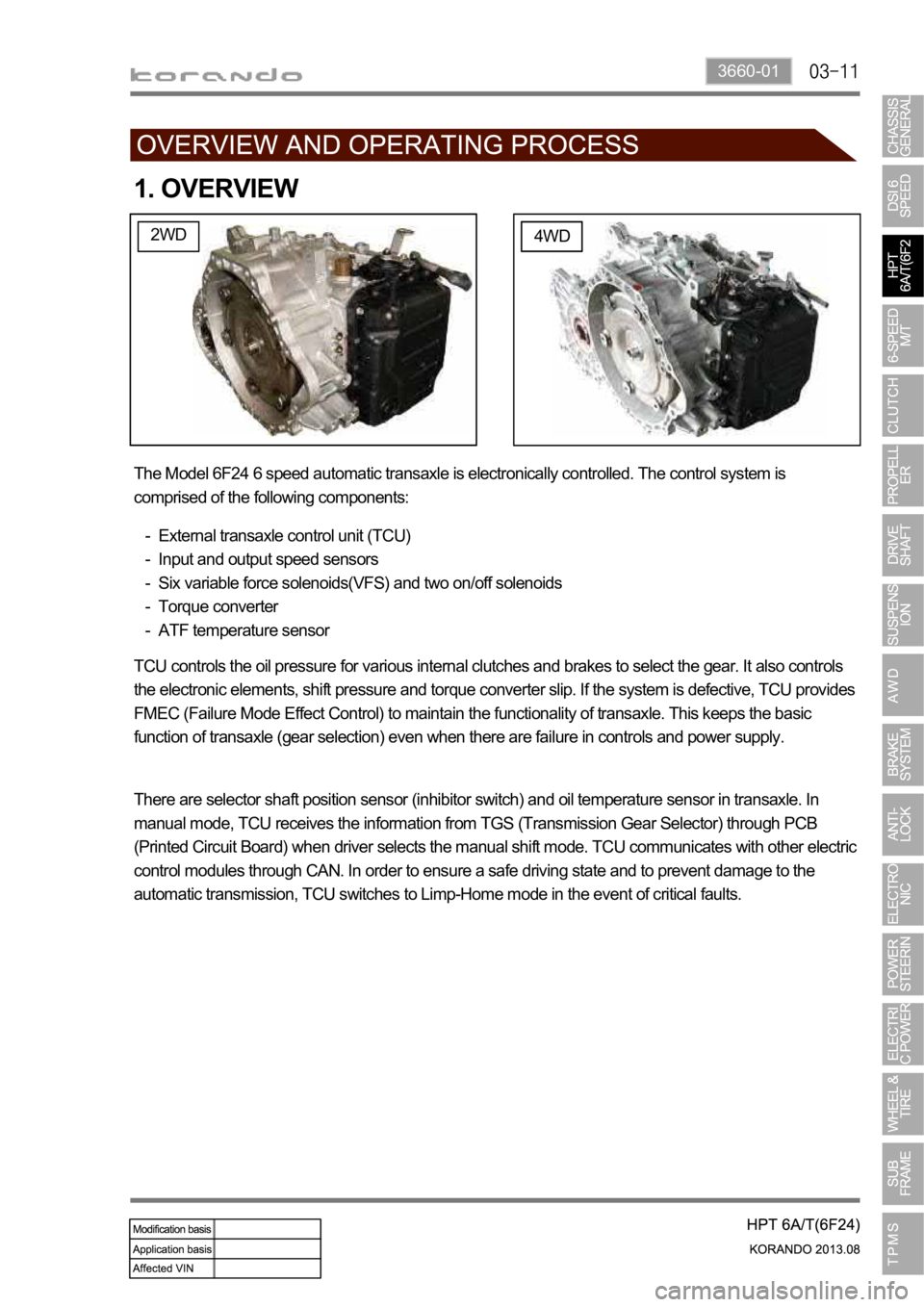

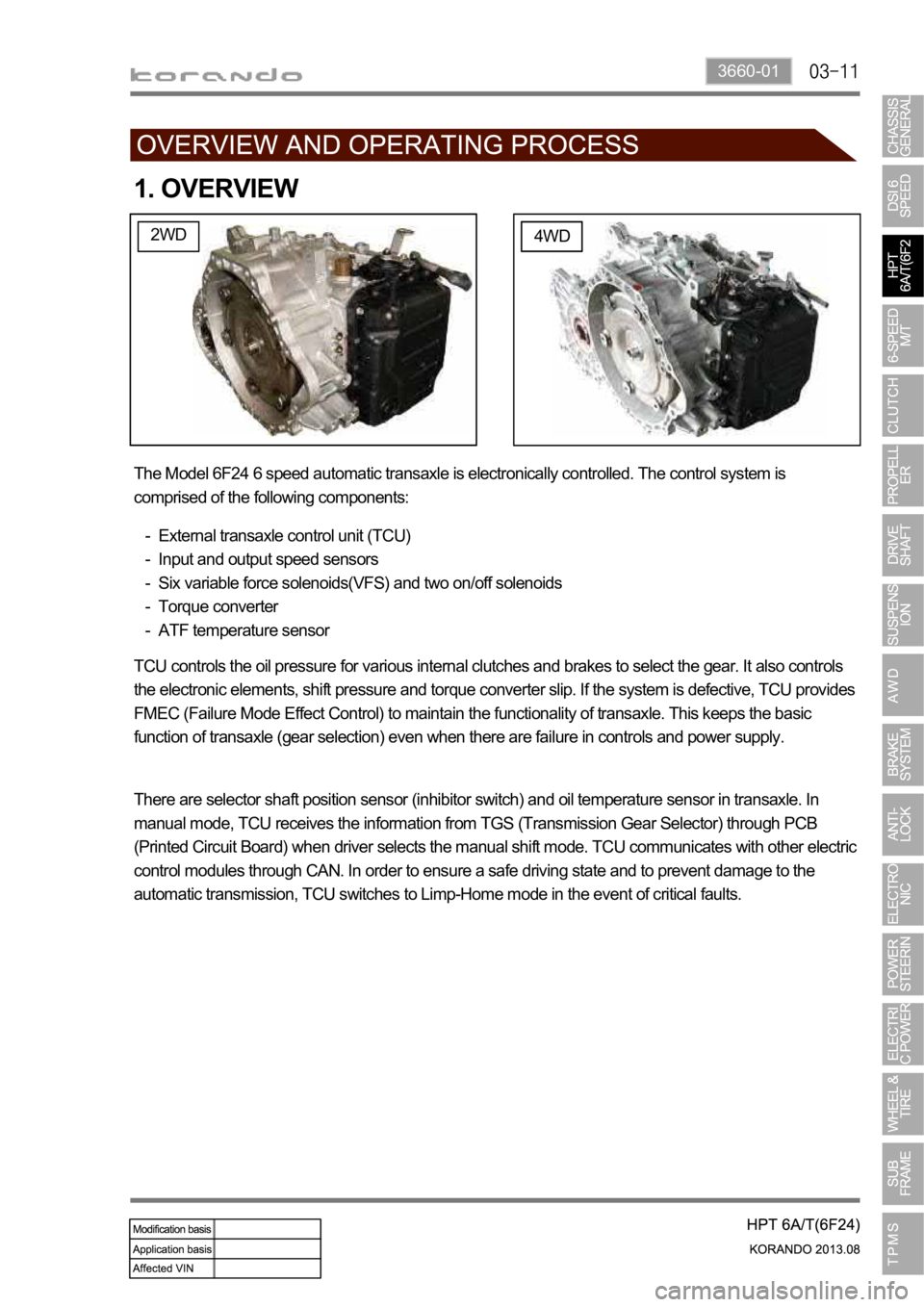

1. OVERVIEW

2WD4WD

The Model 6F24 6 speed automatic transaxle is electronically controlled. The control system is

comprised of the following components:

External transaxle control unit (TCU)

Input and output speed sensors

Six variable force solenoids(VFS) and two on/off solenoids

Torque converter

ATF temperature sensor -

-

-

-

-

TCU controls the oil pressure for various internal clutches and brakes to select the gear. It also controls

the electronic elements, shift pressure and torque converter slip. If the system is defective, TCU provides

FMEC (Failure Mode Effect Control) to maintain the functionality of transaxle. This keeps the basic

function of transaxle (gear selection) even when there are failure in controls and power supply.

There are selector shaft position sensor (inhibitor switch) and oil temperature sensor in transaxle. In

manual mode, TCU receives the information from TGS (Transmission Gear Selector) through PCB

(Printed Circuit Board) when driver selects the manual shift mode. TCU communicates with other electric

control modules through CAN. In order to ensure a safe driving state and to prevent damage to the

automatic transmission, TCU switches to Limp-Home mode in the event of critical faults.

Page 1038 of 1336

2. FEATURES

1) Advantages

Early Downshift with Hard Braking and Skip Shifts

When heavy braking is detected, the transaxle downshifts early and skips gears to provide increased

engine braking to provide gear selection for tip-in.

Gear Hold going Uphill/Downhill

If the accelerator pedal is released when traveling uphill, upshifts are prevented to reduce busyness on

grades. If the accelerator pedal is released when traveling downhill, upshifts are prevented to enhance

engine braking.

Drive and Reverse Engagement

A soft engagement feature avoids harsh take up of drive when selecting Drive or Reverse. This is

achieved by limiting engine speed and engine torque which results in a rapid, but progressive

engagement of either Drive or Reverse when moving from the Park or Neutral positions. Drive and

Reverse engagements from either Park or Neutral are performed in less than 2.2 seconds. There is no

drive engagement prevention strategy implemented on the transaxle system as there is sufficient engine

strategy to protect the system. However, reverse engagement is prevented until vehicle speed is less

than 7 km/h.

Page 1039 of 1336

3660-01

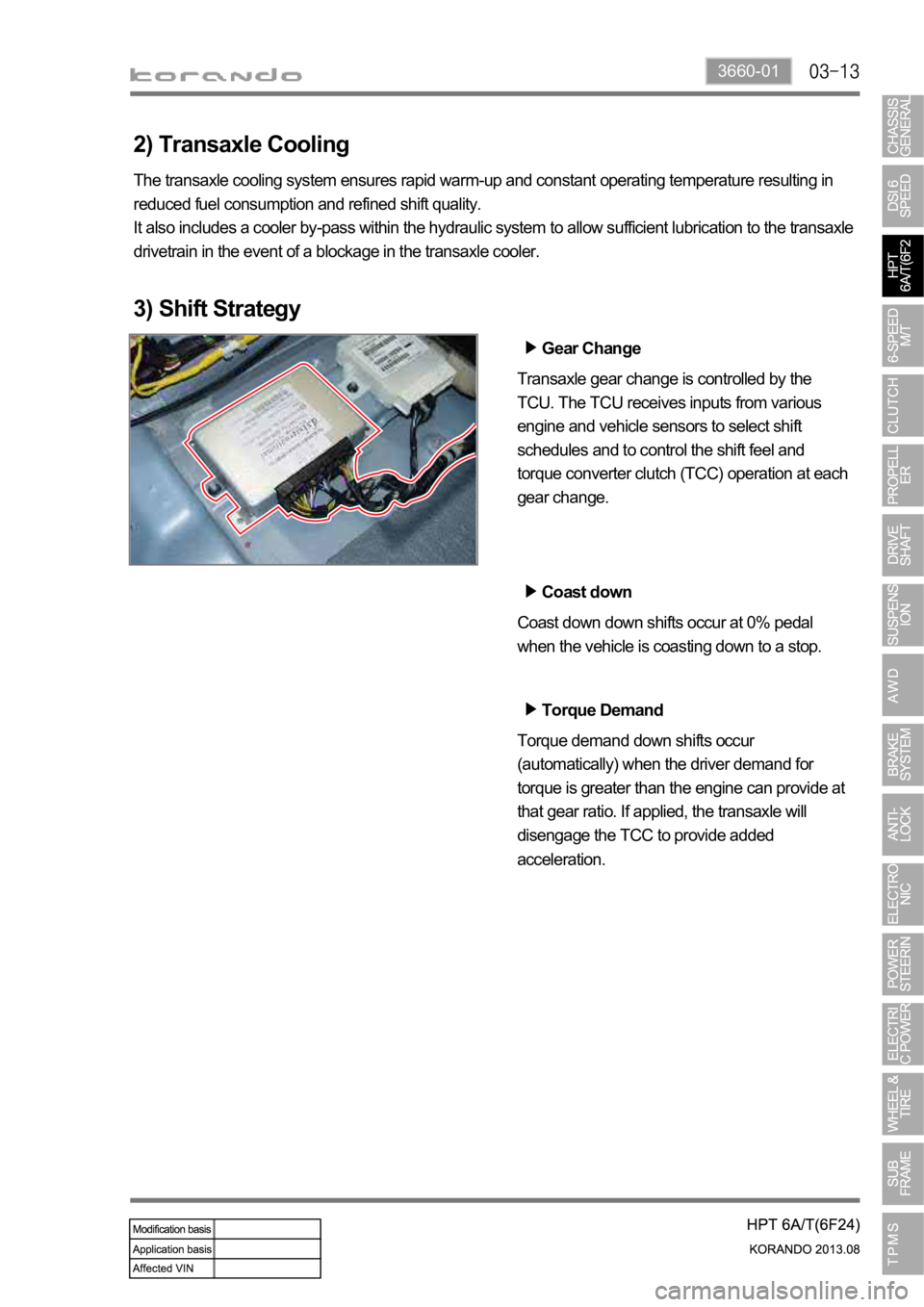

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 1040 of 1336

3. MODES AND FUNCTIONS

This allows the driver to define the highest

position. When the lever is first moved to the

one lower gear than current gear.

When driving on a slippery road, push the tip switch forward into the "+" position in "M" position.

This causes the transaxle to shift into the 2nd gear which is better for smooth driving on a slippery

road.

Trending: fuel filter, brakes, glove box, stop start, turn signal, fuel cap release, maintenance schedule