engine SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 441 of 1336

Fuel and engine oil system

The engine oil and fuel damages the painted surfaces and rubber material of the vehicle.

Disconnect the negative cable from the battery before servicing the fuel system, and prepare the

service plug grip.

When working with the fuel or oil systems in enclosed area, always keep the working area well-

ventilated and never allow anybody to smoke.

Do not allow the gasoline to contact to rubber or leather parts.

Carefully separate the pipe between high pressure fuel pump and fuel injector so that any fuel can

be spilled out.

Fully release the pressure from the fuel system before removing any parts of fuel system.

To release the fuel pressure in high pressure line, let the engine fully cool down.

Gaskets and seals on the fuel and oil systems should be replaced with new ones. All bolts and nuts

should be tightened as specified.

Prolonged exposure to the engine oil make cause a skin cancer or an irritation.

Used engine cotains the hazardous material that may cause the skin cancer. Do not allow the used

engine to make contact with your skin.

Make sure to wear the protection gloves and goggle when handling the engine oil. If contact

happens, rinse affected areas immediately with plenty of water. Do not wash it with gasoline or

solvent. If irritation persists, consult a doctor.

Improperly disposed engine oil can pollute the environment. Dispose the used engine oil and oil

filter in accordance with local environmental regulations.

Make sure to check the connections for leak after installation. -

-

-

-

-

-

-

-

-

-

-

-

Electric devices

To prevent any damage to electric systems, make sure to disconnect the negative (-) cable from the

battery and place the ignition switch to OFF position before servicing.

Use only the specified parts with same ratings when replacing the electric devices. Check the

grounds and connections for looseness. -

- Extraordinary care should be taken when servicing the electric systems. Currently, the engine uses a lot

of electric devices. Short circuit and poor contact may cause the low engine performance, incomplete

combustion and other abnormalities.

Page 442 of 1336

1337-04

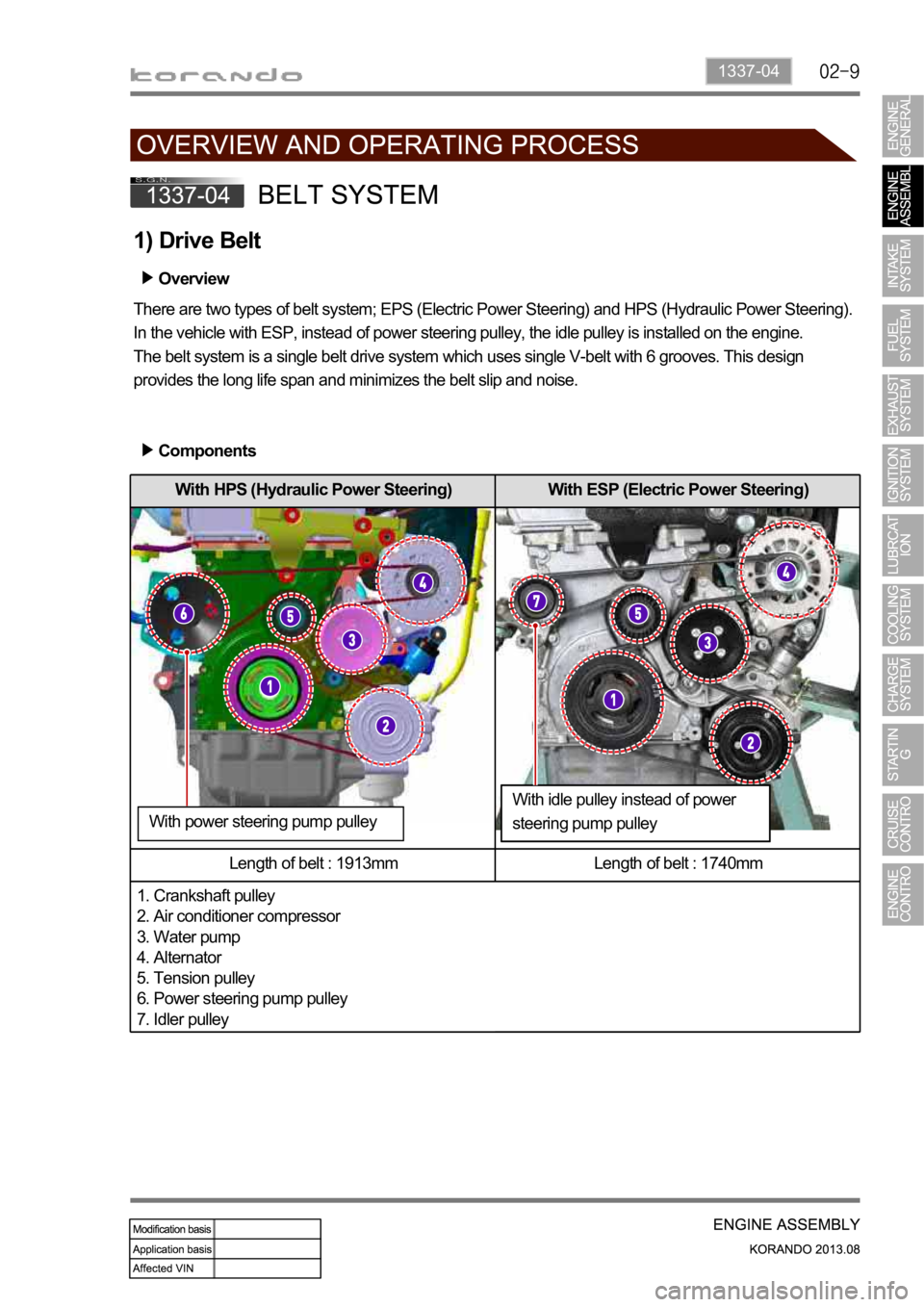

With HPS (Hydraulic Power Steering) With ESP (Electric Power Steering)

Length of belt : 1913mm Length of belt : 1740mm

1. Crankshaft pulley

2. Air conditioner compressor

3. Water pump

4. Alternator

5. Tension pulley

6. Power steering pump pulley

7. Idler pulley

1) Drive Belt

Overview

There are two types of belt system; EPS (Electric Power Steering) and HPS (Hydraulic Power Steering).

In the vehicle with ESP, instead of power steering pulley, the idle pulley is installed on the engine.

The belt system is a single belt drive system which uses single V-belt with 6 grooves. This design

provides the long life span and minimizes the belt slip and noise.

Components

With idle pulley instead of power

steering pump pulley With power steering pump pulley

Page 443 of 1336

2) Hydraulic Tensioner Assembly

The hydraulic tensioner maintains the belt tension to minimize the slip and vibration and provides long

life span of the belt. Hydraulic tensioner consists of hydraulic tension spring, hydraulic damper, lever arm

and tension pulley.

To transfer the tension to the belt from the hydraulic tensioner in small working space in G20DF engine,

the belt system uses the longer lever arm.Overview

Location and Components

Hydraulic tensioner assembly

Components

No Name

1 Tensioner pulley cap

2 Tensioner pulley mounting bolt

3 Tensioner pulley

4 Lever arm

5 Hydraulic tensioner bolt

6 Hydraulic tensioner

Page 445 of 1336

Location

Front mounting assembly

Location: Front side of transaxle housing and

front side of sub frame

Location Front mountingRight mounting assembly

Location: Engine block side and body side

member

Location Right mounting

Left mounting assembly

Location: Upper side of transaxle housing and

body side member

Location Left mountingRear mounting assembly

Location: Rear side of transaxle housing and front

side of sub frame

Location Rear mounting

Page 453 of 1336

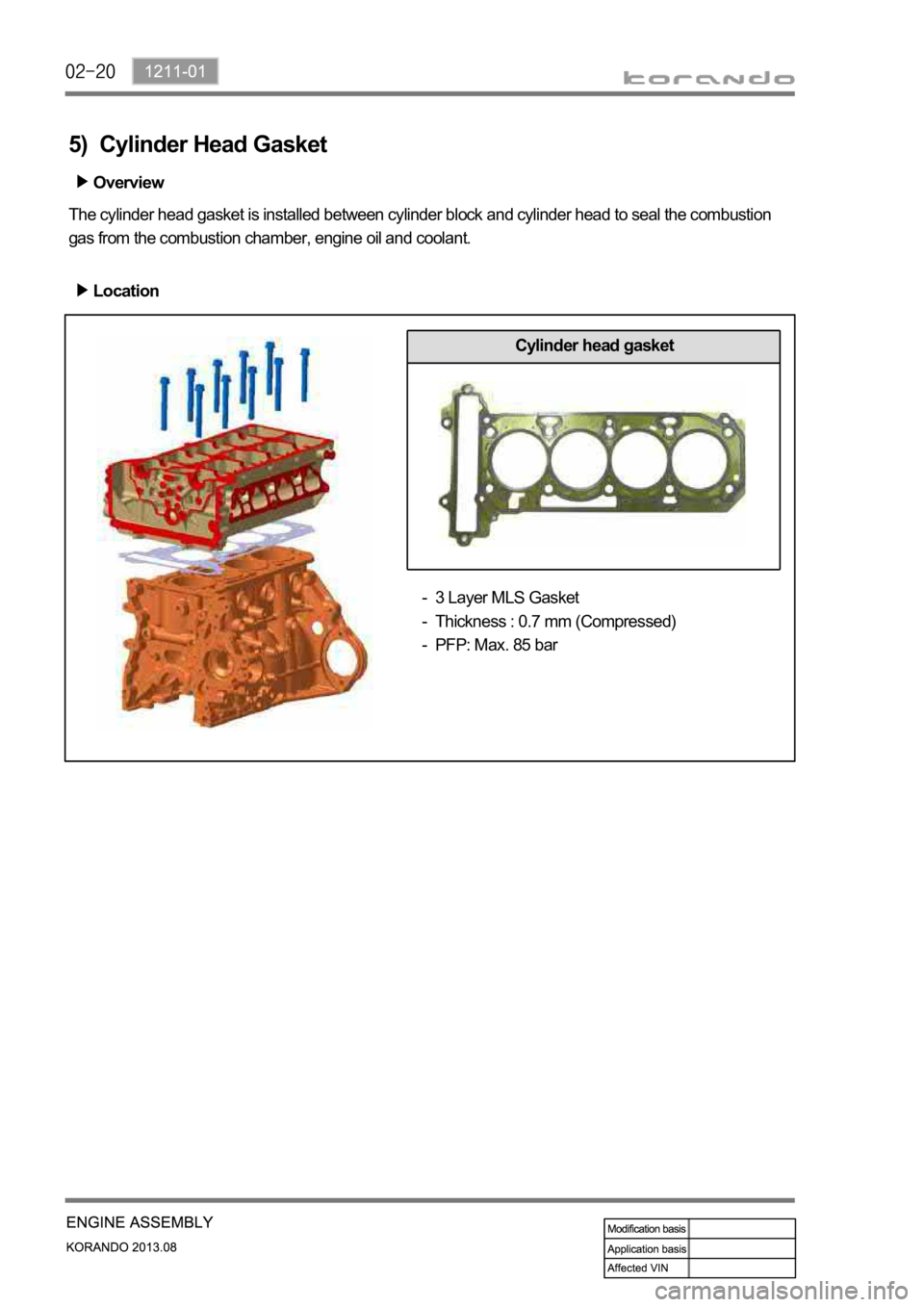

5) Cylinder Head Gasket

The cylinder head gasket is installed between cylinder block and cylinder head to seal the combustion

gas from the combustion chamber, engine oil and coolant.Overview

Location

Cylinder head gasket

3 Layer MLS Gasket

Thickness : 0.7 mm (Compressed)

PFP: Max. 85 bar -

-

-

Page 455 of 1336

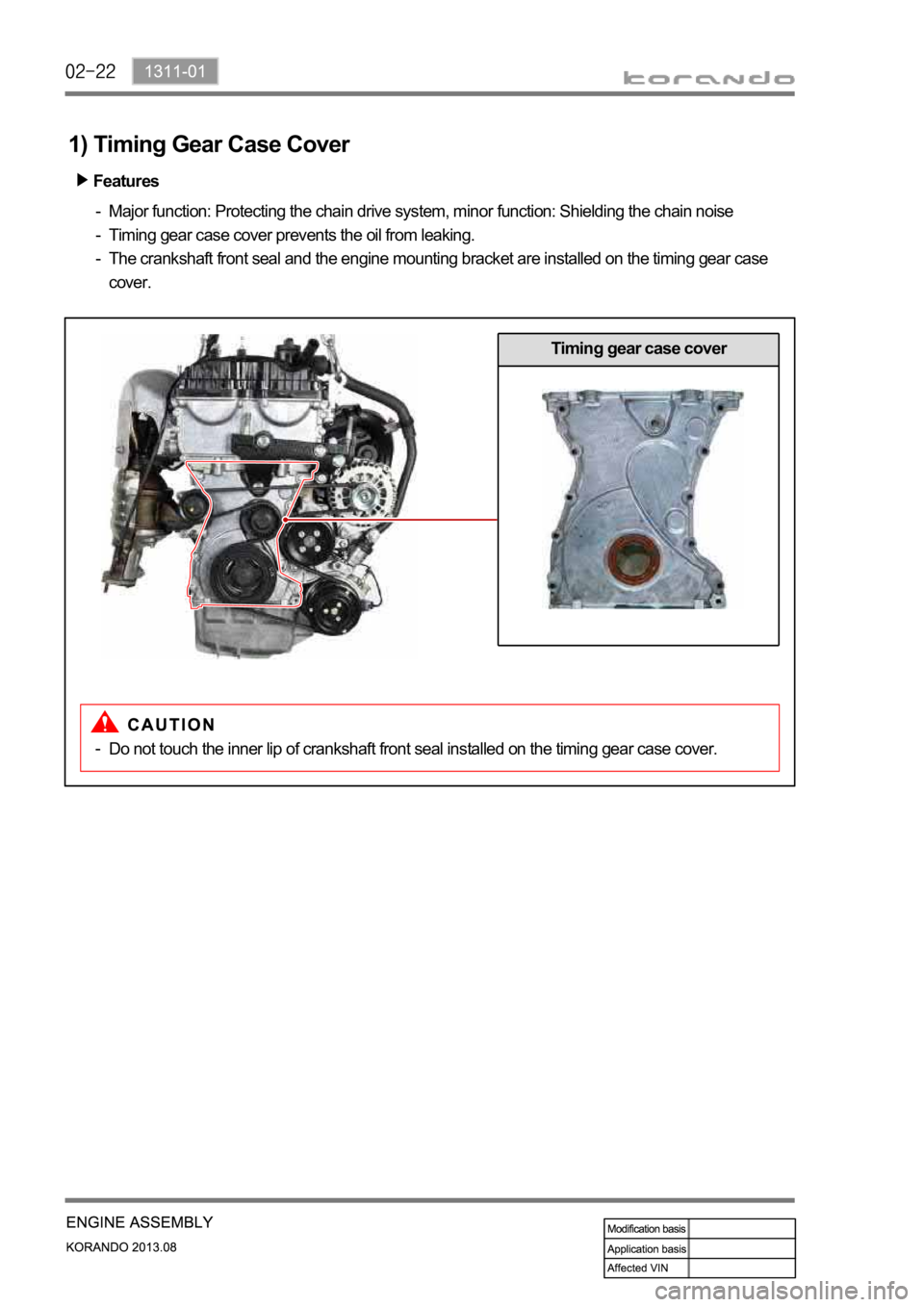

1) Timing Gear Case Cover

Features

Major function: Protecting the chain drive system, minor function: Shielding the chain noise

Timing gear case cover prevents the oil from leaking.

The crankshaft front seal and the engine mounting bracket are installed on the timing gear case

cover. -

-

-

Timing gear case cover

Do not touch the inner lip of crankshaft front seal installed on the timing gear case cover. -

Page 456 of 1336

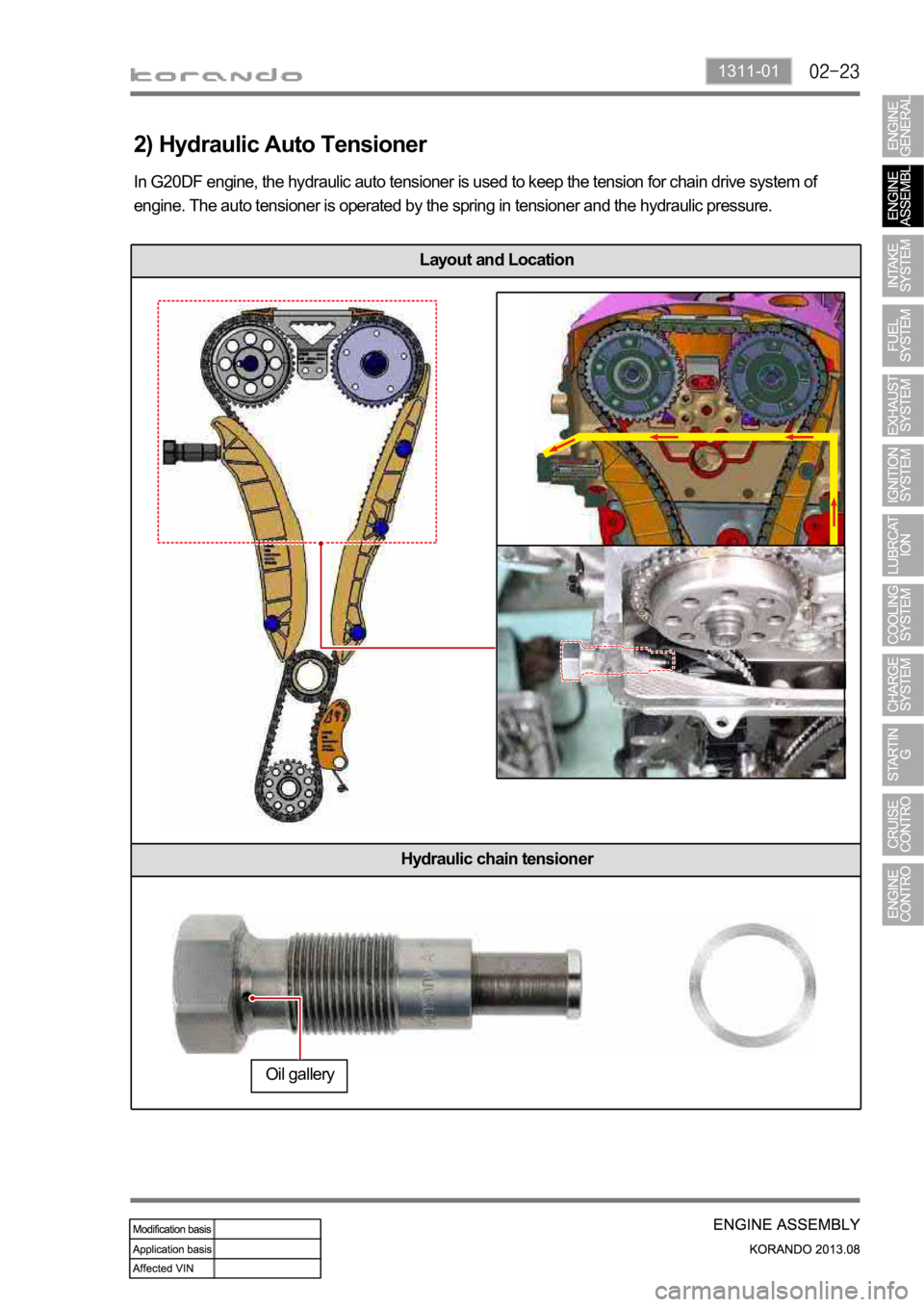

1311-01

Layout and Location

Hydraulic chain tensioner

In G20DF engine, the hydraulic auto tensioner is used to keep the tension for chain drive system of

engine. The auto tensioner is operated by the spring in tensioner and the hydraulic pressure.

2) Hydraulic Auto Tensioner

Oil gallery

Page 459 of 1336

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

5) Chain Rails

The chain rails are used for optimizing the movement of chain drive system. And they also prevent the

chain from contacting each other when the chain is loose, and reduces the chain wear. The chain rail is

normally made of PA (Polyamide nylon), and PA66 and PA46 are used for the chain rails in G20DF

engine. For the tensioner rail, PA46 is used to provide high anti-wear function and high strength since

the load to the rail is huge. Ther is an open area for shoulder bolt hole in the clamping rail. The chain

rails are installed by shoulder bolts.

Tensioner rail

Installed between

exhaust camshaft

sprocket and crankshaft

sprocket

Page 460 of 1336

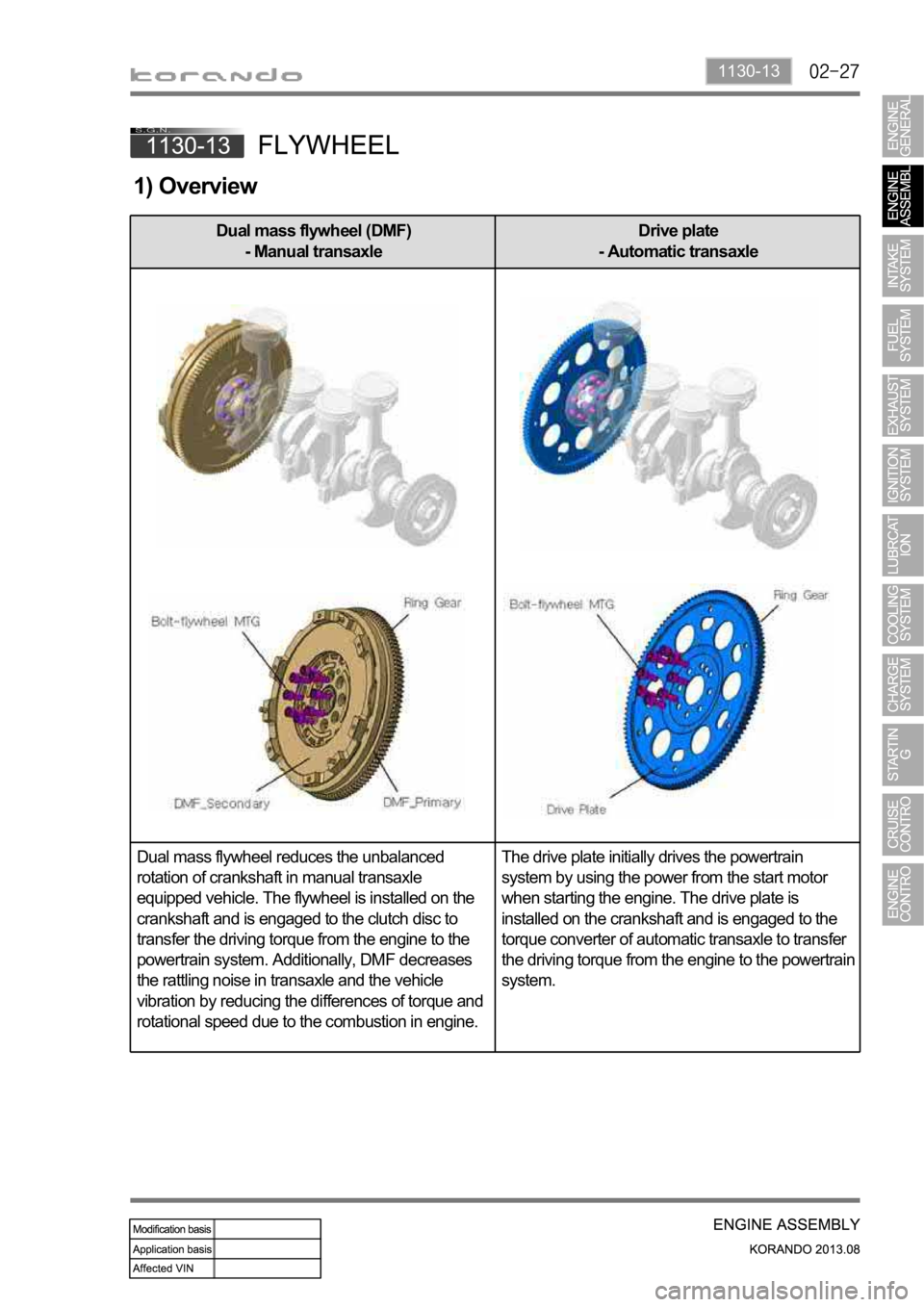

1130-13

1) Overview

Dual mass flywheel (DMF)

- Manual transaxleDrive plate

- Automatic transaxle

Dual mass flywheel reduces the unbalanced

rotation of crankshaft in manual transaxle

equipped vehicle. The flywheel is installed on the

crankshaft and is engaged to the clutch disc to

transfer the driving torque from the engine to the

powertrain system. Additionally, DMF decreases

the rattling noise in transaxle and the vehicle

vibration by reducing the differences of torque and

rotational speed due to the combustion in engine.The drive plate initially drives the powertrain

system by using the power from the start motor

when starting the engine. The drive plate is

installed on the crankshaft and is engaged to the

torque converter of automatic transaxle to transfer

the driving torque from the engine to the powertrain

system.

Page 461 of 1336

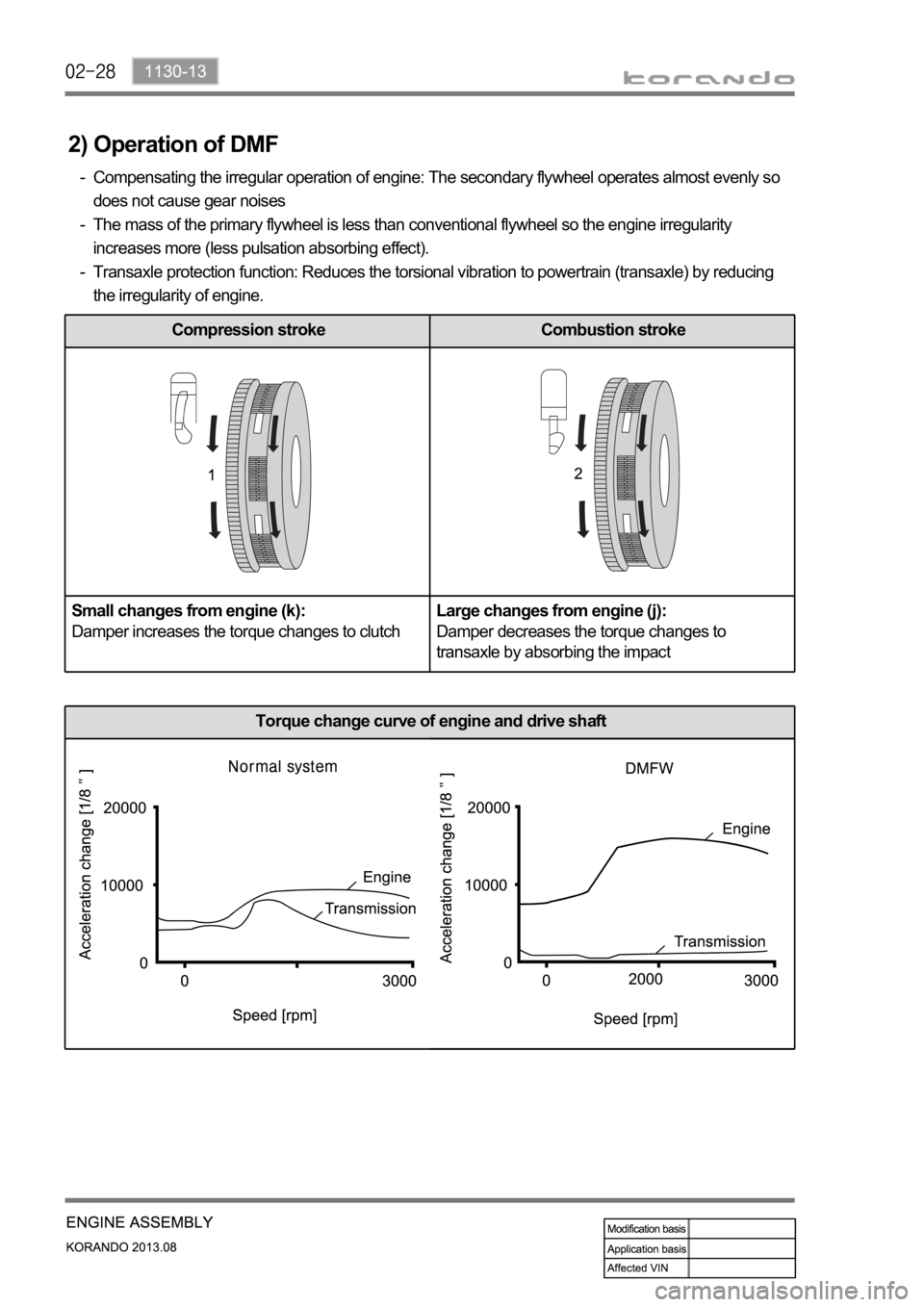

2) Operation of DMF

Compensating the irregular operation of engine: The secondary flywheel operates almost evenly so

does not cause gear noises

The mass of the primary flywheel is less than conventional flywheel so the engine irregularity

increases more (less pulsation absorbing effect).

Transaxle protection function: Reduces the torsional vibration to powertrain (transaxle) by reducing

the irregularity of engine. -

-

-

Compression stroke Combustion stroke

Small changes from engine (k):

Damper increases the torque changes to clutchLarge changes from engine (j):

Damper decreases the torque changes to

transaxle by absorbing the impact

Torque change curve of engine and drive shaft