Intake SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 274 of 1336

3) Inspection of Turbine

Thoroughly check the followings.

Interference: In case where is trace of interference or smallest damage on the compressor wheel

means, most of times, that abrasion has occurred on the journal bearing. Must inspect after the

overhaul.

Oil Leakage: The reason for oil leakage at the compressor section is the air cleaner, clogged by

substances such as dust, causes the compressor inlet negative pressure. -

-

Rotating in high speed at no-load for extended period of time can cause oil leakage to the

compressor section as oil pressure within the center housing gets higher than pressure within the

compressor housing.

Overuse of engine break (especially in low gear) in down hill makes significantly low exhaust gas

energy compared to the time where great amount of air is required during idling conditions of the

engine. Therefore, amount of air in the compressor inlet increases but the turbocharge pressure

is not high, which makes negative pressure at the compressor section causing the oilleakage

within the center housing. a.

b.

No problem will occur with the turbocharger if above conditions are found in early stage but oil

leaked over long period of time will solidify at each section causing to breakout secondary

defects.

Damages by foreign materials: In case where the compressor wheel is damaged by foreign materials

requires having an overhaul. At this time, it's necessary to check whether the foreign materials have

contaminated intake/exhaust manifold or inside of engine.

Must absolutely not operate the turbocharger with the compressor outlet and inlet opened

as it could damage the turbocharger or be hazardous during inspection.

Page 279 of 1336

0000-00

3. TROUBLESHOOTING

The followings are cautions to take in handling defects of turbocharger, which must be fully aware of.

1) Cautions

After stopping the engine, check whether the bolts on pipe connecting section are

loose as well as the connecting condition of vacuum port and modulator, which is

connected to the actuator.

During idling of the engine, check for leakage in the connecting section of pipe (hoses

and pipes, duct connections, after the turbocharger) by applying soap water. The

leakage condition in the engine block and turbine housing opening can be determined

by the occurrence of abnormal noise of exhaust.

By running the engine at idle speed, abnormal vibration and noise can be checked.

Immediately stop the engine when abnormal vibration and noise is detected and make

thorough inspection whether the turbocharger shaft wheel has any damages as well as

checking the condition of connections between pipes.

In case where the noise of engine is louder than usual, there is possibility of dampness

in the areas related with air cleaner and engine or engine block and turbocharger. And

it could affect the smooth supply of engine oil and discharge.

Check for damp condition in exhaust gas when there is sign of thermal discoloration or

discharge of carbon in connecting area of the duct.

When the engine rotates or in case where there is change in noise level, check for

clogging of air cleaner or air cleaner duct or if there is any significant amount of dust in

the compressor housing.

During the inspection of center housing, inspect inside of the housing by removing the

oil drain pipe to check for sludge generation and its attachment condition at shaft area

or turbine side.

Inspect or replace the air cleaner when the compressor wheel is damaged by inflow of

foreign materials.

Inspect both side of the turbocharger wheel after removing inlet and outlet pipe of the

turbocharger.

- Is the rotation smooth when the rotor is rotated by hand?

- Is the movement of bearing normal?

- Inspect whether there has been any signs of interference between two wheels. 1.

2.

3.

4.

5.

6.

7.

8.

9.

It's important not to drive the engine when the intake manifold hose has been removed.

Page 285 of 1336

0000-00

1. SYSTEM DESCRIPTION OF E-VGT

(Electric-Variable Geometry Turbine)

A turbocharger is a centrifugal compressor powered by a high speed turbine that is driven by an engine's

exhaust gases. Its benefit lies with the compressor increasing the mass of air entering the engine (forced

induction), thereby resulting in greater performance (for either, or both, power and efficiency). As the

turbine, at exhaust end, is rotated by exhaust gas pressure the impeller, at intake end, gets rotated to

send air around center of the impeller, being circumferentially accelerated by the centrifugal force, into

the diffuser. The air, which has been introduced to the diffuser having a passage with big surface,

transforms its speed energy into the pressure energy while being supplied to the cylinder improving the

volume efficiency. Also, the exhaust efficiency improves as the exhaust turbine rotates. The

turbocharger is often referred to as the exhaust turbine turbocharger.

The E-VGT system installed to the D20DTF engine variably controls the passages of the turbine

housing to regulate the flow rate of the exhaust gas. The actuator of E-VGT is a DC motor actuator (E-

Actuator) which controls more quickly and precisely than the previous vacuum type actuator.

The engine ECU controls the E-Actuator electronically as follows:

Diffuser: With the meaning of spreading out it is a device that transforms fluid's speed energy into the

pressure energy by enlarging the fluid's passage to slow down the flow.

At low speed: Narrows the flow passage for the exhaust gas, resulting in increasing the flow speed

of the exhaust gas and running the turbine quickly and powerfully.

At high speed: Expands the flow passage for the exhaust gas, resulting in increasing the mass flow

of the exhaust gas and running the turbine more powerfully. -

-

Page 286 of 1336

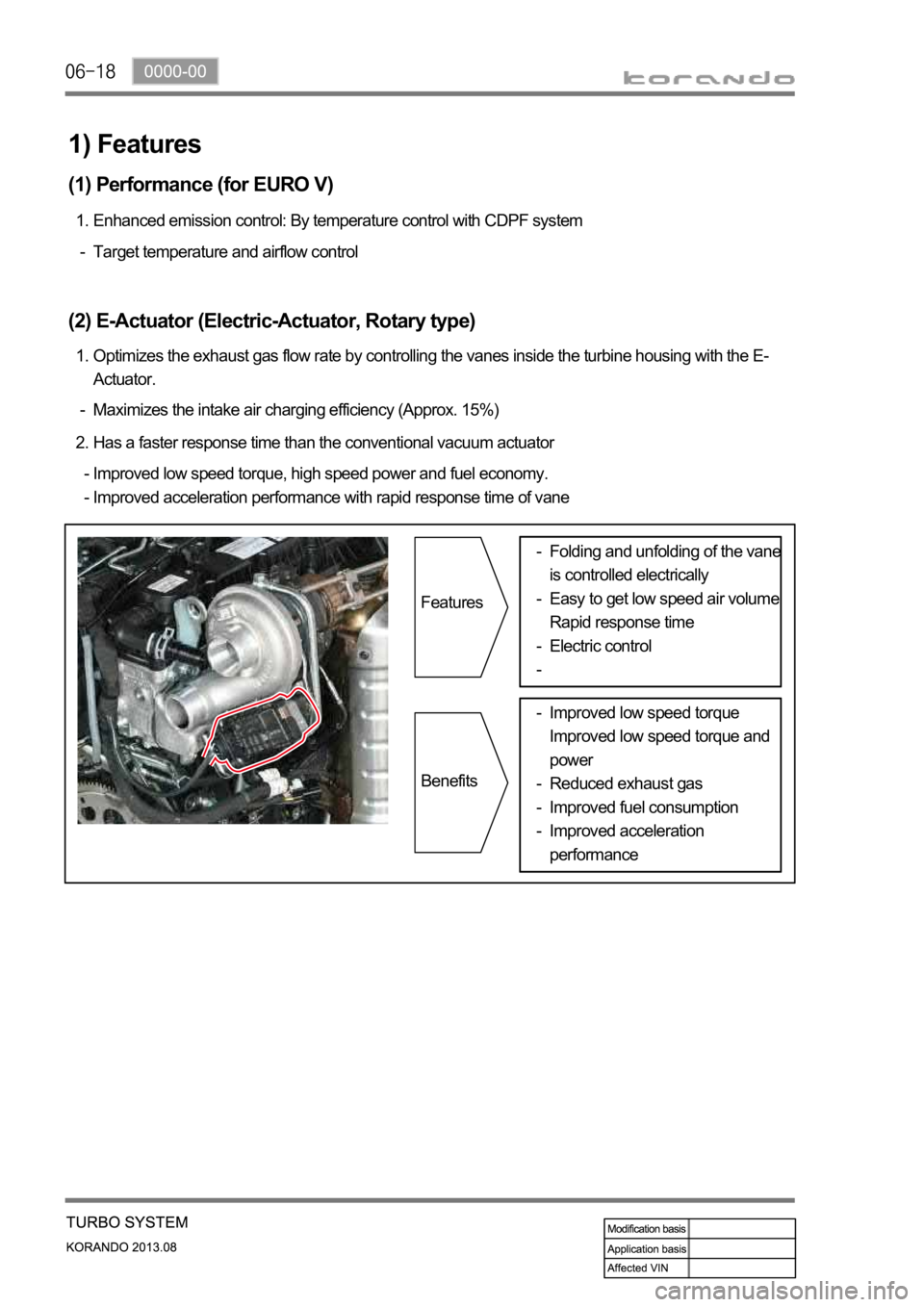

Maximizes the intake air charging efficiency (Approx. 15%) -Optimizes the exhaust gas flow rate by controlling the vanes inside the turbine housing with the E-

Actuator. 1.

(2) E-Actuator (Electric-Actuator, Rotary type)

Target temperature and airflow control -Enhanced emission control: By temperature control with CDPF system 1.

(1) Performance (for EURO V)

Has a faster response time than the conventional vacuum actuator 2.

Improved low speed torque, high speed power and fuel economy.

Improved acceleration performance with rapid response time of vane -

-

1) Features

Features

BenefitsFolding and unfolding of the vane

is controlled electrically

Easy to get low speed air volume

Rapid response time

Electric control -

-

-

-

Improved low speed torque

Improved low speed torque and

power

Reduced exhaust gas

Improved fuel consumption

Improved acceleration

performance -

-

-

-

Page 289 of 1336

0000-00

Basic principle at low speed

At low speed, it utilizes the principle of venturi. For

example, when air flows through the venturi tube,

the flow speed is faster and the pressure is lower

at the point "A". In this case, if the inner diameter

of venturi is more narrowed, the flow speed is so

much faster (refer to the equation).

Control

rangeTurbocharger driving

mechanismControl method

EffectImproved

performance

At low

speedNarrows the flow

passage for the

exhaust gas by

folding the vanesThe flow rate is

increased as the

exhaust gas passes

the narrow passage

turbine & impeller

speed, Increased

compressive forceImproved

low speed torque

4. OPERATING PRINCIPLES

The E-VGT is designed to get more improved engine power in all ranges by controlling the turbine as

follows:

1) How it Works at Low Speed

Normal turbocharger cannot get the turbo effect because the amount of exhaust gas is not enough and

the flow speed is slow in a low speed zone, but VGT allows the flow passage of exhaust to narrow,

resulting in increasing the flow speed of exhaust gas and running the turbine quickly and powerfully.

Therefore, as VGT can intake more air than normal turbocharger, it can give the benefit of the increased

output even in a low speed zone.

Turbocharger lag

The turbocharger is at idle speed when there is no load or it is in the normal driving condition. During

this period, the amount of exhaust gas passing through the turbine is not enough to turn the

compressor wheel (impeller) fast. Therefore, the intake air is not compressed as needed.

Because of this, it takes time for turbocharger to supply the additional power after the accelerator

pedal is depressed. This is called "turbocharger lag".

Page 290 of 1336

2) How it Works at High Speed

In a high speed zone, the amount of exhaust gas increases and it is accompanied with a great force.

Therefore, if the inner diameter of venturi is more widened, the turbine in the turbocharger by the

releasing force of abundant exhaust gas can deliver a more increased energy to the compressor. The

output will increase in submission to the increase of intake air volume.

Control

rangeTurbocharger driving

mechanismControl method

EffectImproved

performance

At high

speedExpands the flow

passage for the

exhaust gas by

unfolding the vanesThe flow rate is

increased due to the

Increased turbine &

impeller speed,

Increased

compressive forceImproved

maximum

power

Page 322 of 1336

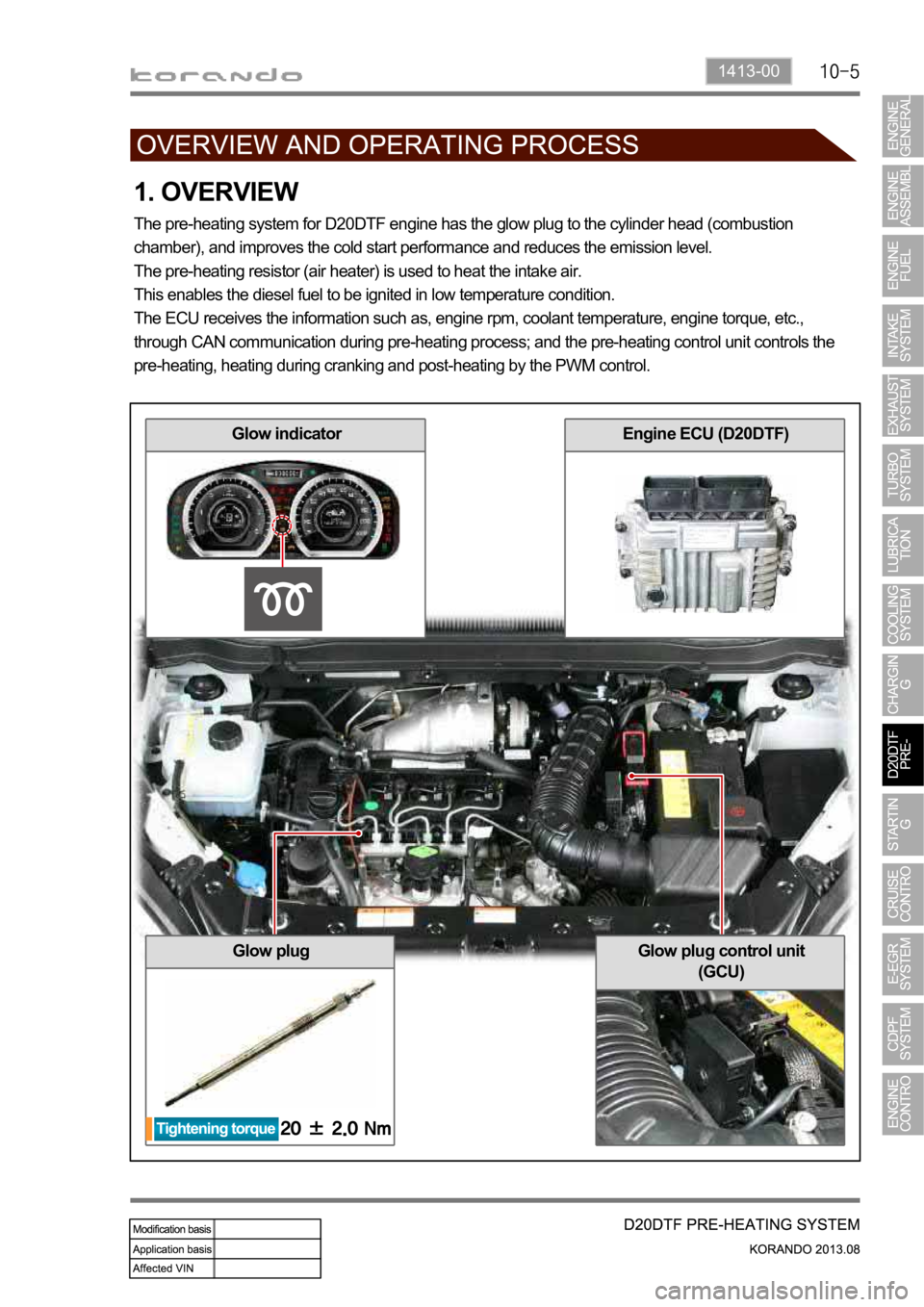

1413-00

1. OVERVIEW

The pre-heating system for D20DTF engine has the glow plug to the cylinder head (combustion

chamber), and improves the cold start performance and reduces the emission level.

The pre-heating resistor (air heater) is used to heat the intake air.

This enables the diesel fuel to be ignited in low temperature condition.

The ECU receives the information such as, engine rpm, coolant temperature, engine torque, etc.,

through CAN communication during pre-heating process; and the pre-heating control unit controls the

pre-heating, heating during cranking and post-heating by the PWM control.

Glow plugGlow plug control unit

(GCU)

Glow indicatorEngine ECU (D20DTF)

Page 355 of 1336

1. SYSTEM DESCRIPTION

1) Overview

The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating

some of the exhaust gas to the intake system.

To meet Euro-V regulation, the capacity and response rate of E-EGR valve in D20DTF engine have

been greatly improved. The EGR cooler with high capacity reduces the Nox, and the bypass valve

reduces the CO and HC due to EGR gas before warming up.

Also, the engine ECU adjusts the E-EGR opening by using the air mass signal through HFM sensor. If

the exhaust gas gets into the intake manifold when the EGR valve is open, the amount of fresh air

through HFM sensor should be decreased.

Benefits of E-EGR valve

Improved accuracy and response through electric control

Feedback function (Potentiometer)

Preventing chattering of EGR valve and improved durability

Self-cleaning function -

-

-

-

Page 356 of 1336

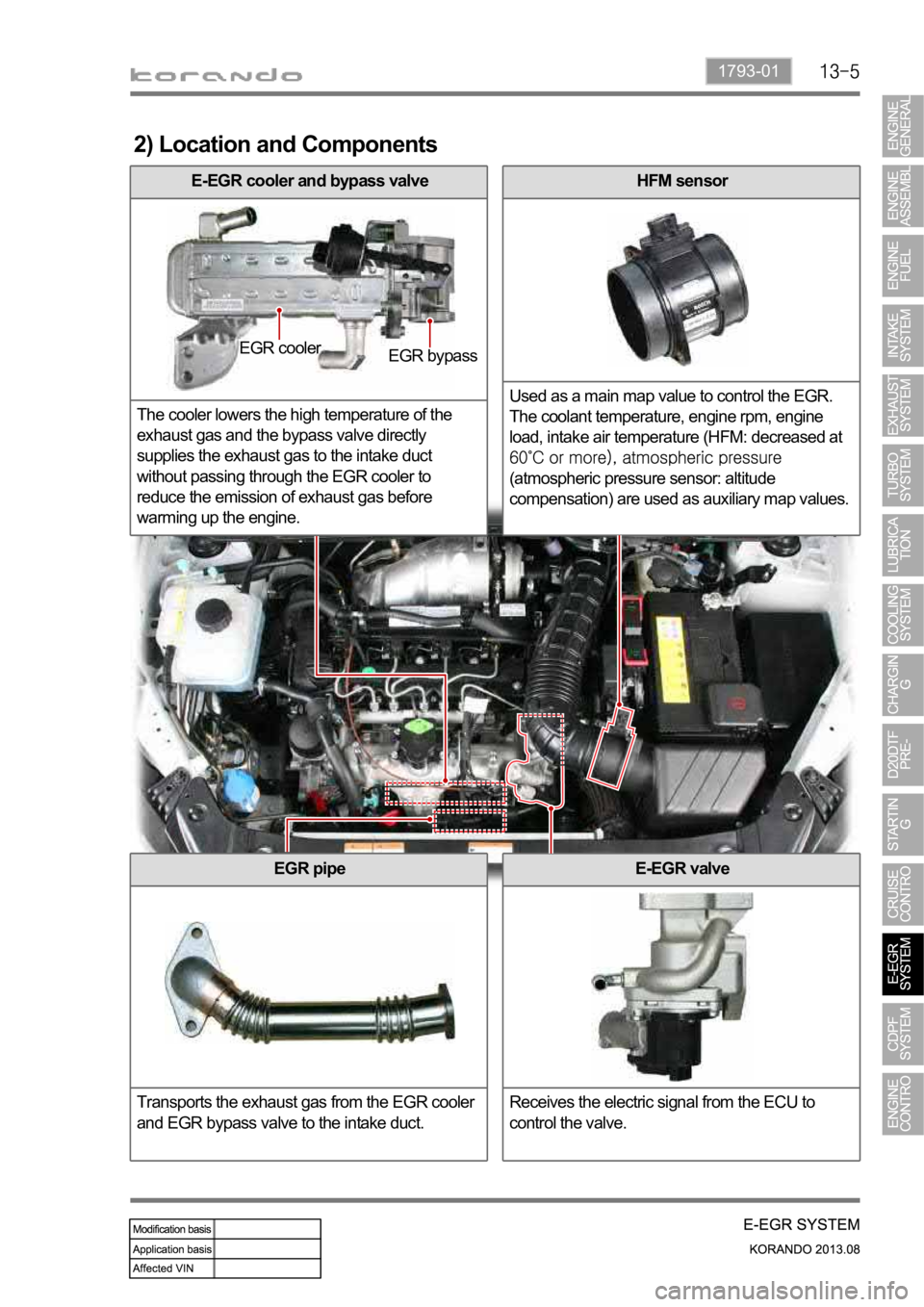

1793-01

2) Location and Components

HFM sensor

Used as a main map value to control the EGR.

The coolant temperature, engine rpm, engine

load, intake air temperature (HFM: decreased at

(atmospheric pressure sensor: altitude

compensation) are used as auxiliary map values.

EGR pipe

Transports the exhaust gas from the EGR cooler

and EGR bypass valve to the intake duct.

E-EGR cooler and bypass valve

The cooler lowers the high temperature of the

exhaust gas and the bypass valve directly

supplies the exhaust gas to the intake duct

without passing through the EGR cooler to

reduce the emission of exhaust gas before

warming up the engine.

E-EGR valve

Receives the electric signal from the ECU to

control the valve.

EGR cooler

EGR bypass

Page 358 of 1336

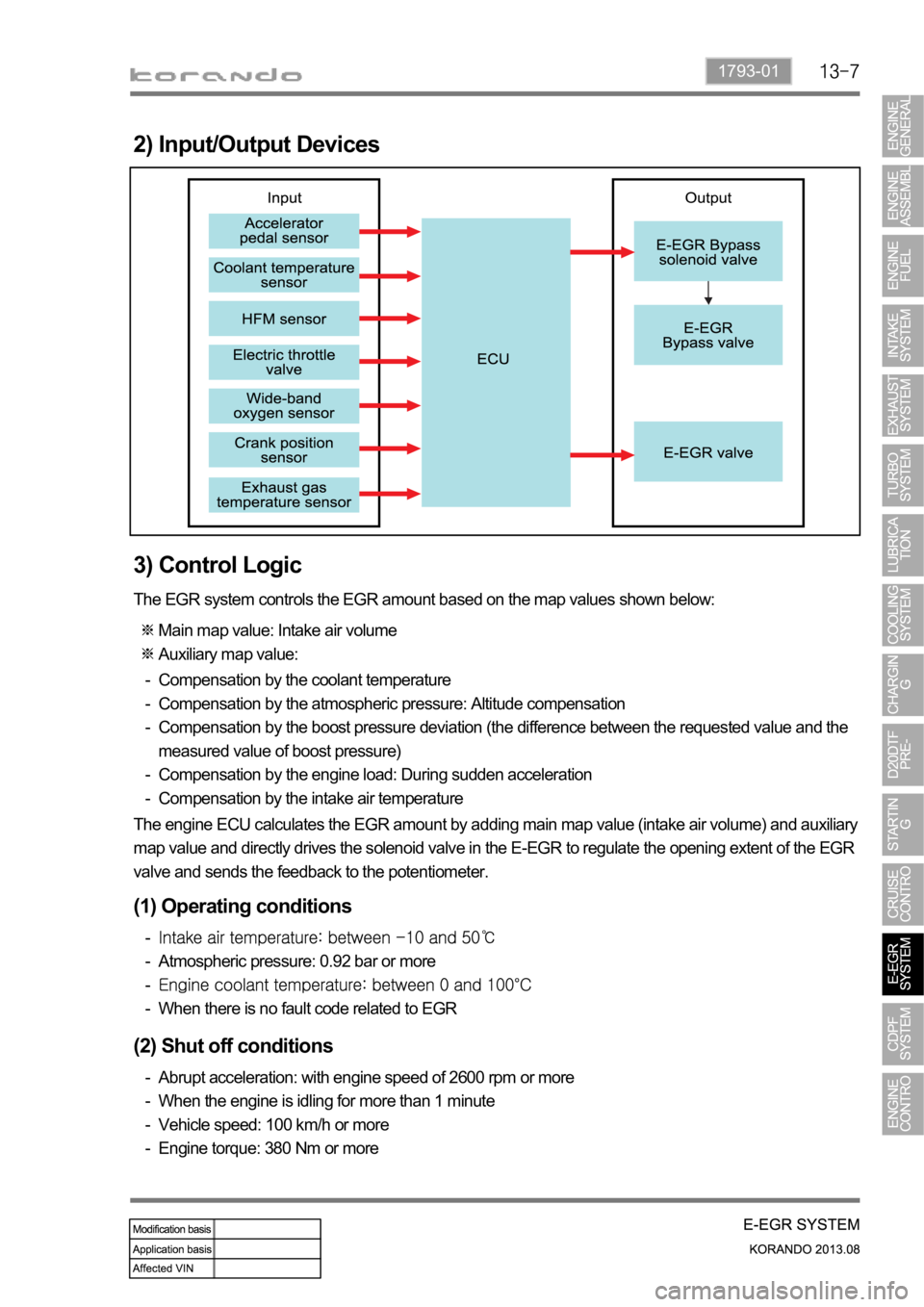

1793-01

2) Input/Output Devices

3) Control Logic

The EGR system controls the EGR amount based on the map values shown below:

Main map value: Intake air volume

Auxiliary map value:

Compensation by the coolant temperature

Compensation by the atmospheric pressure: Altitude compensation

Compensation by the boost pressure deviation (the difference between the requested value and the

measured value of boost pressure)

Compensation by the engine load: During sudden acceleration

Compensation by the intake air temperature -

-

-

-

-

The engine ECU calculates the EGR amount by adding main map value (intake air volume) and auxiliary

map value and directly drives the solenoid valve in the E-EGR to regulate the opening extent of the EGR

valve and sends the feedback to the potentiometer.

(1) Operating conditions

Atmospheric pressure: 0.92 bar or more

When there is no fault code related to EGR -

-

-

-

(2) Shut off conditions

Abrupt acceleration: with engine speed of 2600 rpm or more

When the engine is idling for more than 1 minute

Vehicle speed: 100 km/h or more

Engine torque: 380 Nm or more -

-

-

-