torque SSANGYONG KORANDO 2013 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 462 of 1336

1130-13

3) Features of DMF

Reduced vibration noise from the powertrain by blocking the torsional vibrations

Enhanced vehicle silence and riding comforts: reduced engine torque fluctuation

Reduced shifting shocks

Smooth acceleration and deceleration -

-

-

-

4) Advantages of DMF

Improved torque response by using 2-stage type spring: Strengthens the torque response in all

ranges (low, medium, and high speed) by applying respective spring constant at each

range.

Stable revolution of the primary and secondary wheel by using planetary gear: Works as auxiliary

damper against spring changes

Less heat generation due to no direct friction against spring surface: Plastic material is covered on the

spring outer surface

Increased durability by using plastic bushing (extends the lifetime of grease) -

-

-

-

Page 514 of 1336

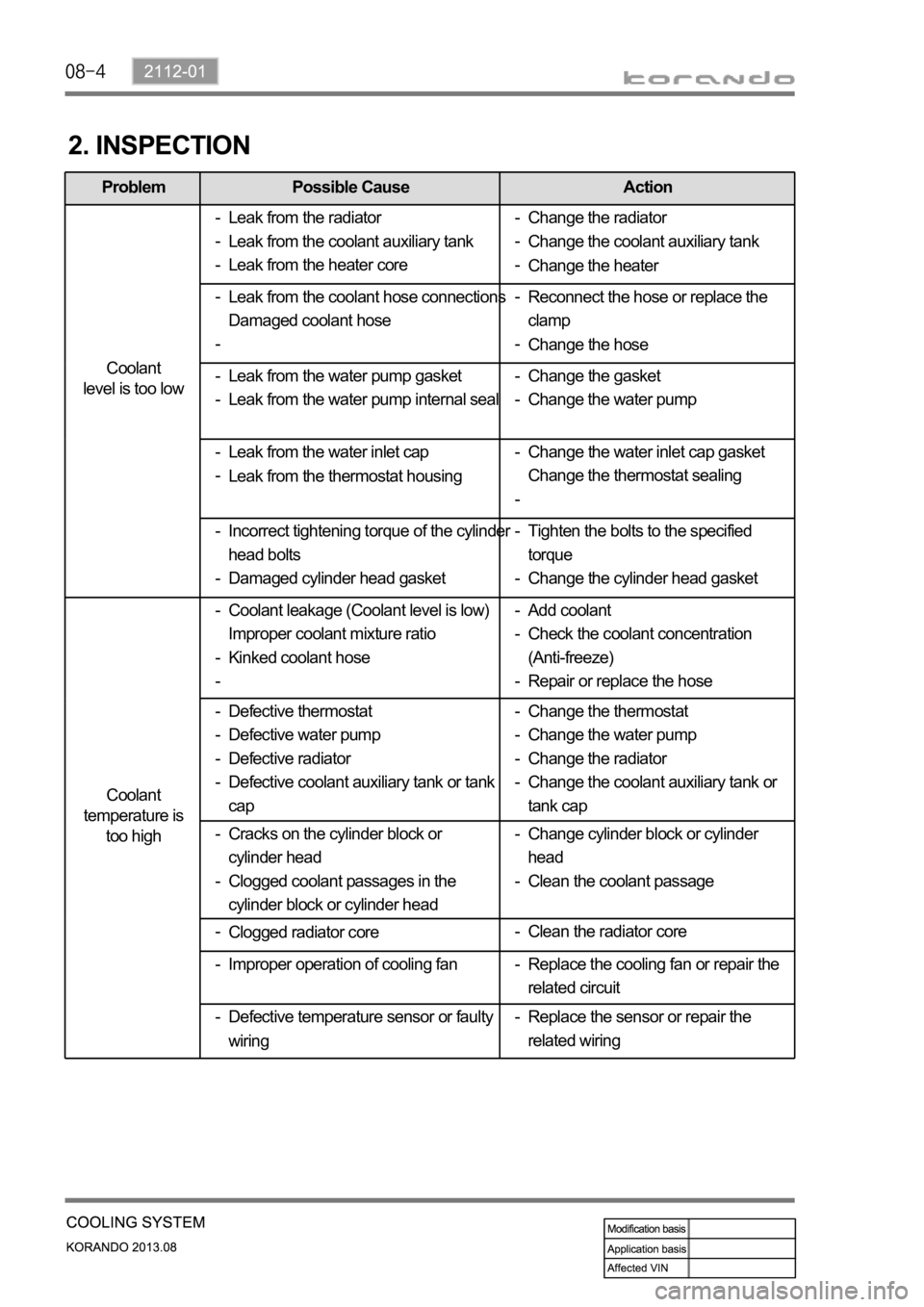

Problem Possible Cause Action

Coolant

level is too low

Coolant

temperature is

too high

2. INSPECTION

Leak from the radiator

Leak from the coolant auxiliary tank

Leak from the heater core -

-

-

Leak from the water inlet cap

Leak from the thermostat housing -

-Reconnect the hose or replace the

clamp

Change the hose -

- Leak from the coolant hose connections

Damaged coolant hose -

-

Change the gasket

Change the water pump -

- Leak from the water pump gasket

Leak from the water pump internal seal -

-

Tighten the bolts to the specified

torque

Change the cylinder head gasket -

- Incorrect tightening torque of the cylinder

head bolts

Damaged cylinder head gasket -

-Change the water inlet cap gasket

Change the thermostat sealing -

-

Coolant leakage (Coolant level is low)

Improper coolant mixture ratio

Kinked coolant hose -

-

-Add coolant

Check the coolant concentration

(Anti-freeze)

Repair or replace the hose -

-

-

Defective thermostat

Defective water pump

Defective radiator

Defective coolant auxiliary tank or tank

cap -

-

-

-Change the thermostat

Change the water pump

Change the radiator

Change the coolant auxiliary tank or

tank cap -

-

-

-Change the radiator

Change the coolant auxiliary tank

Change the heater -

-

-

Cracks on the cylinder block or

cylinder head

Clogged coolant passages in the

cylinder block or cylinder head -

-Change cylinder block or cylinder

head

Clean the coolant passage -

-

Clogged radiator core -

Replace the sensor or repair the

related wiring - Improper operation of cooling fan -Clean the radiator core -

Defective temperature sensor or faulty

wiring -Replace the cooling fan or repair the

related circuit -

Page 557 of 1336

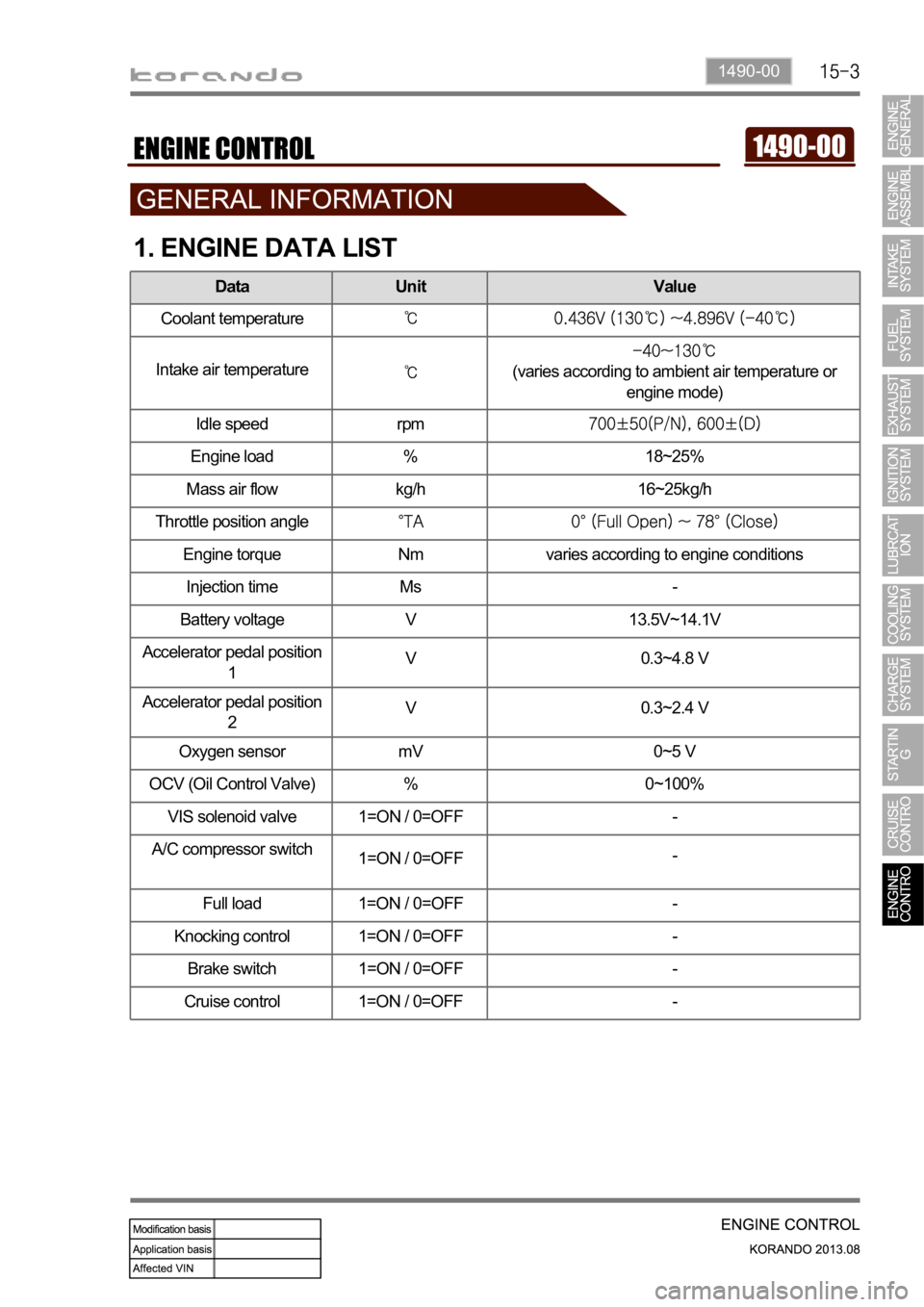

1490-00

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature

Intake air temperature(varies according to ambient air temperature or

engine mode)

Idle speed rpm

Engine load % 18~25%

Mass air flow kg/h 16~25kg/h

Throttle position angle

Engine torque Nm varies according to engine conditions

Injection time Ms -

Battery voltage V 13.5V~14.1V

Accelerator pedal position

1V 0.3~4.8 V

Accelerator pedal position

2V 0.3~2.4 V

Oxygen sensor mV 0~5 V

OCV (Oil Control Valve) % 0~100%

VIS solenoid valve 1=ON / 0=OFF -

A/C compressor switch

1=ON / 0=OFF-

Full load 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 569 of 1336

0000-00

(4) Features

Determines the ignition timing according to input signal

The ECU always analyzes the following elements when determining the ignition timing. 1.

Crankshaft position sensor

Camshaft position sensor

Coolant temperature sensor

Intake air temperature/air mass -

-

-

-

Warm-up of catalytic converter

The ignition timing is retarded for about 20 seconds to operate the catalytic converter according to the

operating temperature under the following conditions: 2.

The idle speed is increased by the idle speed control to help warming up of the catalytic converter -

-

Idle speed control

The ignition timing control can be performed faster than the control through the throttle valve.

Fuel cut-off in deceleration

The ignition timing is retarded temporarily to prevent abrupt increase of the torque when the

combustion is restarted.

Intake air temperature/coolant temperature

The ignition timing is retarded to prevent knocking if the intake air temperature or coolant temperature

is high. The ignition timing is retarded in the following cases. 3.

4.

5.

-

-

The ignition timing retard for intake air temperature and for coolant temperature is added up for

correction.

ESP/ASR control mode

The ignition timing is retarded to reduce engine torque as fast as possible under the ESP/ASR

control mode.

Knocking control

If knocking occurs in the cylinder, the ignition angle of the corresponding cylinder is retarded. The

6.

7.

Page 572 of 1336

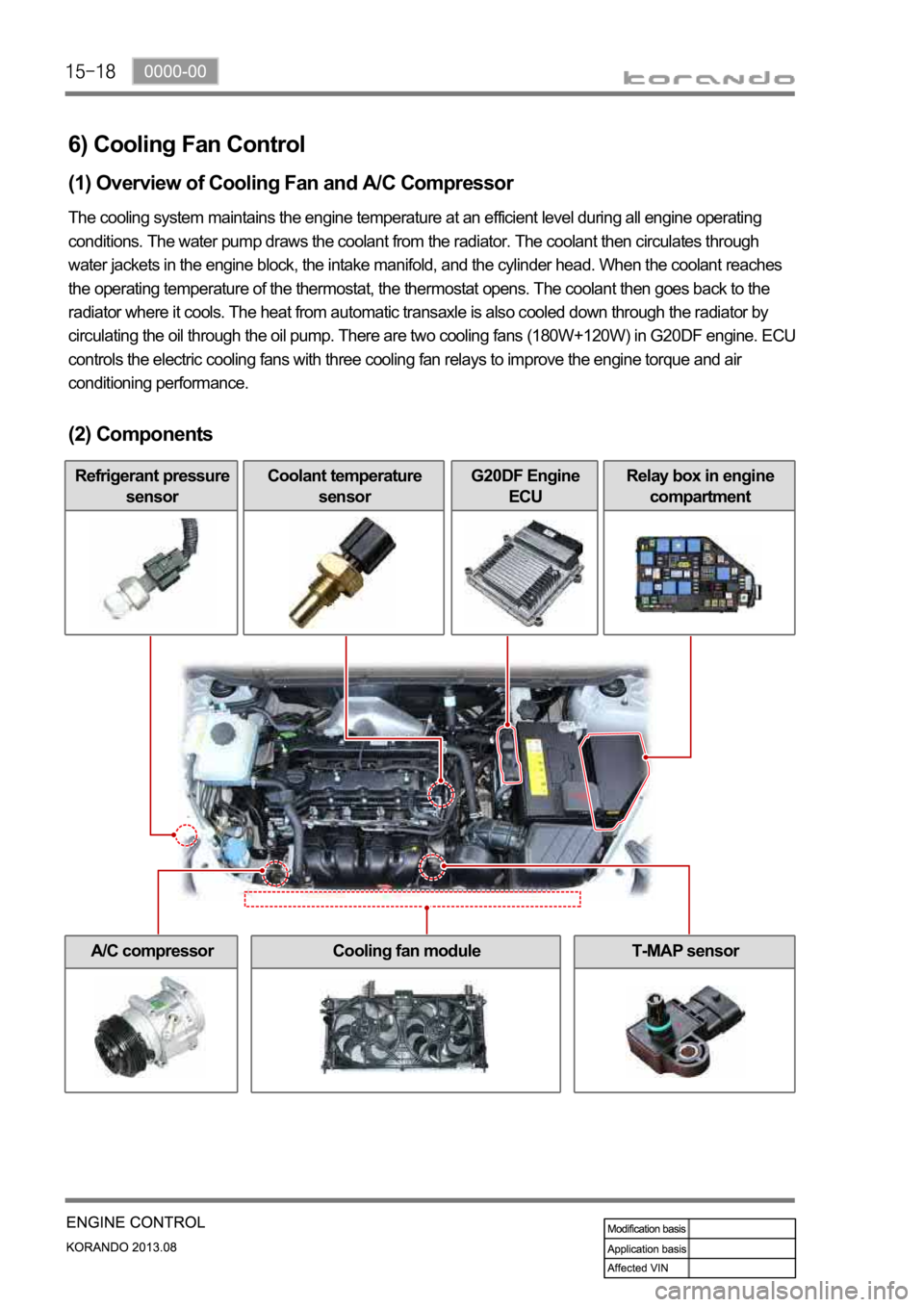

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 599 of 1336

0000-00

3. BASIC INSPECTION

1) Battery Terminal

Make sure the terminal connections are

securely tightened. If the terminals are

corroded, clean them or replace the battery. -

* Cleaning

Remove the corrosion or dirt with a wire brush

or sand paper, and then wash out with

lukewarm soapy water.

2) Measuring the Voltage Drop

Measuring at battery terminal

Measure the voltage between battery

terminal (+. -) and wiring clamp. -

Specified valuebelow 0.3V

If the terminals are corroded, clean and

retightening them. If the specified tightening

torque cannot be kept, replace the clamp.

Terminal (+)

Terminal (-)

Terminal (+): 4 ~ 5 Nm

Page 864 of 1336

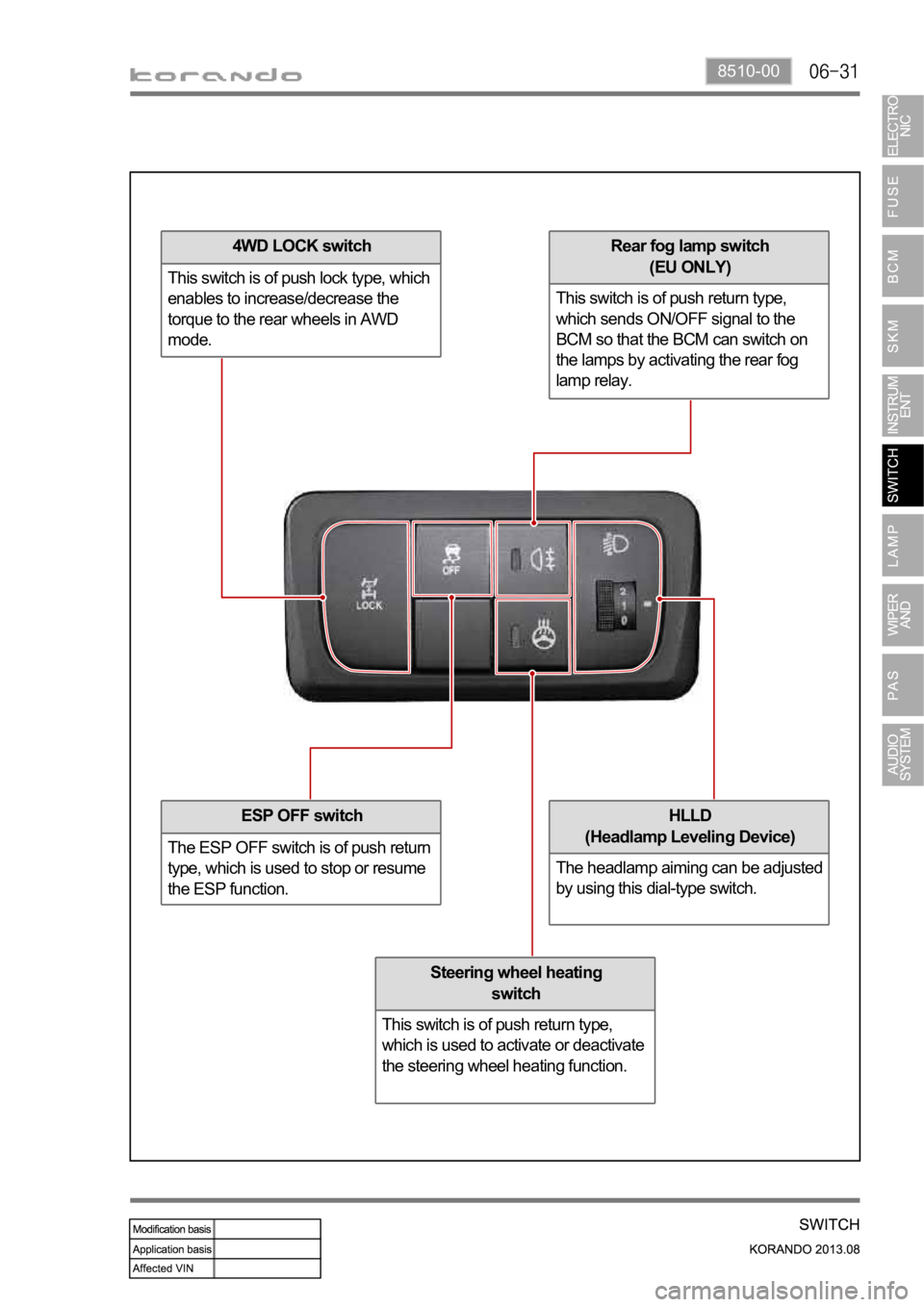

8510-00

4WD LOCK switch

This switch is of push lock type, which

enables to increase/decrease the

torque to the rear wheels in AWD

mode.

Steering wheel heating

switch

This switch is of push return type,

which is used to activate or deactivate

the steering wheel heating function.

ESP OFF switch

The ESP OFF switch is of push return

type, which is used to stop or resume

the ESP function.

4WD LOCK switch

This switch is of push lock type, which

enables to increase/decrease the

torque to the rear wheels in AWD

mode.

HLLD

(Headlamp Leveling Device)

The headlamp aiming can be adjusted

by using this dial-type switch.

Rear fog lamp switch

(EU ONLY)

This switch is of push return type,

which sends ON/OFF signal to the

BCM so that the BCM can switch on

the lamps by activating the rear fog

lamp relay.

Page 984 of 1336

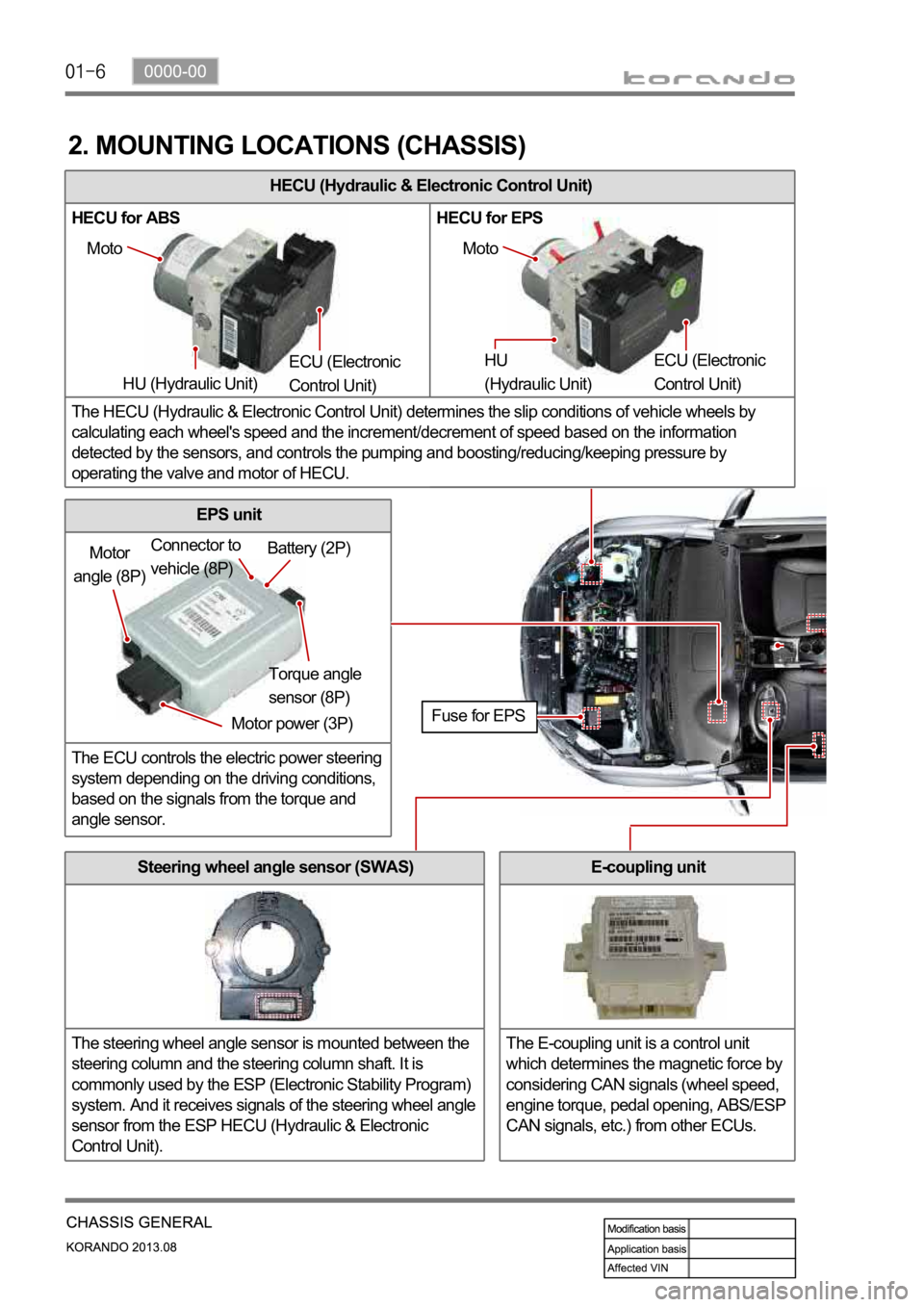

HECU (Hydraulic & Electronic Control Unit)

HECU for ABS HECU for EPS

The HECU (Hydraulic & Electronic Control Unit) determines the slip conditions of vehicle wheels by

calculating each wheel's speed and the increment/decrement of speed based on the information

detected by the sensors, and controls the pumping and boosting/reducing/keeping pressure by

operating the valve and motor of HECU.

2. MOUNTING LOCATIONS (CHASSIS)

Moto

HU (Hydraulic Unit) ECU (Electronic

Control Unit) Moto

HU

(Hydraulic Unit) ECU (Electronic

Control Unit)

Motor

angle (8P)

Motor power (3P)Torque angle

sensor (8P) Battery (2P) Connector to

vehicle (8P)

Fuse for EPS

Steering wheel angle sensor (SWAS)

The steering wheel angle sensor is mounted between the

steering column and the steering column shaft. It is

commonly used by the ESP (Electronic Stability Program)

system. And it receives signals of the steering wheel angle

sensor from the ESP HECU (Hydraulic & Electronic

Control Unit).

EPS unit

The ECU controls the electric power steering

system depending on the driving conditions,

based on the signals from the torque and

angle sensor.

E-coupling unit

The E-coupling unit is a control unit

which determines the magnetic force by

considering CAN signals (wheel speed,

engine torque, pedal opening, ABS/ESP

CAN signals, etc.) from other ECUs.

Page 986 of 1336

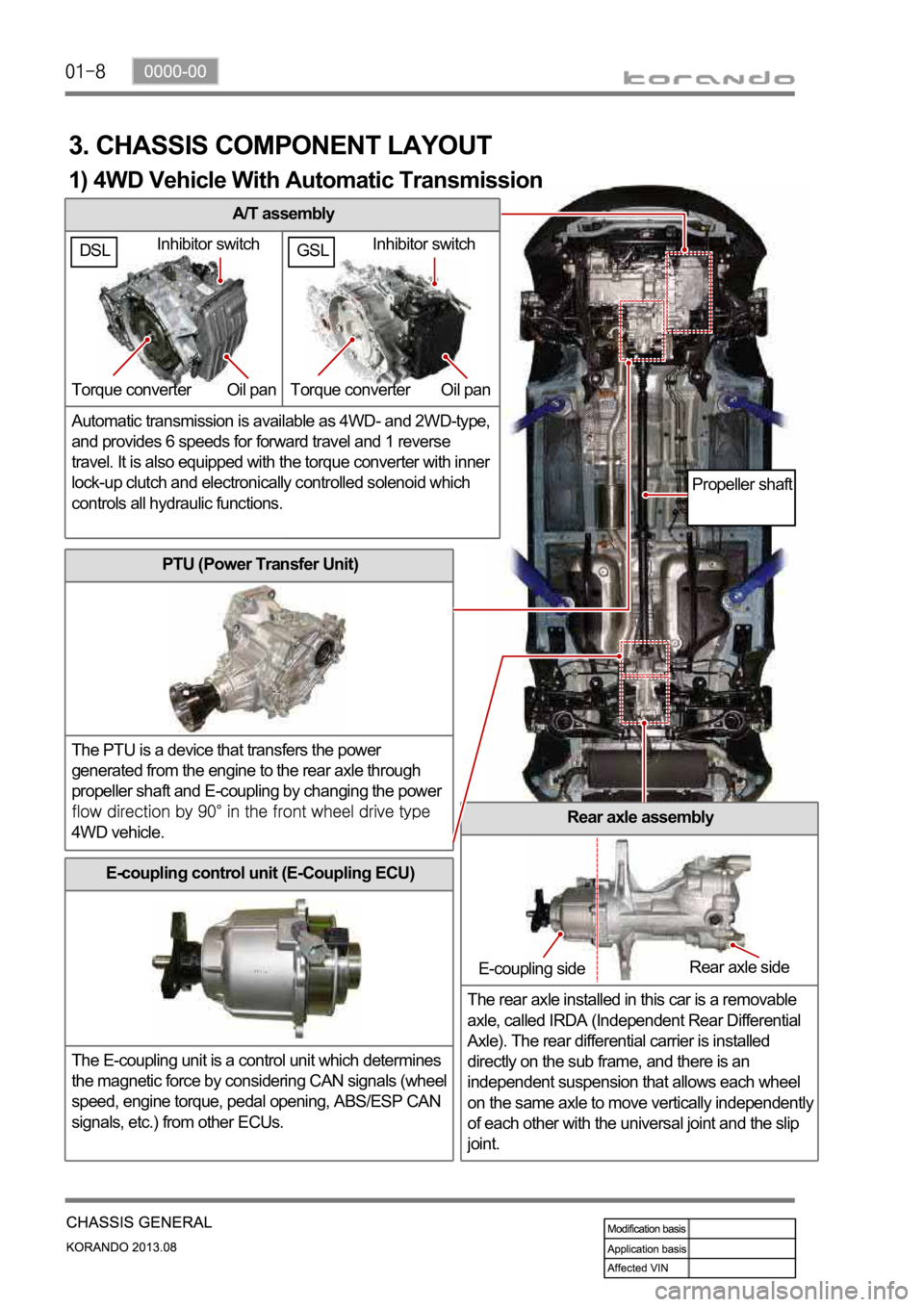

A/T assembly

Automatic transmission is available as 4WD- and 2WD-type,

and provides 6 speeds for forward travel and 1 reverse

travel. It is also equipped with the torque converter with inner

lock-up clutch and electronically controlled solenoid which

controls all hydraulic functions.

3. CHASSIS COMPONENT LAYOUT

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle through

propeller shaft and E-coupling by changing the power

4WD vehicle.Rear axle assembly

The rear axle installed in this car is a removable

axle, called IRDA (Independent Rear Differential

Axle). The rear differential carrier is installed

directly on the sub frame, and there is an

independent suspension that allows each wheel

on the same axle to move vertically independentl

y

of each other with the universal joint and the slip

joint.

E-coupling control unit (E-Coupling ECU)

The E-coupling unit is a control unit which determines

the magnetic force by considering CAN signals (wheel

speed, engine torque, pedal opening, ABS/ESP CAN

signals, etc.) from other ECUs.

Inhibitor switch

Torque converter Oil pan

E-coupling sideRear axle side

Propeller shaft

1) 4WD Vehicle With Automatic Transmission

GSLDSLInhibitor switch

Torque converter Oil pan

Page 987 of 1336

0000-00

M6LF1 manual transmission

M6LF1 manual transmission is a model modified from the

one that used in other vehicle so that it can be applied to FF

(Front engine-Front wheel driving) type vehicle, and has an

axle in one piece. The engine torque and gear ratio of this

transmission have been optimized to maximize driving

performance. It provides 6 speeds for forward travel and 1

reverse travel.

Clutch assembly

M6LF1 manual transmission is a model modified from the

one that used in other vehicle so that it can be applied to FF

(Front engine-Front wheel driving) type vehicle, and has an

axle in one piece. The engine torque and gear ratio of this

transmission have been optimized to maximize driving

performance. It provides 6 speeds for forward travel and 1

reverse travel.

The 2WD vehicle with manual transmission is a front wheel drive type vehicle that doesn't have PTU,

propeller shaft, E-coupling and rear axle which are applied to 4WD vehicle. Its under structure is very

simple.

Manual gear selector lever

Transmission sideControl shaft assembly

Transaxle side

Concentric slave assembly

Pressure plate

2) 2WD Vehicle With Manual Transmission

Clutch disc