torque SSANGYONG KORANDO 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 988 of 1336

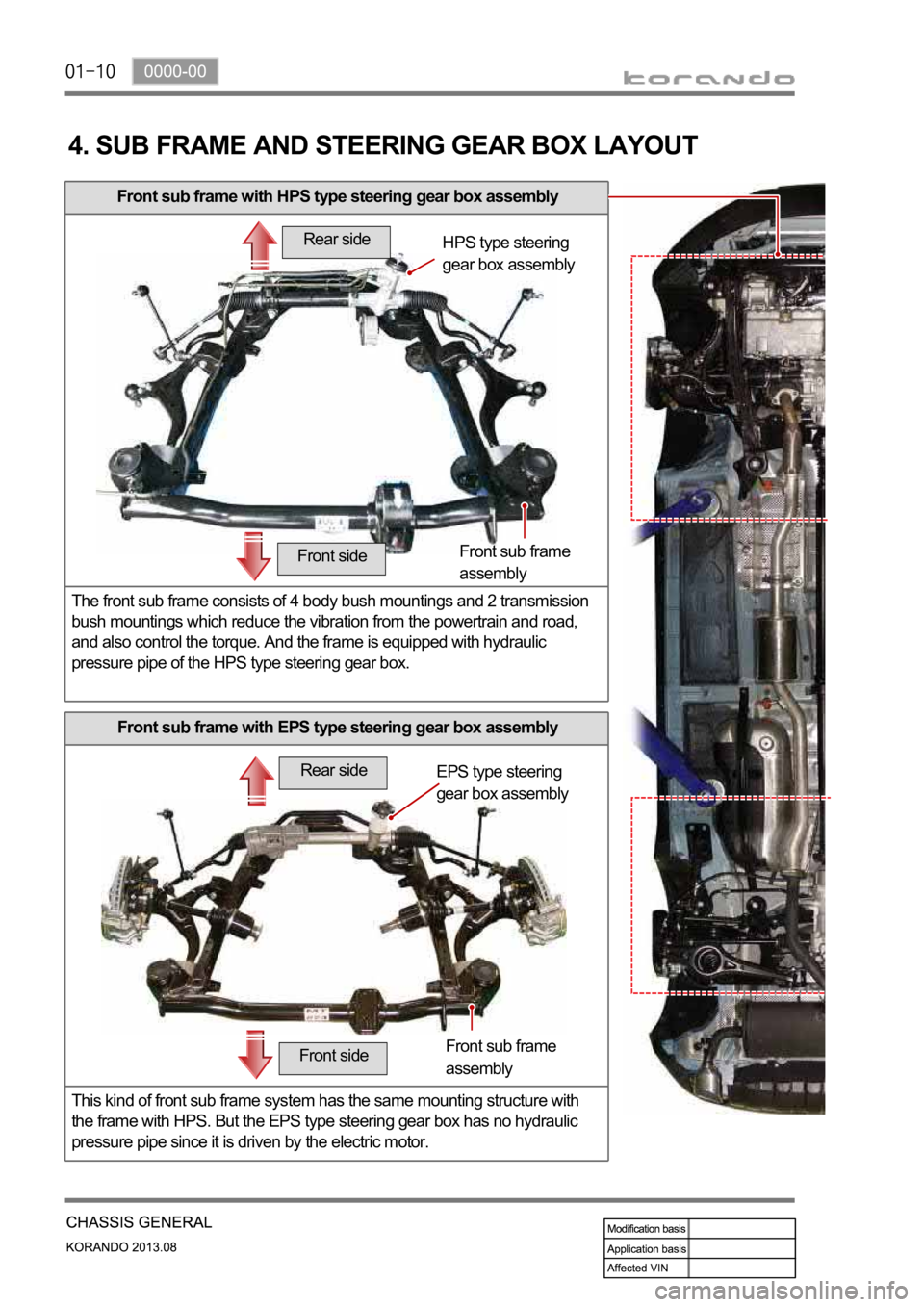

Front sub frame with HPS type steering gear box assembly

The front sub frame consists of 4 body bush mountings and 2 transmission

bush mountings which reduce the vibration from the powertrain and road,

and also control the torque. And the frame is equipped with hydraulic

pressure pipe of the HPS type steering gear box.

4. SUB FRAME AND STEERING GEAR BOX LAYOUT

Front sub frame with EPS type steering gear box assembly

This kind of front sub frame system has the same mounting structure with

the frame with HPS. But the EPS type steering gear box has no hydraulic

pressure pipe since it is driven by the electric motor.

Rear side

Front sideHPS type steering

gear box assembly

Front sub frame

assembly

Rear side

Front side

EPS type steering

gear box assembly

Front sub frame

assembly

Page 989 of 1336

0000-00

Rear sub frame assembly for 4WD

The rear sub frame for 4WD vehicle consists of 4 body (bush)

mountings and 2 axle (direct) mountings which reduce the vibration from

the powertrain and road, and also control the torque.

Rear side

Front side Body mounting

Rear sub frame assembly for 2WD

The rear sub frame for 2WD vehicle functions in the same way as the

one for 4WD vehicle, but the structure is different from the one for 4WD.

It consists of 4 body (bush) mountings.

Body mounting

Body mounting Body mountingAxle mounting

Front side

Body mounting Body mounting

Rear sideBody mountingBody mounting

Page 996 of 1336

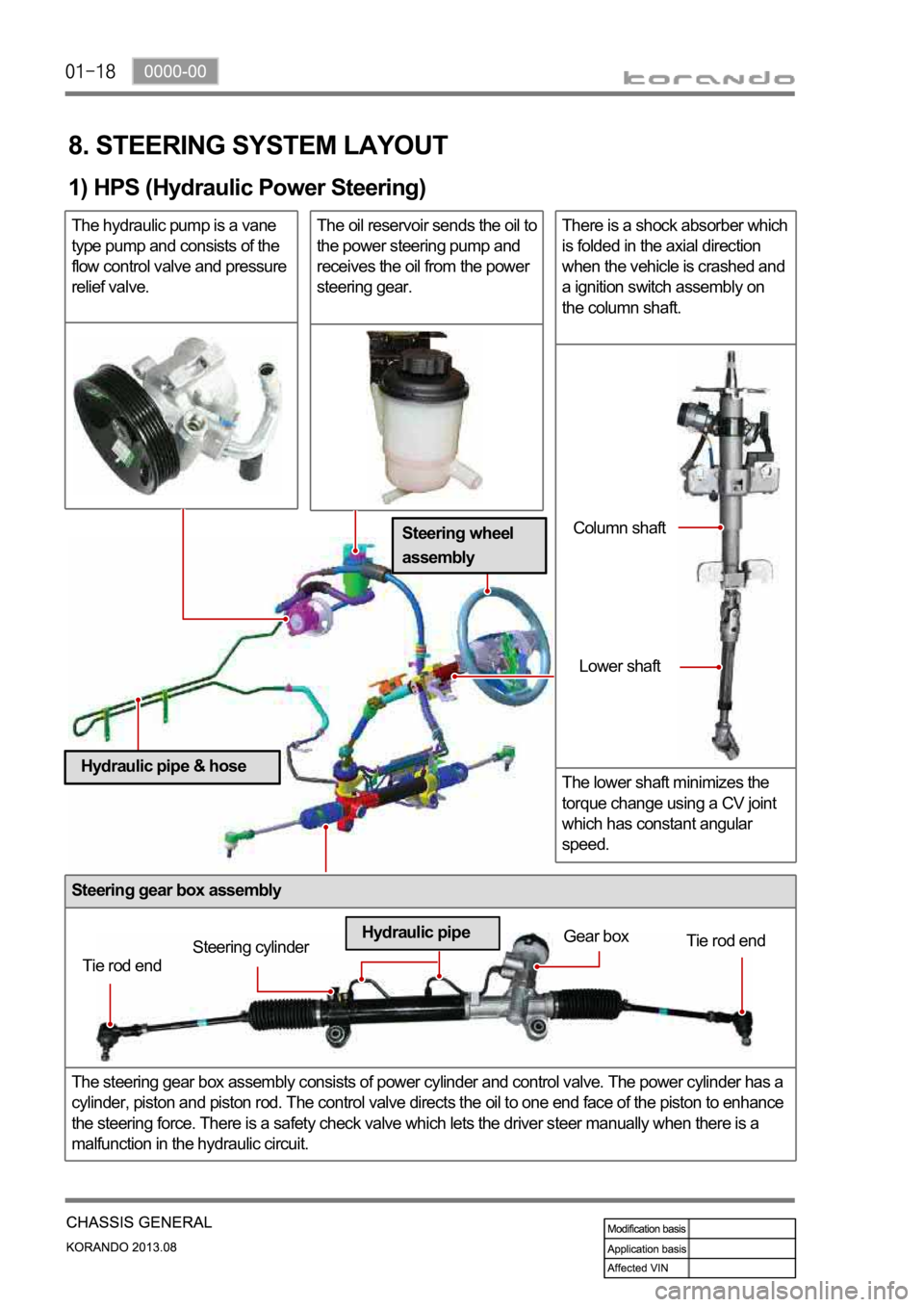

Steering gear box assembly

The steering gear box assembly consists of power cylinder and control valve. The power cylinder has a

cylinder, piston and piston rod. The control valve directs the oil to one end face of the piston to enhance

the steering force. There is a safety check valve which lets the driver steer manually when there is a

malfunction in the hydraulic circuit.

8. STEERING SYSTEM LAYOUT

1) HPS (Hydraulic Power Steering)

The hydraulic pump is a vane

type pump and consists of the

flow control valve and pressure

relief valve.The oil reservoir sends the oil to

the power steering pump and

receives the oil from the power

steering gear.There is a shock absorber which

is folded in the axial direction

when the vehicle is crashed and

a ignition switch assembly on

the column shaft.

The lower shaft minimizes the

torque change using a CV joint

which has constant angular

speed.

Tie rod endSteering cylinderGear box

Tie rod end

Hydraulic pipeColumn shaft

Lower shaft

Steering wheel

assembly

Hydraulic pipe & hose

Page 997 of 1336

0000-00

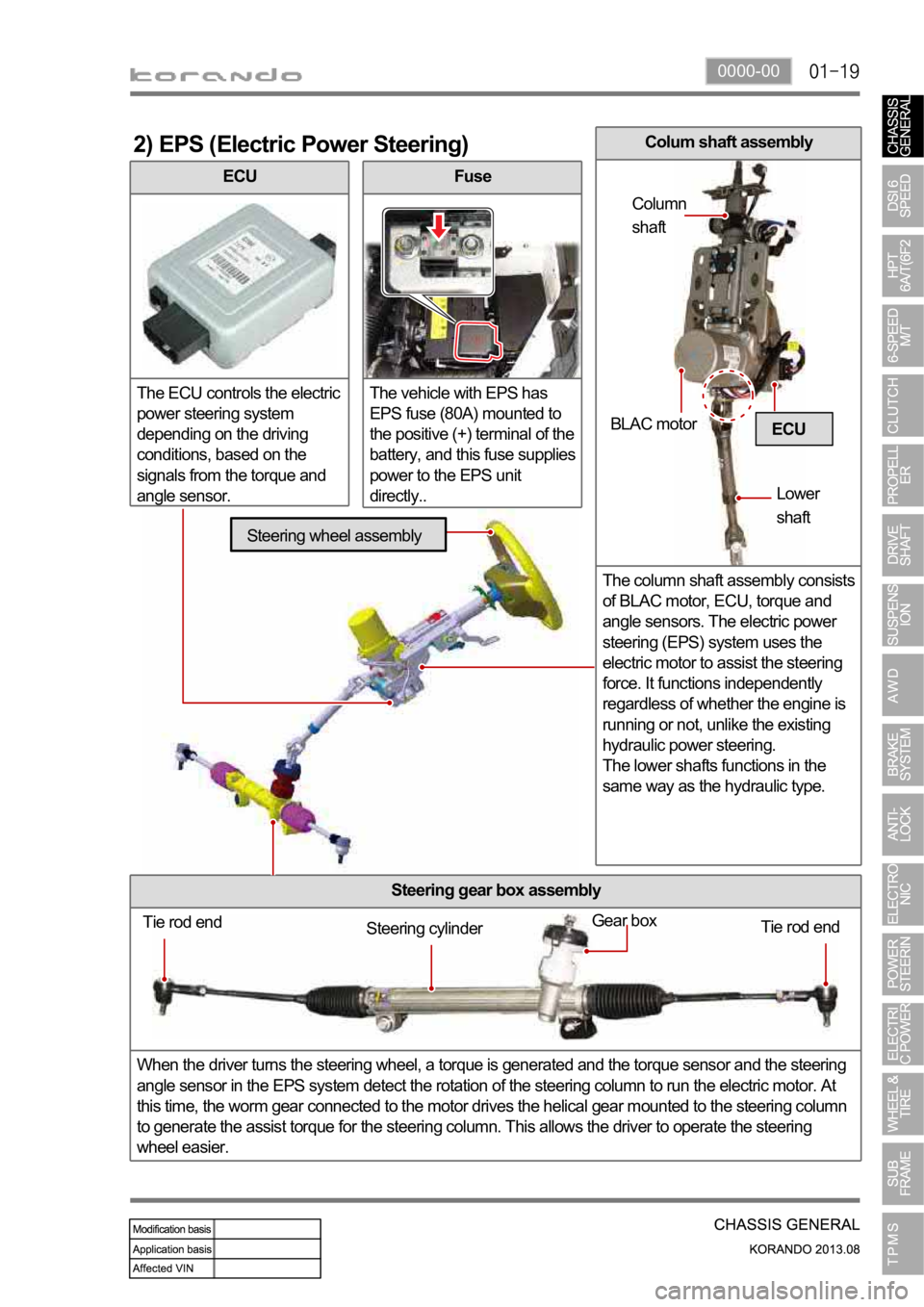

ECU

The ECU controls the electric

power steering system

depending on the driving

conditions, based on the

signals from the torque and

angle sensor.

2) EPS (Electric Power Steering)

Fuse

The vehicle with EPS has

EPS fuse (80A) mounted to

the positive (+) terminal of the

battery, and this fuse supplies

power to the EPS unit

directly..

Steering gear box assembly

When the driver turns the steering wheel, a torque is generated and the torque sensor and the steering

angle sensor in the EPS system detect the rotation of the steering column to run the electric motor. At

this time, the worm gear connected to the motor drives the helical gear mounted to the steering column

to generate the assist torque for the steering column. This allows the driver to operate the steering

wheel easier.

ECU

Tie rod end

Tie rod end Gear boxSteering cylinder

Steering wheel assembly

BLAC motor

Lower

shaft Column

shaft

Colum shaft assembly

The column shaft assembly consists

of BLAC motor, ECU, torque and

angle sensors. The electric power

steering (EPS) system uses the

electric motor to assist the steering

force. It functions independently

regardless of whether the engine is

running or not, unlike the existing

hydraulic power steering.

The lower shafts functions in the

same way as the hydraulic type.

Page 999 of 1336

0000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

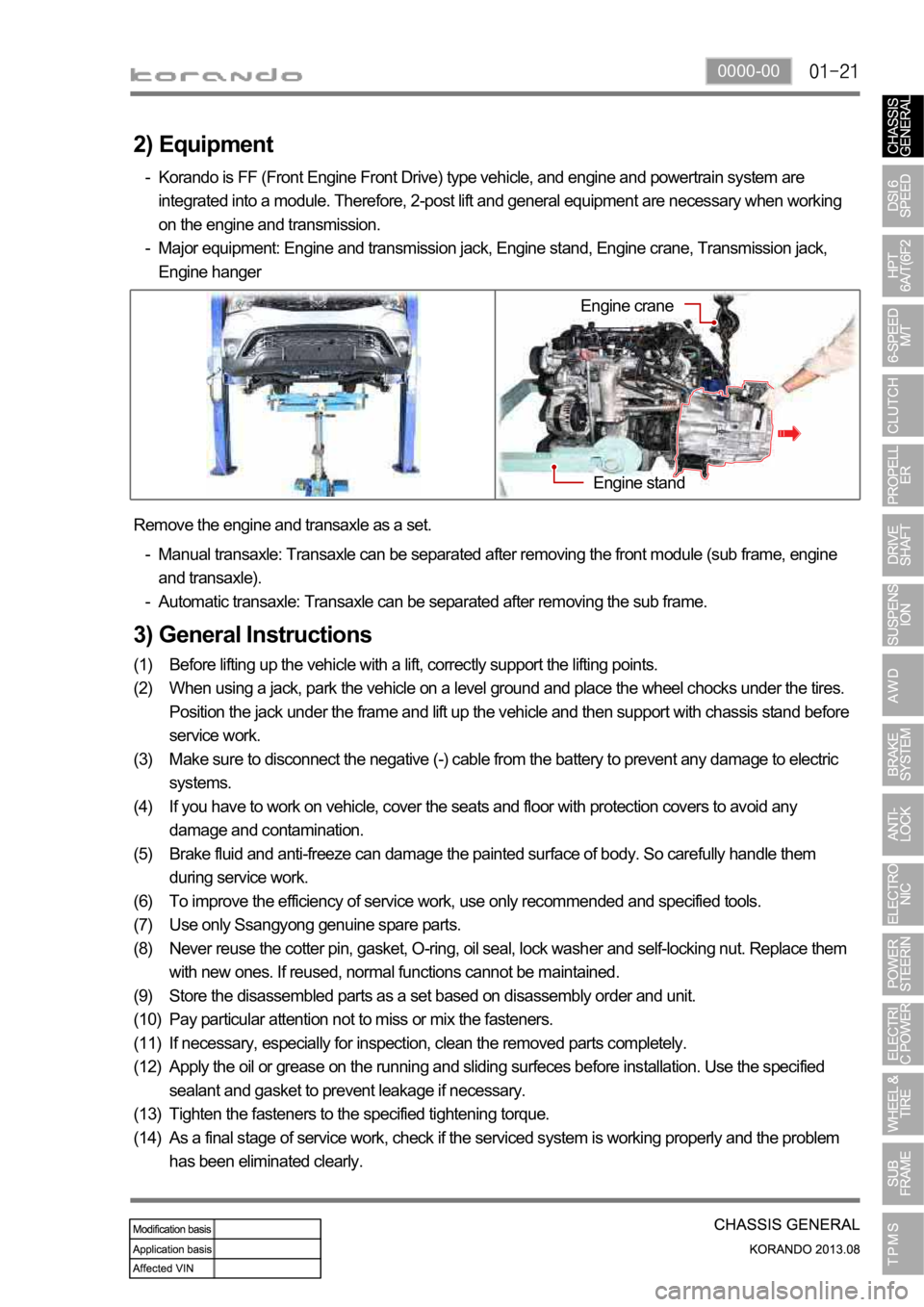

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 1002 of 1336

3. STANDARD BOLTS SPECIFICATIONS

Metric bolt strength is embossed on the head of each bolt. The strength of bolt can be classified as

4T, 7T, 8.8T, 10.9T, 11T and 12.9T in general.

Observe standard tightening torque during bolt tightening works and can adjust torque to be proper

within 15 % if necessary. Try not to over max. allowable tightening torque if not required to do so.

Determine extra proper tightening torque if tightens with washer or packing.

If tightens bolts on the below materials, be sure to determine the proper torque. 1)

2)

3)

4)

Aluminum alloy: Tighten to 80 % of above torque table.

Plastics: Tighten to 20 % of above torque table. -

-

Page 1003 of 1336

3680-01

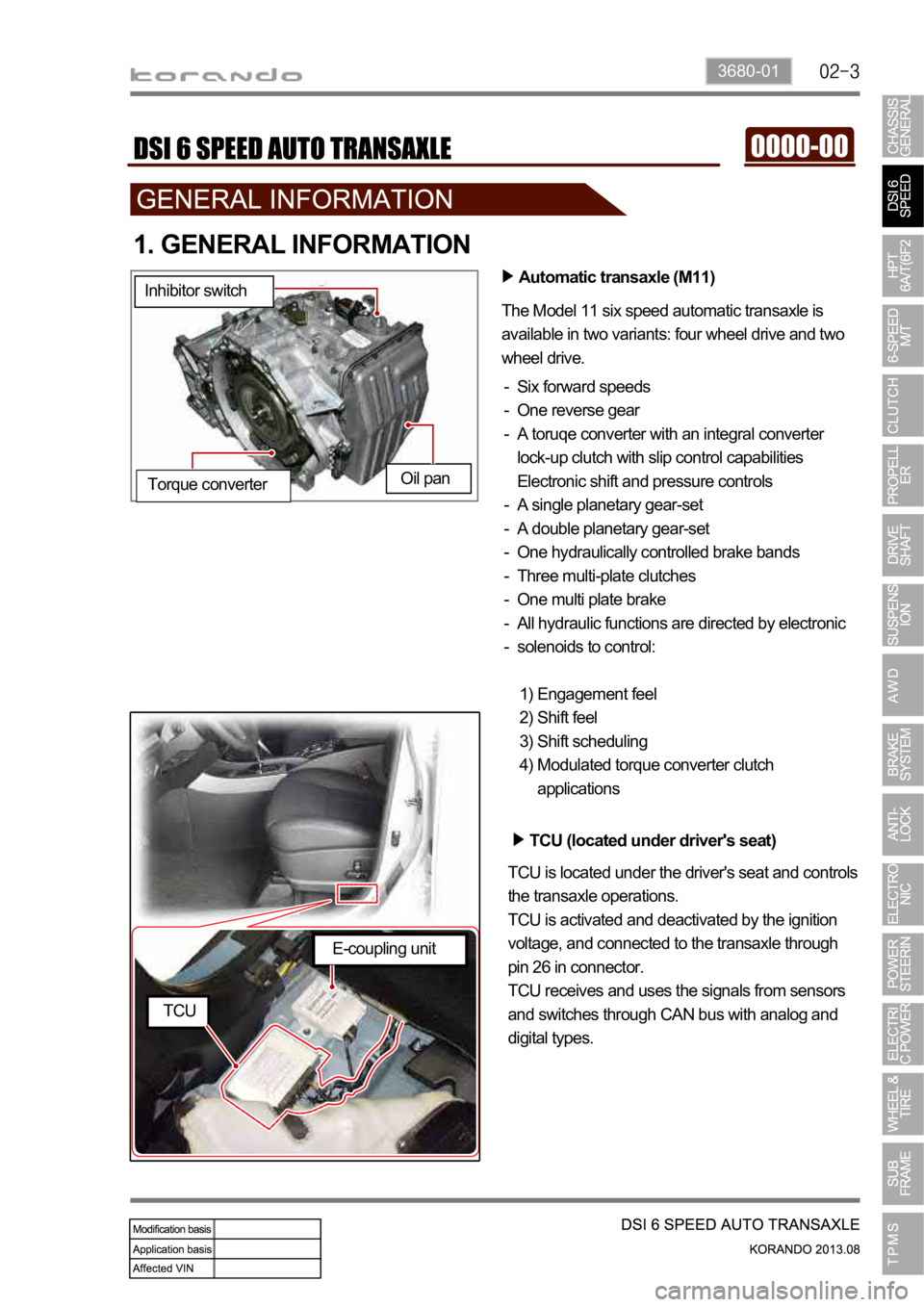

1. GENERAL INFORMATION

Automatic transaxle (M11)

The Model 11 six speed automatic transaxle is

available in two variants: four wheel drive and two

wheel drive.

Six forward speeds

One reverse gear

A toruqe converter with an integral converter

lock-up clutch with slip control capabilities

Electronic shift and pressure controls

A single planetary gear-set

A double planetary gear-set

One hydraulically controlled brake bands

Three multi-plate clutches

One multi plate brake

All hydraulic functions are directed by electronic

solenoids to control: -

-

-

-

-

-

-

-

-

-

Engagement feel

Shift feel

Shift scheduling

Modulated torque converter clutch

applications 1)

2)

3)

4) Inhibitor switch

Oil pan

Torque converter

TCU (located under driver's seat)

TCU is located under the driver's seat and controls

the transaxle operations.

TCU is activated and deactivated by the ignition

voltage, and connected to the transaxle through

pin 26 in connector.

TCU receives and uses the signals from sensors

and switches through CAN bus with analog and

digital types.

E-coupling unit

TCU

Page 1005 of 1336

3680-01

2. SPECIFICATIONS

1) Specifications

Type/Weight M11 6-speed automatic transaxle /

approx. 102 kg (including ATF)

TORQUE 400 Nm

Overall length / Center length 367 mm / 205 mm

Descriptions Specification

Gear ratio 1st gear 4.156

2nd gear 2.375

3rd gear 1.522

4th gear 1.144

5th gear 0.859

6th gear 0.676

Reverse gear 3.178

Oil Type Fuchs TITAN ATF 3292

Capacity approx. 7.5 L

Change interval EU: Inspect every 20,000 km or 12 months (But,

change every 60,000 km under severe condition)

General: Inspect every 15,000 km or 12 months

(But, change every 60,000 km under severe

condition)

Resistance of oil

temperature sensor-20

0

20

100

D

N

P

R

Inhibitor switch

Page 1006 of 1336

2) Sectional Diagram

Double planetary gear-set

Clutch packSingle planetary gear-set

Oil pump

Torque converter

Input shaft

Intermediate shaft

Differential assembly

Page 1007 of 1336

3680-01

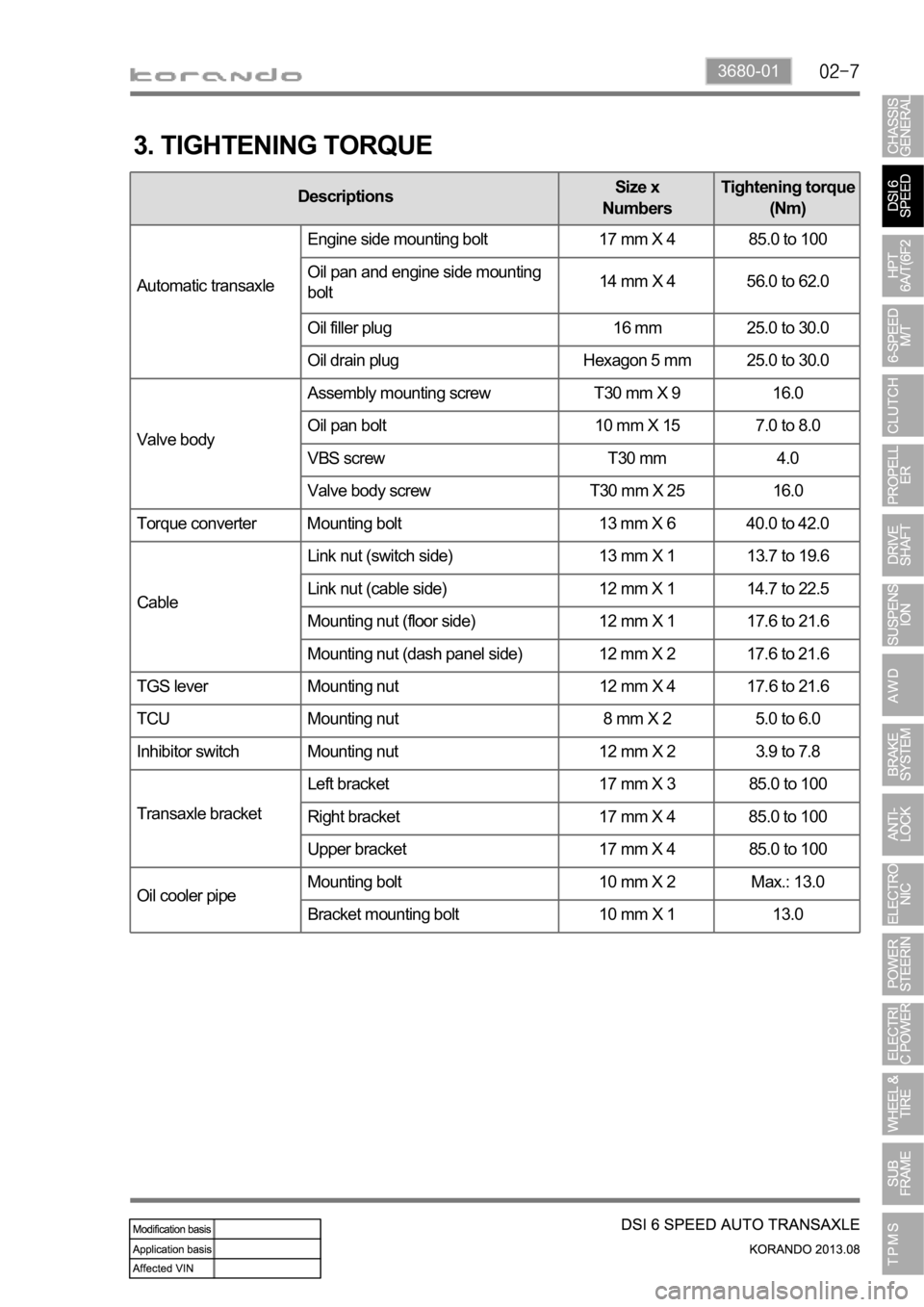

3. TIGHTENING TORQUE

DescriptionsSize x

NumbersTightening torque

(Nm)

Automatic transaxleEngine side mounting bolt 17 mm X 4 85.0 to 100

Oil pan and engine side mounting

bolt14 mm X 4 56.0 to 62.0

Oil filler plug 16 mm 25.0 to 30.0

Oil drain plug Hexagon 5 mm 25.0 to 30.0

Valve bodyAssembly mounting screw T30 mm X 9 16.0

Oil pan bolt 10 mm X 15 7.0 to 8.0

VBS screw T30 mm 4.0

Valve body screw T30 mm X 25 16.0

Torque converter Mounting bolt 13 mm X 6 40.0 to 42.0

CableLink nut (switch side) 13 mm X 1 13.7 to 19.6

Link nut (cable side) 12 mm X 1 14.7 to 22.5

Mounting nut (floor side) 12 mm X 1 17.6 to 21.6

Mounting nut (dash panel side) 12 mm X 2 17.6 to 21.6

TGS lever Mounting nut 12 mm X 4 17.6 to 21.6

TCU Mounting nut 8 mm X 2 5.0 to 6.0

Inhibitor switch Mounting nut 12 mm X 2 3.9 to 7.8

Transaxle bracketLeft bracket 17 mm X 3 85.0 to 100

Right bracket 17 mm X 4 85.0 to 100

Upper bracket 17 mm X 4 85.0 to 100

Oil cooler pipeMounting bolt 10 mm X 2 Max.: 13.0

Bracket mounting bolt 10 mm X 1 13.0