engine coolant SSANGYONG KORANDO 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 572 of 1336

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

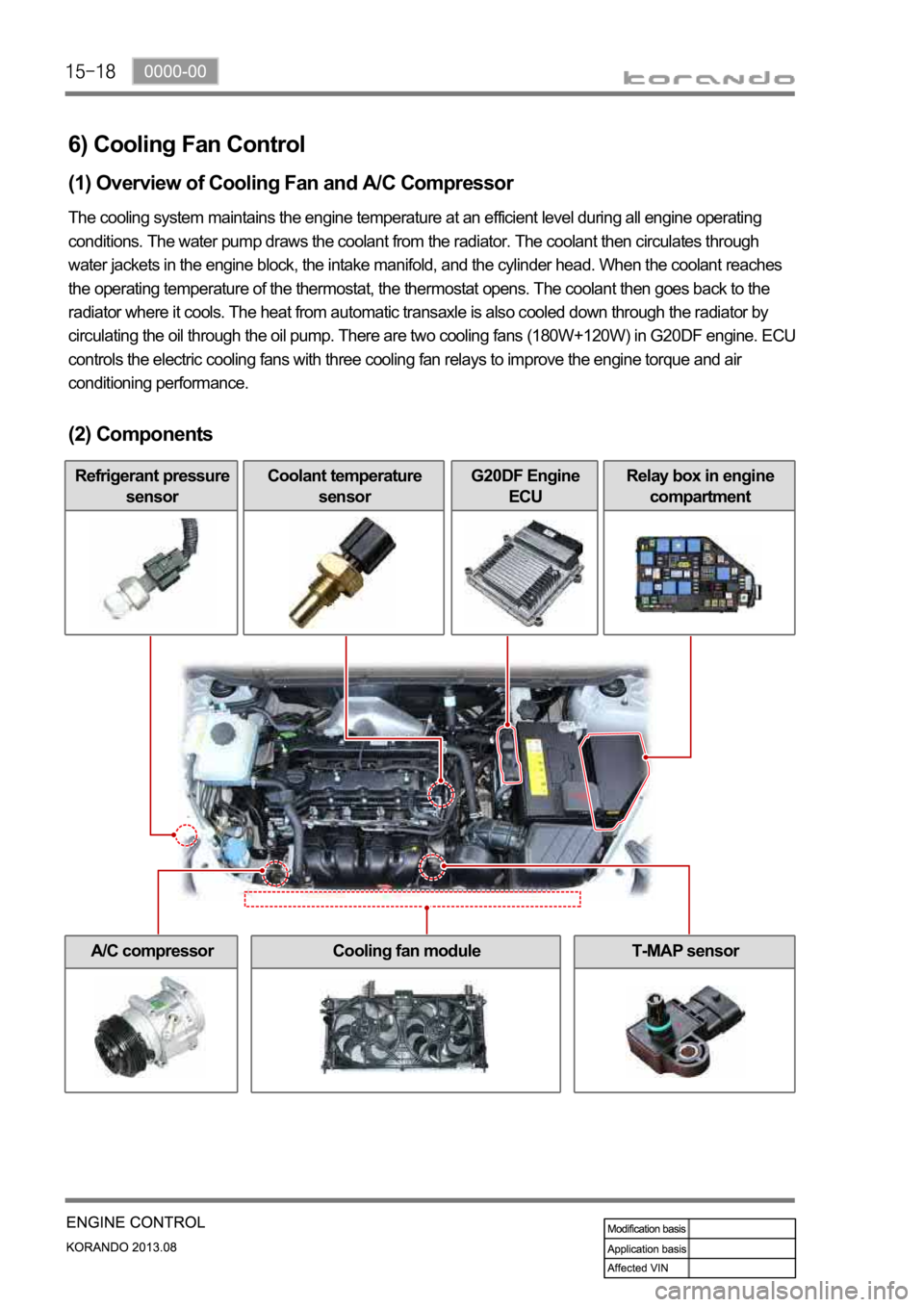

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 574 of 1336

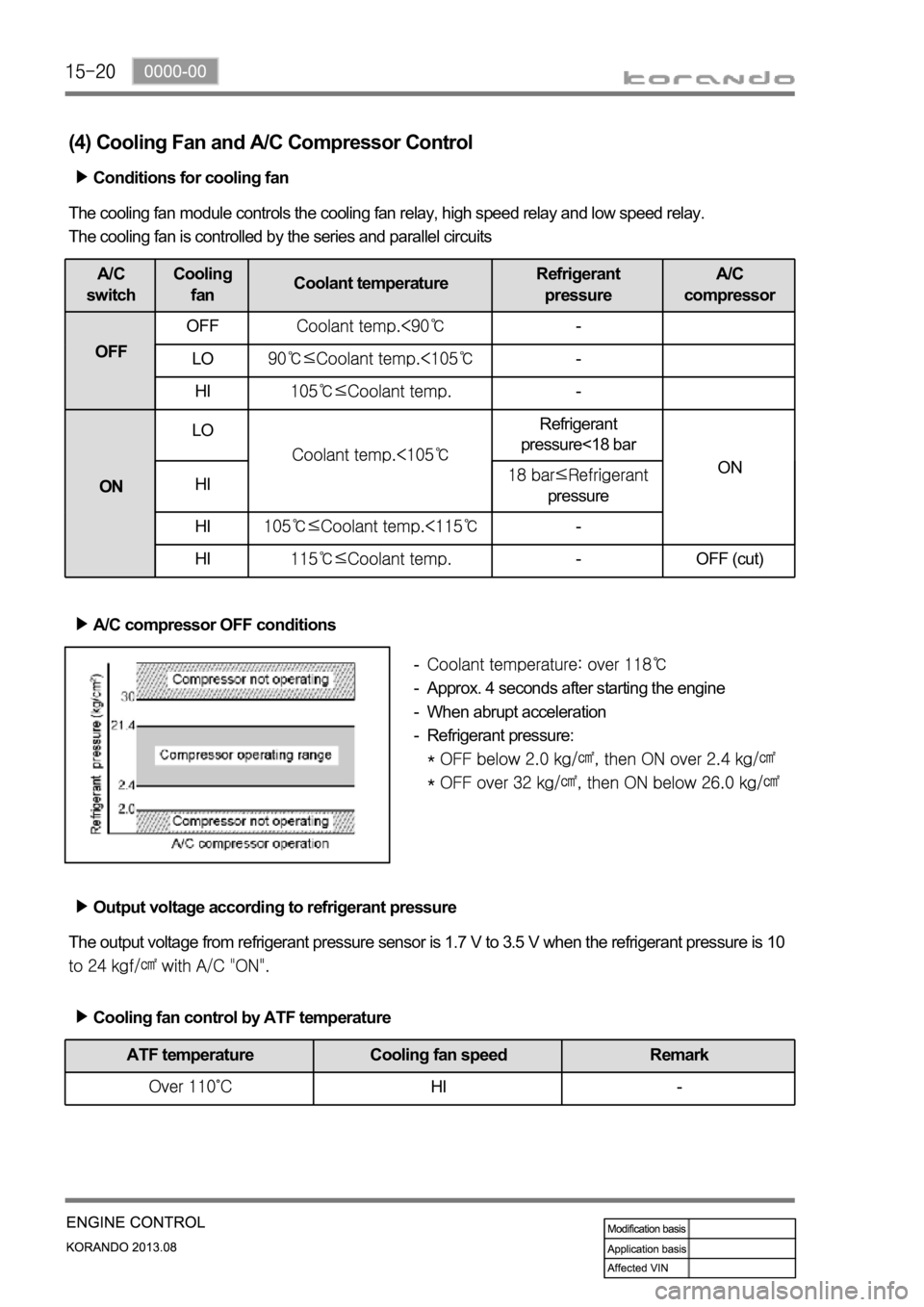

(4) Cooling Fan and A/C Compressor Control

Conditions for cooling fan

The cooling fan module controls the cooling fan relay, high speed relay and low speed relay.

The cooling fan is controlled by the series and parallel circuits

A/C

switchCooling

fanCoolant temperatureRefrigerant

pressureA/C

compressor

OFFOFF

-

LO

-

HI

-

ONLO

Refrigerant

pressure<18 bar

ON

HI

pressure

HI

-

HI

- OFF (cut)

A/C compressor OFF conditions

Approx. 4 seconds after starting the engine

When abrupt acceleration

Refrigerant pressure:

-

-

-

-

Output voltage according to refrigerant pressure

The output voltage from refrigerant pressure sensor is 1.7 V to 3.5 V when the refrigerant pressure is 10

Cooling fan control by ATF temperature

ATF temperature Cooling fan speed Remark

HI -

Page 774 of 1336

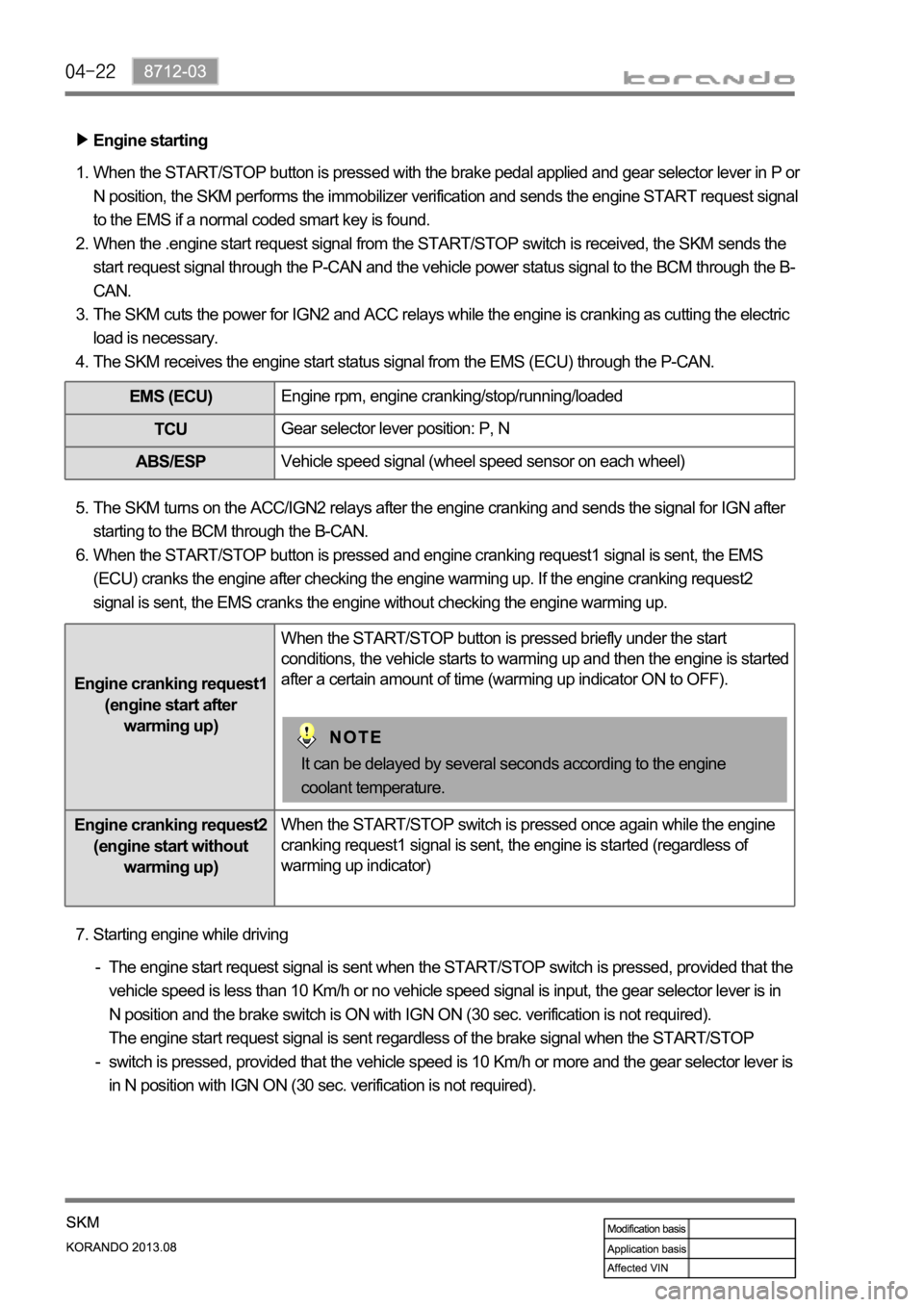

Engine starting

When the START/STOP button is pressed with the brake pedal applied and gear selector lever in P or

N position, the SKM performs the immobilizer verification and sends the engine START request signal

to the EMS if a normal coded smart key is found.

When the .engine start request signal from the START/STOP switch is received, the SKM sends the

start request signal through the P-CAN and the vehicle power status signal to the BCM through the B-

CAN.

The SKM cuts the power for IGN2 and ACC relays while the engine is cranking as cutting the electric

load is necessary.

The SKM receives the engine start status signal from the EMS (ECU) through the P-CAN. 1.

2.

3.

4.

EMS (ECU)Engine rpm, engine cranking/stop/running/loaded

TCUGear selector lever position: P, N

ABS/ESPVehicle speed signal (wheel speed sensor on each wheel)

The SKM turns on the ACC/IGN2 relays after the engine cranking and sends the signal for IGN after

starting to the BCM through the B-CAN.

When the START/STOP button is pressed and engine cranking request1 signal is sent, the EMS

(ECU) cranks the engine after checking the engine warming up. If the engine cranking request2

signal is sent, the EMS cranks the engine without checking the engine warming up. 5.

6.

Engine cranking request1

(engine start after

warming up)When the START/STOP button is pressed briefly under the start

conditions, the vehicle starts to warming up and then the engine is started

after a certain amount of time (warming up indicator ON to OFF).

Engine cranking request2

(engine start without

warming up)When the START/STOP switch is pressed once again while the engine

cranking request1 signal is sent, the engine is started (regardless of

warming up indicator)

It can be delayed by several seconds according to the engine

coolant temperature.

Starting engine while driving 7.

The engine start request signal is sent when the START/STOP switch is pressed, provided that the

vehicle speed is less than 10 Km/h or no vehicle speed signal is input, the gear selector lever is in

N position and the brake switch is ON with IGN ON (30 sec. verification is not required).

The engine start request signal is sent regardless of the brake signal when the START/STOP

switch is pressed, provided that the vehicle speed is 10 Km/h or more and the gear selector lever is

in N position with IGN ON (30 sec. verification is not required). -

-

Page 854 of 1336

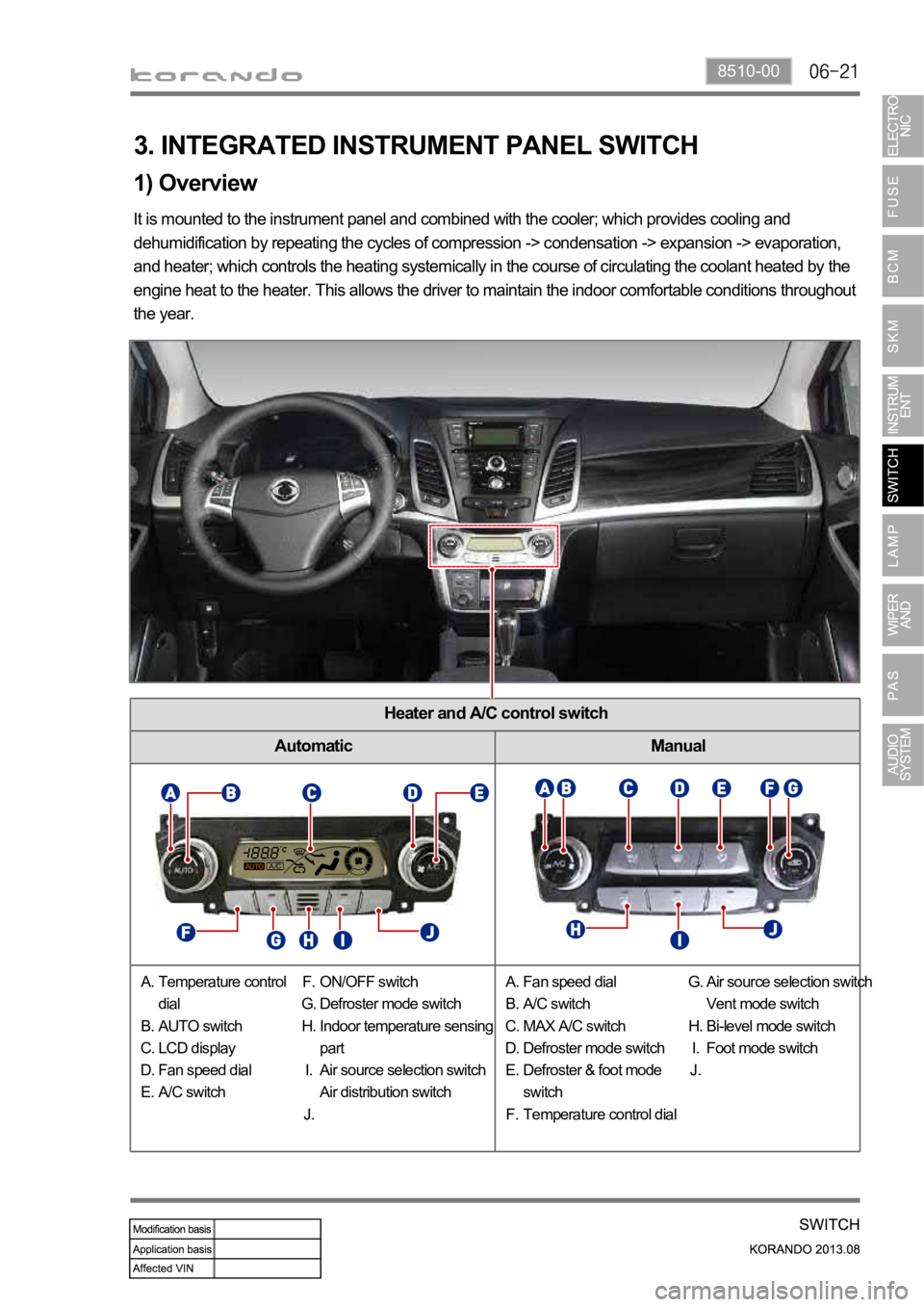

8510-00

Heater and A/C control switch

Automatic Manual

1) Overview

3. INTEGRATED INSTRUMENT PANEL SWITCH

It is mounted to the instrument panel and combined with the cooler; which provides cooling and

dehumidification by repeating the cycles of compression -> condensation -> expansion -> evaporation,

and heater; which controls the heating systemically in the course of circulating the coolant heated by the

engine heat to the heater. This allows the driver to maintain the indoor comfortable conditions throughout

the year.

Temperature control

dial

AUTO switch

LCD display

Fan speed dial

A/C switch A.

B.

C.

D.

E.ON/OFF switch

Defroster mode switch

Indoor temperature sensing

part

Air source selection switch

Air distribution switch F.

G.

H.

I.

J.Fan speed dial

A/C switch

MAX A/C switch

Defroster mode switch

Defroster & foot mode

switch

Temperature control dial A.

B.

C.

D.

E.

F.Air source selection switch

Vent mode switch

Bi-level mode switch

Foot mode switch G.

H.

I.

J.

Page 1000 of 1336

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 1014 of 1336

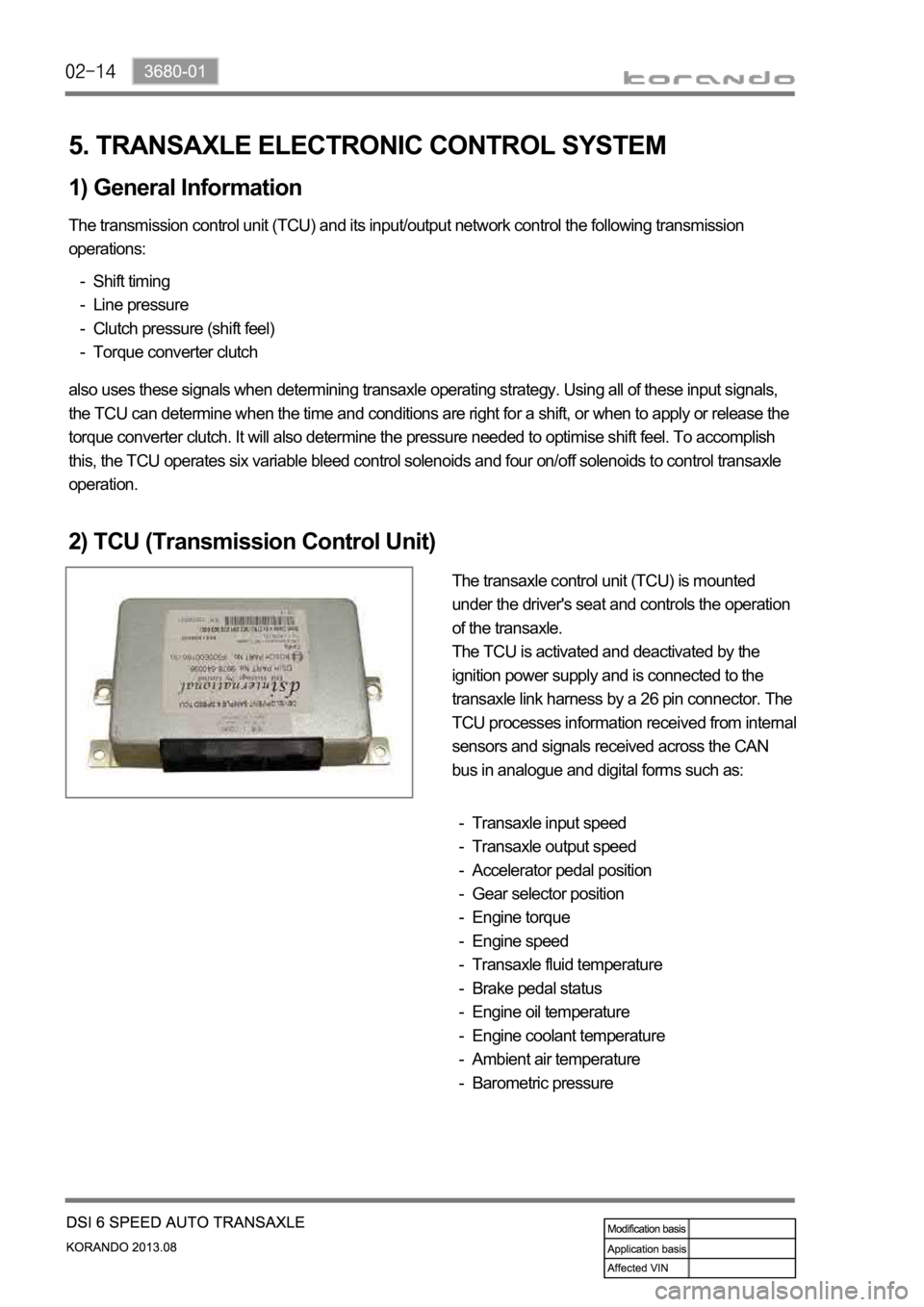

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel. To accomplish

this, the TCU operates six variable bleed control solenoids and four on/off solenoids to control transaxle

operation.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

The TCU is activated and deactivated by the

ignition power supply and is connected to the

transaxle link harness by a 26 pin connector. The

TCU processes information received from internal

sensors and signals received across the CAN

bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

Page 1043 of 1336

3660-01

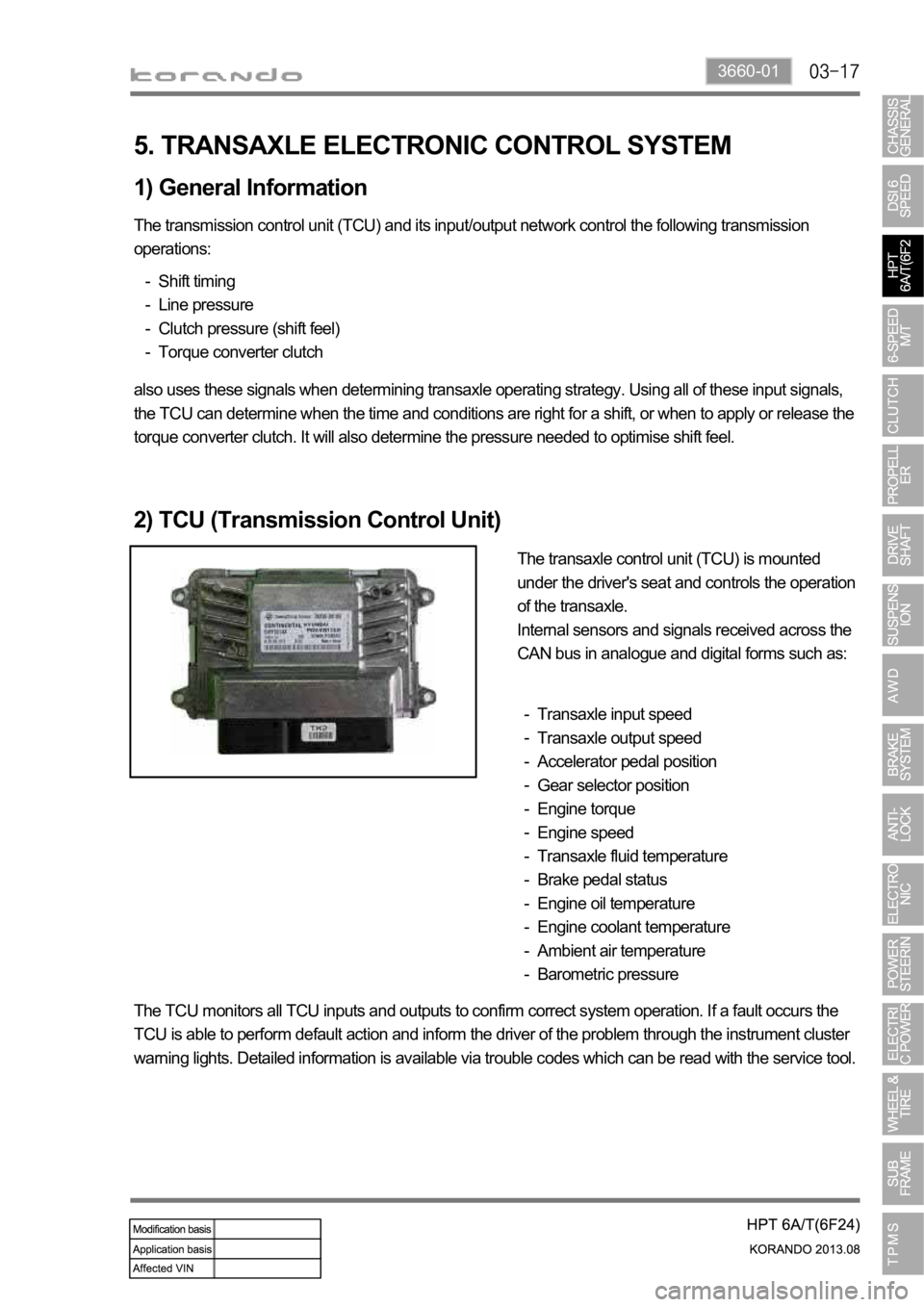

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 1194 of 1336

2. LAYOUT

1) Exterior Layout

Liquid and suction pipe

The high/low-pressure A/C refrigerant flows

through this pipe. It is fitted with the refrigerant

pressure sensor.

Electric fan

It cools down the A/C condenser to speed up the

compression for the refrigerant in the condenser.

Refrigerant pressure sensor

It is mounted to the latter part of the right

headlamp. It converts the A/C refrigerant pressure

to voltage value and sends it to the engine ECU.

A/C compressor

It is installed to the left side of the engine

assembly, compresses the low-temperature and

low-pressure coolant and converts it to the high-

temperature and high-pressure coolant. Then, it

sends the coolant to the A/C condenser.

Page 1197 of 1336

6810-00

Intake sensor

It is mounted to the side of

evaporator core and detects the

temperature of the evaporator

core.Water temperature

sensor

It is mounted to the heater pipe

part and detects the coolant

temperature.

3) Air Conditioner Module Layout

Temp actuator

It changes the air mix door

opening according to the

control command from the

heater and A/C control

assembly.Evaporator core

It cools the surrounding air by

passing through the low-

temperature and low-pressure

refrigerant sprayed from the

expansion valve.

Heater core

It is mounted to the left-hand of

the air conditioner module and

heats the indoor using the heat

of the engine coolant.

Mode actuator

It controls the air outlet damper

to the five directions according

to the control command from

the heater and A/C control

assembly.

Page 1202 of 1336

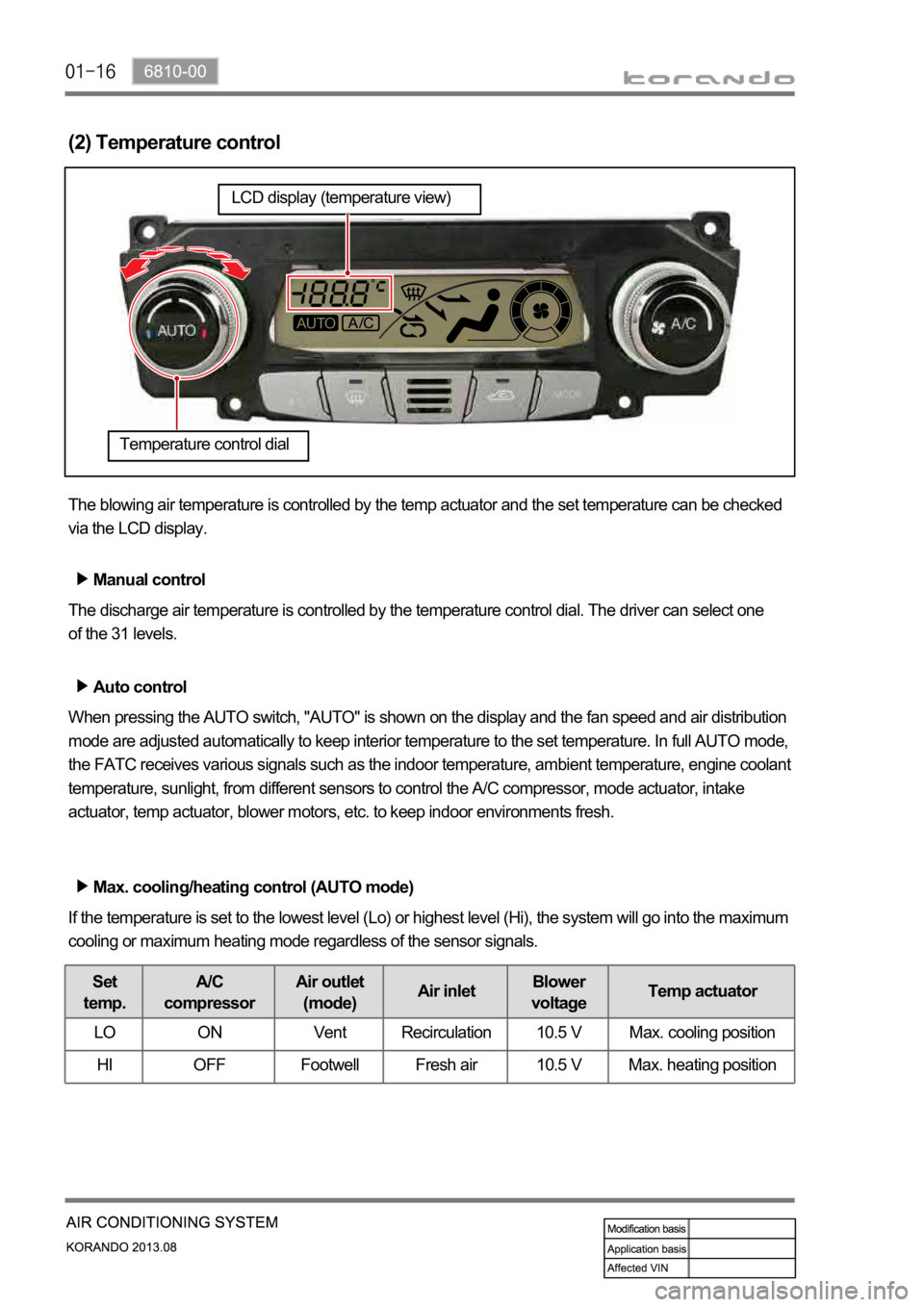

(2) Temperature control

The blowing air temperature is controlled by the temp actuator and the set temperature can be checked

via the LCD display.

Manual control

The discharge air temperature is controlled by the temperature control dial. The driver can select one

of the 31 levels.

Auto control

When pressing the AUTO switch, "AUTO" is shown on the display and the fan speed and air distribution

mode are adjusted automatically to keep interior temperature to the set temperature. In full AUTO mode,

the FATC receives various signals such as the indoor temperature, ambient temperature, engine coolant

temperature, sunlight, from different sensors to control the A/C compressor, mode actuator, intake

actuator, temp actuator, blower motors, etc. to keep indoor environments fresh.

Max. cooling/heating control (AUTO mode)

If the temperature is set to the lowest level (Lo) or highest level (Hi), the system will go into the maximum

cooling or maximum heating mode regardless of the sensor signals.

Set

temp.A/C

compressorAir outlet

(mode)Air inletBlower

voltageTemp actuator

LO ON Vent Recirculation 10.5 V Max. cooling position

HI OFF Footwell Fresh air 10.5 V Max. heating position

Temperature control dial

LCD display (temperature view)