ABS SSANGYONG KORANDO 2013 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1137 of 1336

Circuit description

When compared to the vehicle equipped with ABS/EBD only, the internal hydraulic circuit has a

normally-open separation valve and a shuttle valve in primary circuit and in secondary circuit.

When the vehicle brakes are not applied during engine running or when applying the non-ABS operating

brakes, the normally-open separation valve and the inlet valve are open, whereas the normally-closed

shuttle valve and the outlet valve are closed.

When the ESP system is operating, the normally-open separation valve will be closed by the solenoid

valve operation and the hydraulic circuit will be established by the shuttle valve. Then, the inlet and outlet

valves will be closed or open depending on the braking pressure RISE, HOLD or DUMP conditions.

Flashing warning lamp and warning sound during ESP operation

When the ESP operates while the vehicle is moving, the ESP warning lamp on the instrument panel

flickers and the buzzer sounds at every 0.1 second. The ESP lamp operation is to inform a driver that the

vehicle is extremely unstable.

The ESP system is just a supplementary system for the vehicle and it cannot control the vehicle over the

physical limit. Do not solely rely on the system but be advised to drive the vehicle safely.

Drive feeling during ESP operation

When the ESP system activates, the driving feeling can be different depending on vehicle driving

conditions. For example, it will feel different when the ESP system is activated while the ABS is operated

by depressing the brake pedal and when the ESP system is in control without the brake pedal

depressed on the same curve.

If the ESP system operates with the brake applied, the brake pressure will be increased on the

corresponding wheel which already has braking pressure for the ESP controls. In other words, the ESP

system would make the driver feel more abruptly braked compared to the situation that the braking

pressure is applied to wheel which had no braking force.

Noise and vibration that driver senses during ESP operation

The ESP system may transfer noise and vibration to a driver due to the pressure changes caused by the

motor and valve operations in a very short period of time.

Extreme cornering will trigger the ESP operation and this will make the driver sense noise and vibration

due to sudden brake application.

Also, the ESP system controls the engine power. Therefore, the driver may notice the engine power

decreases even when the accelerator pedal is depressed.

Page 1139 of 1336

2) DUMP (ESP is working) Mode

The pressure decreases just before the wheel speed drops and the wheels are locked.

The inlet valve closes and the outlet valve opens as in the ABS HECU and the oil is gathered at the low

pressure chamber while no additional oil is being supplied. Then the pump operates to allow fast oil

drainage. The shuttle valve and the separation valve do not operate while decompression.

Page 1141 of 1336

4) RISE (ESP is working) Mode

The shuttle valve and inlet valve will be open and the separation valve and outlet valve will be closed.

Then, the pump is operated. When ESP operates while the ABS is operating, the pressure will be

increased continuously until just before the corresponding wheel gets locked.

Page 1142 of 1336

0000-00

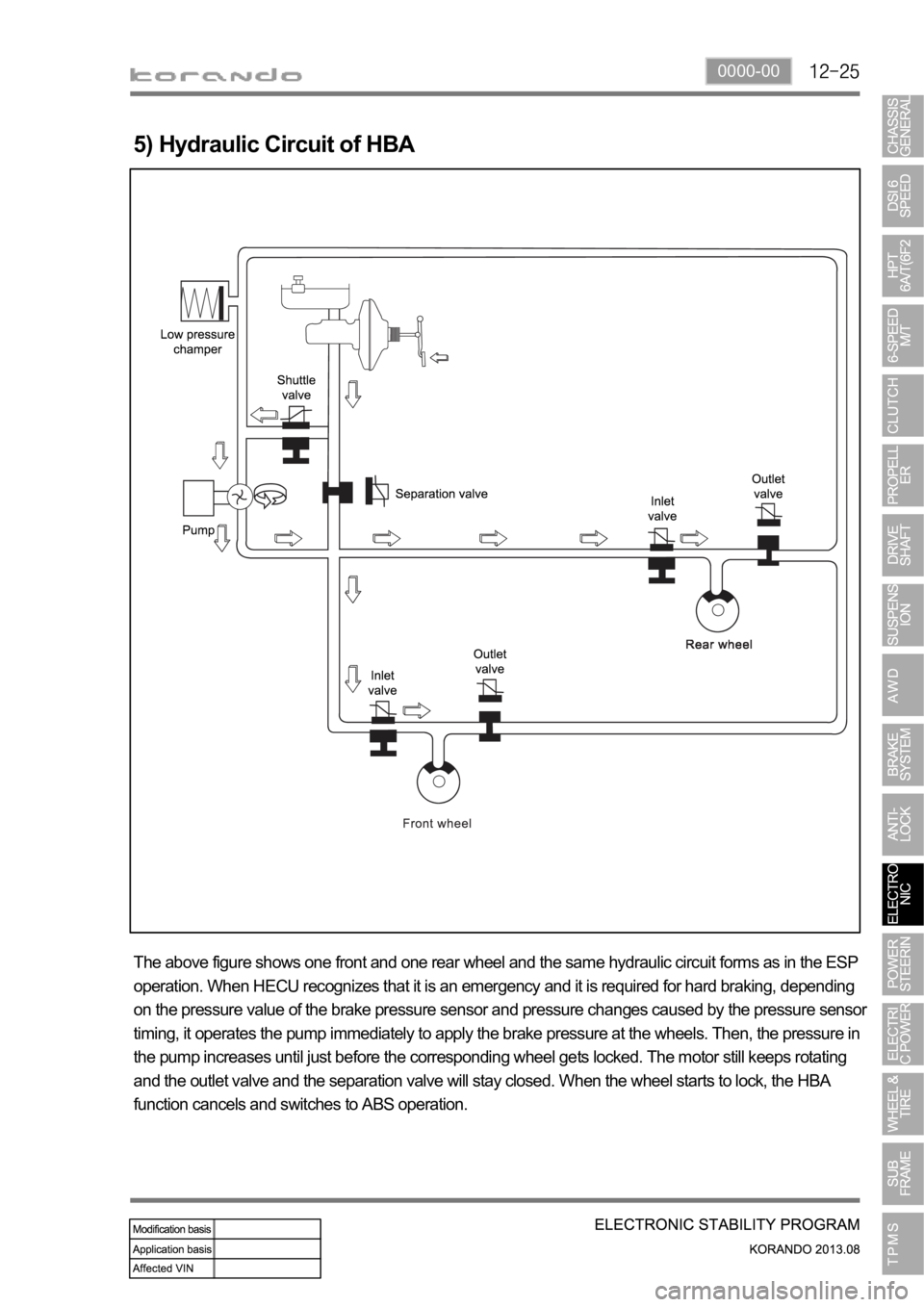

5) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the ESP

operation. When HECU recognizes that it is an emergency and it is required for hard braking, depending

on the pressure value of the brake pressure sensor and pressure changes caused by the pressure sensor

timing, it operates the pump immediately to apply the brake pressure at the wheels. Then, the pressure in

the pump increases until just before the corresponding wheel gets locked. The motor still keeps rotating

and the outlet valve and the separation valve will stay closed. When the wheel starts to lock, the HBA

function cancels and switches to ABS operation.

Page 1143 of 1336

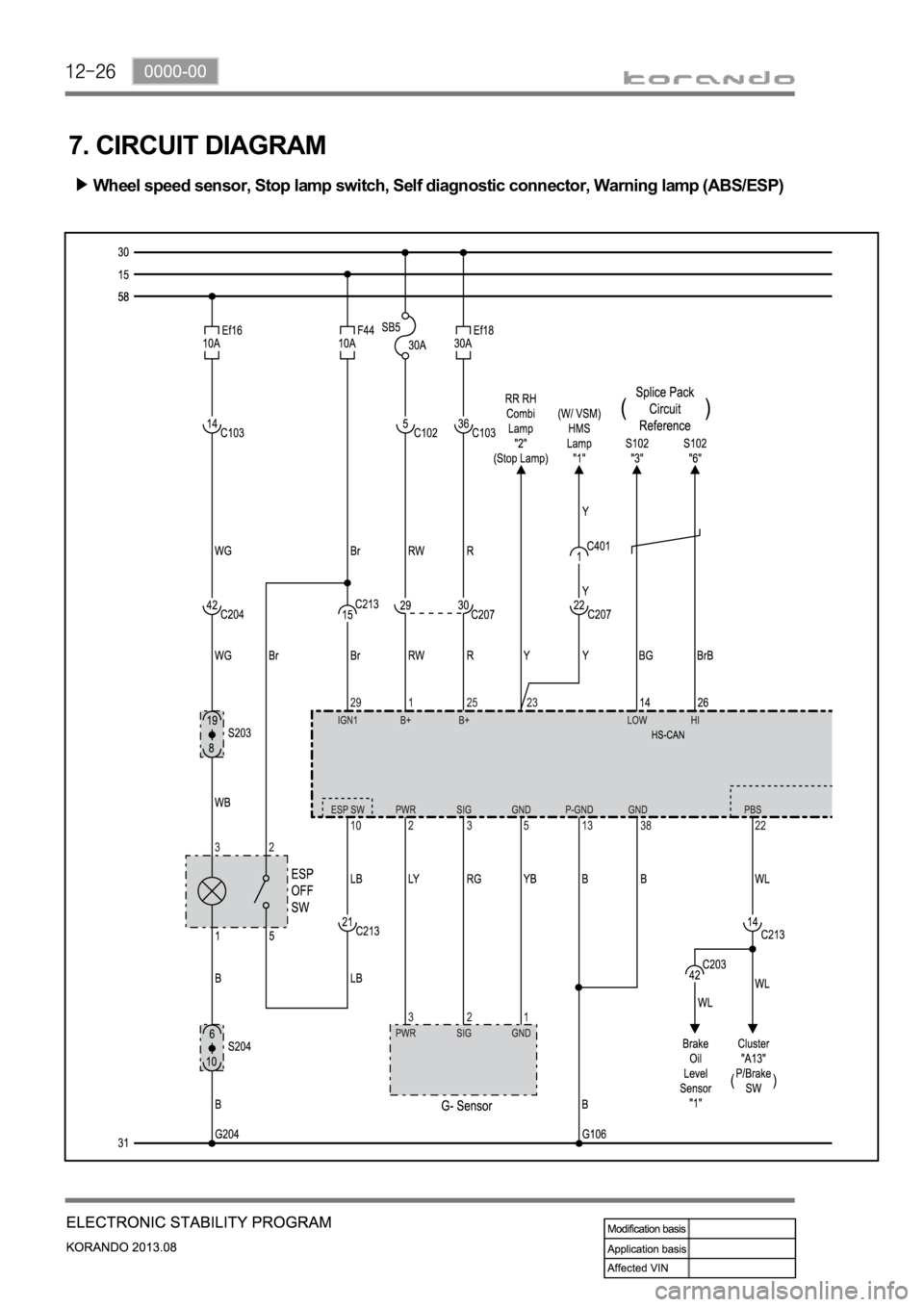

7. CIRCUIT DIAGRAM

Wheel speed sensor, Stop lamp switch, Self diagnostic connector, Warning lamp (ABS/ESP)

Page 1158 of 1336

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct line from

one bead to the other across the tread. In addition, a radial tire has a belt overwrap under the tread

surface to provide greater structural stability. The belt overwrap of a radial tire distortion while the radial

structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6 mm from

mark on the shoulder to let the driver find the wear mark easily. To measure the tire groove depth,

measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire inflation

pressure, changed tire location, etc.

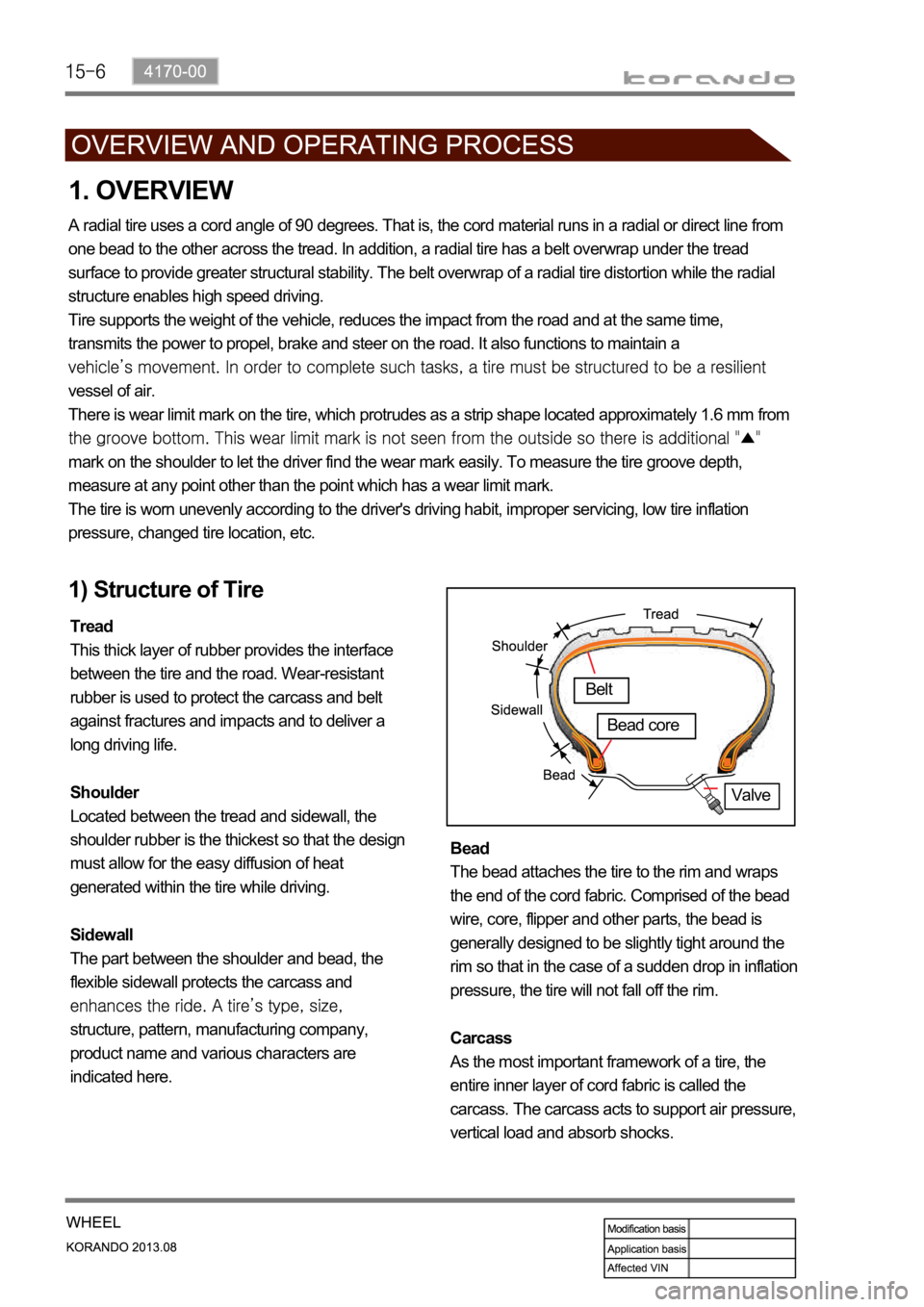

1) Structure of Tire

Tread

This thick layer of rubber provides the interface

between the tire and the road. Wear-resistant

rubber is used to protect the carcass and belt

against fractures and impacts and to deliver a

long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the design

must allow for the easy diffusion of heat

generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and wraps

the end of the cord fabric. Comprised of the bead

wire, core, flipper and other parts, the bead is

generally designed to be slightly tight around the

rim so that in the case of a sudden drop in inflation

pressure, the tire will not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air pressure,

vertical load and absorb shocks.

Valve

Belt

Bead core