length SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 307 of 1336

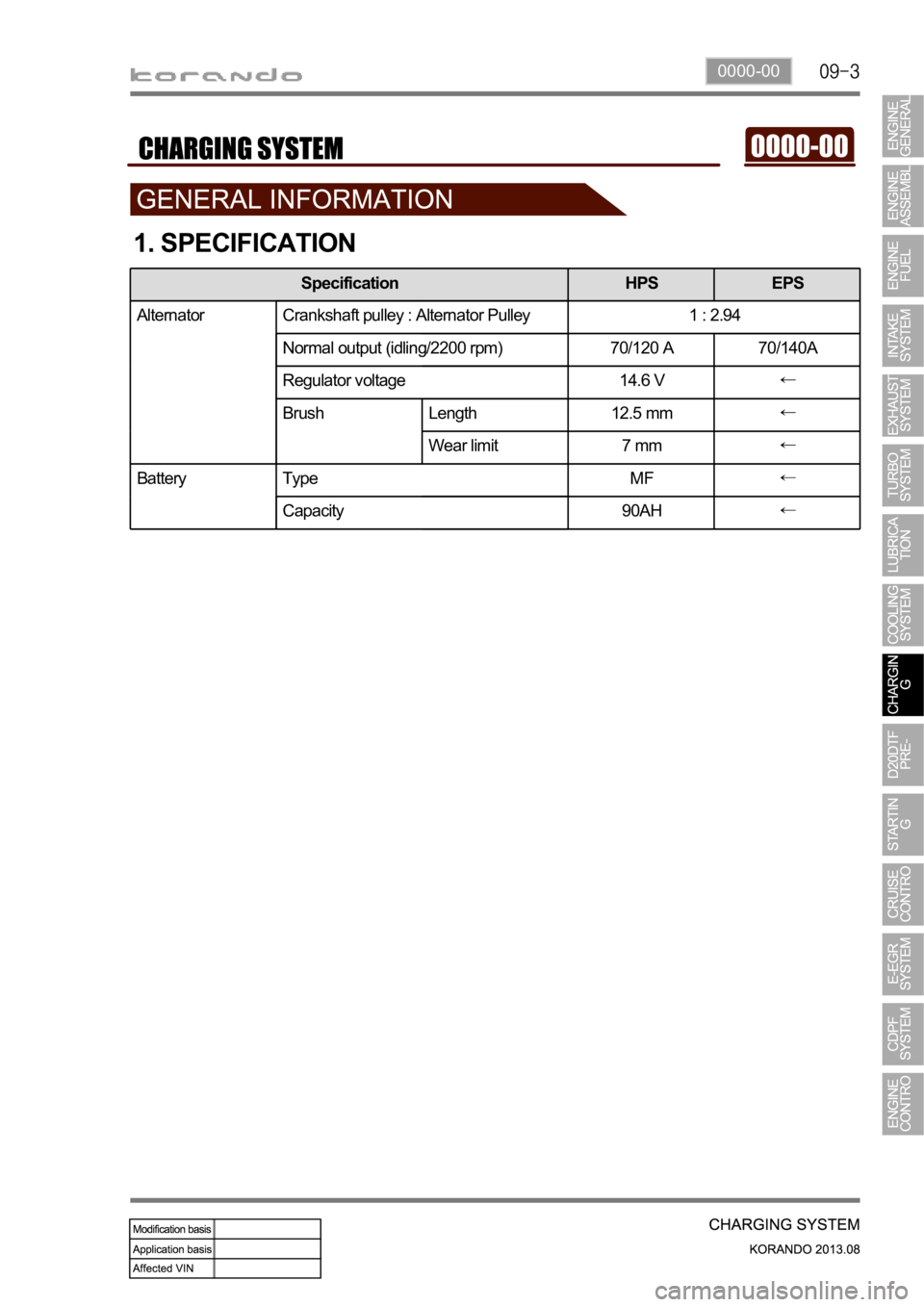

0000-00

1. SPECIFICATION

Specification HPS EPS

Alternator Crankshaft pulley : Alternator Pulley 1 : 2.94

Normal output (idling/2200 rpm) 70/120 A 70/140A

Regulator voltage 14.6 V

Brush Length 12.5 mm

Wear limit 7 mm

Battery Type MF

Capacity 90AH

Page 436 of 1336

1116-01

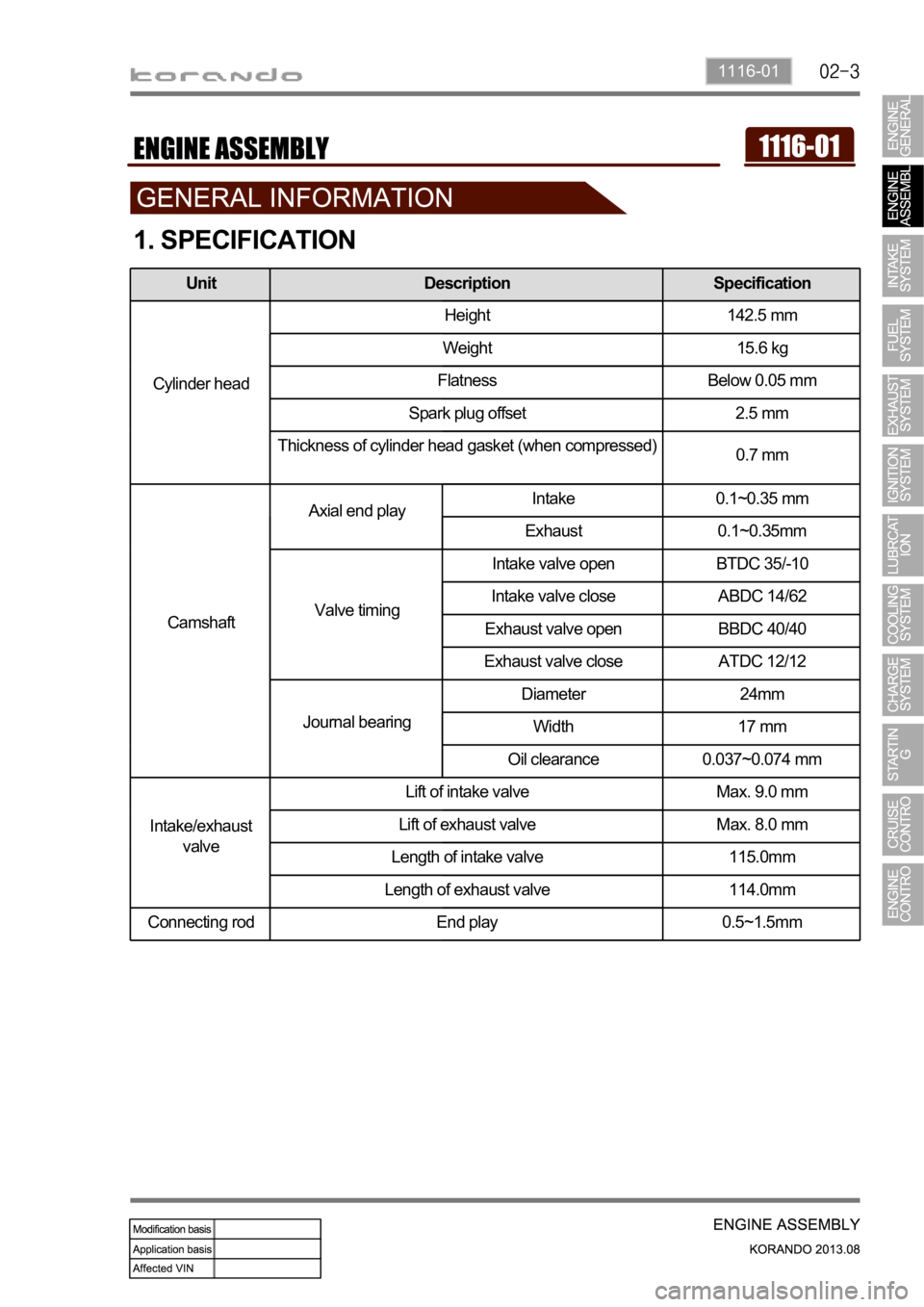

1. SPECIFICATION

Unit Description Specification

Cylinder headHeight 142.5 mm

Weight 15.6 kg

Flatness Below 0.05 mm

Spark plug offset 2.5 mm

Thickness of cylinder head gasket (when compressed)

0.7 mm

CamshaftAxial end playIntake 0.1~0.35 mm

Exhaust 0.1~0.35mm

Valve timingIntake valve open BTDC 35/-10

Intake valve close ABDC 14/62

Exhaust valve open BBDC 40/40

Exhaust valve close ATDC 12/12

Journal bearingDiameter 24mm

Width 17 mm

Oil clearance 0.037~0.074 mm

Intake/exhaust

valveLift of intake valve Max. 9.0 mm

Lift of exhaust valve Max. 8.0 mm

Length of intake valve 115.0mm

Length of exhaust valve 114.0mm

Connecting rod End play 0.5~1.5mm

Page 442 of 1336

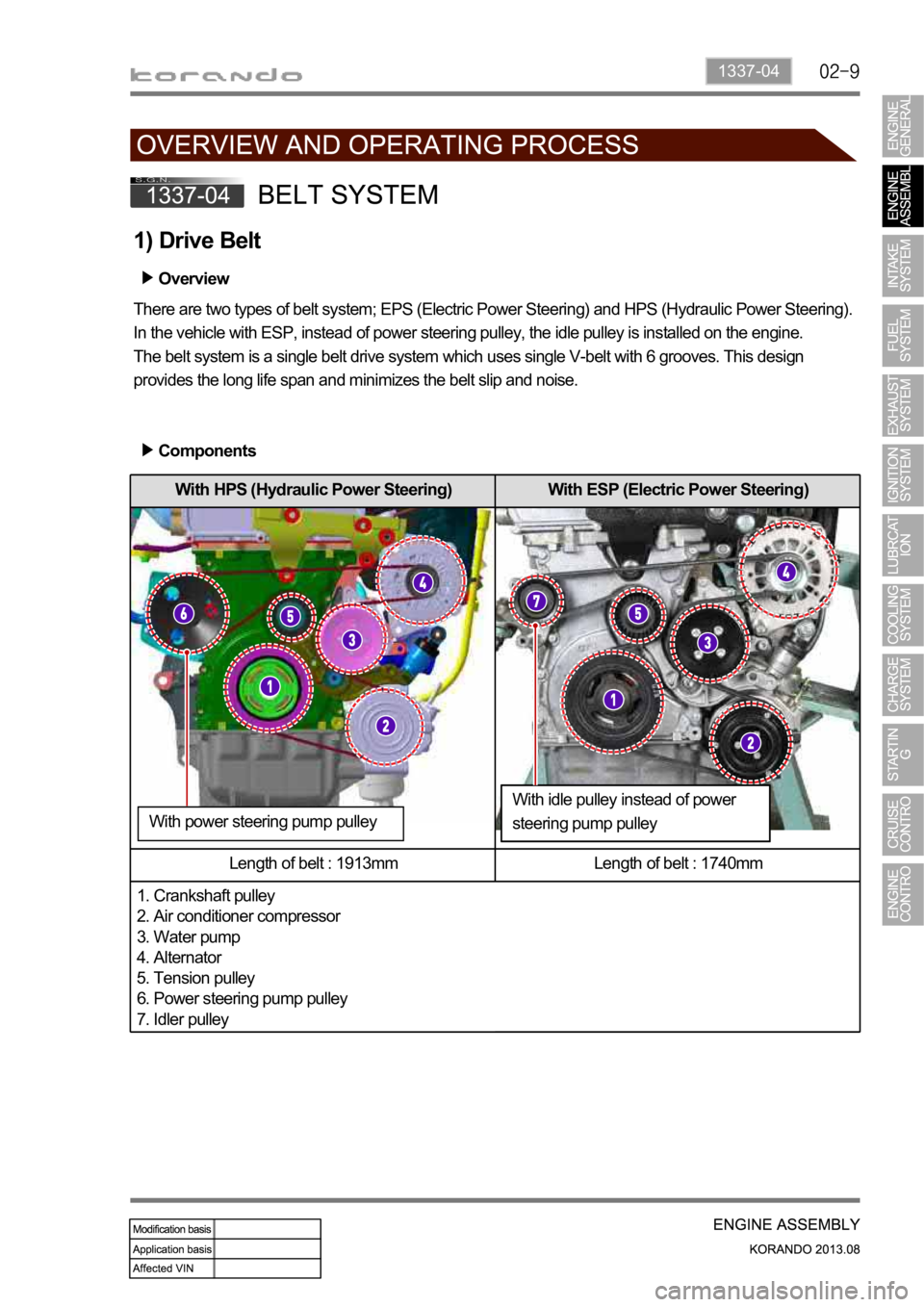

1337-04

With HPS (Hydraulic Power Steering) With ESP (Electric Power Steering)

Length of belt : 1913mm Length of belt : 1740mm

1. Crankshaft pulley

2. Air conditioner compressor

3. Water pump

4. Alternator

5. Tension pulley

6. Power steering pump pulley

7. Idler pulley

1) Drive Belt

Overview

There are two types of belt system; EPS (Electric Power Steering) and HPS (Hydraulic Power Steering).

In the vehicle with ESP, instead of power steering pulley, the idle pulley is installed on the engine.

The belt system is a single belt drive system which uses single V-belt with 6 grooves. This design

provides the long life span and minimizes the belt slip and noise.

Components

With idle pulley instead of power

steering pump pulley With power steering pump pulley

Page 526 of 1336

1452-01

1. SPECIFICATION

Unit Description Specification

AlternatorType HPS EPS

Crankshaft pulley : Alternator pulley 1 : 2.66

Normal output

(idle/2200rpm)70/140A

Regulator voltage 12V

BrushLength 12.5mm

Wear limit 7.0mm

BatteryType MF

Capacity 90AH

Page 963 of 1336

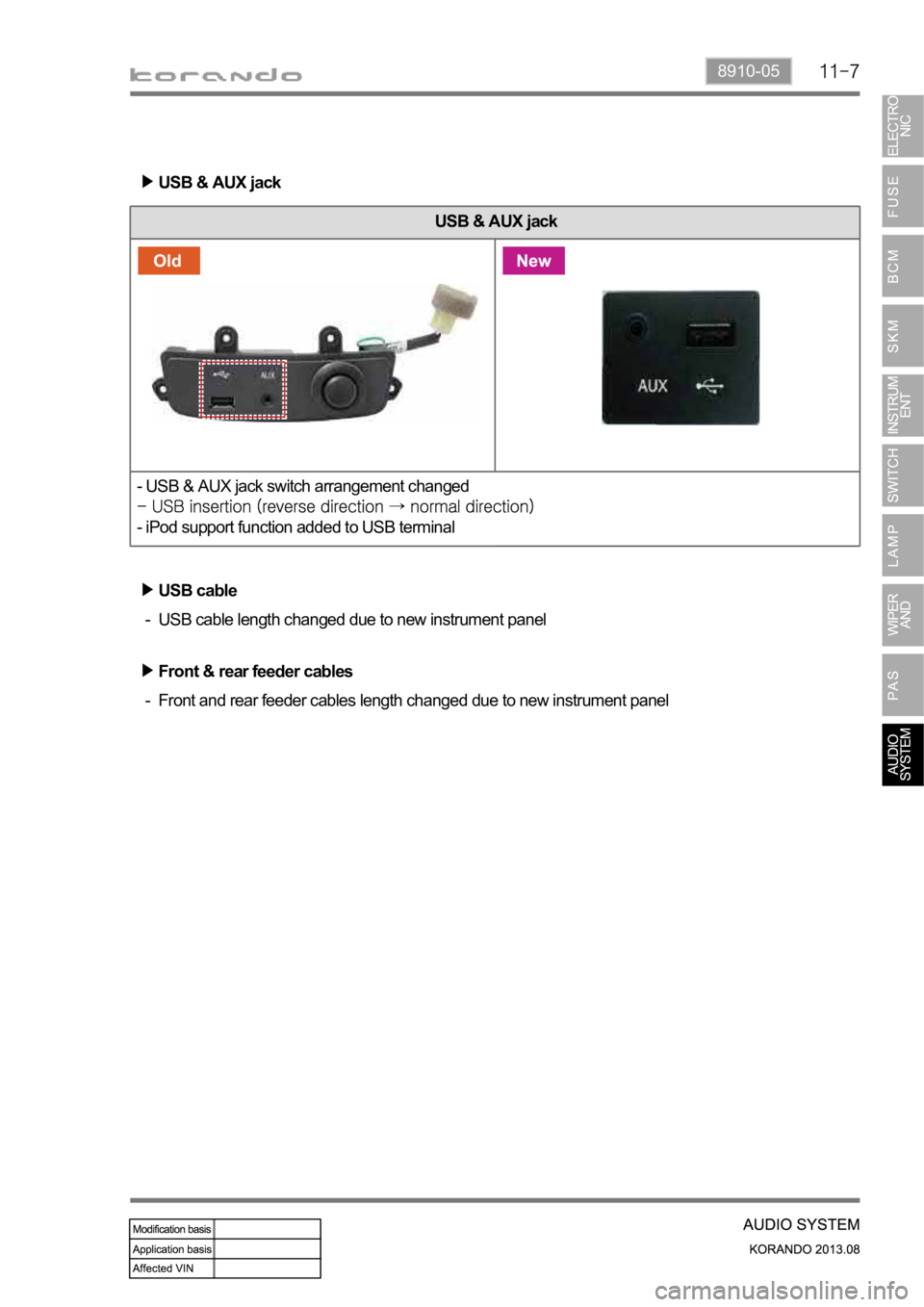

8910-05

USB & AUX jack

- USB & AUX jack switch arrangement changed

- iPod support function added to USB terminal

USB & AUX jack

USB cable

USB cable length changed due to new instrument panel -

Front & rear feeder cables

Front and rear feeder cables length changed due to new instrument panel -

Page 1005 of 1336

3680-01

2. SPECIFICATIONS

1) Specifications

Type/Weight M11 6-speed automatic transaxle /

approx. 102 kg (including ATF)

TORQUE 400 Nm

Overall length / Center length 367 mm / 205 mm

Descriptions Specification

Gear ratio 1st gear 4.156

2nd gear 2.375

3rd gear 1.522

4th gear 1.144

5th gear 0.859

6th gear 0.676

Reverse gear 3.178

Oil Type Fuchs TITAN ATF 3292

Capacity approx. 7.5 L

Change interval EU: Inspect every 20,000 km or 12 months (But,

change every 60,000 km under severe condition)

General: Inspect every 15,000 km or 12 months

(But, change every 60,000 km under severe

condition)

Resistance of oil

temperature sensor-20

0

20

100

D

N

P

R

Inhibitor switch

Page 1032 of 1336

3. SPECIFICATIONS

1) Specifications

Type/Weight 6F24 6-speed automatic transaxle /

approx. 86 kg (including ATF)

TORQUE 230 Nm

Overall length / Center length 373.1 mm / 204 mm

Descriptions Specification

Gear ratio 1st gear 4.212

2nd gear 2.637

3rd gear 1.800

4th gear 1.386

5th gear 1.000

6th gear 0.772

Reverse gear 3.385

Shift pattern Variable

Shift range 4 Range (P-R-N-D) + Manual mode

Shift range valve VFS : 6EA

Planetary gear 3EA (Front, Middle, Rear)

Clutch 2EA

Brake 3EA

O.W.C 1EA

Oil Type ATF SP-IV M

Capacity approx. 7.1 L

Change interval Maintenance free. However, under the severe

conditions or commercially used, change the oil at

every 100,000 km (EU: 90,000 km).

Resistance of oil

temperature sensor-20

0

20

100

Weight 2WD 87.5kg

4WD 88.5kg

Page 1054 of 1336

3190-01

1. SPECIFICATION

DG20DD

Model name WM6F1

Overall length 370 mm

Distance between shafts 205 mm / 70 mm

Weight (except transmission fluid) 62 kgf (2WD) / 63 kgf (4WD)

Gear ratio 1st 3.538 3.385 3.616

2nd 1.909 1.708 1.957

3rd 1.179 1.033 1.207

4th 0.814 0.786 0.905

5th 0.734 0.730 0.842

6th 0.628 0.595 0.714

Reverse 3.910 3.747 3.747

Synchronizer ring

type1st T: Triple-cone

2nd T: Triple-cone

3rd T: Triple-cone

4th D: Double-cone

5th D: Double-cone

6th S: Single-cone

Reverse T: Triple-cone

Shifting Type Remote (Cable type)

Gear selector lever

positionReversing:

Reverse ring

pull type

ItemSpecification

Remark

D20DTFD20DTF +

Low CO

G20DF

Page 1068 of 1336

0000-00

Operating Elements

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch system

releases the clutch by using release lever and release fork. This system provides higher efficiency than

conventional clutch system, and its durability is superior.

Clutch master cylinder (mounted on clutch pedal)

Concentric slave cylinder pipe (mounted inside of transmission) -

-Driving elements

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The clutch

pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the splines

of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted by a

diaphragm spring in the clutch cover pressure plate assembly.

2) Overview

Page 1071 of 1336

3310-02

1. SPECIFICATION

Description Specification

Structure 2-piece type with CV joint, spider, and rubber

coupling

Weight below 12.0 kg

Joint type CV joint, spider, rubber coupling

Spider Numbers one (installed on center bearing side)

External diameter

Overall size

Dimension

(Length x Dia.)No.1 shaft (TM to spider)

No. 2 shaft (spider to axle)

Runout of tube (after installation) 0.3 mm

Unbalance 80g.mm @ 3,000rpm

(second measurement: 120 g.mm)

U-joint Starting torque 0.3 to 0.7 Nm

Minimum starting angle

Amount of grease in CV joint 210+-10g

2. TIGHTENING TORQUE

Fastener Tightening torque

Bolt/nut for rubber coupling (rear axle side) 39.2 to 49.0 Nm

Bolt/nut for CV joint (transaxle side) 29.4 to 39.2 Nm

Mounting bolt for center bearing 58.8 to 68.6 Nm