check oil SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1112 of 1463

MANUAL TRANSMISSION 5B-5

Check

Clutch not releasing.

Improper or low transmission oil.

Shift or shift rail binding.

Binding of sliding synchronizers or gears.

If reverse only, faulty backup switch.

Worn or damaged flywheel pilot bushing.Check

Control lever assembly broken or damaged.

Damaged offset lever, shift fork, selector place or

selector arm.

DIAGNOSIS

WILL NOT SHIFT(CONTROL LEVER MOVES)

Action

Replace control lever and housing assembly.

Remove extension, adapter or case cover.

Check or replace damaged parts.

HARD SHIFT OR CONTROL LEVER WILL NOT MOVE INTO GEAR

Action

Adjust or replace clutch.

Add or replace with specified oil.

Remove extension, adapter or case cover.

Check or replace damaged parts.

Remove extension, adapter or case cover.

Check synchronizers and gears and replace

damaged parts.

Check or replace backup switch.

Replace pilot bushing.

GEARS CRASH WHEN SHIFTING

Check

Engine idle speed too high.

Damaged or faulty clutch.

Pilot bearing between input shaft and output shaft binding.

Damaged synchronizer.

Bell housing misaligned.

Damaged gear(s).

Worn or damaged flywheel pilot bushing.Action

Adjust idle speed to specified speed.

Adjust or replace clutch.

Replace or check roller bearings.

Check or replace synchronizer parts.

Align bell housing and bore.

Check or replace gear(s).

Replace pilot bushing.

Page 1113 of 1463

5B-6 MANUAL TRANSMISSION

Check

Loosened transmission or flywheel housing bolts,

improper alignment.

Synchronizer damaged or excessively worn.

Blocking ring damaged, worn index slots or friction

surfaces worn or damaged.

Excessive countershaft end play.

Worn or damaged fork due to loosened shaft, rail or

shifting fork.

TRANSMISSION JUMPS OUT

Action

Tighten bolts to specified value. Realign if necessary.

Check or replace synchronizer parts.

Check or replace blocking ring.

Check worn or damaged parts. Adjust shim thickness

using roller bearings if necessary.

Check for wear or damaged. Replace worn or

damaged parts.

Check

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever, shaft or rail.

Worn or damaged synchronizer.

Worn or damaged gears.

TRANSMISSION LOCKED IN ONE GEAR

Action

Replace extension, adapter or case cover. Check or

replace loose parts on shaft or rail. Replace roll pin(s).

Remove extension, adapter or case cover. Check for

wear or damaged. Replace damaged parts.

Check worn or damaged synchronizer parts and

replace if necessary.

Check worn or damaged gears and replace if neces-

sary.

Check

Improper or low transmission oil.

Loose bolts or other attaching parts.

Improper flywheel housing to engine crankshaft

alignment.

Noisy transmission bearing.

Noisy gears.

TRANSMISSION NOISE

Action

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly.

Check bearings, bearing rollers and parts for wear or

damage.

Replace if necessary.

Check for worn or damaged gears

(including speedometer gear).

Replace if necessary.

Page 1114 of 1463

MANUAL TRANSMISSION 5B-7

TRANSMISSION LEAKAGE

Check

Leakage from transmission.

Vent or breather clogged.

Too much oil.

Loose bolts at sealing faces.

Improperly applied sealant.

Worn or damaged oil seal.Action

Clean all exposed surfaces, then check for leaks.

Clean or replace vent or breather.

Check oil level.

Tighten as specified.

Clean leaking surfaces.

Reapply sealant.

Replace oil seal.

Page 1157 of 1463

5C-4 CLUTCH

Checks

Oily Facing

Hard or Faulty Facing

Burnt Torsion Spring

Faulty Pressure Plate

Bent Clutch Diaphragm Spring

Hard or Bent Flywheel

Engine Mounts Loose or Burnt LeverAction

Adjust Pedal Freeplay

Repair Release Cylinder

Repair or Replace

Repair as Necessary

Replace Checks

Excessive Clutch Pedal Free play

Faulty Clutch Release Cylinder

Worn Disc, Excessive Run-out, Damaged Lining

Dirty or Burred Splines on Input Shaft or Clutch Disc

Damaged Clutch Pressure PlateChecks

Vibration or Excessive Run-out of Disc

Rust or Wear of Disc Spline

Oily Facing

Damaged Diaphragm Spring

Excessive Clutch Pedal Free play

DIAGNOSIS

CLUTCH SLIPS

Checks

Excessive Wear of Facing

Hard or Oily Facing

Damaged Pressure Plate or Flywheel

Damaged or Burnt Diaphragm Spring

Clutch Pedal Free play Insufficient

Faulty Operation of Clutch Pedal

Worn or Damaged Clutch DiscAction

Replace

Repair or Replace

Replace

Replace

Adjust

Repair or Replace

Replace

POOR DISENGAGEMENT

Action

Replace

Repair or Replace

Repair or Replace

Replace

Adjust

HARD TO SHIFT OR WILL NOT SHIFT

CLUTCH CHATTERS WHEN STARTING

Action

Repair or Replace

Replace

Replace

Replace

Replace

Repair or Replace

Tighten or Replace

Page 1165 of 1463

5C-12 CLUTCH

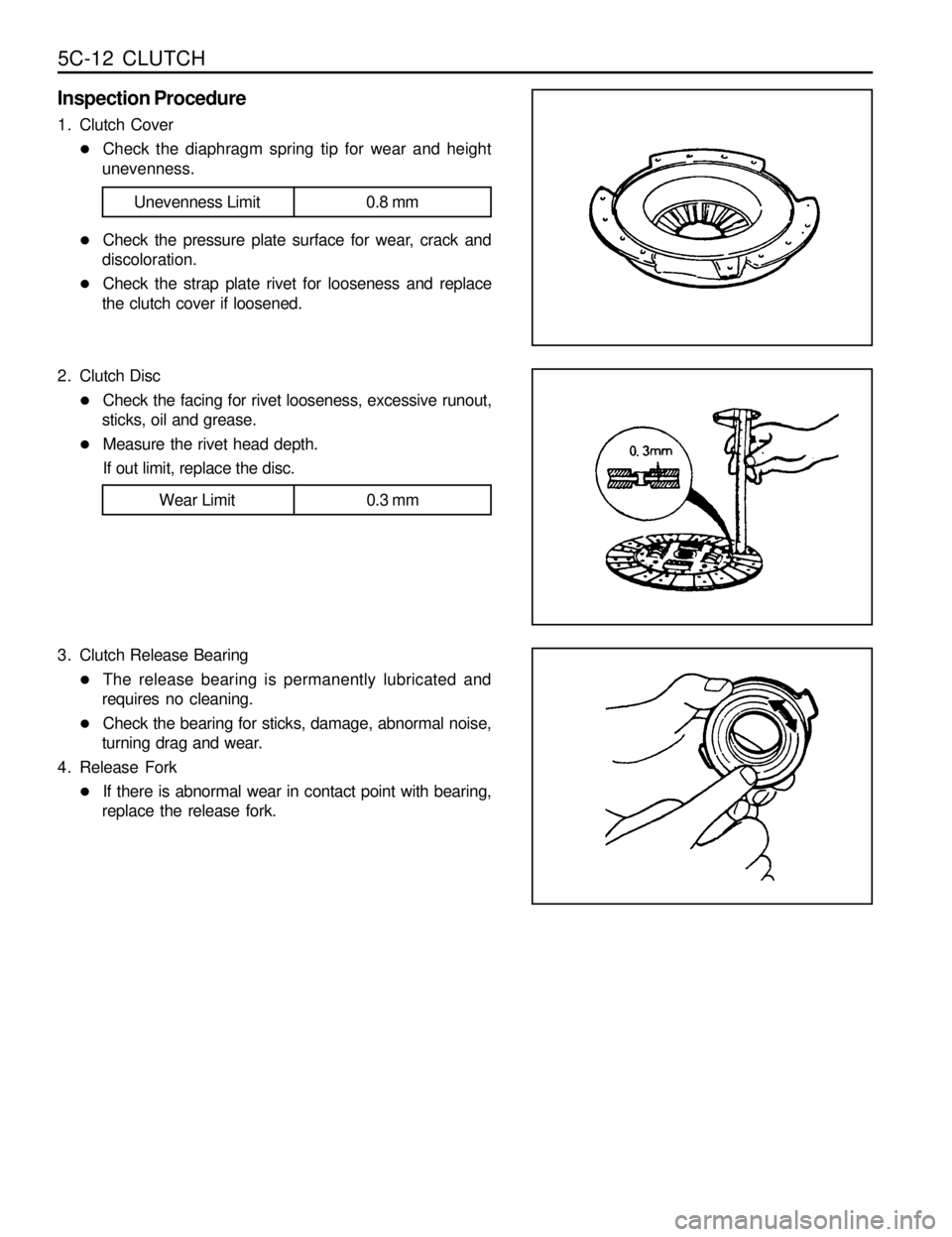

Inspection Procedure

1. Clutch Cover

lCheck the diaphragm spring tip for wear and height

unevenness.

lCheck the pressure plate surface for wear, crack and

discoloration.

lCheck the strap plate rivet for looseness and replace

the clutch cover if loosened.

Unevenness Limit 0.8 mm

2. Clutch Disc

lCheck the facing for rivet looseness, excessive runout,

sticks, oil and grease.

lMeasure the rivet head depth.

If out limit, replace the disc.

3. Clutch Release Bearing

lThe release bearing is permanently lubricated and

requires no cleaning.

lCheck the bearing for sticks, damage, abnormal noise,

turning drag and wear.

4. Release Fork

lIf there is abnormal wear in contact point with bearing,

replace the release fork.

Wear Limit 0.3 mm

Page 1171 of 1463

Model

Type

Gear Ratio

Oil

Manufacturer

WeightPart-Time 4408 (E)

E.S.O.F. Type

1 : 1

2.48 : 1

ATF S-3, S-4 or DEXRON II, III

1.2 L

Check : Every 15,000 km

Replace : Every 50,000 km

Borg Warner

30 kg

SECTION 5D1

TRANSFER CASE (PART TIME 4408)

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 5D1-1

General Specifications . . . . . . . . . . . . . . . . . 5D1-1

Schematic and Routing Diagram . . . . . . . . 5D1-2

Part Time Transfer Case - 4408 . . . . . . . . . . 5D1-2

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 5D1-3

Self-Diagnosis . . . . . . . . . . . . . . . . . . . . . . 5D1-4

System Description . . . . . . . . . . . . . . . . . . . . 5D1-4

Self-Diagnosis Test . . . . . . . . . . . . . . . . . . . . 5D1-8Diagnostic Diagram . . . . . . . . . . . . . . . . . . . 5D1-9

Maintenance and Repair . . . . . . . . . . . . . 5D1-10

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 5D1-10

Maintenance of Transfer Case Lubricant . . 5D1-10

Transfer Case . . . . . . . . . . . . . . . . . . . . . . . 5D1-11

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 5D1-14

Transfer Case . . . . . . . . . . . . . . . . . . . . . . . 5D1-14

Transfer Case Control Unit (TCCU) . . . . . . 5D1-36

High

Low

Specification

Capacity

Lubrication ApplicationDescription

Page 1173 of 1463

TRANSFER CASE (PART TIME 4408) 5D1-3

Cannot Front Wheel Drive when Shifted 4H,4L

DIAGNOSIS

Electric Shift Problems

Action

Overhaul and check, replace if necessary.

Overhaul and check for wear and damage.

Replace if necessary.

Check sliding parts, replace if necessary. Checks

Faulty or Damaged TCCU, Speed Sensor, Motor, Clutch

or Internal Wirings

Damaged or Worn Shift Cam, Hub, Fork and Rail Shift

Binding Shift Fork, Hub Collar or Gear

Checks

Broken Drive ChainAction

Check sliding parts, replace if necessary.

Noise in 4WD Operation

Checks

Improper or low oil

Loosened bolts or mounted parts

Noisy T/C bearing

Noisy gearsAction

Drain and replace with specified oil.

Retighten as specified.

Disassemble bearings and parts and check for wear or

damage. Replace if necessary.

Check for wear and damage including speedometer

gear, replace if necessary.

Noise in 4H or 4L

Checks

Worn or Damaged Sprockets or Drive Chain

Incorrect Tire PressureAction

Disassemble and check for wear and damage, replace

if necessary.

Adjust tire pressure.

Transfer Case Oil Leakage

Action

Replace the case.

Clean case and parts and check for leakage.

Remove breather hose and clean, replace if necessary.

Use specified oil and adjust oil level.

Retighten

Use specified sealant and retighten.

Replace Checks

Cracked Transfer Case

Leakage from Other Parts

Breather Clogging

Improper or too much Oil

Loosened Sealing Bolts

Improperly Applied Sealant

Worn or Damaged Oil Seal

Page 1180 of 1463

5D1-10 TRANSFER CASE (PART TIME 4408)

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

MAINTENANCE OF TRANSFER CASE

LUBRICANT

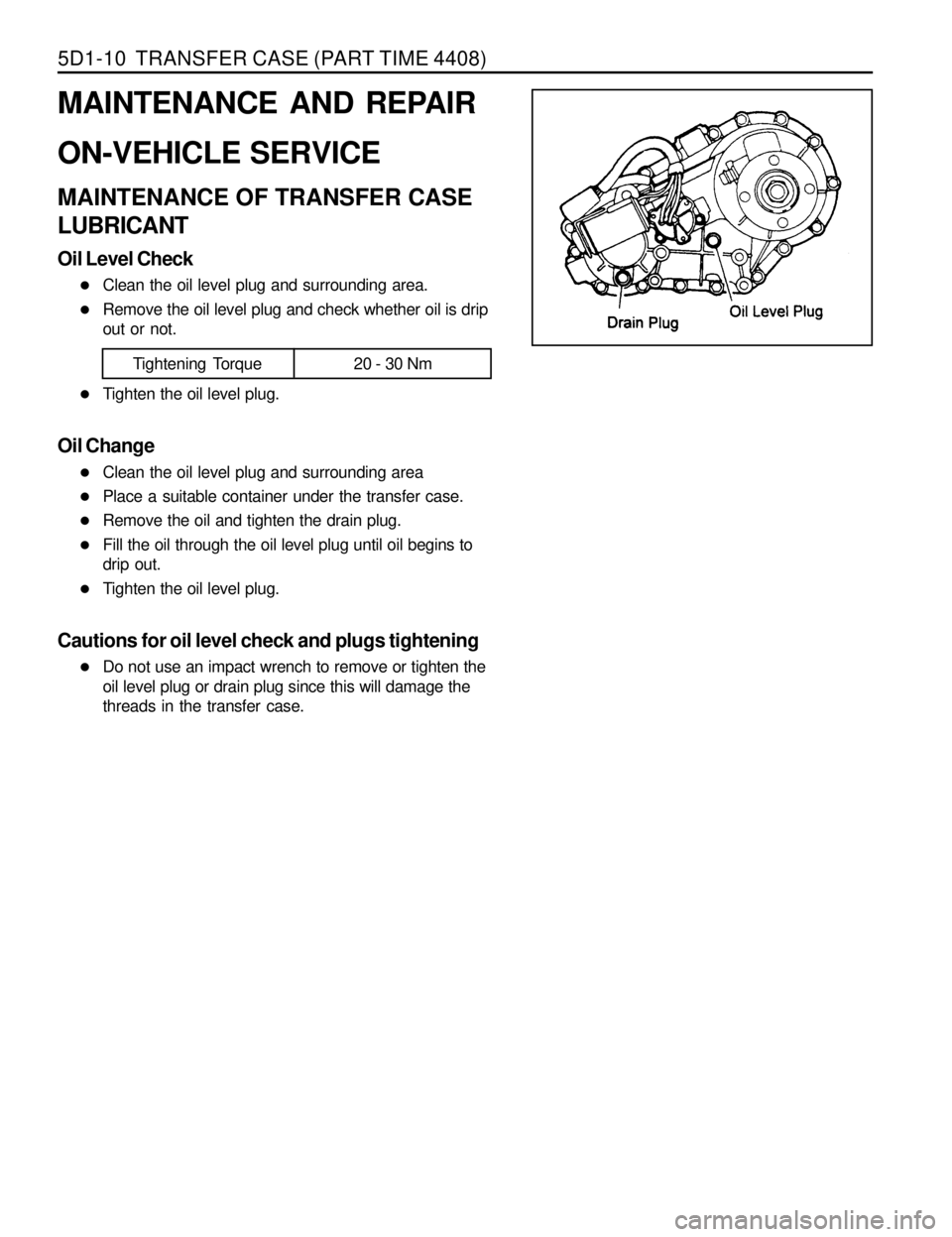

Oil Level Check

lClean the oil level plug and surrounding area.

lRemove the oil level plug and check whether oil is drip

out or not.

lTighten the oil level plug.

Oil Change

lClean the oil level plug and surrounding area

lPlace a suitable container under the transfer case.

lRemove the oil and tighten the drain plug.

lFill the oil through the oil level plug until oil begins to

drip out.

lTighten the oil level plug.

Cautions for oil level check and plugs tightening

lDo not use an impact wrench to remove or tighten the

oil level plug or drain plug since this will damage the

threads in the transfer case.

Tightening Torque 20 - 30 Nm

Page 1192 of 1463

5D1-22 TRANSFER CASE (PART TIME 4408)

Cleaning Procedure

Notice

Before cleaning, check the magnet for the

presence of metal particles which indicate internal

chipping of the transfer case.

1. Using cleaning solvent, clean the residual oil and dirt

deposits.

Notice

During cleaning, be careful not to damage the metal

surfaces.

2. After cleaning, dry the parts with low pressure (Max. 20 psi)

compressed air.

3. Lubricate the ball bearings and needle bearings with transfer

case oil after cleaning.

Notice

Protect the lubricated bearings from dust.

Inspection Procedure

1. Visually check the all removed parts.

Notice

Always replace the hose coupling, O-ring and oil seal with

new parts.

2. Inspection Terms

lBurr : Local rise of material forming protruding sharp

edge

lChip : An area from which a small fragment has been

broken off or cut

lCrack : Surface break of line nature indicating partial or

complete separation of material.

lExcessive wear : Heavy or obvious wear beyond

expectations considering conditions of operation.

lIndentation : Displacement of material caused by localized

heavy contact.

lGalling : Breakdown of metal surface due to excessive

friction between parts. Particles of the softer material

are torn loose and welded to the harder material.

lNick : Local break or notch, usually displacement of

material rather than loss.

lScoring : Tear or break in metal surface from contact

under abnormal pressure.

lStep wear : Heavy wear that produces a step that can

be seen or felt between adjacent contact and noncontact

surfaces.

lUneven wear : Condition of localized, unevenly distributed

wear Includes hollows, shiny spots, uneven polish and

other visual indications.

Page 1232 of 1463

TRANSFER CASE (TOD) 5D2-25

Error in electro - magnetic clutch : fault code

“1721”, “1722”

lPhenomenon

1. Upon diagnosis by SCAN-100, it displays on fault

codes “1721,1722”.

lCause

1. Defect in electro - magnetic clutch

2. Defect in connector or wiring

- Open or short from EMC to the supply : 1721

- Short EMC to ground : 1722

Ye s

No

C1

Ye s

No Ye s

No

11-15Vdc

Ye s

No

C2

Ye s

No

Test Stage / ContentsResult

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check relevant connector connection status.

1. Check relevant connector connection status with TOD

control unit.

- Does it connect correctly ?

2. Check connection status of speed sensor and clutch

coil connector (7 pin) in transfer case.

- Does it connect correctly ?

3. In case of bad connection, connect it correctly then

perform the follows :

a. Delete the memorized fault code in control unit with

Scan - 100.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCAN-100

- Does it display on fault codes “1721,1722” ?

Check supply voltage into electro-magnetic clutch.

1. Ignition “ON”

2. Measure voltage between pin 4/19(+) and 17/18(-) in

TOD control unit connector.

- Specified value

- Measured value is within specified range ?

3. If the specified value would not be measured, perform

the follows :

a. Check battery voltage (charging condition)

b. Check open circuit on No.13 fuse (20A)

c. Check relevant wires.

- Is the above 3a, 3b, 3c normal ?Perform C1-2 stage

Perform C1-3 stage

Perform C2 stage

Normal system Perform C2 stage

Perform C1-3 stage

Perform C3 stage

Perform C2-3 stage

Perform C3 stage

lCharging/

Replace battery

lReplace fuse

lRepair wires