check oil SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 534 of 1463

OM600 ENGINE COOLING 1D3-13

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermoswich connector from radiator.

3. Remove the each coolant hose.

4. Remove the auto T/M oil cooling hose and cooling line.

Installation Notice

5. Loosen the radiator upper mounting bolt and remove the

mounting stopper and insulator.

6. Remove the radiator.

7. Check the radiator pin for crack, leakage and bending and

replace it if necessany.

8. Installation should follow the removal procedure in the

reverse order.

Tightening TorqueHose : 29 - 40Nm

Page 549 of 1463

M162 ENGINE ELECTRICAL 1E1-11

Circuit Diagram

Inspection & Maintenance Procedure (for MSE)

1. While the ignition switch is in 'OFF' position, remove the

wiring connectors (1 and 15) from ignition coil and measure

the primary resistance between terminal No.1 and No.15.

2. During engine cranking, measure primary voltage (T1/1)

between ECU terminal No. 71 and No. 69. Notice

If out of specified value, replace the ignition coil.

Specified Value 0.9 - 1.6 W (20°C)

Specified Value 200 - 350 V

Notice

lMeasure remaining cables.

- T1/2 : No. 72 and 69.

- T1/3 : No. 70 and 69.

lIf out of specified value, check ignition cable and ECU.

3. Using a multi-tester, measure the secondary coil resistance

between 5a and 5b.

Specified Value 6 - 8.5 kW

Page 561 of 1463

M161 ENGINE ELECTRICAL 1E2-11

Inspection & Maintenance (for E2.3 MSE)

1. Measure the primary resistance between the cable terminals

1 and 15 after removing the ignition cable wiring connector

(1 and 15) with ignition switch OFF.

Notice

Replace the ignition coil if out of the specified resistance.

lT1/2 : between No.71 and No.69

Notice

Check the ignition cable and the ECU if out of the

specified value.

3. Measure the secondary cable resistance between the

ignition coil 5a and 5b using a multimeter. 2. Measure the primary voltage(T1/1) between the ECU

terminals No.72 and No.69 during the engine cranking

(starter motor activated).

Specified Value 6 - 8.5 KW

Specified Value 0.9 - 1.6 W

Specified Value 200 - 350 V

Page 591 of 1463

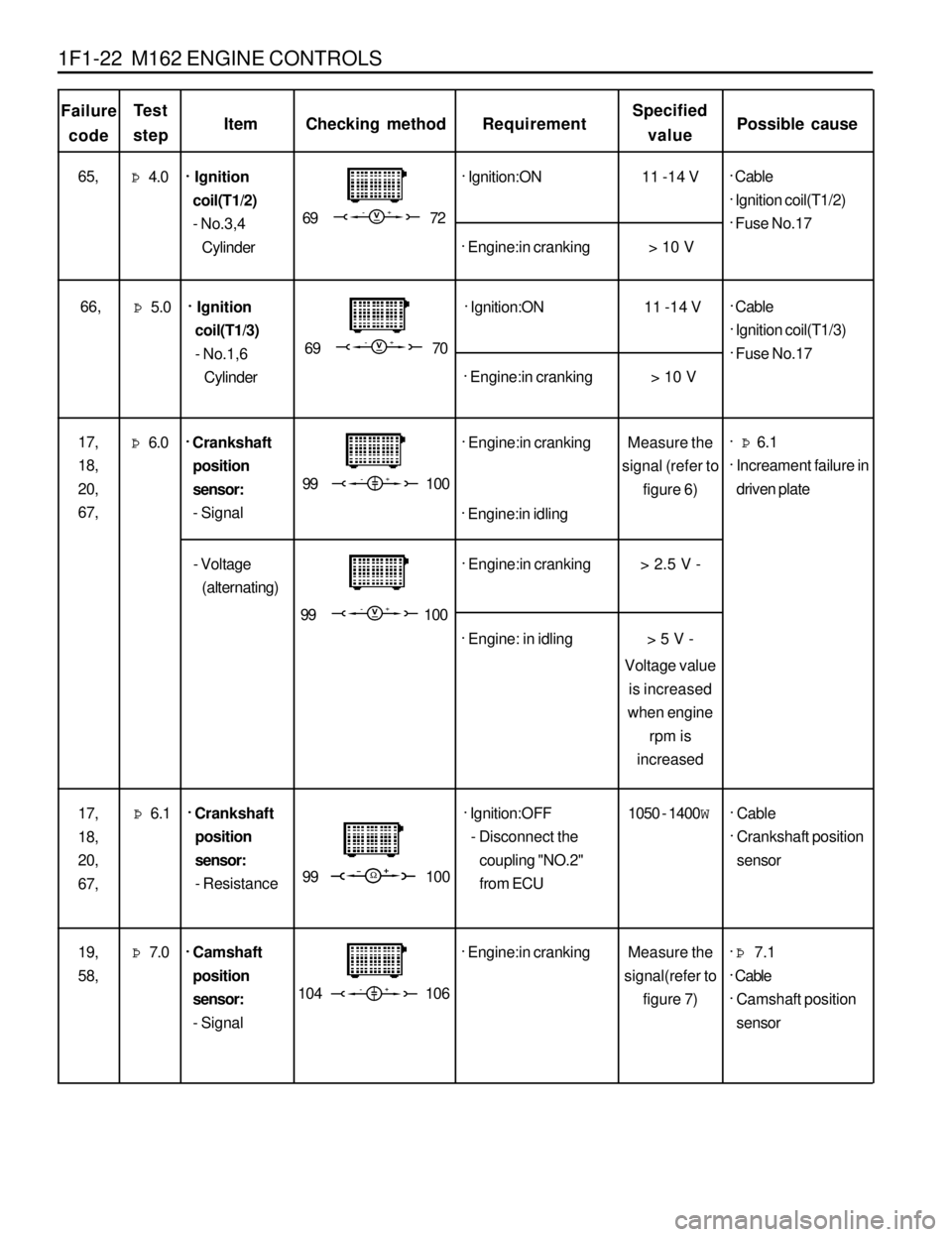

M162 ENGINE CONTROLS 1F1-21

Failure

codeItemChecking method Test

stepRequirementSpecified

valuePossible cause

10 1211 - 14V

· ·· ·

· ECU:power

supply

- terminal

30(TM.30)

Þ 2.2· ·· ·

· Power

supply:

- terminal

87(TM.87)· Ignition:ON· Power supply cable

· OVPR

IGNITION SYSTEM TEST

08,· Þ 1.1

· Þ 1.2

Þ 1.1

· Ignition:ON

10 211 - 14V· ·· ·

· Ground

cable:

- Battery

ground· Ground cable

· Ground condition

(figure 1)Diagnosis

socket

69 2

Diagnosis

socket

Þ 1.2· Ignition:ON

11211 - 14V· ·· ·

· Power

supply:

- terminal

30(TM.30)· Power supply cable

· Fuse No.8Diagnosis

socket

Þ 2.0· Ignition:ON

51111 -14V· ·· ·

· ECU:power

supply

- terminal

87(TM.87)08,· Þ 2.1

· Þ 2.2

Þ 2.1

· Ignition:ON 11 - 14V· ·· ·

· Ground

cable

- Electronic

ground· Ground cable

52

Diagnosis

socket

111

Diagnosis

socket

· Ignition:OFF

11 - 14V

< 1V

Þ 3.0· Ignition:ON

6911 - 14 V· ·· ·

· Ignition

coil(T1/1)

- No.2,5

Cylinder64,· Cable

· Ignition coil(T1/1)

· Fuse No.17

· Engine:in cranking > 10 V

Page 592 of 1463

1F1-22 M162 ENGINE CONTROLS

Failure

codeItemChecking method Te s t

stepRequirementSpecified

valuePossible cause

Þ 6.1· ·· ·

· Crankshaft

position

sensor:

- Resistance· Ignition:OFF

- Disconnect the

coupling "NO.2"

from ECU· Cable

· Crankshaft position

sensor Þ 6.0

· Engine:in cranking

99 100Measure the

signal (refer to

figure 6)· ·· ·

· Crankshaft

position

sensor:

- Signal17,

18,

20,

67,· Þ 6.1

· Increament failure in

driven plate

> 5 V - 99 100

99 100

1050 - 1400W

Þ 7.0

· Engine:in cranking

104 106· Þ 7.1

· Cable

· Camshaft position

sensor Measure the

signal(refer to

figure 7)

· ·· ·

· Camshaft

position

sensor:

- Signal

Þ 4.0· Ignition:ON

69 7211 -14 V· ·· ·

· Ignition

coil(T1/2)

- No.3,4

Cylinder65,· Cable

· Ignition coil(T1/2)

· Fuse No.17

· Engine:in cranking > 10 V

· Engine:in idling

- Voltage

(alternating)

· Engine:in cranking

· Engine: in idling> 2.5 V -

19,

58,

Þ 5.0· Ignition:ON

69 7011 -14 V· ·· ·

· Ignition

coil(T1/3)

- No.1,6

Cylinder66,· Cable

· Ignition coil(T1/3)

· Fuse No.17

· Engine:in cranking > 10 V

17,

18,

20,

67,Voltage value

is increased

when engine

rpm is

increased

Page 593 of 1463

M162 ENGINE CONTROLS 1F1-23

Failure

codeItemChecking method Te s t

stepRequirementSpecified

valuePossible cause

106 11The value will

be changed in

1.2 - 1.7 V - Voltage

(alternating)

0.9 - 1.6 W 71 11

71 72

· Engine:in cranking

Þ 7.1

· Ignition:ON

- Remove the

connector from the

Camshaft position

sensor between

No.1 terminal and

No.3 terminal. 1311 -14 V· ·· ·

· Camshaft

position

sensor

(E23 only)

- Power

supply· Cable

· OVPR

· ·· ·

· Ignition

coil(T1/1)

- primary coil

voltage

(No.2 and 5

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)

· Ignition:OFF200 - 350 V

Camshaft position

sensor

64,Þ 8.0· Þ 8.1

Þ 8.1

· ·· ·

· Connecting

resistance of

ignition coil

between T1/

1 and T1/2· Cable

· Ignition coil T1/1

· Ignition coil T1/2

72 11

· ·· ·

· Ignition

coil(T1/2)

- primary coil

voltage

(No.3 and 4

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)200 - 350 V 65,Þ 9.0· Þ 9.1

0.9 - 1.6 W

72 71

· Ignition:OFFÞ 9.1· ·· ·

· Connecting

resistance of

ignition coil

between T1/

2 and T1/1· Cable

· Ignition coil T1/1

· Ignition coil T1/2 The

resistance of

ignition coil at

20°C is

approached

0.6W

The

resistance of

ignition coil at

20°C is

approached

0.6W

Page 594 of 1463

1F1-24 M162 ENGINE CONTROLS

Failure

codeItemChecking method Test

stepRequirementSpecified

valuePossible cause

8 - 20 KV· ·· ·

· Ignition coil

(T1/1, T1/2,

T1/3)

- Secondary

ignition

voltage

> 10 MW

11 7 11 8· Engine:in cranking

- Select the ignition

coil in order of T1/1,

T1/2

- Measuring range:

20KV

- Time range:100 %

· Ignition:OFF

- Disconnect the

coupling "No.2" from

ECU.Þ 12.0· ·· ·

· Knock

sensor 1

- Resistance

(cylinder

No1, 2, 3)· Connecting

condition

· Cable

· ECU Þ 11.0 64,

65,

66,

Engine tester· Þ 11.1

· Ignition plug

· ECU

· High tension cable

6 - 8.5 KW

· ·· ·

· Ignition coil

(T1/1, T1/2,

T1/3)

- Secondary

coil

resistance· Remove the high

tension cable of T1/

1, T1/2, T1/3. Þ 11.1Ignition coil

(T1/1, T1/2, T1/3)· Ignition coil T1/1

· Ignition coil T1/2

· Ignition coil T1/3TM.4a

TM.4b

56,

11

· ·· ·

· Ignition

coil(T1/3)

- primary coil

voltage

(No.1 and 6

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %200 - 350 V 66,Þ 10.0· Þ 10.1

0.9 - 1.6 W

70 72

· Ignition:OFFÞ 10.1· ·· ·

· Connecting

resistance of

ignition coil

between T1/

3 and T1/2· Cable

· Ignition coil T1/3

· Ignition coil T1/2

> 10 MW

11 4 11 5· Ignition:OFF

- Disconnect the

coupling "No.2" from

ECU.Þ 13.0· ·· ·

· Knock

sensor 2

- Resistance

(cylinder

No.4, 5, 6)· Connecting

condition

· Cable

· ECU 57,

The

resistance of

ignition coil at

20°C is

approached

0.6W

Page 617 of 1463

M162 ENGINE CONTROLS 1F1-47

3. Disconnect the vacuum hose.

4. Disconnect the circlip and remove the fuel pressure

regulator.

5. Apply the oil to O-ring lightly and then replace it.

6. Installation should follow the removal procedure in the

reverse order.

7. Check for fuel pressure and internal leaks by operating the

engine. 2. Discharge the pressure in fuel supply system by pressing

the service valve.

Removal & Installation Procedure

1. Remove the fuel pressure test connector.

Page 625 of 1463

M162 ENGINE CONTROLS 1F1-55

Removal & Installation Procedure

1. Remove the O-ring.

Check for damage and replace it if necessary.

2. Remove the injector bracket from the injector.

Installation Notice

Exactly seat the anti-twist lock into the square groove in

injector.

3. Separate the injector from the fuel distributor.

Inspection & Maintenance

Inspection of the Injector operation and spray pattern

1. Connect the contact box to the ECU.

2. Connect the shop made test plug to the injector and place

it into the tank.

3. Position the ignition switch to ON.

4. Connect the pin 63(+) and 69(-) of the contact box with a

test cable.

5. Check the injector spray pattern.

Notice

Replace the injector if the injector spray pattern is abnormal

or the fuel doesn't inject.

Injector Resistance Inspection

1. Remove the injector connector.

2. Measure the injector coil resistance using a resistance

tester.

Notice

Replace the injector if the measured values is out of the

specified values. Check the connector and wire connection

between the ECU and the injector if the measured values

are normal.

Specified Value

14 - 17 W

Page 669 of 1463

1F2-20 M161 ENGINE CONTROLS

Failure

codeItem

Þ 1.0

Checking method

· Ignition:ON

Test

stepRequirementSpecified

valuePossible cause

10 1211 - 14V

· ·· ·

· ECU:power

supply

- terminal 30

(TM.30)

Þ 2.2· ·· ·

· Power

supply:

- terminal 87

(TM.87)· Ignition:ON· Power supply cable

· OVPR

IGNITION SYSTEM TEST

08,· Þ 1.1

· Þ 1.2

Þ 1.1

· Ignition:ON

10 211 - 14V· ·· ·

· Ground

cable:

- Battery

ground· Ground cable

· Ground condition

(figure 1)Diagnosis

socket

69 2

Diagnosis

socket

Þ 1.2· Ignition:ON

11211 - 14V· ·· ·

· Power

supply:

- terminal 30

(TM.30)· Power supply cable

Diagnosis

socket

Þ 2.0· Ignition:ON

51111 -14V· ·· ·

· ECU:power

supply

- terminal 87

(TM.87)08,· Þ 2.1

· Þ 2.2

Þ 2.1

· Ignition:ON 11 - 14V· ·· ·

· Ground

cable

- Electronic

ground· Ground cable

52

Diagnosis

socket

111

Diagnosis

socket

· Ignition:OFF

11 - 14V

< 1V

Þ 3.0· Ignition:ON

69 7211 - 14 V· ·· ·

· Ignition

coil(T1/1)

- No.1,4

Cylinder64,· Cable

· Ignition coil(T1/1)

· Fuse No.17

· Engine:in cranking > 10 V