check engine SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 534 of 1463

OM600 ENGINE COOLING 1D3-13

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermoswich connector from radiator.

3. Remove the each coolant hose.

4. Remove the auto T/M oil cooling hose and cooling line.

Installation Notice

5. Loosen the radiator upper mounting bolt and remove the

mounting stopper and insulator.

6. Remove the radiator.

7. Check the radiator pin for crack, leakage and bending and

replace it if necessany.

8. Installation should follow the removal procedure in the

reverse order.

Tightening TorqueHose : 29 - 40Nm

Page 536 of 1463

OM600 ENGINE COOLING 1D3-15

Removal & Installation Procedure

Cooling Fan Shroud

1. Remove the radiator deaeration hose and tube.

Installation Notice

Tightening Torque 3 - 7 Nm

Tightening torque 3-7Nm

2. Check the shroud.

3. Installation should follow the removal procedure in the

reverse order.

Coolant Sub-Tank

1. Drain the coolant from radiator.

2. Remove the each hose.

3. Loosen the mounting bolt of sub-tank and remove the

coolant sub-tank.

Installation Notice

4. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 3 - 7 Nm

Page 549 of 1463

M162 ENGINE ELECTRICAL 1E1-11

Circuit Diagram

Inspection & Maintenance Procedure (for MSE)

1. While the ignition switch is in 'OFF' position, remove the

wiring connectors (1 and 15) from ignition coil and measure

the primary resistance between terminal No.1 and No.15.

2. During engine cranking, measure primary voltage (T1/1)

between ECU terminal No. 71 and No. 69. Notice

If out of specified value, replace the ignition coil.

Specified Value 0.9 - 1.6 W (20°C)

Specified Value 200 - 350 V

Notice

lMeasure remaining cables.

- T1/2 : No. 72 and 69.

- T1/3 : No. 70 and 69.

lIf out of specified value, check ignition cable and ECU.

3. Using a multi-tester, measure the secondary coil resistance

between 5a and 5b.

Specified Value 6 - 8.5 kW

Page 550 of 1463

1E1-12 M162 ENGINE ELECTRICAL

UNIT REPAIR

BATTERY

Inspection

Notice

lWhen charging the battery, do not leave the inflammable

objects around it.

lWhen checking the electrolyte of battery, put on

an eye protector and gloves.

1. Inspect the surface of the battery and replace if any defects

were found on it.

2. Check if the specific gravity of the electrolyte is within the

specified value.

Notice

lReplace the battery if the maximum tolerance of the

electrolyte between cells is out of the specified value.

lMeasure the specific gravity in the approx. 20°C

of ambient temperature.

3. Replenish the electrolyte if necessary.Battery capacity(Ah)

Battery specific gravity

Max. tolerance between cells85

³ 1.24

³ 0.04

Page 561 of 1463

M161 ENGINE ELECTRICAL 1E2-11

Inspection & Maintenance (for E2.3 MSE)

1. Measure the primary resistance between the cable terminals

1 and 15 after removing the ignition cable wiring connector

(1 and 15) with ignition switch OFF.

Notice

Replace the ignition coil if out of the specified resistance.

lT1/2 : between No.71 and No.69

Notice

Check the ignition cable and the ECU if out of the

specified value.

3. Measure the secondary cable resistance between the

ignition coil 5a and 5b using a multimeter. 2. Measure the primary voltage(T1/1) between the ECU

terminals No.72 and No.69 during the engine cranking

(starter motor activated).

Specified Value 6 - 8.5 KW

Specified Value 0.9 - 1.6 W

Specified Value 200 - 350 V

Page 562 of 1463

1E2-12 M161 ENGINE ELECTRICAL

UNIT REPAIR

BATTERY

Inspection

Notice

lWhen charging the battery, do not leave the inflammable

objects around it.

lWhen checking the electrolyte of battery, put on

an eye protector and gloves.

1. Inspect the surface of the battery and replace if any defects

were found on it.

2. Check if the specific gravity of the electrolyte is within the

specified value.

Notice

lReplace the battery if the maximum tolerance of the

electrolyte between cells is out of the specified value.

lMeasure the specific gravity in the approx. 20°C

of ambient temperature.

3. Replenish the electrolyte if necessary.Battery Capacity(Ah)

Battery Specific Gravity

Max. Tolerance between Cells75

³ 1.24

³ 0.04

Page 578 of 1463

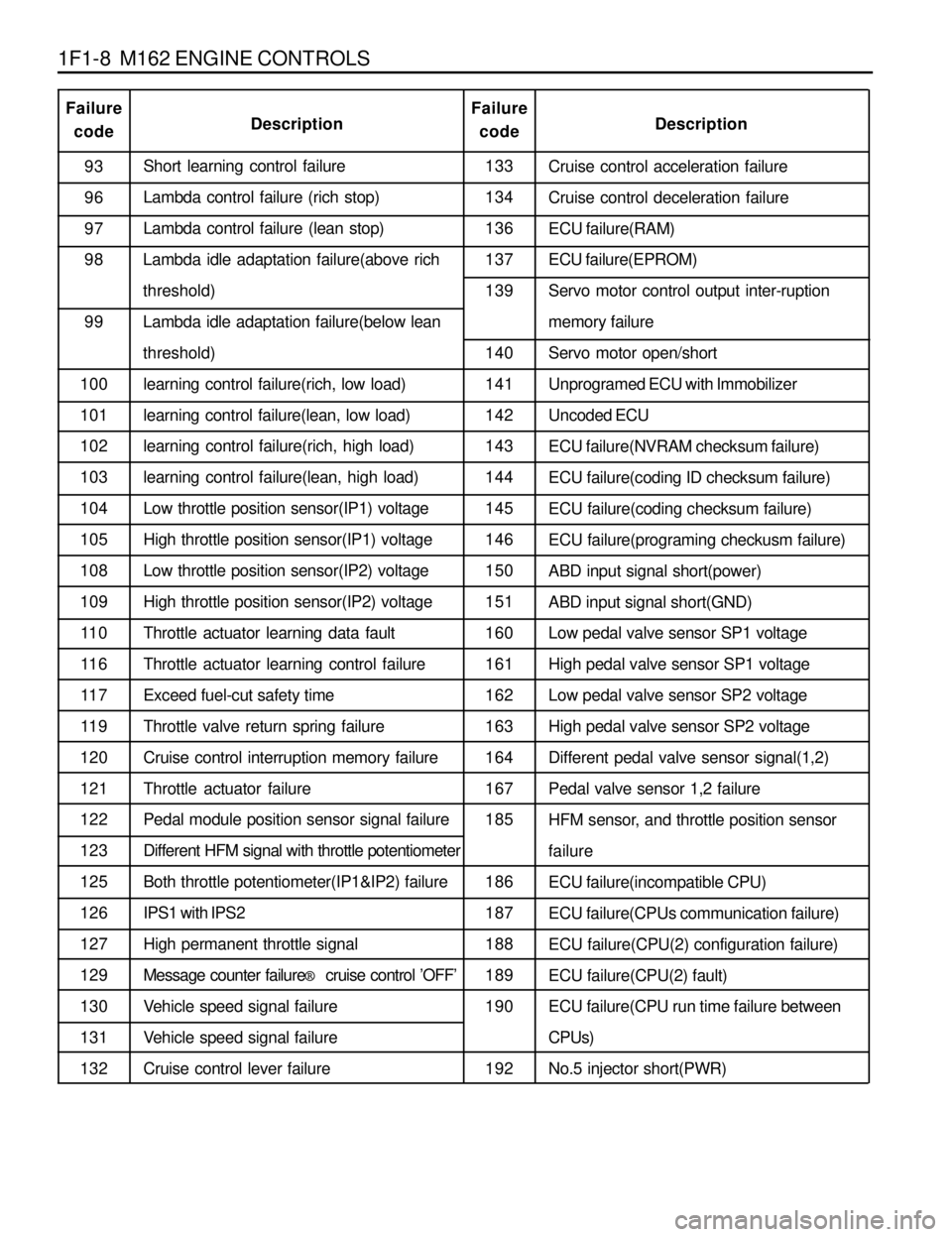

1F1-8 M162 ENGINE CONTROLS

Cruise control acceleration failure

Cruise control deceleration failure

ECU failure(RAM)

ECU failure(EPROM)

Servo motor control output inter-ruption

memory failure

Servo motor open/short

Unprogramed ECU with Immobilizer

Uncoded ECU

ECU failure(NVRAM checksum failure)

ECU failure(coding ID checksum failure)

ECU failure(coding checksum failure)

ECU failure(programing checkusm failure)

ABD input signal short(power)

ABD input signal short(GND)

Low pedal valve sensor SP1 voltage

High pedal valve sensor SP1 voltage

Low pedal valve sensor SP2 voltage

High pedal valve sensor SP2 voltage

Different pedal valve sensor signal(1,2)

Pedal valve sensor 1,2 failure

HFM sensor, and throttle position sensor

failure

ECU failure(incompatible CPU)

ECU failure(CPUs communication failure)

ECU failure(CPU(2) configuration failure)

ECU failure(CPU(2) fault)

ECU failure(CPU run time failure between

CPUs)

No.5 injector short(PWR) 93

96

97

98

99

100

101

102

103

104

105

108

109

11 0

11 6

11 7

11 9

120

121

122

123

125

126

127

129

130

131

132Short learning control failure

Lambda control failure (rich stop)

Lambda control failure (lean stop)

Lambda idle adaptation failure(above rich

threshold)

Lambda idle adaptation failure(below lean

threshold)

learning control failure(rich, low load)

learning control failure(lean, low load)

learning control failure(rich, high load)

learning control failure(lean, high load)

Low throttle position sensor(IP1) voltage

High throttle position sensor(IP1) voltage

Low throttle position sensor(IP2) voltage

High throttle position sensor(IP2) voltage

Throttle actuator learning data fault

Throttle actuator learning control failure

Exceed fuel-cut safety time

Throttle valve return spring failure

Cruise control interruption memory failure

Throttle actuator failure

Pedal module position sensor signal failure

Different HFM signal with throttle potentiometer

Both throttle potentiometer(IP1&IP2) failure

IPS1 with IPS2

High permanent throttle signal

Message counter failure® cruise control ’OFF’

Vehicle speed signal failure

Vehicle speed signal failure

Cruise control lever failure133

134

136

137

139

140

141

142

143

144

145

146

150

151

160

161

162

163

164

167

185

186

187

188

189

190

192

Failure

codeDescriptionFailure

codeDescription

Page 581 of 1463

M162 ENGINE CONTROLS 1F1-11

FUEL INJECTION SYSTEM TEST (MSE3.62)

Failure

codeItem

Þ 1.0

Checking method

· Ignition:ON

Test

stepRequirementSpecified

valuePossible cause

10 1211 -14V

· ·· ·

· ECU:power

supply

- terminal

30(TM.30)

Þ 2.2· ·· ·

· Power

supply:

- terminal

87(TM.87)· Ignition:ON· Power supply cable

· OVPR 08,

·Þ 1.1

·Þ 1.2

Þ 1.1

· Ignition:ON

10 211 -14V· ·· ·

· Ground

cable:

- Battery

ground· Ground cable

· Ground conditionDiagnosis

socket

69 2

Diagnosis

socket

Þ 1.2· Ignition:ON

11211 -14V· ·· ·

· Power

supply:

- terminal

30(TM.30)· Power supply cable

Diagnosis

socket

Þ 2.0· Ignition:ON

51111 -14V· ·· ·

· ECU:power

supply

- terminal

87(TM.87)08,·Þ 1.1

·Þ 2.1

Þ 2.1

· Ignition:ON 11 -14V· ·· ·

· Ground

cable

- Electronic

ground· Ground cable

52

Diagnosis

socket

111

Diagnosis

socket· Ignition:OFF

11 -14V

< 1V

Þ 3.0

· Engine:in Cranking

52· Cable

· Ignition switch 11 -14

(during engine

cranking)

· ·· ·

· Start signal:

- terminal

50(TM.50)

Page 582 of 1463

1F1-12 M162 ENGINE CONTROLS

Failure

codeItem

09,

10,

11,

Checking method Te s t

stepRequirementSpecified

valuePossible cause

Þ 4.0· ·· ·

· HFM sensor

signal

105 81· Ignition:ON0.9 - 1.1V· Þ 4.1 - 4.3

· Cable

· External air inflow

· HFM sensor

· Engine:in Idle

(Coolant temperature

: > 70°C )

: voltage value is

increased when

engine rpm is

increased1.3 - 1.7V

Þ 4.1

105 4

· Ignition:ON

· HFM sensor

connector removed4.7 - 5.2V

· Cable

· ECU coupling

· ·· ·

· HFM sensor:

- 5V power

supplyHFM

sensor

Þ 4.2

3 108· Ignition:ON

· HFM sensor

connector removed4.7 - 5.2V

· Þ 4.3

· Cable

· ·· ·

· HFM sensor:

- 5V power

supplyHFM

sensor

Þ 4.3

104 2· Ignition:ON

· HFM sensor

connector removed11 - 14V

· Cable

· OVPR

· ·· ·

· HFM sensor:

- 12V power

supplyHFM

sensor

03,

04,

05,Þ 5.0· ·· ·

· Intake air

temperature

sensor:

- Voltage105 80· Ignition:ON· Þ 5.1

· ECU

± 5%

Þ 5.1· Ignition:OFF

· No.2 ECU coupling

removed 105 80

· Cable

· HFM sensor

· ·· ·

· Intake air

temperature

sensor:

- Resistance°C

10

20

30

40

50

60

± 5%W

3600

2420

1662

1166

853

600 °C

10

20

30

40

50

60V

3.1

2.65

2.18

1.76

1.4

1.1

Page 583 of 1463

M162 ENGINE CONTROLS 1F1-13

Failure

codeItemChecking method Te s t

stepRequirement

Specified

valuePossible cause

Þ 6.1· Ignition:ON0.1 - 0.3A· Cable

· Fuel pump relay

· ECU

· ·· ·

· Fuel pump

relay:

- Current

consumption

00,

01,

02,

06,Þ 7.0· ·· ·

· Coolant

temperature

sensor:

- Voltage79 78· Ignition:ON°CV

20 3.57

80 1.22

100 0.78· Þ 7.1

· ECU

±5% Þ 6.0

· Ignition:ON

(Fuel pump relay will

operate for 1 - 2

seconds when the

ignition switch is

turned to "ON" after

stopping the engine)

· Engine:cranking 33 11

· Cable

· Fuel pump relay

· ·· ·

· Fuel pump

relay:

- Operation34,11 - 14V

(approx.1-

2sec.)

11 - 14V

(Cranking or

driving)

533

Þ 7.1· Ignition:OFF

(Remove the No.2

coupling from ECU) 79 78· Þ 7.2

· Cable

· ·· ·

· Coolant

temperature

sensor:

- Resistance

& cable°CW

20 2500

80 322

100 185

±5%

Þ 7.2· ·· ·

· Coolant

temperature

sensor:

- ResistanceCoolant temperature

sensor:

14

· Remove the

connector from

coolant temperature

sensor and measure

the resistance

between No.1 and

No.2 pin with

multimeter.· Þ refer to

specified

resistance

value of 7.1· Coolant

temperature

sensor 34,

35,