tire type SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 15 of 1463

GENERAL INFORMATION 0B-3

662LA

MB

W4A040

3.871

2.247

1.436

1.000

5.586

5.38

9 - 9.5

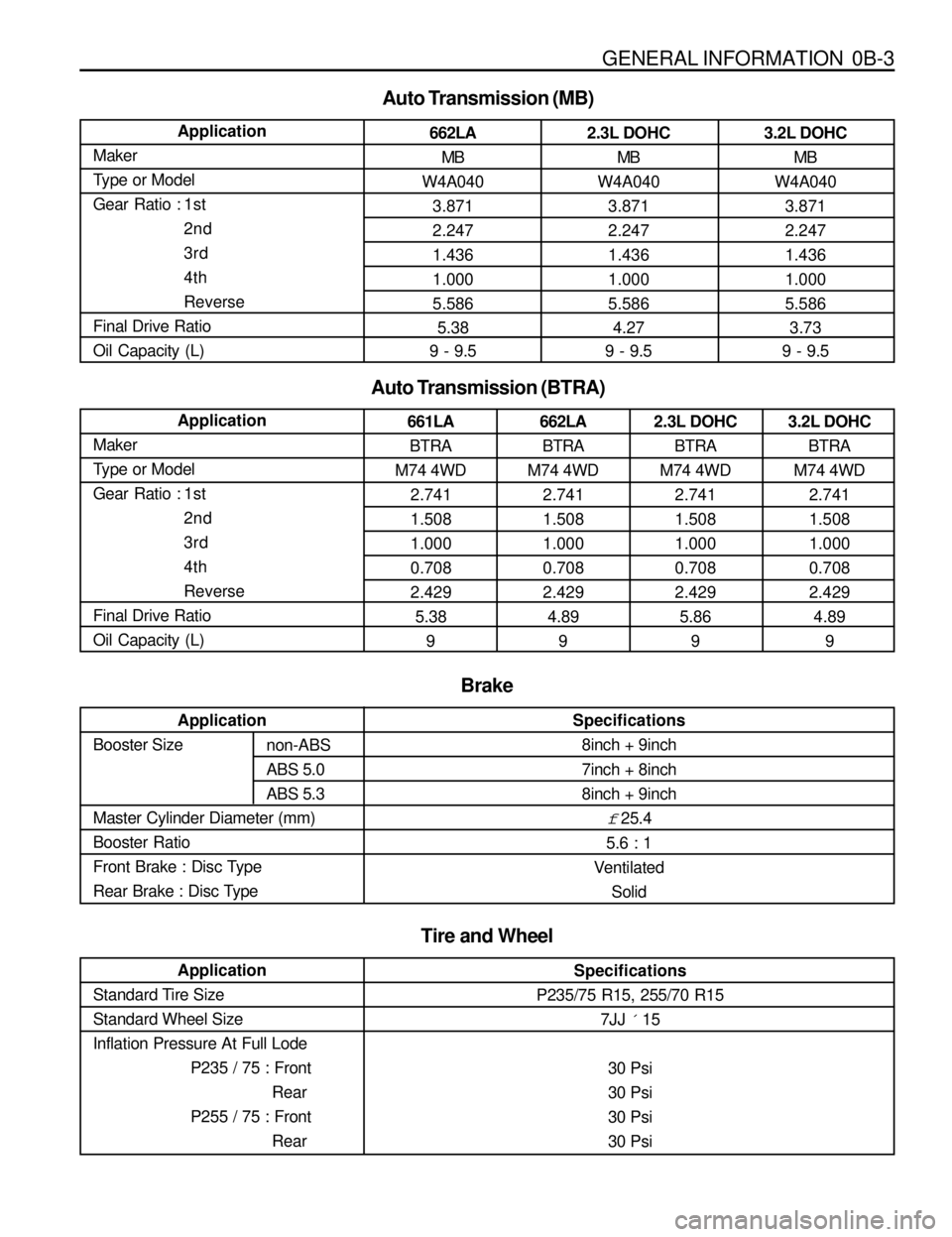

Auto Transmission (MB)

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

Reverse

Final Drive Ratio

Oil Capacity (L)2.3L DOHC

MB

W4A040

3.871

2.247

1.436

1.000

5.586

4.27

9 - 9.53.2L DOHC

MB

W4A040

3.871

2.247

1.436

1.000

5.586

3.73

9 - 9.5

661LA

BTRA

M74 4WD

2.741

1.508

1.000

0.708

2.429

5.38

9

Auto Transmission (BTRA)

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

Reverse

Final Drive Ratio

Oil Capacity (L)662LA

BTRA

M74 4WD

2.741

1.508

1.000

0.708

2.429

4.89

92.3L DOHC

BTRA

M74 4WD

2.741

1.508

1.000

0.708

2.429

5.86

93.2L DOHC

BTRA

M74 4WD

2.741

1.508

1.000

0.708

2.429

4.89

9

Tire and Wheel

Specifications

P235/75 R15, 255/70 R15

7JJ ´ 15

30 Psi

30 Psi

30 Psi

30 Psi Application

Standard Tire Size

Standard Wheel Size

Inflation Pressure At Full Lode

P235 / 75 : Front

Rear

P255 / 75 : Front

Rear Application

Booster Size

Master Cylinder Diameter (mm)

Booster Ratio

Front Brake : Disc Type

Rear Brake : Disc Type

Specifications

8inch + 9inch

7inch + 8inch

8inch + 9inch

f 25.4

5.6 : 1

Ventilated

Solid

Brake

non-ABS

ABS 5.0

ABS 5.3

Page 19 of 1463

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

Fuel Filter Replacement

Replace the engine fuel filter every.

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 45,000km (24,000 miles)

Spark Plug Replacement

Replace spark plugs with same type.

lType : BOSCH : F8DC4

BERU : 14F-8DU4

Champion : C11YCC

lGap : 0.8 ± 0.1 mm

Spark Plug Wire Replacement

Clean wires and inspect them for burns, cracks or other

damage. Check the wire boot fit at the Distributor and at

the spark plugs. Replace the wires as needed.

Brake System Service

Check the disc brake pads or the drum brake linings.

Check the pad and the lining thickness carefully.

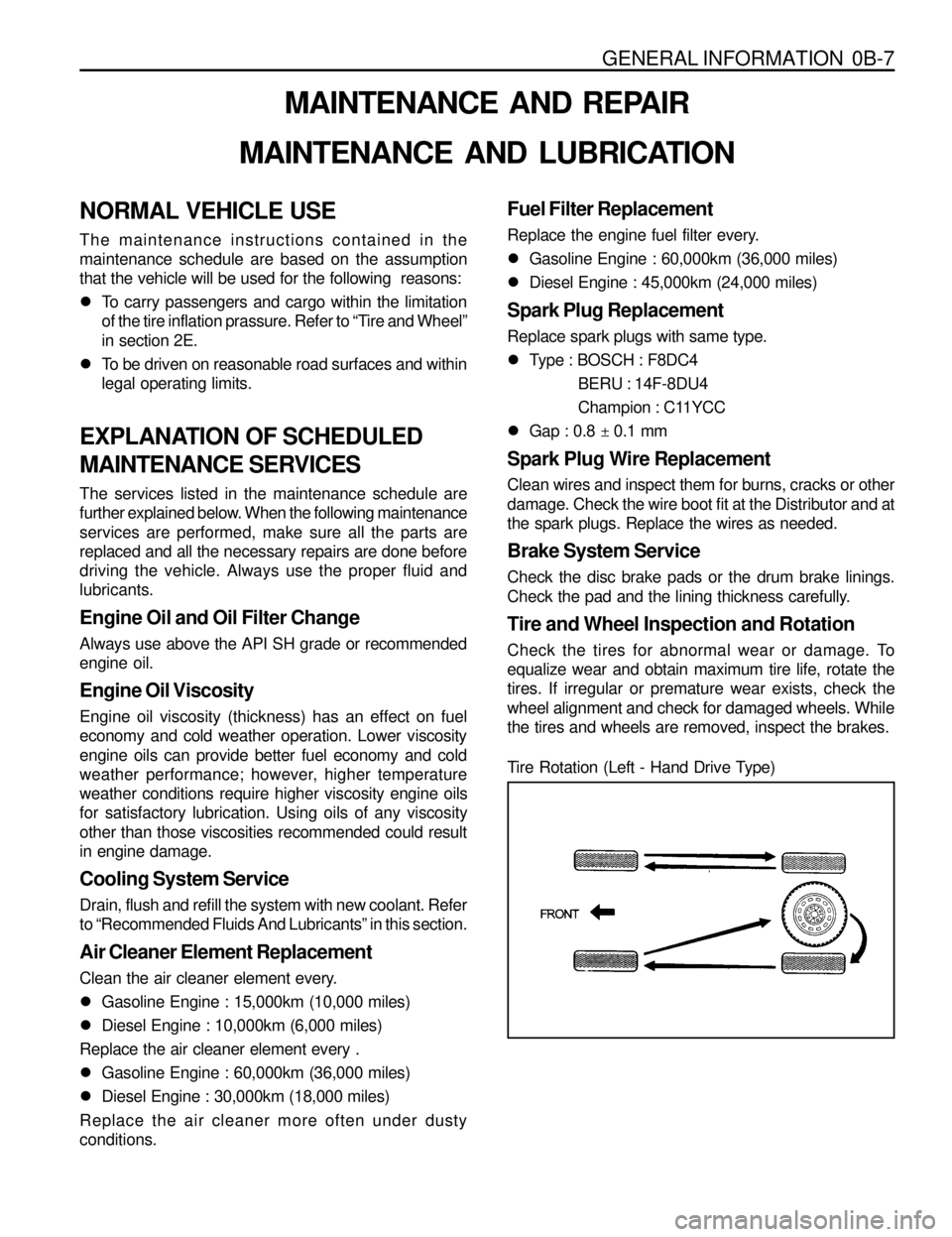

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To

equalize wear and obtain maximum tire life, rotate the

tires. If irregular or premature wear exists, check the

wheel alignment and check for damaged wheels. While

the tires and wheels are removed, inspect the brakes.

NORMAL VEHICLE USE

The maintenance instructions contained in the

maintenance schedule are based on the assumption

that the vehicle will be used for the following reasons:

lTo carry passengers and cargo within the limitation

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E.

lTo be driven on reasonable road surfaces and within

legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are

further explained below. When the following maintenance

services are performed, make sure all the parts are

replaced and all the necessary repairs are done before

driving the vehicle. Always use the proper fluid and

lubricants.

Engine Oil and Oil Filter Change

Always use above the API SH grade or recommended

engine oil.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel

economy and cold weather operation. Lower viscosity

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

lGasoline Engine : 15,000km (10,000 miles)

lDiesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions.

Tire Rotation (Left - Hand Drive Type)

Page 862 of 1463

Description

Alumimun

7JJ X 15

Radial Tire

P215 / 75R 15 - 30psi

P235 / 75R 15 - 30psi

P255 / 70R 15 - 30psi Application

Wheel

SECTION 2E

TIRES AND WHEELS

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Wheel BoltNlm

80 - 120

110 - 130

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2E-1

General Specifications . . . . . . . . . . . . . . . . . . 2E-1

Fastener Tightening Specifications . . . . . . . . . 2E-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 2E-2

Wear Pattern Diagnosis . . . . . . . . . . . . . . . . . 2E-2

Identification . . . . . . . . . . . . . . . . . . . . . . . . . 2E-3

Radial Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . 2E-3Wheel Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . 2E-3

Component Locator . . . . . . . . . . . . . . . . . . . 2E-4

Wheel and Tire . . . . . . . . . . . . . . . . . . . . . . . . 2E-4

Maintenance and Repair . . . . . . . . . . . . . . . 2E-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 2E-5

Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . 2E-5

Material

Size

Tire

Type

Size and Tire Pressure

Steel

Alumimum

Page 1226 of 1463

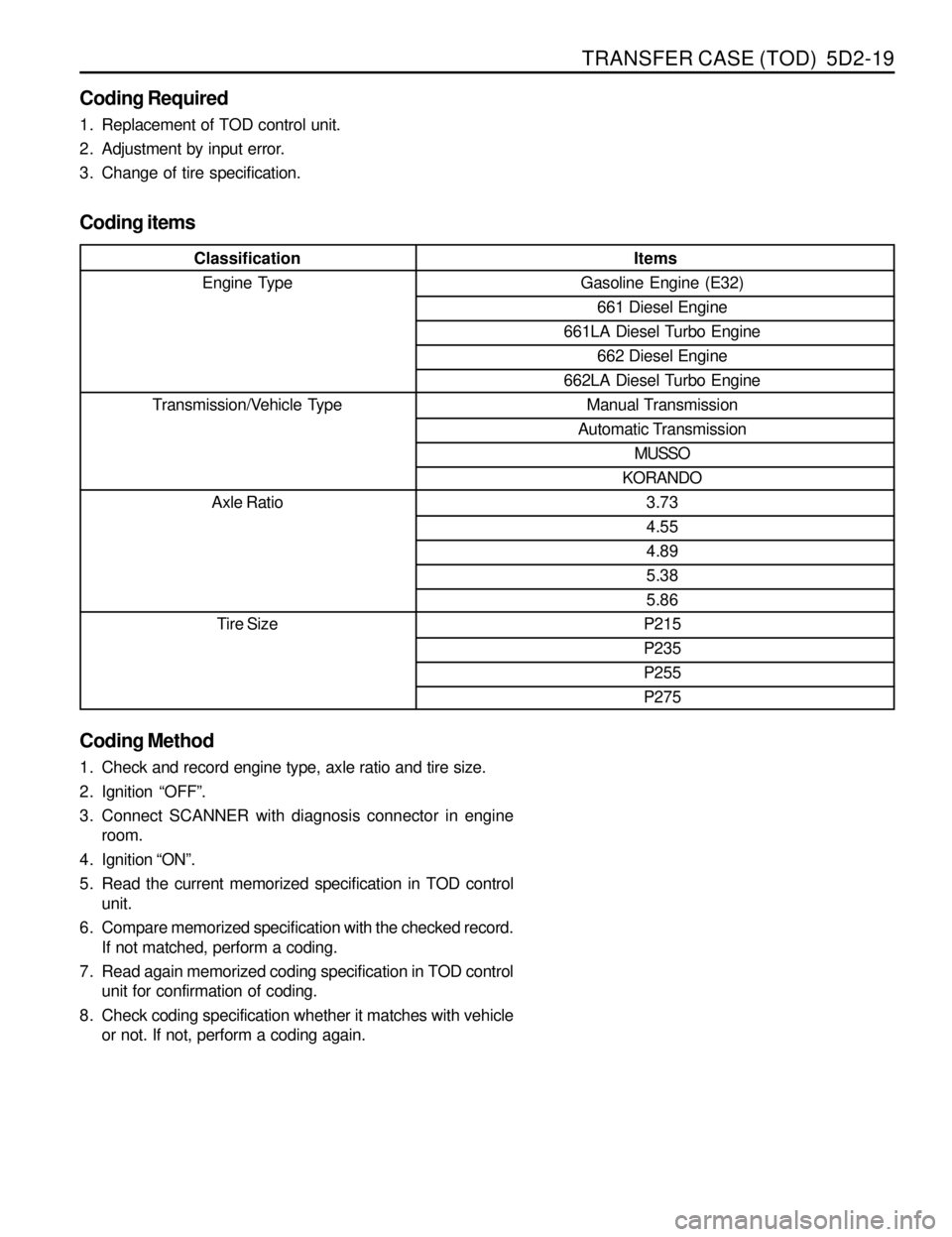

TRANSFER CASE (TOD) 5D2-19

Classification

Engine Type

Transmission/Vehicle Type

Axle Ratio

Tire Size

Coding Required

1. Replacement of TOD control unit.

2. Adjustment by input error.

3. Change of tire specification.

Items

Gasoline Engine (E32)

661 Diesel Engine

661LA Diesel Turbo Engine

662 Diesel Engine

662LA Diesel Turbo Engine

Manual Transmission

Automatic Transmission

MUSSO

KORANDO

3.73

4.55

4.89

5.38

5.86

P215

P235

P255

P275

Coding Method

1. Check and record engine type, axle ratio and tire size.

2. Ignition “OFF”.

3. Connect SCANNER with diagnosis connector in engine

room.

4. Ignition “ON”.

5. Read the current memorized specification in TOD control

unit.

6. Compare memorized specification with the checked record.

If not matched, perform a coding.

7. Read again memorized coding specification in TOD control

unit for confirmation of coding.

8. Check coding specification whether it matches with vehicle

or not. If not, perform a coding again.

Coding items