height SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 302 of 1463

M161 ENGINE MECHANICAL 1B2-113

Measurement of Mating Surface

1. Measure the height (H) of the cylinder head (refer to Service

data standard

).

2. Check the mating surface of the cylinder head.

3. Mill the sharp edge of the combustion chamber.

4. Re-measure the height (H) of the cylinder head.

5. Seal the intake and exhaust valves.

6. Measure the dimension (T) between the camshaft bearing

and the valve system (refer to

Service data standard).

7. Mill the cylinder head valve seat (refer to

Service data

standard

).

Universal Tool

Surface Grinding MachineSceledum, Type RTY

Roaro

Schio/Italy

Page 306 of 1463

1B3-4 OM600 ENGINE MECHANICAL

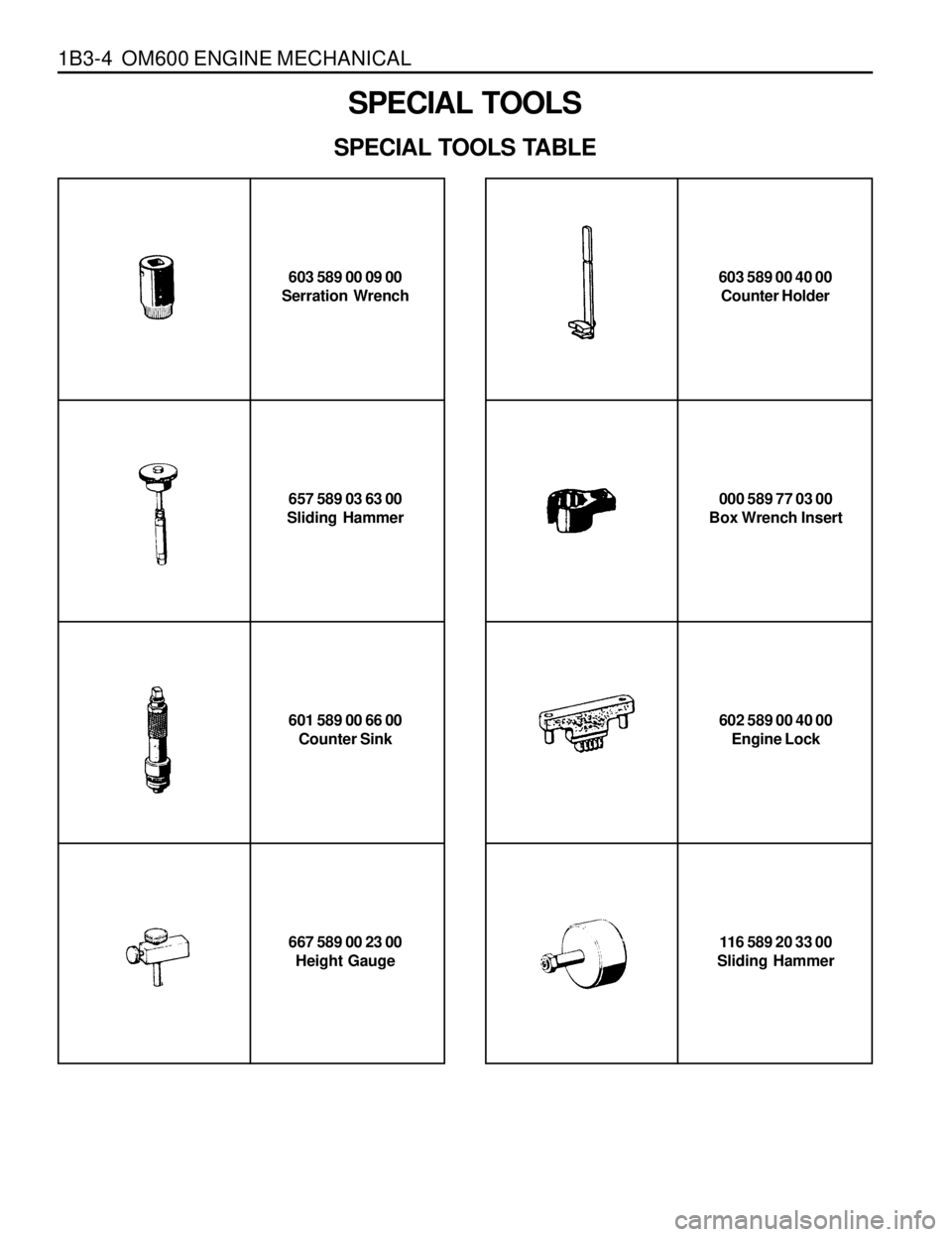

SPECIAL TOOLS

SPECIAL TOOLS TABLE

603 589 00 09 00

Serration Wrench

657 589 03 63 00

Sliding Hammer000 589 77 03 00

Box Wrench Insert

601 589 00 66 00

Counter Sink

667 589 00 23 00

Height Gauge602 589 00 40 00

Engine Lock

116 589 20 33 00

Sliding Hammer603 589 00 40 00

Counter Holder

Page 334 of 1463

1B3-32 OM600 ENGINE MECHANICAL

MILLING OF PRECHAMBER SEALING SURFACE

1 Drift

2 Sleeve

3 Milling Cutter4 Counter Sink (Special Tool - 601 589 00 66)

5 Cylinder Head

Tightening Torque 0.3, 0.6, 1.0 mm

Milling of the Prechamber Sealing Surface

Notice

The prechamber sealing surface may only be remachined

once with the cylinder head fitted. It is essential to adhere

to the specified projection ‘C’ of the prechamber of 7.6 -

8.1mm.

This ensures that the required clearance exists between

prechamber and piston crown with the piston in TDC. For

this reason, spacer rings should be inserted on remachined

sealing surfaces.

If a spacer ring is already fitted, or a marking is made on the

cylinder head, the cylinder head must be removed and size

‘C’ measured if further remachining is necessary on a

prechamber sealing surface. Tools Required

601 589 00 66 00 Counter Sink

667 589 00 23 00 Height Gauge

Page 335 of 1463

OM600 ENGINE MECHANICAL 1B3-33

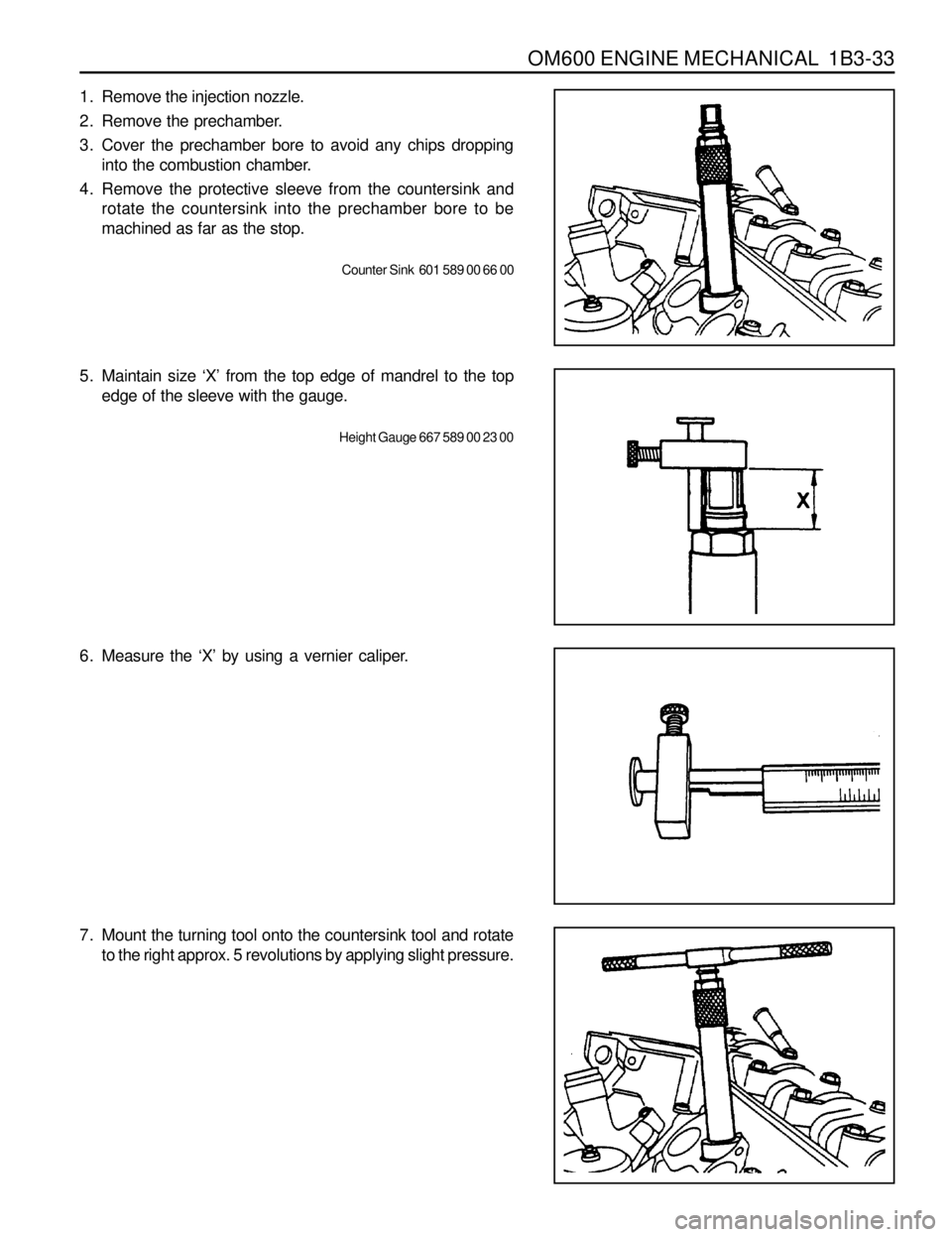

6. Measure the ‘X’ by using a vernier caliper.

7. Mount the turning tool onto the countersink tool and rotate

to the right approx. 5 revolutions by applying slight pressure.

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips dropping

into the combustion chamber.

4. Remove the protective sleeve from the countersink and

rotate the countersink into the prechamber bore to be

machined as far as the stop.

Counter Sink 601 589 00 66 00

5. Maintain size ‘X’ from the top edge of mandrel to the top

edge of the sleeve with the gauge.

Height Gauge 667 589 00 23 00

Page 424 of 1463

1B3-122 OM600 ENGINE MECHANICAL

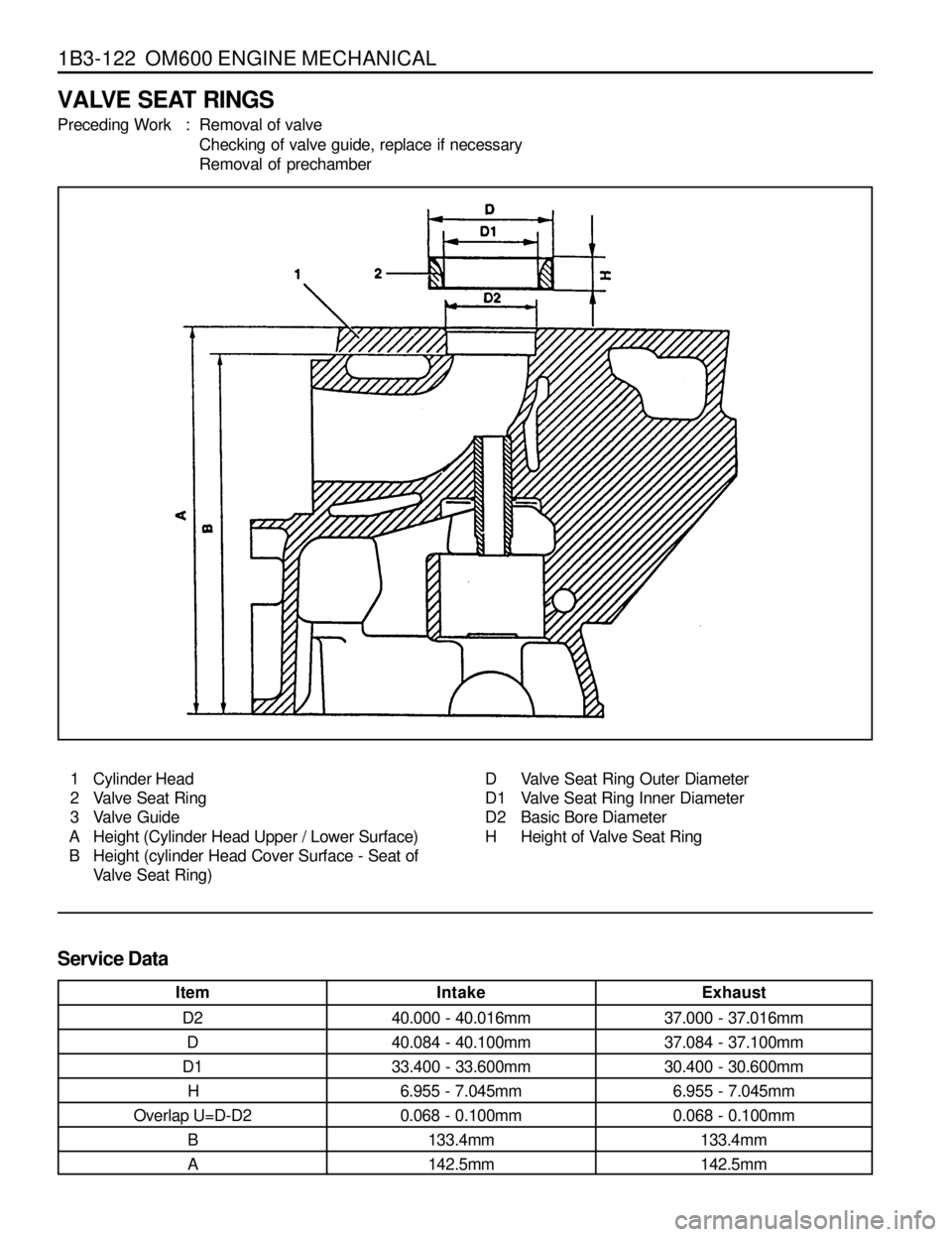

VALVE SEAT RINGS

Preceding Work : Removal of valve

Checking of valve guide, replace if necessary

Removal of prechamber

1 Cylinder Head

2 Valve Seat Ring

3 Valve Guide

A Height (Cylinder Head Upper / Lower Surface)

B Height (cylinder Head Cover Surface - Seat of

Valve Seat Ring)D Valve Seat Ring Outer Diameter

D1 Valve Seat Ring Inner Diameter

D2 Basic Bore Diameter

H Height of Valve Seat Ring

Service Data

Item

D2

D

D1

H

Overlap U=D-D2

B

AIntake

40.000 - 40.016mm

40.084 - 40.100mm

33.400 - 33.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mmExhaust

37.000 - 37.016mm

37.084 - 37.100mm

30.400 - 30.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mm

Page 430 of 1463

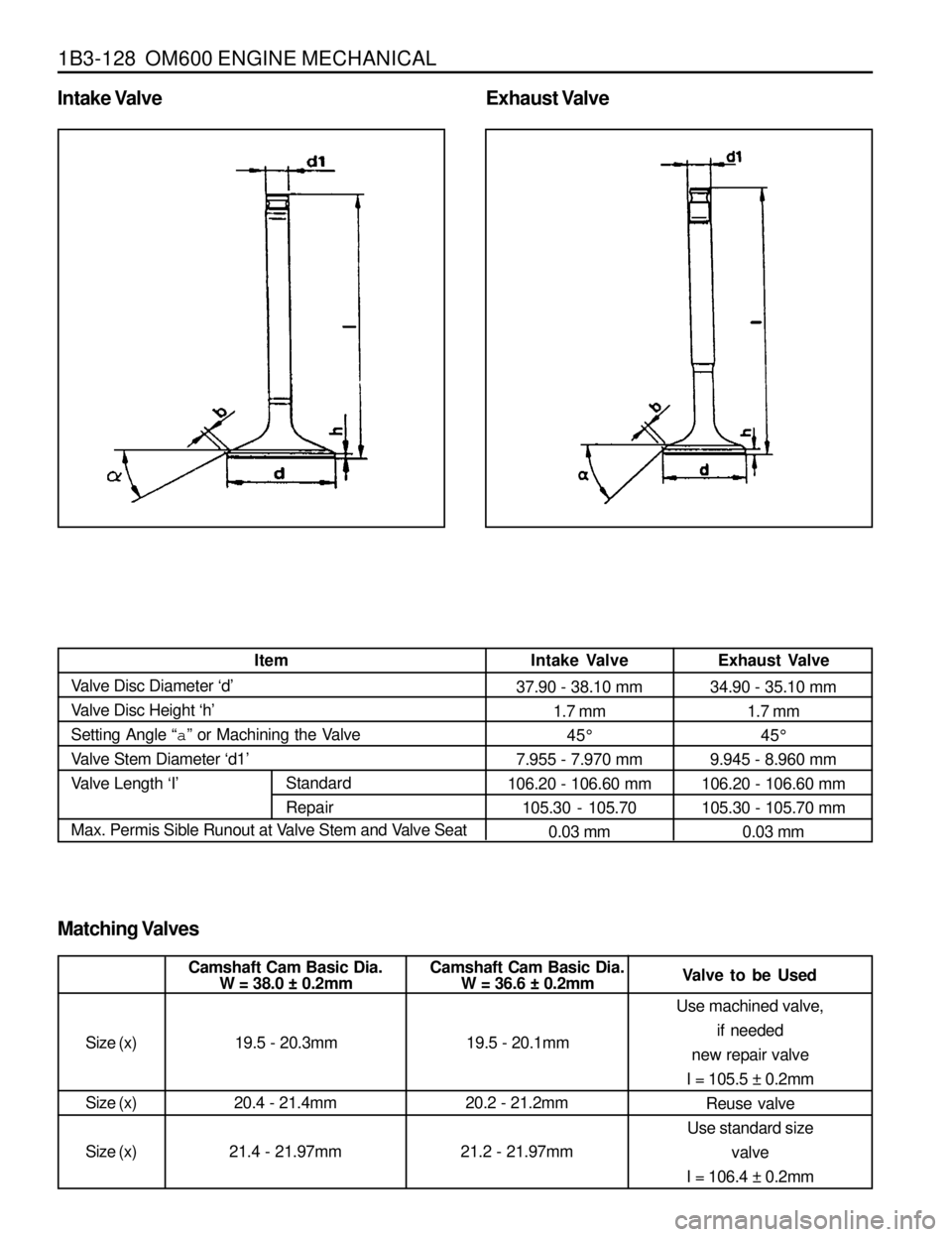

1B3-128 OM600 ENGINE MECHANICAL

Intake Valve Exhaust Valve

Item

Valve Disc Diameter ‘d’

Valve Disc Height ‘h’

Setting Angle “a” or Machining the Valve

Valve Stem Diameter ‘d1’

Valve Length ‘I’Intake Valve

37.90 - 38.10 mm

1.7 mm

45°

7.955 - 7.970 mm

106.20 - 106.60 mm

105.30 - 105.70

0.03 mmExhaust Valve

34.90 - 35.10 mm

1.7 mm

45°

9.945 - 8.960 mm

106.20 - 106.60 mm

105.30 - 105.70 mm

0.03 mm

Standard

Repair

Max. Permis Sible Runout at Valve Stem and Valve Seat

W = 38.0 ± 0.2mm

Matching Valves

Camshaft Cam Basic Dia.

Size (x)

Size (x)

Size (x)19.5 - 20.3mm

20.4 - 21.4mm

21.4 - 21.97mmW = 36.6 ± 0.2mm Camshaft Cam Basic Dia.

19.5 - 20.1mm

20.2 - 21.2mm

21.2 - 21.97mmValve to be Used

Use machined valve,

if needed

new repair valve

I = 105.5 ± 0.2mm

Reuse valve

Use standard size

valve

I = 106.4 ± 0.2mm

Page 431 of 1463

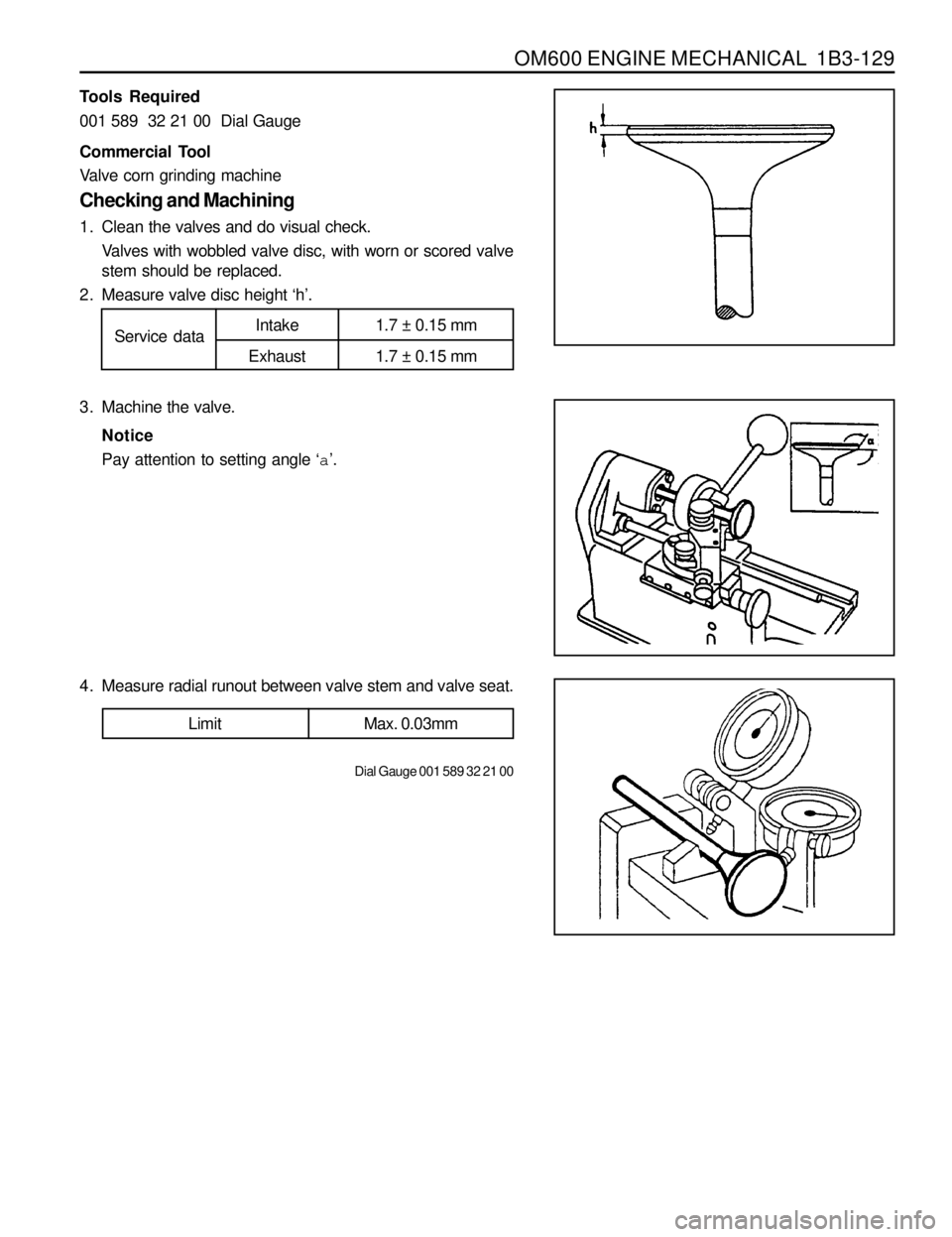

OM600 ENGINE MECHANICAL 1B3-129

Tools Required

001 589 32 21 00 Dial Gauge

Checking and Machining

1. Clean the valves and do visual check.

Valves with wobbled valve disc, with worn or scored valve

stem should be replaced.

2. Measure valve disc height ‘h’.

Service data

Intake

Exhaust1.7 ± 0.15 mm

1.7 ± 0.15 mm

3. Machine the valve.

Notice

Pay attention to setting angle ‘a’.

Commercial Tool

Valve corn grinding machine

4. Measure radial runout between valve stem and valve seat.

Limit Max. 0.03mm

Dial Gauge 001 589 32 21 00

Page 480 of 1463

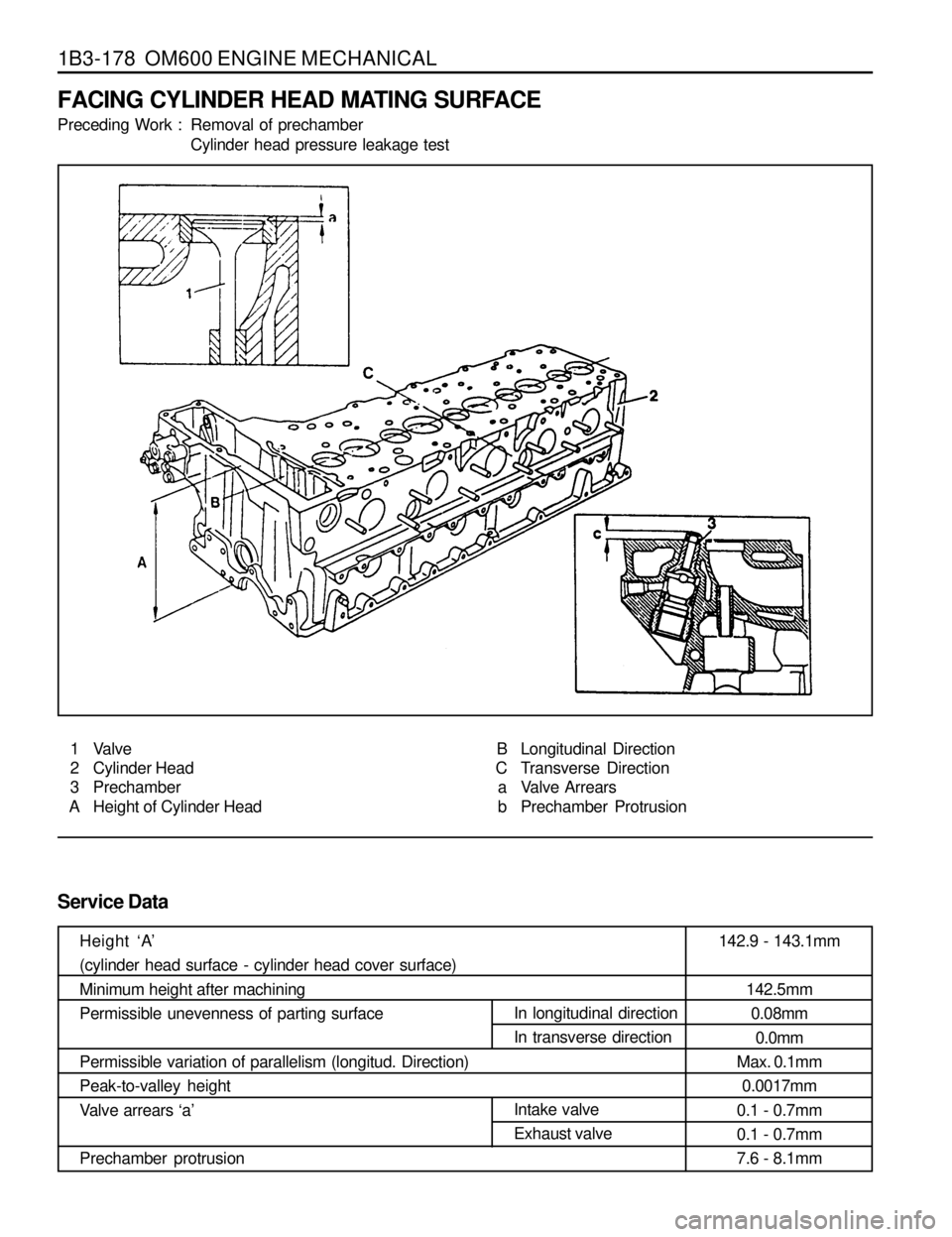

1B3-178 OM600 ENGINE MECHANICAL

Height ‘A’

(cylinder head surface - cylinder head cover surface)

Minimum height after machining

Permissible unevenness of parting surface

Permissible variation of parallelism (longitud. Direction)

Peak-to-valley height

Valve arrears ‘a’

Prechamber protrusion

Service Data

In longitudinal direction

In transverse direction

Intake valve

Exhaust valve142.9 - 143.1mm

142.5mm

0.08mm

0.0mm

Max. 0.1mm

0.0017mm

0.1 - 0.7mm

0.1 - 0.7mm

7.6 - 8.1mm

FACING CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of prechamber

Cylinder head pressure leakage test

1 Valve

2 Cylinder Head

3 Prechamber

A Height of Cylinder HeadB Longitudinal Direction

C Transverse Direction

a Valve Arrears

b Prechamber Protrusion

Page 481 of 1463

OM600 ENGINE MECHANICAL 1B3-179

Measurement Procedure

1. Measure height ‘A’.

Limit 142.5 mm

Notice

If the height is less than 142.5mm, replace the cylinder head.

2. Insert the valve (1) and measure valve arrears ‘a’.

Valve Arrears ‘a’ 0.1 - 0.7 mm

Notice

If out of standard, machine the valve seat.

3. Install the prechamber and measure protrusion ‘C’.

Protrusion ‘C’ 7.6 - 8.1mm

4. Assemble the engine and check the valve timing.

Page 484 of 1463

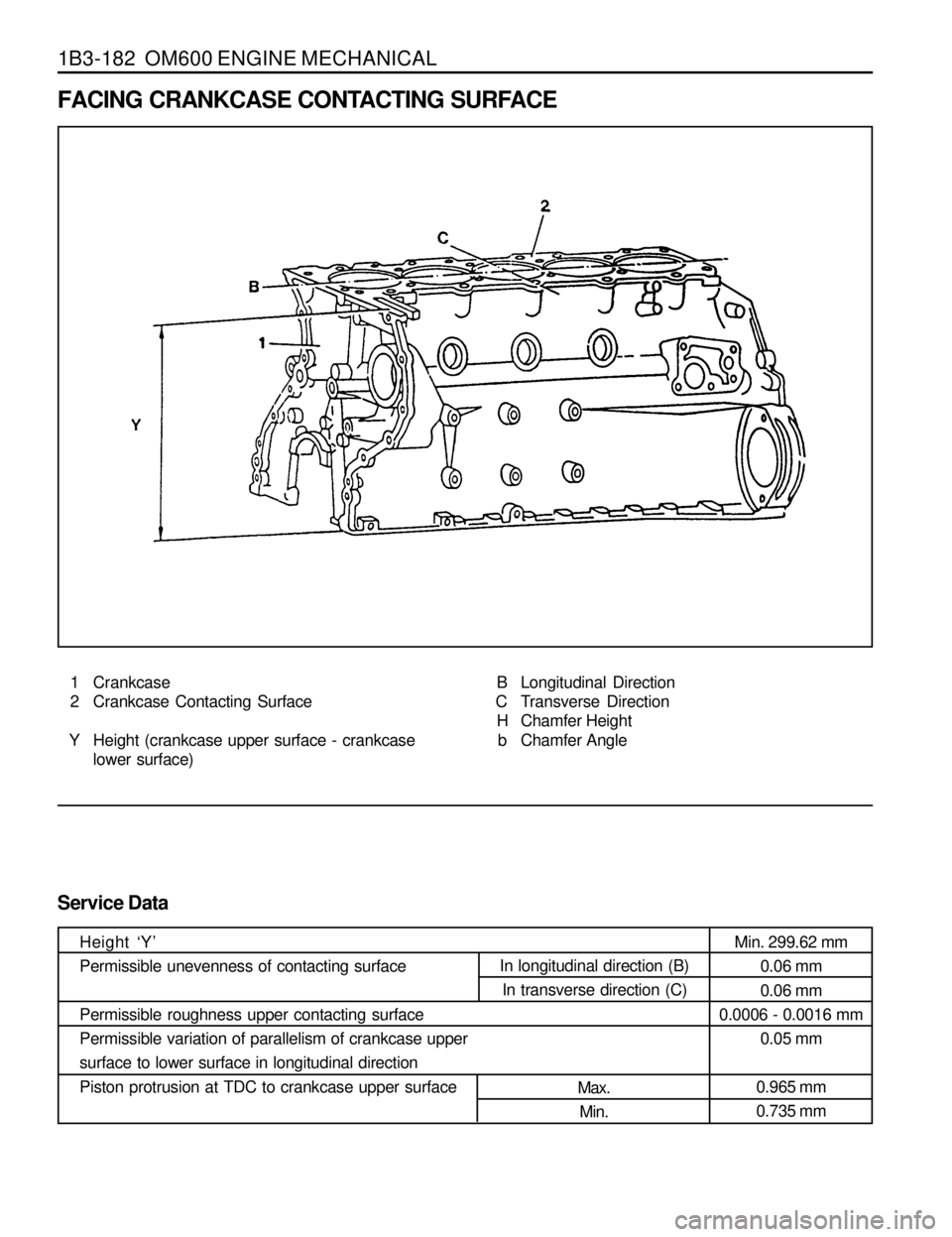

1B3-182 OM600 ENGINE MECHANICAL

Service Data

Height ‘Y’

Permissible unevenness of contacting surface

Permissible roughness upper contacting surface

Permissible variation of parallelism of crankcase upper

surface to lower surface in longitudinal direction

Piston protrusion at TDC to crankcase upper surface

In longitudinal direction (B)

In transverse direction (C)Min. 299.62 mm

0.06 mm

0.06 mm

0.0006 - 0.0016 mm

0.05 mm

0.965 mm

0.735 mm

Max.

Min.

FACING CRANKCASE CONTACTING SURFACE

1 Crankcase

2 Crankcase Contacting Surface

Y Height (crankcase upper surface - crankcase

lower surface)B Longitudinal Direction

C Transverse Direction

H Chamfer Height

b Chamfer Angle