SSANGYONG MUSSO 1998 Workshop Owner's Guide

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owner's Guide

Page 933 of 1463

4B-4 MASTER CYLINDER

6. Loosen the nut of booster and remove the booster from the

dash panel.

Installation Notice

Tightening Torque 8 - 18 Nm

7. Installation should follow the removal procedure in the

reverse order.

8. Add the fluid and bleed.

9. If necessary, adjust the pedal height, pedal stroke and free

play.

Page 937 of 1463

4C-4 POWER BOOSTER

6. Loosen the nut of booster and remove the booster from the

dash panel.

Installation Notice

Tightening Torque 8 - 18 Nm

7. Installation should follow the removal procedure in the

reverse order.

8. Add the fluid and bleed.

9. If necessary, adjust the pedal height, pedal stroke and free

play.

Page 938 of 1463

POWER BOOSTER 4C-5

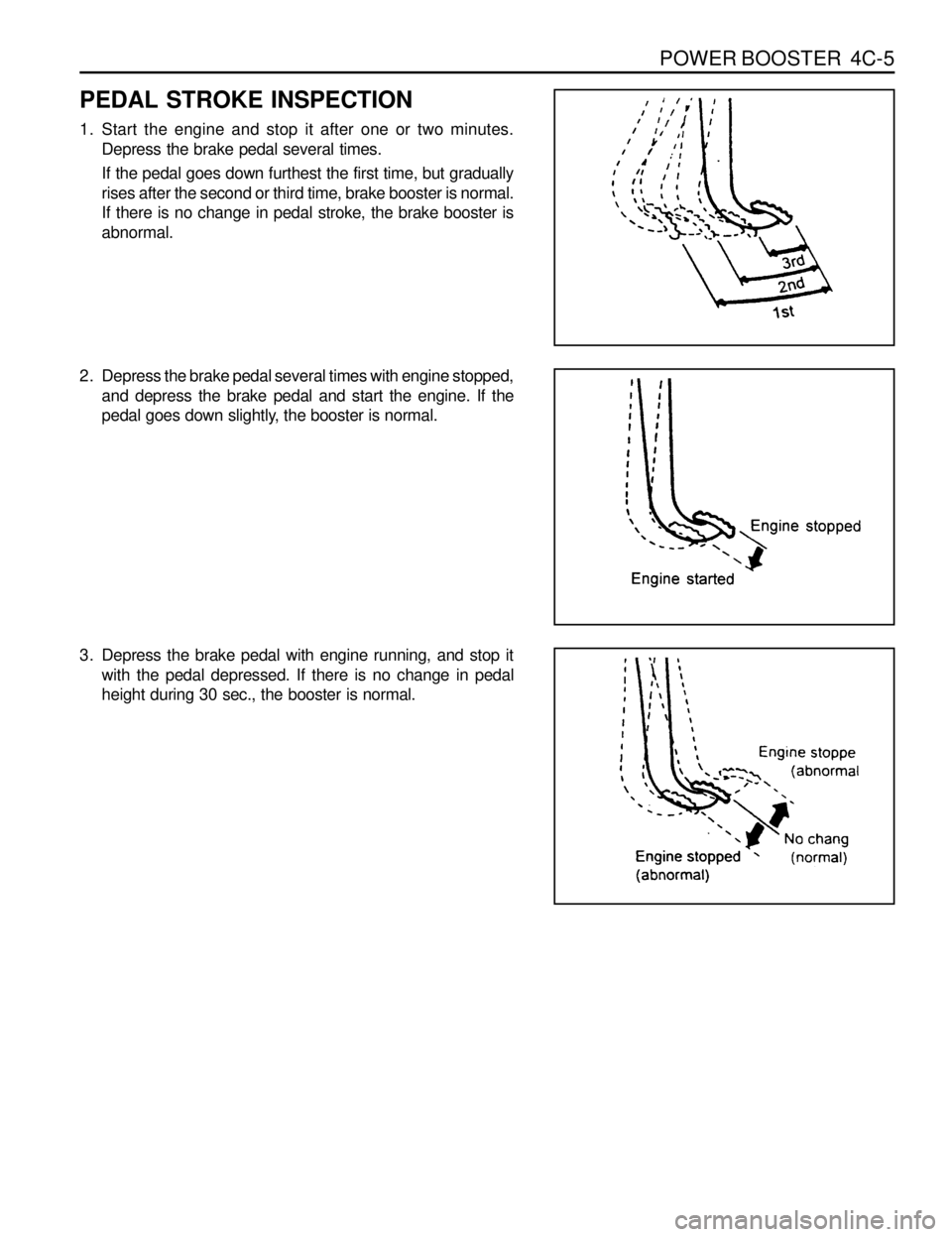

PEDAL STROKE INSPECTION

1. Start the engine and stop it after one or two minutes.

Depress the brake pedal several times.

If the pedal goes down furthest the first time, but gradually

rises after the second or third time, brake booster is normal.

If there is no change in pedal stroke, the brake booster is

abnormal.

2. Depress the brake pedal several times with engine stopped,

and depress the brake pedal and start the engine. If the

pedal goes down slightly, the booster is normal.

3. Depress the brake pedal with engine running, and stop it

with the pedal depressed. If there is no change in pedal

height during 30 sec., the booster is normal.

Page 1165 of 1463

5C-12 CLUTCH

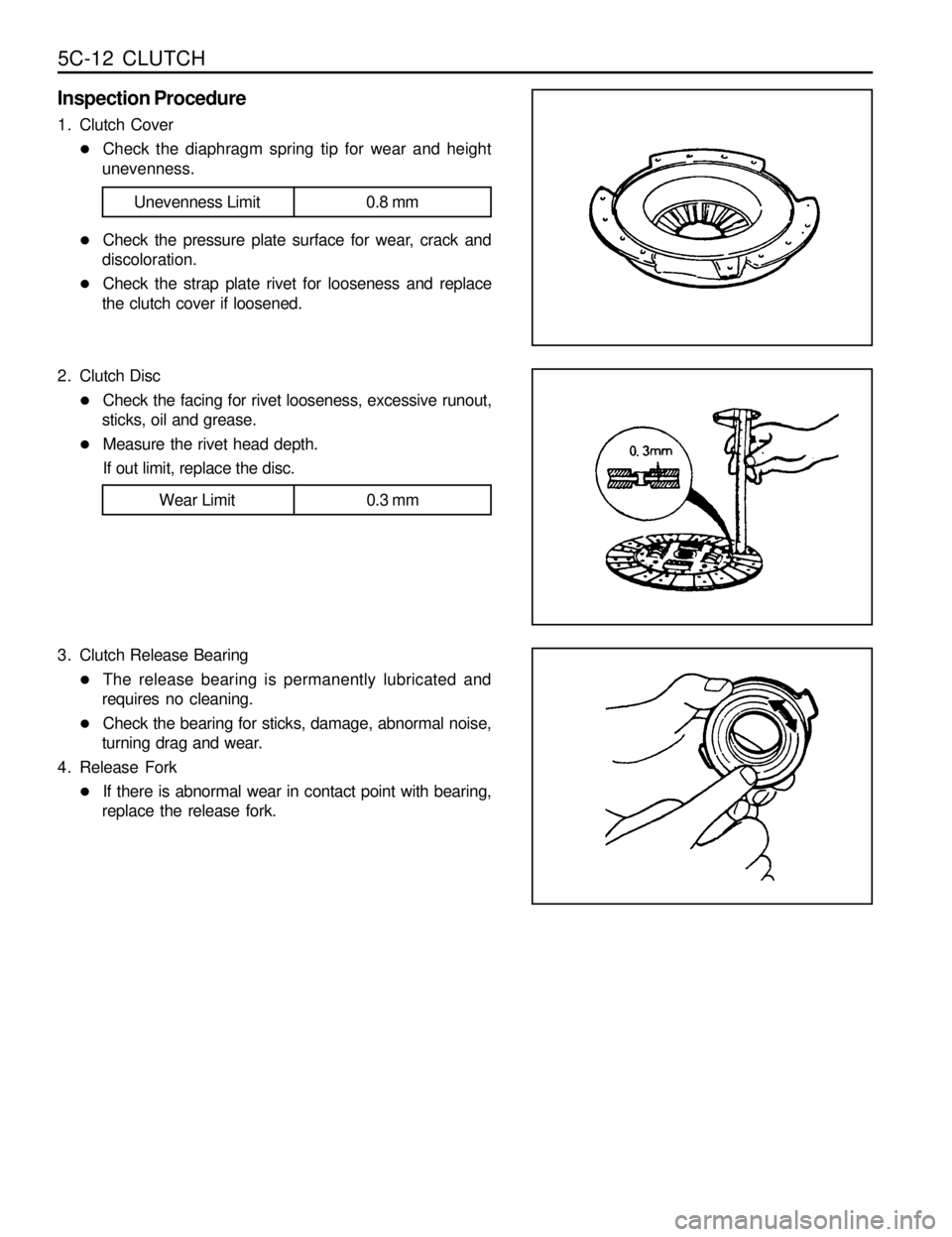

Inspection Procedure

1. Clutch Cover

lCheck the diaphragm spring tip for wear and height

unevenness.

lCheck the pressure plate surface for wear, crack and

discoloration.

lCheck the strap plate rivet for looseness and replace

the clutch cover if loosened.

Unevenness Limit 0.8 mm

2. Clutch Disc

lCheck the facing for rivet looseness, excessive runout,

sticks, oil and grease.

lMeasure the rivet head depth.

If out limit, replace the disc.

3. Clutch Release Bearing

lThe release bearing is permanently lubricated and

requires no cleaning.

lCheck the bearing for sticks, damage, abnormal noise,

turning drag and wear.

4. Release Fork

lIf there is abnormal wear in contact point with bearing,

replace the release fork.

Wear Limit 0.3 mm

Page 1169 of 1463

5C-16 CLUTCH

Inspection Procedure

1. Pedal Stroke (A).

Notice

To adjust the pedal stroke, loosen the lock nut (H) of the

interlock switch (G) and turn the two lock auto until the stroke

is correct.

Max. Stroke 158 mm

2. Pedal Height (B).

Notice

To adjust the pedal height, loosen the lock nut (C) of the

stopper bolt(D) and turn the stopper bolt until the height is

correct.

Height (From the Floor Carpet) 147 - 187 mm

3. Pedal Free Play (E).

Notice

To adjust the pedal free play, loosen the lock nut (F) of the

master cylinder and turn the push rod until the free play is

correct.

4. Check the fulcrum pin and the bushing for wear, the pedal

for bending and the spring for damage.

Free Play 5 - 10 Nm

Page 1352 of 1463

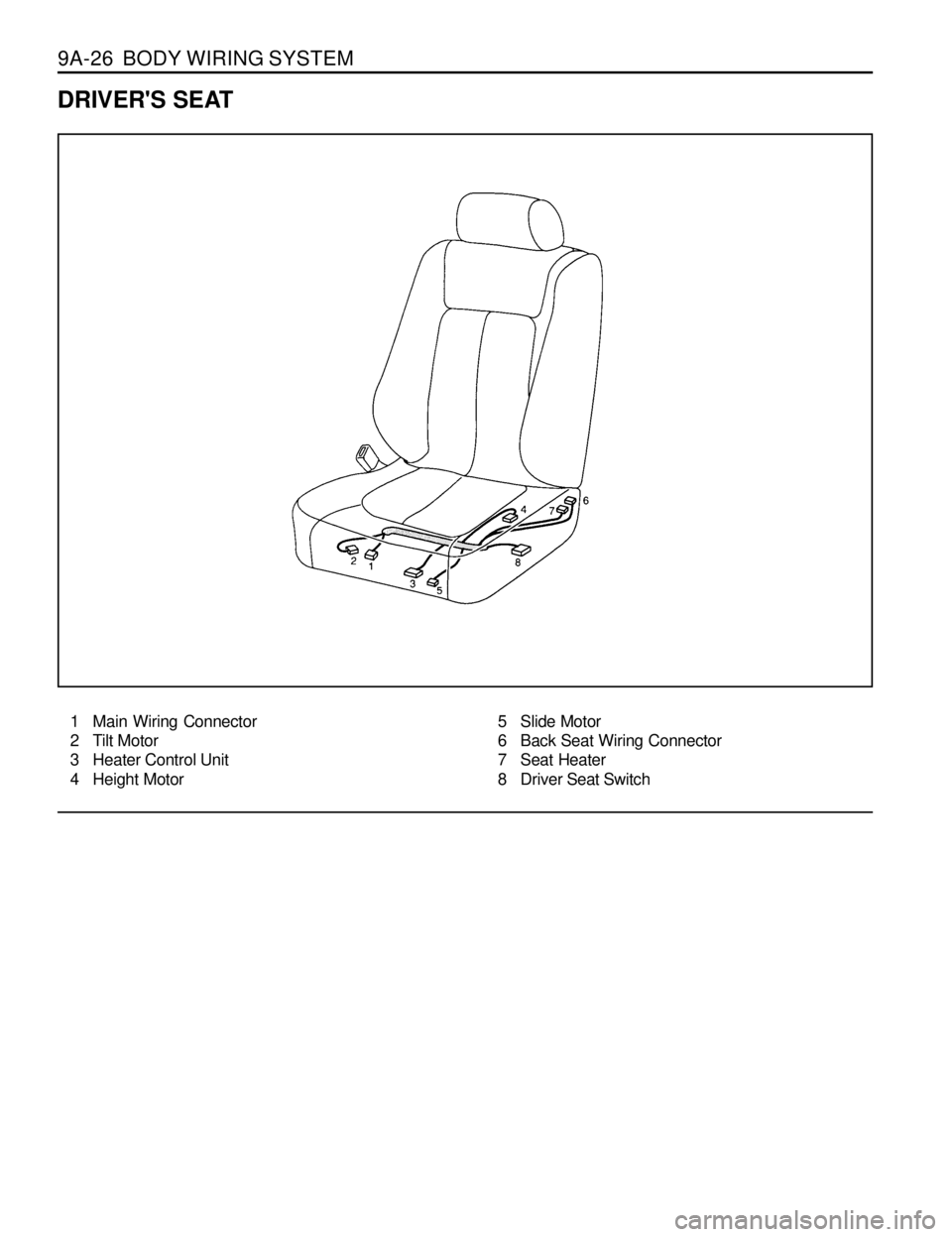

9A-26 BODY WIRING SYSTEM

DRIVER'S SEAT

1 Main Wiring Connector

2 Tilt Motor

3 Heater Control Unit

4 Height Motor5 Slide Motor

6 Back Seat Wiring Connector

7 Seat Heater

8 Driver Seat Switch

Page 1382 of 1463

SECTION 9H

SEATS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 9H-1

General Specifications . . . . . . . . . . . . . . . . . . 9H-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-2

Schematic and Routing Diagrams . . . . . . . . 9H-3

Power Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-3

Seat Warmer . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-4Seat Belt & Tension Reducer Circuit . . . . . . . . 9H-5

Component Locator . . . . . . . . . . . . . . . . . . . 9H-6

Front Seat & Rear Seat . . . . . . . . . . . . . . . . . 9H-6

Maintenance and Repair . . . . . . . . . . . . . . . 9H-7

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 9H-7

SPECIFICATIONS

GENERAL SPECIFICATIONS

Slide

Tilt

Height

Tilt and Height(up)

Slide

Slide

Tilt and Height

Load Rating

Operating Temperature Range

Switch Operating Force Application

Deseription

DC11 - 15V

-30°C - 80°C

20 ± 7mm/sec

10.6 ± 5mm/sec

7 ± 2mm/sec

Tilt:35 ± 2mm, Height:35 ± 2mm

Forward:230mm

Less Then 7A

Less Then 7A

DC12V 1A

-30°C - 80°C

0.3 - 0.7Kgf Operating Voltage

Operating Temperature Range

Seat Operating Speed(at 13.5V)

Seat Operating Distance

Operating Current(at 13.5V)

Seat Heater Switch

Page 1388 of 1463

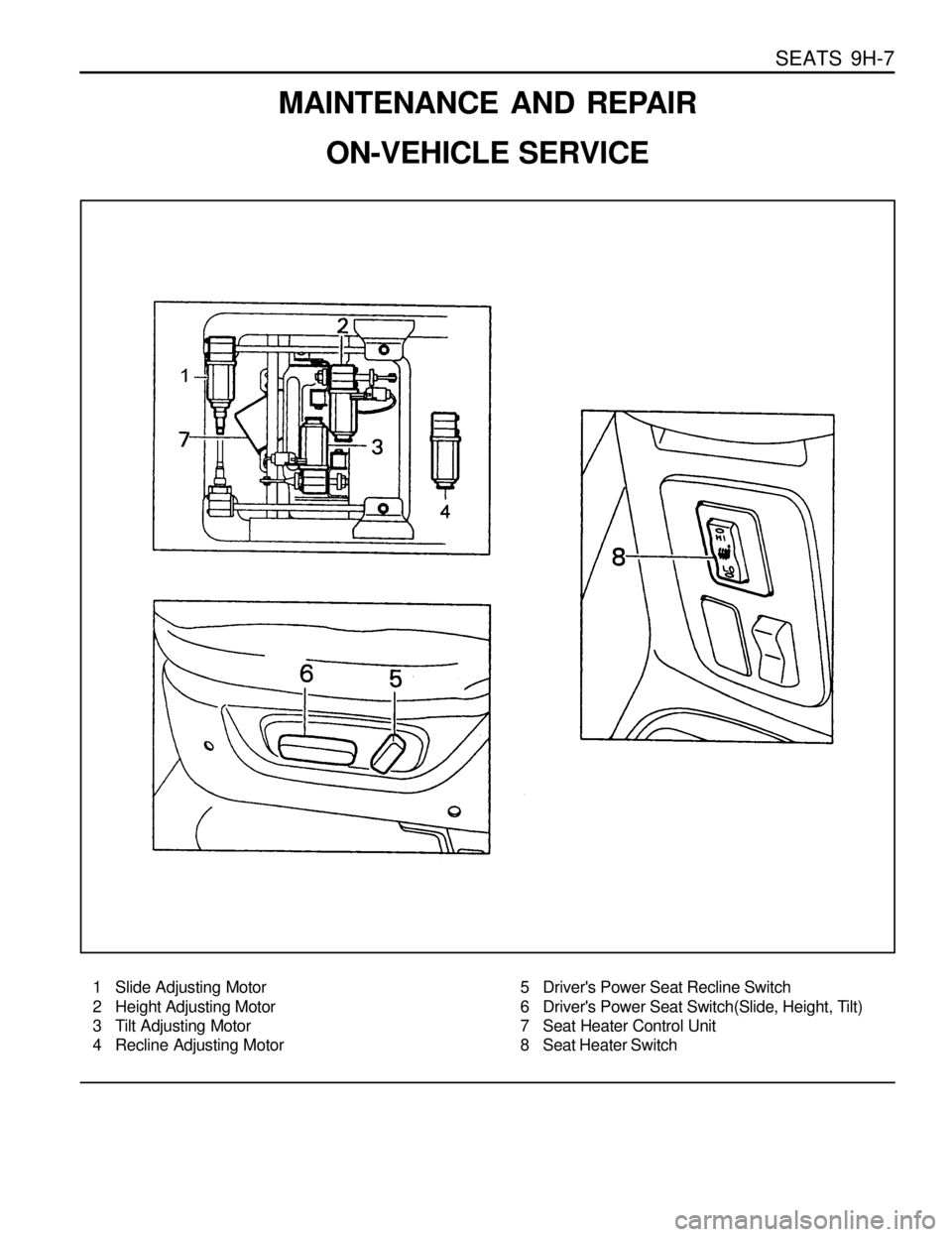

SEATS 9H-7

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

1 Slide Adjusting Motor

2 Height Adjusting Motor

3 Tilt Adjusting Motor

4 Recline Adjusting Motor5 Driver's Power Seat Recline Switch

6 Driver's Power Seat Switch(Slide, Height, Tilt)

7 Seat Heater Control Unit

8 Seat Heater Switch

Page 1389 of 1463

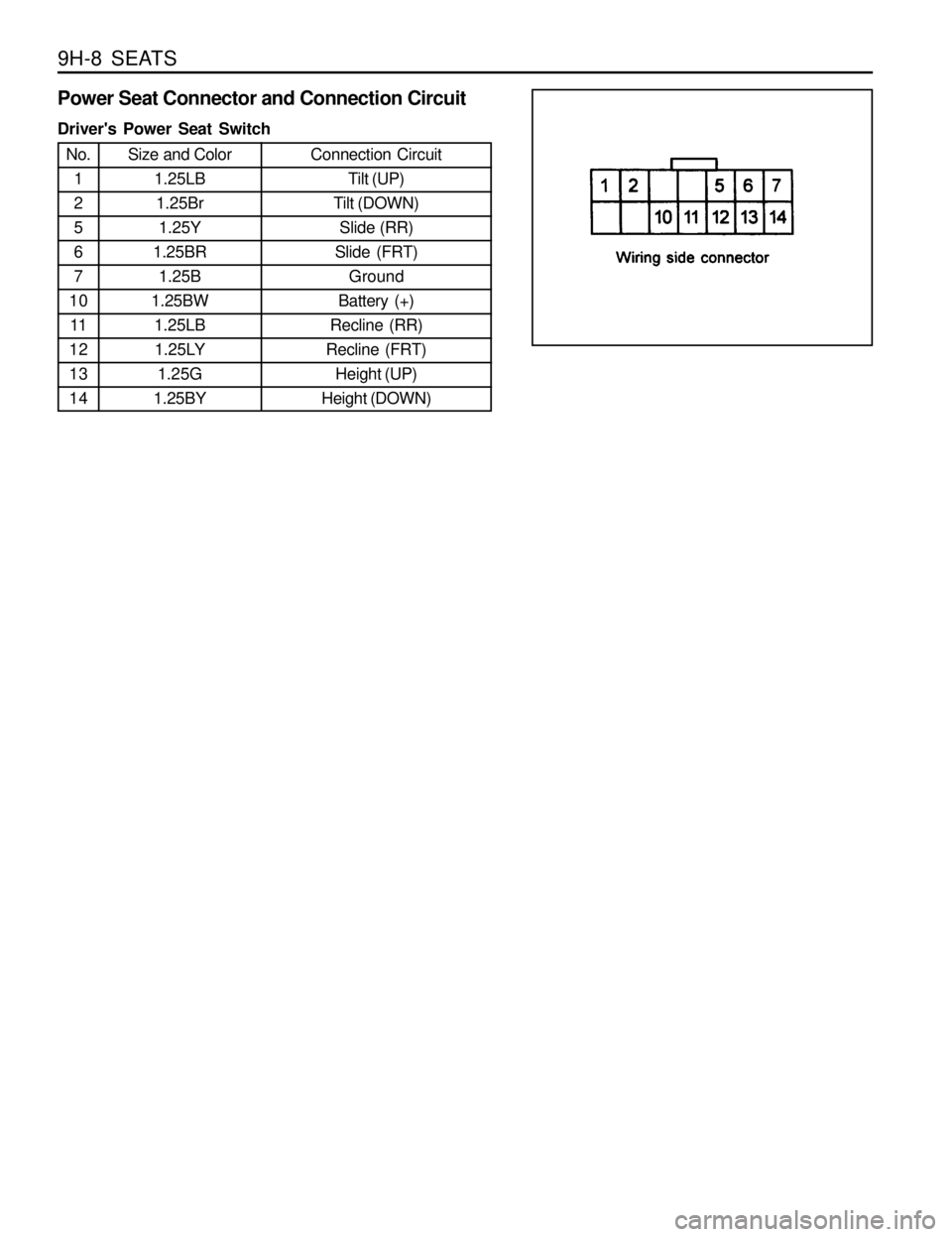

9H-8 SEATS

Power Seat Connector and Connection Circuit

Driver's Power Seat Switch

Size and Color

1.25LB

1.25Br

1.25Y

1.25BR

1.25B

1.25BW

1.25LB

1.25LY

1.25G

1.25BYConnection Circuit

Tilt (UP)

Tilt (DOWN)

Slide (RR)

Slide (FRT)

Ground

Battery (+)

Recline (RR)

Recline (FRT)

Height (UP)

Height (DOWN) No.

1

2

5

6

7

10

11

12

13

14

Page 1420 of 1463

9P-6 DOORS

Adjustment Procedure

1. Adjust the striker in forward / rearward and left / right

directions. Adjust striker height by increasing / decreasing

the shims.

2. Adjust the position of the striker as described above.

3. Adjust the position of the safety hook as described above.