height SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 17 of 1463

GENERAL INFORMATION 0B-5

Application

Overall Length (mm)

Overall Width (mm)

Overall Height (mm)

Wheel Base (mm)

Tread :Front (mm)

Rear (mm)

VEHICLE DIMENSIONS AND WEIGHTS

Vehicle Dimensions

Application

Manual : Curb Weight (kg)

Gross Vehicle Weight (kg)

Automatic : Curb Weight (kg)

Gross Vehicle Weight (kg)

Passenger Capacity

Vehicle Weights

Application

4656

1864

1735

2630

1510

1520

661LA

1860

2520

1916

2520

5662NA

1968

2520

1989

2520

5662LA

1890

2520

2005

2520

52.0L DOHC

1937

2520

-

-

52.3L DOHC

1850

2520

1942

2520

53.2L DOHC

1930

2520

2025

2520

5

Page 161 of 1463

1B1-88 M162 ENGINE MECHANICAL

CONNECTING ROD

Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt

(M9 x 52, 12 m pieces) .. 1st step 40+5 Nm

2nd step 90°+10°

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing Bore Center

Width of The Connecting Rod (B) at Bearing Bore

Width of The Connecting Rod (b) at Bushing Bore

Basic Bore at The Bearing Shell (D1)

Basic Bore at The Bushing (d1)

Bushing Inner Diameter (d)

Clearance Between The Piston Pin and The Bushing

Peak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to Connecting

Rod Bushing Core

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity

Permissible Difference of Each Connecting Rod in Weight145 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm

0.007 - 0.018 mm

0.005 mm

0.15 mm

0.07 mm

0.01 mm

0.4 g

Page 185 of 1463

1B1-112 M162 ENGINE MECHANICAL

Service Data Standard

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore size in

axial and transverse direction at three points (1,2,3).

1,2,3. Measuring Points

A . Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Wear Limit in Longitudinal and Transverse Direction

Permissible Deviation of Cylinder Out-of-round

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)

Basic Peak-to-valley Height After Final Honing and Brushing

Chamfer Angle

Honing AngleWhen new

Wear limit0.1 mm

0.007 mm

0.05 mm

0.05 mm

0.003 - 0.006 mm

60°

50° ± 10°

Page 186 of 1463

M162 ENGINE MECHANICAL 1B1-113

CRANKCASE MATING SURFACE

Service Data Standard

Height of The Crankcase “H” (When new)

Minimum Height After Milling

Flatness

Permissible Deviation of Parallelism of The

Upper to Lower Mating Surface

Peak-to-valley HeightCrankcase Upper Mating Surface

Crankcase Lower Mating Surface

Axial Direction

Transverse Direction

Crankcase Upper Mating Surface

Crankcase Lower Mating Surface282.25 - 282.35mm

281.95mm

0.03mm

0.04mm

0.1mm

0.05mm

0.005 - 0.020mm

0.025mm

Page 188 of 1463

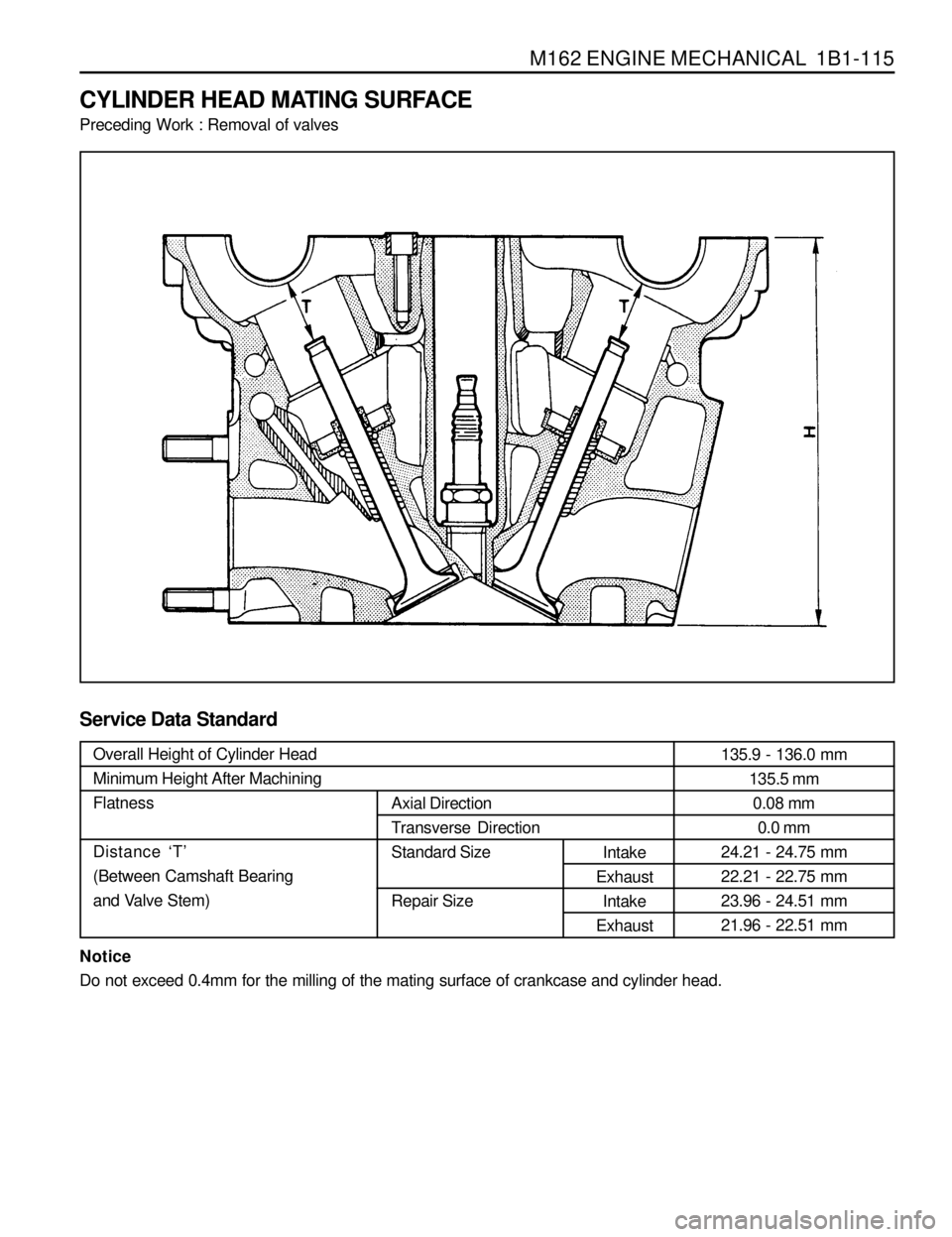

M162 ENGINE MECHANICAL 1B1-115

CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of valves

Service Data Standard

Notice

Do not exceed 0.4mm for the milling of the mating surface of crankcase and cylinder head.Overall Height of Cylinder Head

Minimum Height After Machining

Flatness

Distance ‘T’

(Between Camshaft Bearing

and Valve Stem)Axial Direction

Transverse Direction

Standard Size

Repair Size135.9 - 136.0 mm

135.5 mm

0.08 mm

0.0 mm

24.21 - 24.75 mm

22.21 - 22.75 mm

23.96 - 24.51 mm

21.96 - 22.51 mm

Intake

Exhaust

Intake

Exhaust

Page 189 of 1463

1B1-116 M162 ENGINE MECHANICAL

Measurement of Mating Surface

1. Measure the height (H) of the cylinder head (refer to Service

data standard

).

2. Check the mating surface of the cylinder head.

3. Mill the sharp edge of the combustion chamber.

4. Re-measure the height (H) of the cylinder head.

5. Seal the intake and exhaust valves.

6. Measure the dimension (T) between the camshaft bearing

and the valve system (refer to

Service data standard).

7. Mill the cylinder head valve seat (refer to

Service data

standard

).

Universal Tool

Surface Grinding Machine

Sceledum, Type RTY

Roaro

Schio/Italy

Page 282 of 1463

M161 ENGINE MECHANICAL 1B2-93

CONNECTING ROD

Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt

(M9 x 52, 8 pieces)............1st step 40 Nm

2nd step 90°

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing to Bushing Bore Center

Width of The Connecting Rod (B) at Bearing Bore

Width of The Connecting Rod (b) at Bushing Bore

Basic Bore at The Bearing Shell (D1)

Basic Bore at The Bushing (d1)

Bushing Inner Diameter (d)

Clearance Between The Piston Pin and The Bushing

Peak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to

Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod

Bearing Bore to Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore from

Concentricity

Permissible Difference of Each Connecting Rod in WeightE20 : 154 mm

E23 : 149 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm

0.007 - 0.018 mm

0.005 mm

0.1/100 mm

0.045/100 mm

0.01 mm

0.4 g

Page 298 of 1463

M161 ENGINE MECHANICAL 1B2-109

Service Data Standard

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore size in

axial and transverse direction at three points (1,2,3).

1,2,3 Measuring Points

A . Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Wear Limit in Longitudinal and Transverse Direction

Permissible Deviation of Cylinder Out-of-round

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)

Basic Peak-to-valley Height After Final Honing and Brushing

Chamfer Angle

Honing AngleWhen new

Wear limit0.1 mm

0.007 mm

0.05 mm

0.05 mm

0.003 - 0.006 mm

75°

50° ± 10°

1) The group code letters are carved on the surface of the piston crown and in the mating surface of the crankcase.Type

Standard Size

E20 :

f 89.9

E23 :

f 90.9

1st Repair Size

(Standard Size + 0.25)

2nd Repair Size

(Standard Size + 0.5)Group Code Letter

1)

A

X

B

A

X

B

A

X

BCylinder Bore Size (mm)f 89.900 - f 90.906

f 89.906 - f 89.912

f 89.912 - f 89.918

f 90.150 - f 90.156

f 89.156 - f 90.162

f 90.162 - f 90.168

f 90.400 - f 90.406

f 90.406 - f 90.412

f 90.412 - f 90.418

Page 299 of 1463

1B2-110 M161 ENGINE MECHANICAL

CRANKCASE MATING SURFACE

Service Data Standard

Height of the Crankcase “H” (When New)

Minimum Height After Milling

Flatness

Permissible Deviation of Parallelism of the

Upper to Lower Mating Surface

Peak-to-valley HeightCrankcase Upper Mating Surface

Crankcase Lower Mating Surface

Axial Direction

Transverse Direction

Crankcase Upper Mating Surface

Crankcase Lower Mating Surface289.35 - 289.45mm

289.05mm

0.03mm

0.04mm

0.1mm

0.05mm

0.012 - 0.009mm

0.025 - 0.020mm

Page 301 of 1463

1B2-112 M161 ENGINE MECHANICAL

CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of valves

Service Data Standard

Notice

Do not exceed 0.4mm for the milling of the mating surface of crankcase and cylinder head.Overall Height of Cylinder Head

Minimum Height After Machining

Flatness

Distance ‘T’

(Between Camshaft Bearing

and Valve Stem)Axial Direction

Transverse Direction

Standard Size

Repair Size135.9 - 136.0 mm

135.5 mm

0.08 mm

0.0 mm

24.21 - 24.75 mm

22.21 - 22.75 mm

23.96 - 24.51 mm

21.96 - 22.51 mm

Intake

Exhaust

Intake

Exhaust