length SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 341 of 1463

OM600 ENGINE MECHANICAL 1B3-39

Length(L) When New

80mm

102mm

115mm Thread Dia.

M10

M10

M10Max. Length(L)

82mm

104mm

117mm

The twelve-sided socket head bolts are tightened with each

stages of torque and torque angle.

It is not necessary to retighten the cylinder head bolts at

the 1000~1500km inspection or after 1000~1500km of

repairs.

Notice

The cylinder head may only be removed when the engine

has cooled down. The cylinder head is removed together

with the exhaust manifold. As the cylinder head bolts

undergo a permanent tightening. They require to be

replaced if they exceed the maximum lengthes indicated

in the table.

Page 354 of 1463

1B3-52 OM600 ENGINE MECHANICAL

Length(L)

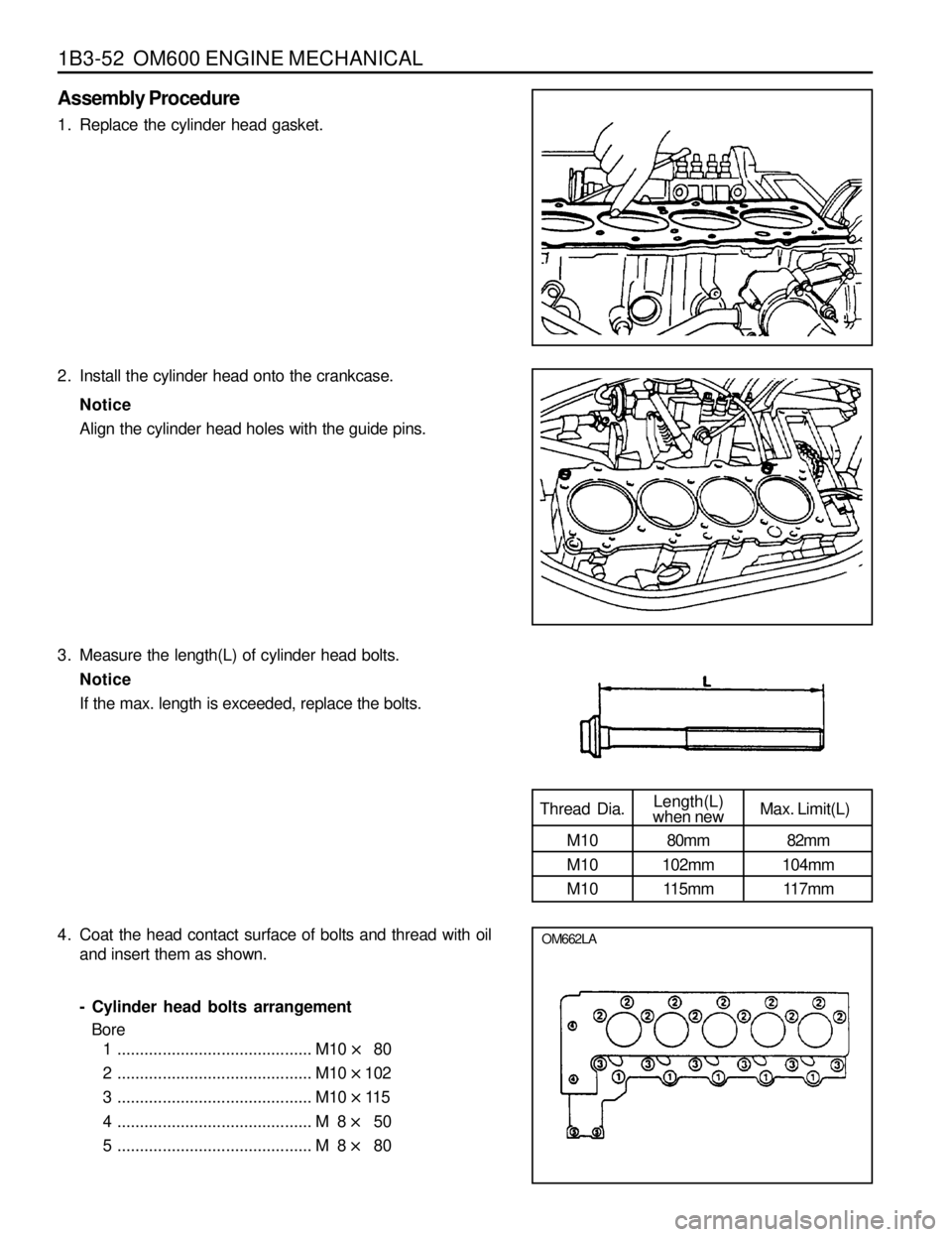

Assembly Procedure

1. Replace the cylinder head gasket.

2. Install the cylinder head onto the crankcase.

Notice

Align the cylinder head holes with the guide pins.

3. Measure the length(L) of cylinder head bolts.

Notice

If the max. length is exceeded, replace the bolts.

Thread Dia. Max. Limit(L)

M10

M10

M1080mm

102mm

115mm82mm

104mm

117mm when new

4. Coat the head contact surface of bolts and thread with oil

and insert them as shown.

- Cylinder head bolts arrangement

Bore

1 ...........................................M10

× 80

2 ...........................................M10

× 102

3 ...........................................M10

× 11 5

4 ........................................... M 8

× 50

5 ........................................... M 8

× 80

OM662LA

Page 360 of 1463

1B3-58 OM600 ENGINE MECHANICAL

24. Install the exhaust manifold and gasket.

25. Install the turbocharger.

26. Install the exhaust pipe onto the turbocharger.

Tightening Torque 25 Nm

Notice

Measure the max. length ‘L’ and replace the bolt if it exceeds

53.6mm.

Page 393 of 1463

OM600 ENGINE MECHANICAL 1B3-91

Notice

If the max. length of bolts(L) exceed 63.8mm, replace them.

19. Coat the new crankshaft with engine oil and place it on the

crankcase.

20. Install the crankshaft bearing caps according to marking

and tighten the bolts.

Tightening Torque 55 Nm + 90°

Notice

Install from No. 1 cap.

22. Rotate the crankshaft with hand and check whether it

rotates smoothly.

23. Measure crankshaft bearing axial clearance.

Clearance 0.100 - 0.245mm

Notice

If the clearance is out of standard, adjust the axial clearance

of crankshaft bearing by replacing the thrust washers.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

Page 397 of 1463

OM600 ENGINE MECHANICAL 1B3-95

3. Remove the flywheel (3), if equipped with manual

transmission.

Installation Notice

Correctly align the position of dowel pin (2).

Tools Required

602 589 00 40 00 Engine Lock

Removal & Installation Procedure

1. Install the engine lock.

Engine Lock 602 589 02 40 00

2. Remove the 12-sided stretch bolts (4).

Installation Notice

Tightening Torque 45 Nm + 90°

Notice

If the length ‘L’ of bolts exceeds 22.5mm, replace the bolts.

Page 407 of 1463

OM600 ENGINE MECHANICAL 1B3-105

VALVE SPRINGS CHECK

Preceding Work : Removal of valve spring

1 Valve Spring

Service Data

Outer diameter

33.1mmWire diameter

4.20mmFree length

50.0mmAt preloaded

Length Tension (new)

680 - 740N 27mmLimit

612N

2 Spring Scale

Page 418 of 1463

1B3-116 OM600 ENGINE MECHANICAL

8.000

- 8.030

9.000

- 9.05039.5 Intake

Exhaust0.029

- 0.051

0.029

- 0.051 Red

White

Red

White

Diameter ‘a’

Service Data

ItemBasic Bore

Repair size 1

Repair size 2

Repair size 1

Repair size 2Outer Diameter ‘D’

14.251

14.440 - 14.451

14.240 - 14.251

14.440 - 14.451Color Code

14.200 - 14.211

14.400 - 14.411

14.200 - 14.211

14.400 - 14.411Overlap

‘D’ - ‘a’Valve Guide

Inner Diameter ‘A’

37.7

Length ‘L’

CHECK AND REPLACEMENT OF VALVE GUIDES

Preceding Work : Removal of cylinder head

Removal of valve spring

Removal of valve

1 Cylinder Head

2 Valve Guide3 Valve Seat Ring

a Basic Bore Diameter

Page 429 of 1463

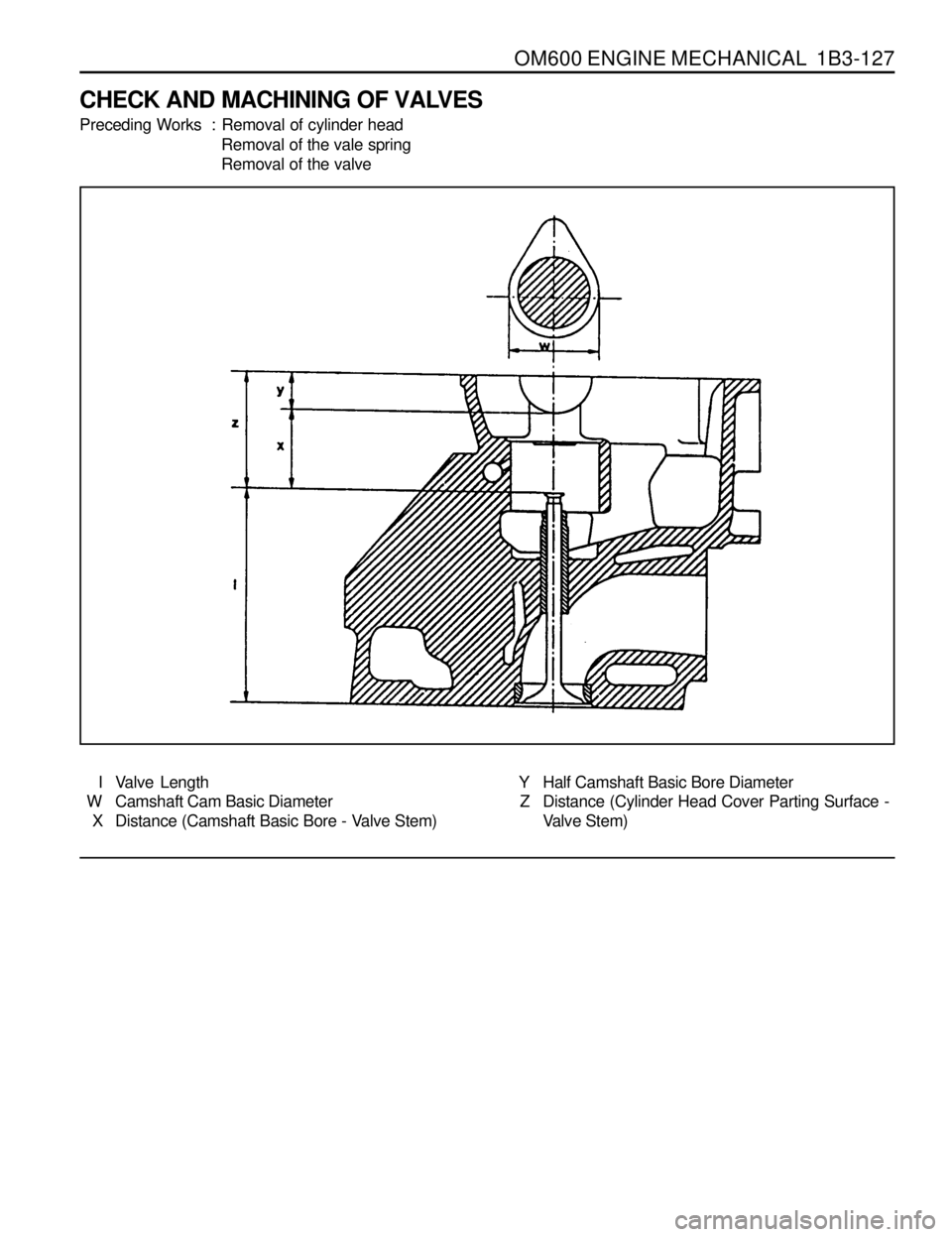

OM600 ENGINE MECHANICAL 1B3-127

CHECK AND MACHINING OF VALVES

Preceding Works : Removal of cylinder head

Removal of the vale spring

Removal of the valve

I Valve Length

W Camshaft Cam Basic Diameter

X Distance (Camshaft Basic Bore - Valve Stem)Y Half Camshaft Basic Bore Diameter

Z Distance (Cylinder Head Cover Parting Surface -

Valve Stem)

Page 430 of 1463

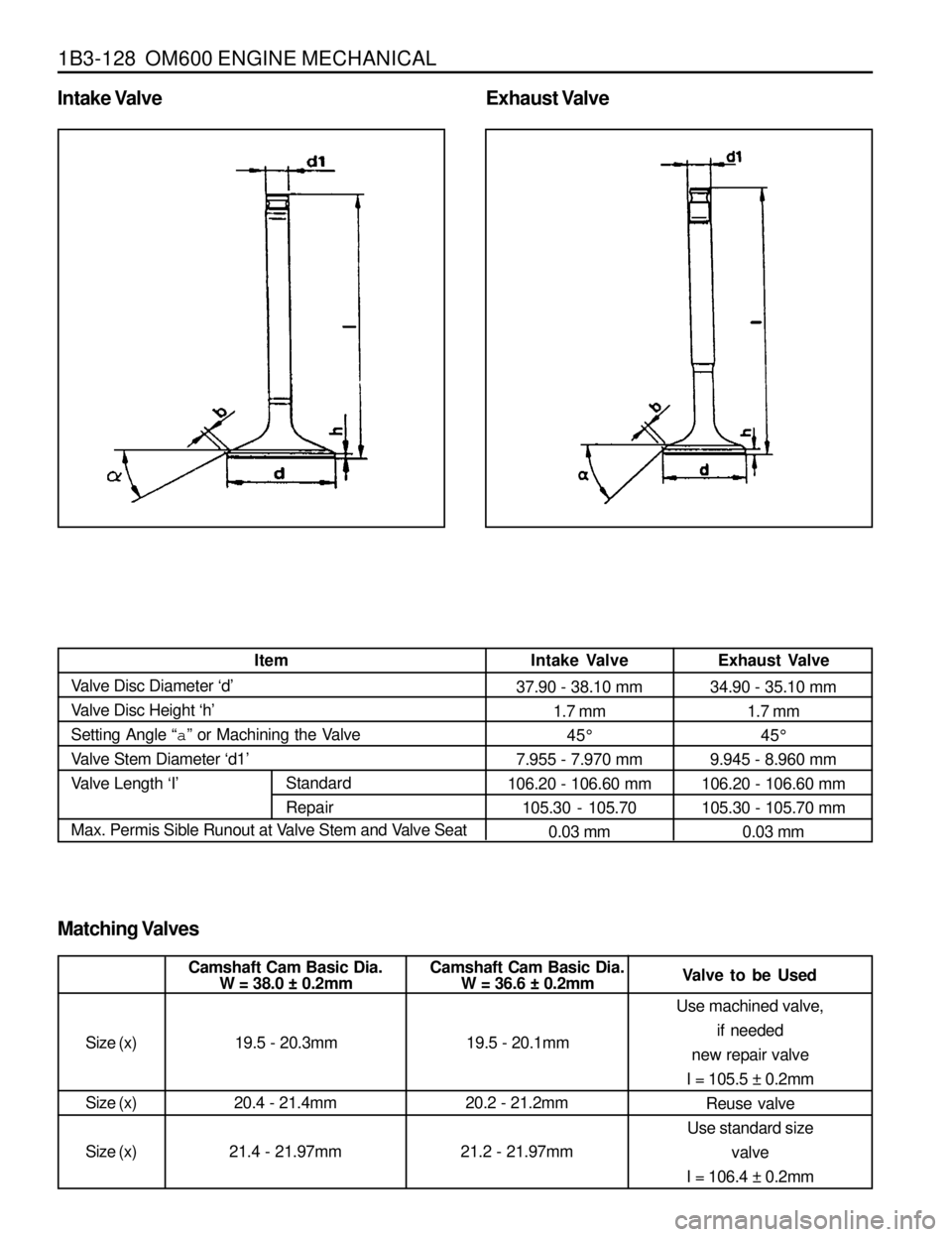

1B3-128 OM600 ENGINE MECHANICAL

Intake Valve Exhaust Valve

Item

Valve Disc Diameter ‘d’

Valve Disc Height ‘h’

Setting Angle “a” or Machining the Valve

Valve Stem Diameter ‘d1’

Valve Length ‘I’Intake Valve

37.90 - 38.10 mm

1.7 mm

45°

7.955 - 7.970 mm

106.20 - 106.60 mm

105.30 - 105.70

0.03 mmExhaust Valve

34.90 - 35.10 mm

1.7 mm

45°

9.945 - 8.960 mm

106.20 - 106.60 mm

105.30 - 105.70 mm

0.03 mm

Standard

Repair

Max. Permis Sible Runout at Valve Stem and Valve Seat

W = 38.0 ± 0.2mm

Matching Valves

Camshaft Cam Basic Dia.

Size (x)

Size (x)

Size (x)19.5 - 20.3mm

20.4 - 21.4mm

21.4 - 21.97mmW = 36.6 ± 0.2mm Camshaft Cam Basic Dia.

19.5 - 20.1mm

20.2 - 21.2mm

21.2 - 21.97mmValve to be Used

Use machined valve,

if needed

new repair valve

I = 105.5 ± 0.2mm

Reuse valve

Use standard size

valve

I = 106.4 ± 0.2mm

Page 435 of 1463

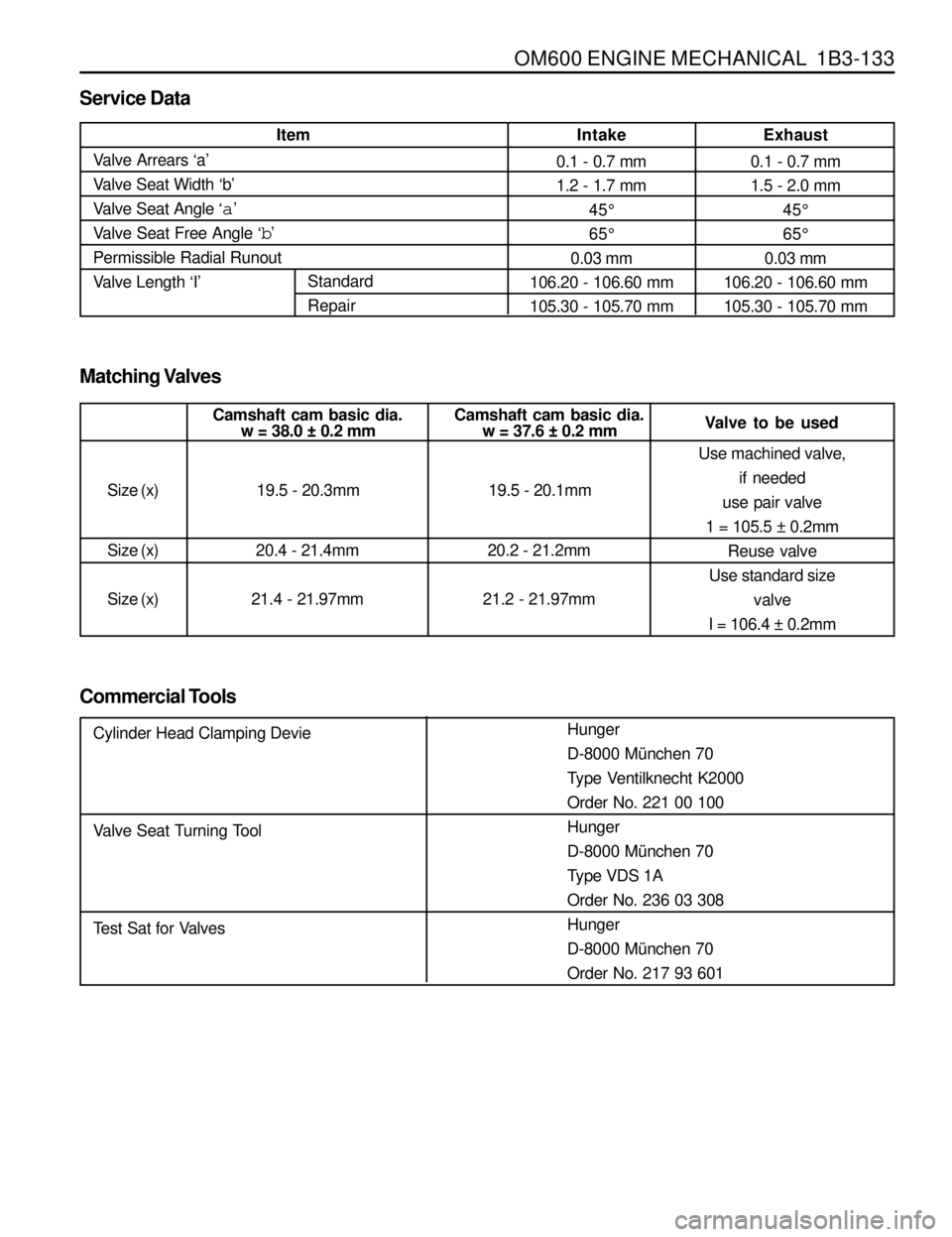

OM600 ENGINE MECHANICAL 1B3-133

Service Data

Item

Valve Arrears ‘a’

Valve Seat Width ‘b’

Valve Seat Angle ‘

a’

Valve Seat Free Angle ‘

b’

Permissible Radial Runout

Valve Length ‘I’Intake

0.1 - 0.7 mm

1.2 - 1.7 mm

45°

65°

0.03 mm

106.20 - 106.60 mm

105.30 - 105.70 mmExhaust

0.1 - 0.7 mm

1.5 - 2.0 mm

45°

65°

0.03 mm

106.20 - 106.60 mm

105.30 - 105.70 mm

Standard

Repair

w = 38.0 ± 0.2 mm

Matching Valves

Camshaft cam basic dia.

Size (x)

Size (x)

Size (x)19.5 - 20.3mm

20.4 - 21.4mm

21.4 - 21.97mmw = 37.6 ± 0.2 mm Camshaft cam basic dia.

19.5 - 20.1mm

20.2 - 21.2mm

21.2 - 21.97mmValve to be used

Use machined valve,

if needed

use pair valve

1 = 105.5 ± 0.2mm

Reuse valve

Use standard size

valve

I = 106.4 ± 0.2mm

Commercial Tools

Hunger

D-8000 München 70

Type Ventilknecht K2000

Order No. 221 00 100

Hunger

D-8000 München 70

Type VDS 1A

Order No. 236 03 308

Hunger

D-8000 München 70

Order No. 217 93 601 Cylinder Head Clamping Devie

Valve Seat Turning Tool

Test Sat for Valves