transmission fluid SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1046 of 1463

AUTOMATIC TRANSMISSION 5A-69

MECHANICAL TESTS

In Vehicle Transmission Checks

Carry out the following tests before removing the transmission.

lSee Checking Transmission Fluid Level, Section 7.2.1.

lCheck that the transmission oil is not burnt (colour and smell are correct).

lEnsure that the transmission is not in limp home mode (LHM).

lCheck that the battery terminals and the earth connections are not corroded or loose.

lCheck the engine stall speed is within the handbook value.

lCheck that the cooler flow is not restricted.

lCheck that all electrical plug connections are tight.

lCarry out a road test to confirm the symptoms, if necessary.

lInspect the oil, ensure that there are no metal or other contaminants in the oil pan.

Diagnosing Oil Leaks

Determine the source of oil leaks by firstly cleaning down the affected area, then driving the vehicle.

Inspect the seals to confirm the source of the leak.

lTo determine the source of a rear servo oil leak, raise the vehicle on a hoist, then carry out a reverse stall.

lTo determine the source of a front servo leak, raise the vehicle on a hoist, then run the vehicle in second gear.

Troubleshooting Charts

The troubleshooting charts are set out as follows:

lTable 6.2.1 Drive Faults,

lTable 6.2.2 Faulty Shift Patterns.

lTable 6.2.3 Shift Quality Faults.

lTable 6.2.4 After Teardown Faults.

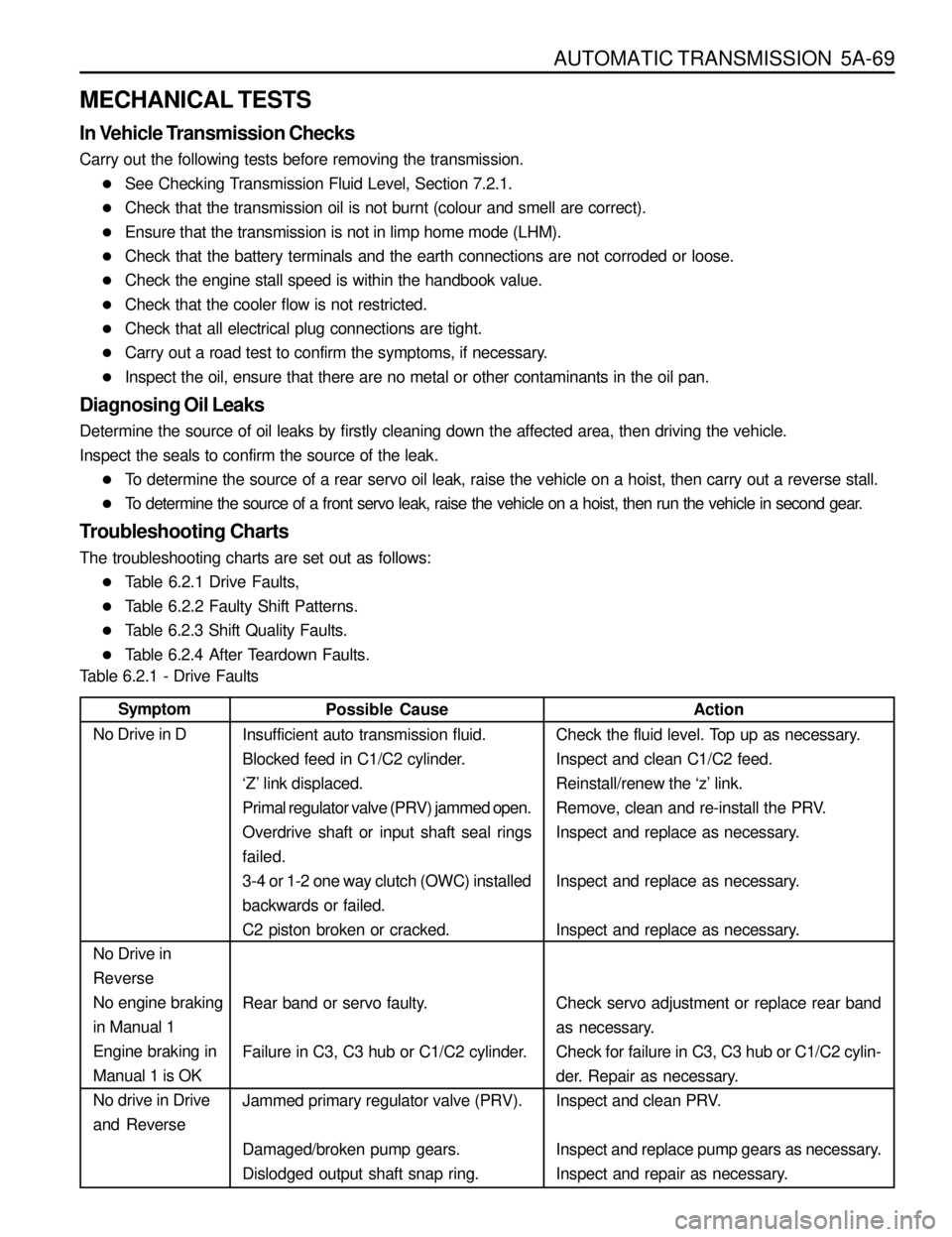

Table 6.2.1 - Drive Faults

Action

Check the fluid level. Top up as necessary.

Inspect and clean C1/C2 feed.

Reinstall/renew the ‘z’ link.

Remove, clean and re-install the PRV.

Inspect and replace as necessary.

Inspect and replace as necessary.

Inspect and replace as necessary.

Check servo adjustment or replace rear band

as necessary.

Check for failure in C3, C3 hub or C1/C2 cylin-

der. Repair as necessary.

Inspect and clean PRV.

Inspect and replace pump gears as necessary.

Inspect and repair as necessary. Possible Cause

Insufficient auto transmission fluid.

Blocked feed in C1/C2 cylinder.

‘Z’ link displaced.

Primal regulator valve (PRV) jammed open.

Overdrive shaft or input shaft seal rings

failed.

3-4 or 1-2 one way clutch (OWC) installed

backwards or failed.

C2 piston broken or cracked.

Rear band or servo faulty.

Failure in C3, C3 hub or C1/C2 cylinder.

Jammed primary regulator valve (PRV).

Damaged/broken pump gears.

Dislodged output shaft snap ring.Symptom

No Drive in D

No Drive in

Reverse

No engine braking

in Manual 1

Engine braking in

Manual 1 is OK

No drive in Drive

and Reverse

Page 1049 of 1463

5A-72 AUTOMATIC TRANSMISSION

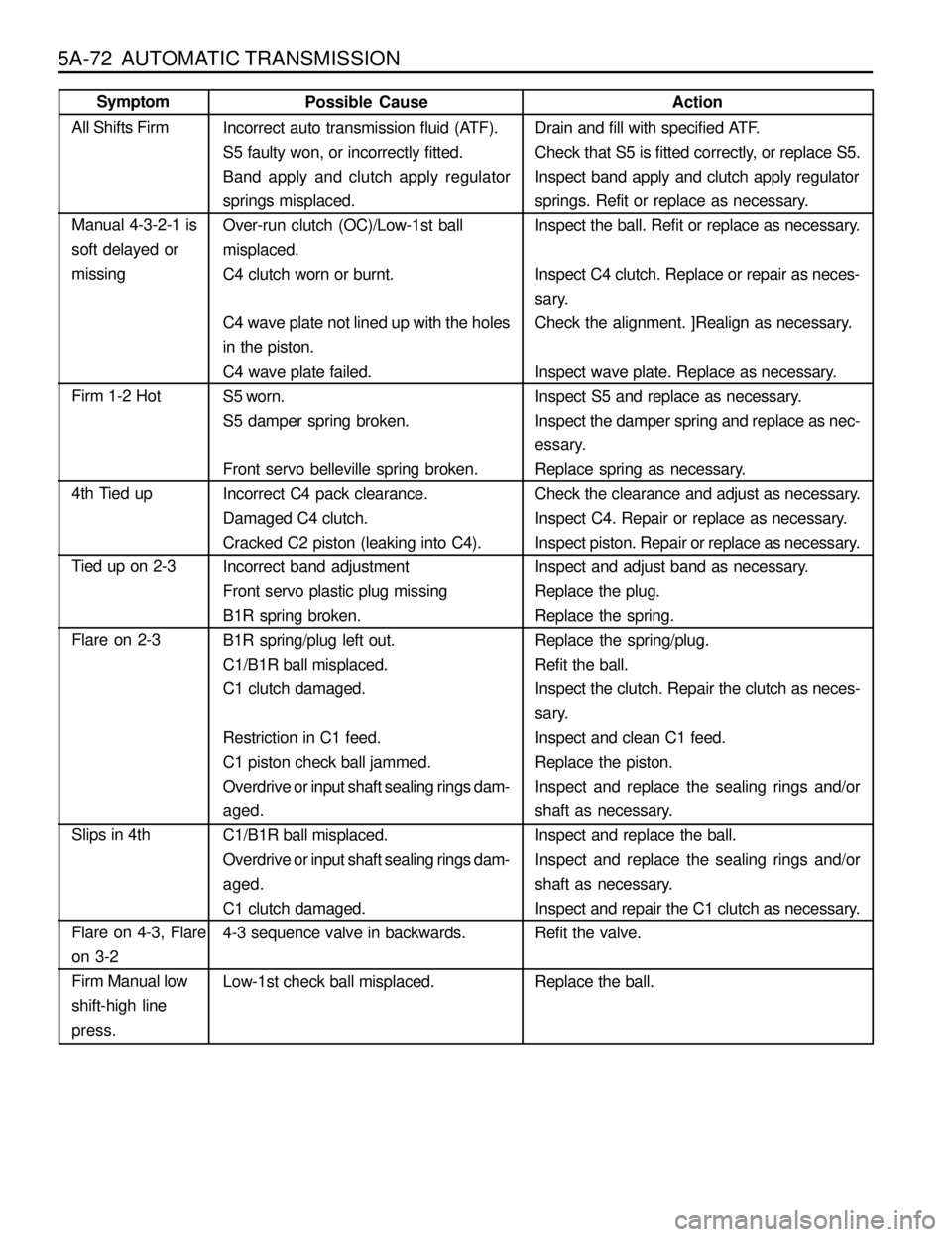

Action

Drain and fill with specified ATF.

Check that S5 is fitted correctly, or replace S5.

Inspect band apply and clutch apply regulator

springs. Refit or replace as necessary.

Inspect the ball. Refit or replace as necessary.

Inspect C4 clutch. Replace or repair as neces-

sary.

Check the alignment. ]Realign as necessary.

Inspect wave plate. Replace as necessary.

Inspect S5 and replace as necessary.

Inspect the damper spring and replace as nec-

essary.

Replace spring as necessary.

Check the clearance and adjust as necessary.

Inspect C4. Repair or replace as necessary.

Inspect piston. Repair or replace as necessary.

Inspect and adjust band as necessary.

Replace the plug.

Replace the spring.

Replace the spring/plug.

Refit the ball.

Inspect the clutch. Repair the clutch as neces-

sary.

Inspect and clean C1 feed.

Replace the piston.

Inspect and replace the sealing rings and/or

shaft as necessary.

Inspect and replace the ball.

Inspect and replace the sealing rings and/or

shaft as necessary.

Inspect and repair the C1 clutch as necessary.

Refit the valve.

Replace the ball. Possible Cause

Incorrect auto transmission fluid (ATF).

S5 faulty won, or incorrectly fitted.

Band apply and clutch apply regulator

springs misplaced.

Over-run clutch (OC)/Low-1st ball

misplaced.

C4 clutch worn or burnt.

C4 wave plate not lined up with the holes

in the piston.

C4 wave plate failed.

S5 worn.

S5 damper spring broken.

Front servo belleville spring broken.

Incorrect C4 pack clearance.

Damaged C4 clutch.

Cracked C2 piston (leaking into C4).

Incorrect band adjustment

Front servo plastic plug missing

B1R spring broken.

B1R spring/plug left out.

C1/B1R ball misplaced.

C1 clutch damaged.

Restriction in C1 feed.

C1 piston check ball jammed.

Overdrive or input shaft sealing rings dam-

aged.

C1/B1R ball misplaced.

Overdrive or input shaft sealing rings dam-

aged.

C1 clutch damaged.

4-3 sequence valve in backwards.

Low-1st check ball misplaced.Symptom

All Shifts Firm

Manual 4-3-2-1 is

soft delayed or

missing

Firm 1-2 Hot

4th Tied up

Tied up on 2-3

Flare on 2-3

Slips in 4th

Flare on 4-3, Flare

on 3-2

Firm Manual low

shift-high line

press.

Page 1056 of 1463

AUTOMATIC TRANSMISSION 5A-79

ADJUSTMENTS

HYDRAULIC SYSTEM

The procedures detailed below should be followed in the event that the self test procedure detailed in section 6, or a

defect symptom, indicates that there is a fault in the hydraulic system.

When making adjustments to the transmission, select the appropriate procedures from the following preliminary

checks.

lConduct a transmission fluid test procedure, refer to section 7.2.

lCheck the manual linkage adjustment (refer to the vehicle workshop manual).

lCheck engine idle speed (refer to Section 7.3).

lConduct a stall test (it is outside the scope of this publication to detail this procedure)

lconduct a road test (it is outside the scope of this publication to detail this procedure).

TRANSMISSION FLUID TEST PROCEDURE

Checking Transmission Fluid Level

This procedure is to be used when checking a concern with the fluid level in a vehicle. A low fluid level will result in

gearshift loss or delay if driven when the vehicle is cold.

The vehicle is first checked for transmission diagnostic messages (refer to section 6). If the vehicle has a speedo fault

it is possible for the oil level to be low.

The vehicle is to be test driven to determine if there is an abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low oil level is a momentary loss of drive when driving the vehicle around a comer. Also when

the transmission fluid level is low, a loss of drive may occur when the transmission oil temperature is low.

If there is no loss of drive when the vehicle is driven warm and a speedo fault is registered, then fluid should be added

to the transmission.

Checking, Adding Fluid and Filling

When adding or changing transmission oil use only Castrol TQ 95 automatic transmission fluid (ATF) or other approved

fluids. The use of incorrect oil will cause the performance and durability of the transmission to be severely degraded.

Do not underfill the transmission. Incorrect tilling may cause damage to the transmission. The fluid level setting

procedure is detailed below.

Notice

When a transmission is at operating temperature hot transmission fluid may come out of the case if the fill plug is

removed. 9 the transmission is at operating temperature allow two hours for cooling prior to removing the plug.

1. If the vehicle is at operating temperature allow the vehicle to cool down for two, but no greater than four hours

before adding transmission fluid (this will allow the transmission to be within the correct temperature

range).

While hot the ATF level is higher and removing the plug may result in oil being expelled from the filler hole. This

will result in the level being low.

2. The transmission selector is to be in Park.

Switch the engine off.

3. Raise the vehicle on a hoist (or leave over a service pit).

4. Clean all dirt from around the service fill plug prior to removing the plug. Remove the oil service fill plug.

Clean the fill plug and check that there is no damage to the ‘O’ ring.

Install the filler pump into the filler hole.

5. Lower the vehicle with the filler pump still connected and partially fill the transmission.

Start the vehicle in Park with the Parking brake and foot brake applied with the engine idling, cycle the transmission

gear selector through all positions, adding ATF until gear application is felt.

Page 1057 of 1463

5A-80 AUTOMATIC TRANSMISSION

6. Switch off the engine and raise the vehicle on the hoist, if applicable, ensuring that the vehicle is level.

7. Three minutes after the engine has stopped, but no longer than one hour, remove the filler pump, The correct

level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATF to the correct level.

8. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle.

9. Tighten the transmission filler plug to specification.

Checking, Adding Fluid and Filling - Drained or Dry Transmission

To set the correct fluid level proceed as follows.

1. Set the transmission selector to Park and switch the engine off.

2. Raise the vehicle on a hoist (or leave over a service pit).

3. Clean all dirt from around the service fill plug prior to removing the plug, Remove the oil service fill plug. Clean the

fill plug and check that there is no damage to the ‘O’ ring. Install the filler pump into the filler hole.

4. Lower the vehicle with the filler pump still connected and partially fill the transmission. This typically requires

approximately :

a. If the transmission torque converter is empty:

9.0 litres - 4WD

9.0 litres - RWD

b. If the transmission torque converter is full:

4.5 litres - 4WD

4.5 litres - RWD

5. Start the vehicle in Park with the Parking brake and foot brake applied with the engine idling, cycle the transmission

gear selector through all positions, adding ATF until gear application is felt.

6. Then add an additional 0.5 litres of ATF.

7. Switch off the engine and raise the vehicle on the hoist. Remove the filler pump and replace the filler plug. The

plug shall be tightened to specification.

8. The vehicle is then to be driven between 3.5 and 4.5 kilometers at light throttle so that the engine does not

exceed 2500 rpm. This should result in the transmission temperature being in the range 50 to 60°C.

9. With the engine idling, cycle the transmission selector through all gear positions with the brake applied.

10. Stop the engine. Raise the vehicle on the hoist, if applicable ensuring the vehicle is level.

11. Three minutes after the engine has stopped, but no longer than one hour, remove the filler plug. The correct

level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATP to the correct level.

12. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle. Tighten the

transmission Filler plug to specification.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustment

Carry out the adjustments to the idle speed as detailed in the workshop manual.

Throttle Position Calibration

Should the throttle position data stored in the TCU be lost or be out of specification, as indicated by a diagnostic

trouble message, it may be re-established by the following procedure.

lCheck that the hot engine idle speed is within specification.

lAllow the engine to idle in ‘Drive’ for 60 seconds with the air conditioner (if fitted) turned off. The closed throttle

reference point in the TCU has now been set.

Switch the engine off but leave the ignition on. Hold the accelerator pedal on the floor for 60 seconds. The wide open

throttle reference point in the TCU has now been set.

Page 1062 of 1463

AUTOMATIC TRANSMISSION 5A-85

UNIT REPAIR

REBUILD WARNINGS

Prior to rebuilding a transmission system, the following warnings

are to be noted.

lEnsure that, before replacing a transmission the cooler

lines are flushed out to remove any debris. This can be

done by applying compressed air to the rear cooler line

forcing oil and any contaminants out of the front cooler

line.

lThe cooler flow should be checked after the transmission

has been fitted. With the front cooler line connected

and the rear line run into a suitable container, measure

the flow over 15 seconds with the vehicle idling in park.

lThe flow rate should exceed 1 liter in 15 seconds.

lBe wary of any situation where water enters the

transmission. This may result in fluid foaming and leaking

through the breather.

lEnsure that both earth straps (one at the batted terminal

and one on the vehicle body) are connected in the

vehicle before connecting the positive side of the

battery.

lFollow the throttle position calibration procedure in

section 7 of this manual if the powertrain control module

transmission control unit (PCM/TCU) is swapped.

DISASSEMBLY PROCEDURE

Transmission

Notice

Remove the inhibitor switch before washing the transmission

in solvent or hot wash.

It is assumed that the transmission fluid has been drained

when the transmission was removed from the

vehicle and that the ‘special tools’ quoted are available.

The transmission is dismantled in a modular fashion, and the

details of disassembly for each module are given under the

appropriate subject. Refer to table 9.10 in section 9.6 for details

of all special tools required when performing disassembly

procedures.

Technicians overhauling these transmissions will also require

a selection of good quality Torx bit sockets, in particular

numbers 30, 40 and 50, and an 8 mm,10 mm and 12 mm

double hex socket.

To disassemble the transmission, proceed as follows:

1. Remove the converter and the converter housing.

2. Mount the transmission on the bench cradle

No.0555-331895.

3. Remove the sump and the sump seal.

Page 1075 of 1463

5A-98 AUTOMATIC TRANSMISSION

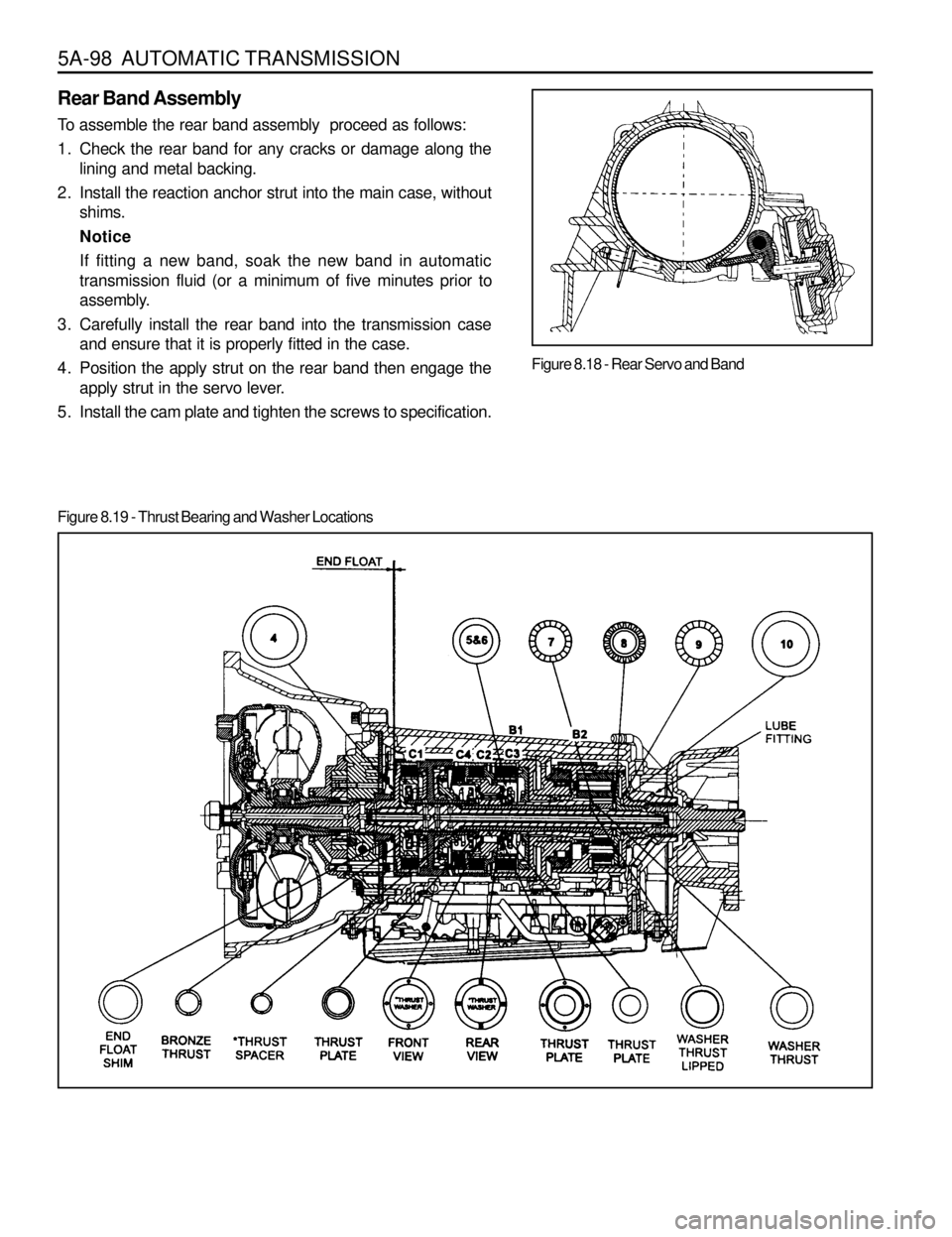

Rear Band Assembly

To assemble the rear band assembly proceed as follows:

1. Check the rear band for any cracks or damage along the

lining and metal backing.

2. Install the reaction anchor strut into the main case, without

shims.

Notice

If fitting a new band, soak the new band in automatic

transmission fluid (or a minimum of five minutes prior to

assembly.

3. Carefully install the rear band into the transmission case

and ensure that it is properly fitted in the case.

4. Position the apply strut on the rear band then engage the

apply strut in the servo lever.

5. Install the cam plate and tighten the screws to specification.

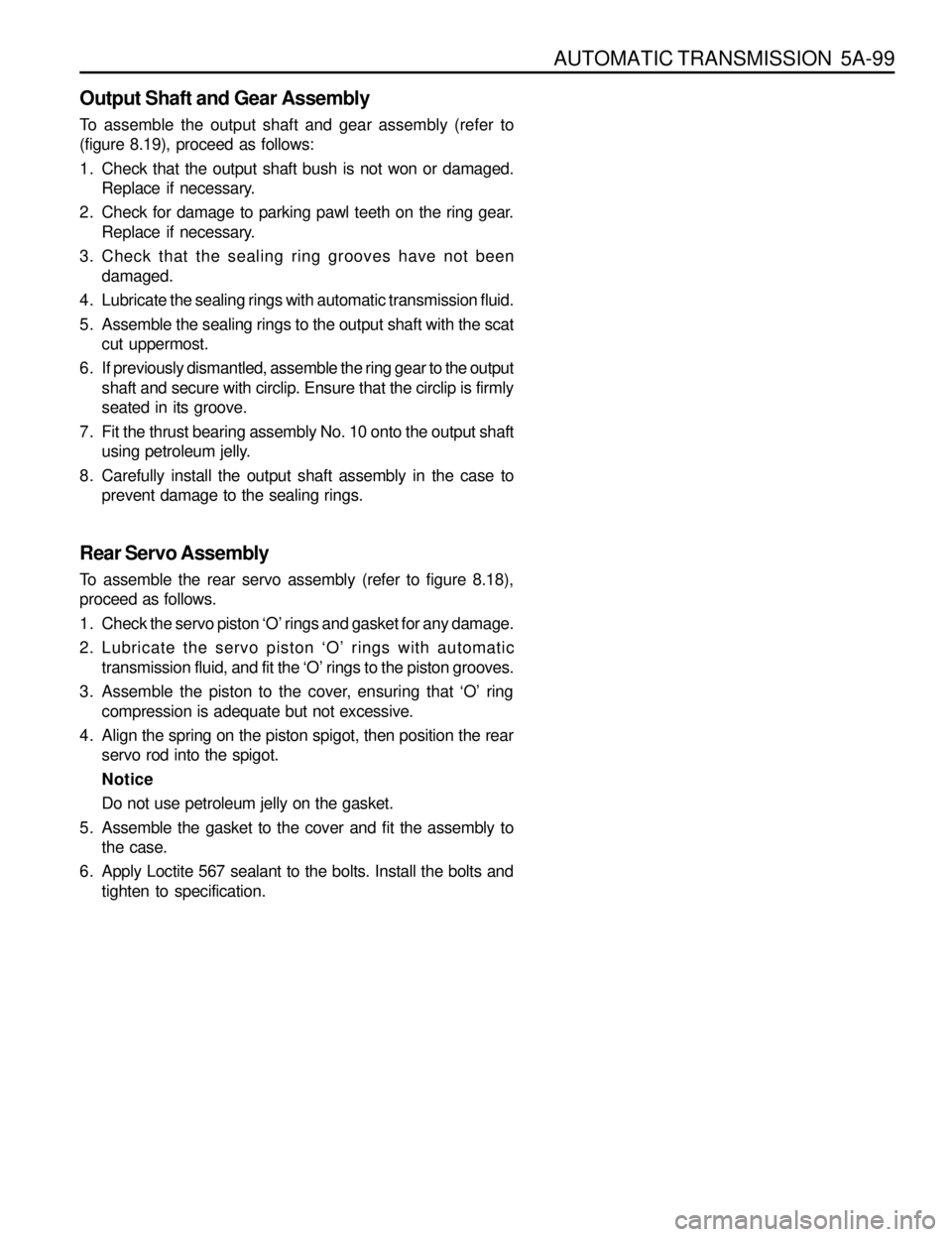

Figure 8.19 - Thrust Bearing and Washer LocationsFigure 8.18 - Rear Servo and Band

Page 1076 of 1463

AUTOMATIC TRANSMISSION 5A-99

Output Shaft and Gear Assembly

To assemble the output shaft and gear assembly (refer to

(figure 8.19), proceed as follows:

1. Check that the output shaft bush is not won or damaged.

Replace if necessary.

2. Check for damage to parking pawl teeth on the ring gear.

Replace if necessary.

3. Check that the sealing ring grooves have not been

damaged.

4. Lubricate the sealing rings with automatic transmission fluid.

5. Assemble the sealing rings to the output shaft with the scat

cut uppermost.

6. If previously dismantled, assemble the ring gear to the output

shaft and secure with circlip. Ensure that the circlip is firmly

seated in its groove.

7. Fit the thrust bearing assembly No. 10 onto the output shaft

using petroleum jelly.

8. Carefully install the output shaft assembly in the case to

prevent damage to the sealing rings.

Rear Servo Assembly

To assemble the rear servo assembly (refer to figure 8.18),

proceed as follows.

1. Check the servo piston ‘O’ rings and gasket for any damage.

2. Lubricate the servo piston ‘O’ rings with automatic

transmission fluid, and fit the ‘O’ rings to the piston grooves.

3. Assemble the piston to the cover, ensuring that ‘O’ ring

compression is adequate but not excessive.

4. Align the spring on the piston spigot, then position the rear

servo rod into the spigot.

Notice

Do not use petroleum jelly on the gasket.

5. Assemble the gasket to the cover and fit the assembly to

the case.

6. Apply Loctite 567 sealant to the bolts. Install the bolts and

tighten to specification.

Page 1077 of 1463

5A-100 AUTOMATIC TRANSMISSION

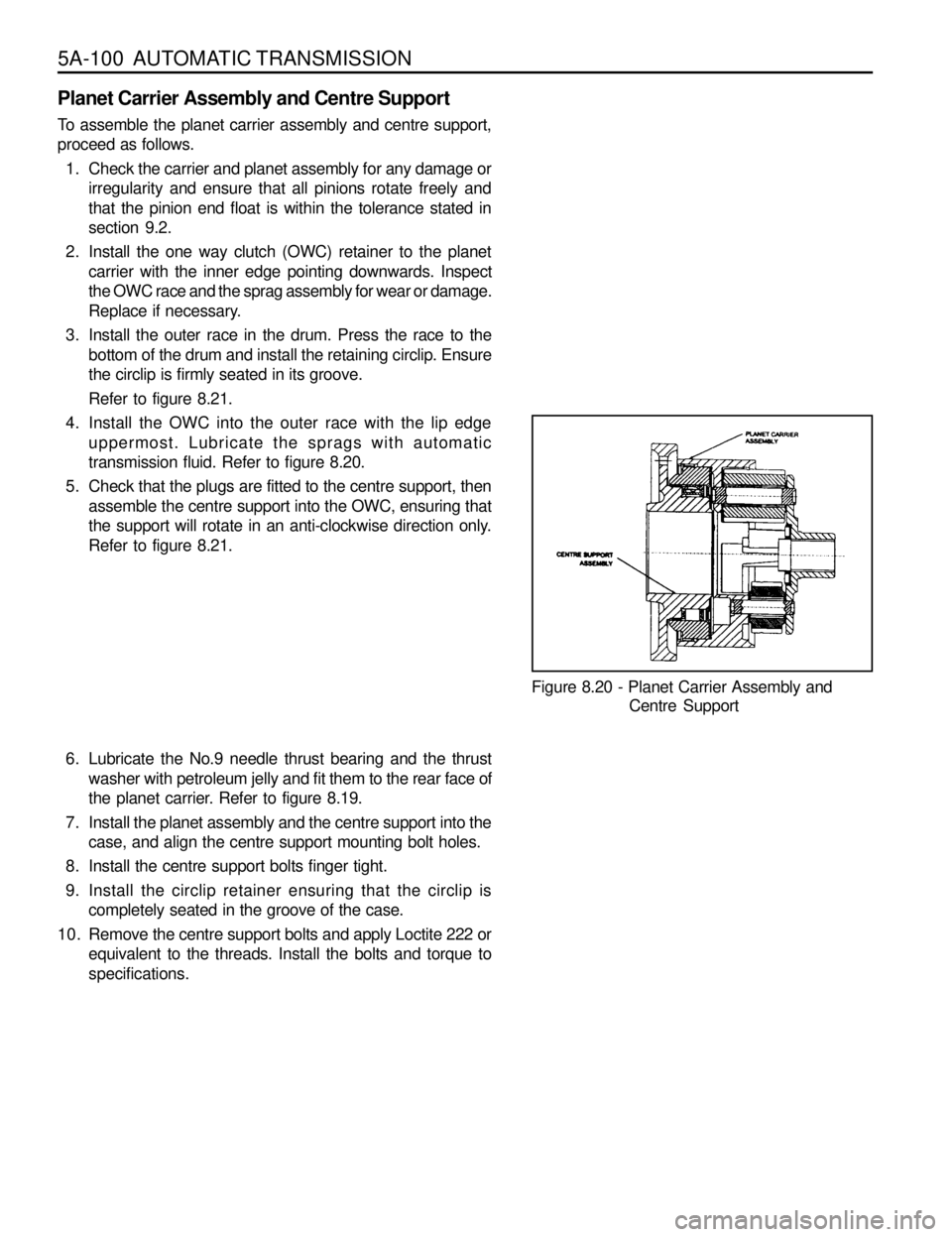

Planet Carrier Assembly and Centre Support

To assemble the planet carrier assembly and centre support,

proceed as follows.

1. Check the carrier and planet assembly for any damage or

irregularity and ensure that all pinions rotate freely and

that the pinion end float is within the tolerance stated in

section 9.2.

2. Install the one way clutch (OWC) retainer to the planet

carrier with the inner edge pointing downwards. Inspect

the OWC race and the sprag assembly for wear or damage.

Replace if necessary.

3. Install the outer race in the drum. Press the race to the

bottom of the drum and install the retaining circlip. Ensure

the circlip is firmly seated in its groove.

Refer to figure 8.21.

4. Install the OWC into the outer race with the lip edge

uppermost. Lubricate the sprags with automatic

transmission fluid. Refer to figure 8.20.

5. Check that the plugs are fitted to the centre support, then

assemble the centre support into the OWC, ensuring that

the support will rotate in an anti-clockwise direction only.

Refer to figure 8.21.

Figure 8.20 - Planet Carrier Assembly and

Centre Support

6. Lubricate the No.9 needle thrust bearing and the thrust

washer with petroleum jelly and fit them to the rear face of

the planet carrier. Refer to figure 8.19.

7. Install the planet assembly and the centre support into the

case, and align the centre support mounting bolt holes.

8. Install the centre support bolts finger tight.

9. Install the circlip retainer ensuring that the circlip is

completely seated in the groove of the case.

10. Remove the centre support bolts and apply Loctite 222 or

equivalent to the threads. Install the bolts and torque to

specifications.

Page 1078 of 1463

AUTOMATIC TRANSMISSION 5A-101

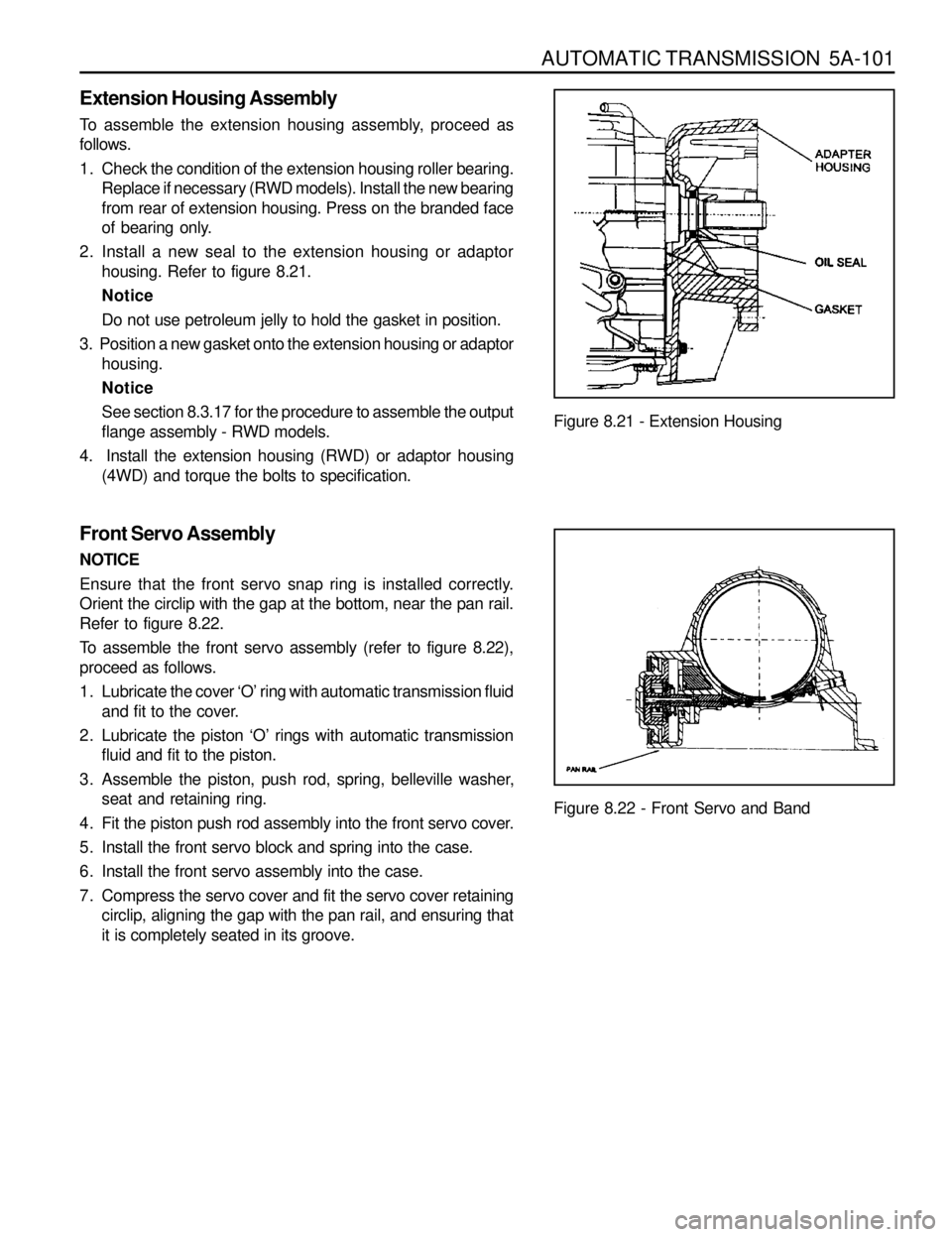

Extension Housing Assembly

To assemble the extension housing assembly, proceed as

follows.

1. Check the condition of the extension housing roller bearing.

Replace if necessary (RWD models). Install the new bearing

from rear of extension housing. Press on the branded face

of bearing only.

2. Install a new seal to the extension housing or adaptor

housing. Refer to figure 8.21.

Notice

Do not use petroleum jelly to hold the gasket in position.

3. Position a new gasket onto the extension housing or adaptor

housing.

Notice

See section 8.3.17 for the procedure to assemble the output

flange assembly - RWD models.

4. Install the extension housing (RWD) or adaptor housing

(4WD) and torque the bolts to specification.

Front Servo Assembly

NOTICE

Ensure that the front servo snap ring is installed correctly.

Orient the circlip with the gap at the bottom, near the pan rail.

Refer to figure 8.22.

To assemble the front servo assembly (refer to figure 8.22),

proceed as follows.

1. Lubricate the cover ‘O’ ring with automatic transmission fluid

and fit to the cover.

2. Lubricate the piston ‘O’ rings with automatic transmission

fluid and fit to the piston.

3. Assemble the piston, push rod, spring, belleville washer,

seat and retaining ring.

4. Fit the piston push rod assembly into the front servo cover.

5. Install the front servo block and spring into the case.

6. Install the front servo assembly into the case.

7. Compress the servo cover and fit the servo cover retaining

circlip, aligning the gap with the pan rail, and ensuring that

it is completely seated in its groove.

Figure 8.21 - Extension Housing

Figure 8.22 - Front Servo and Band

Page 1079 of 1463

5A-102 AUTOMATIC TRANSMISSION

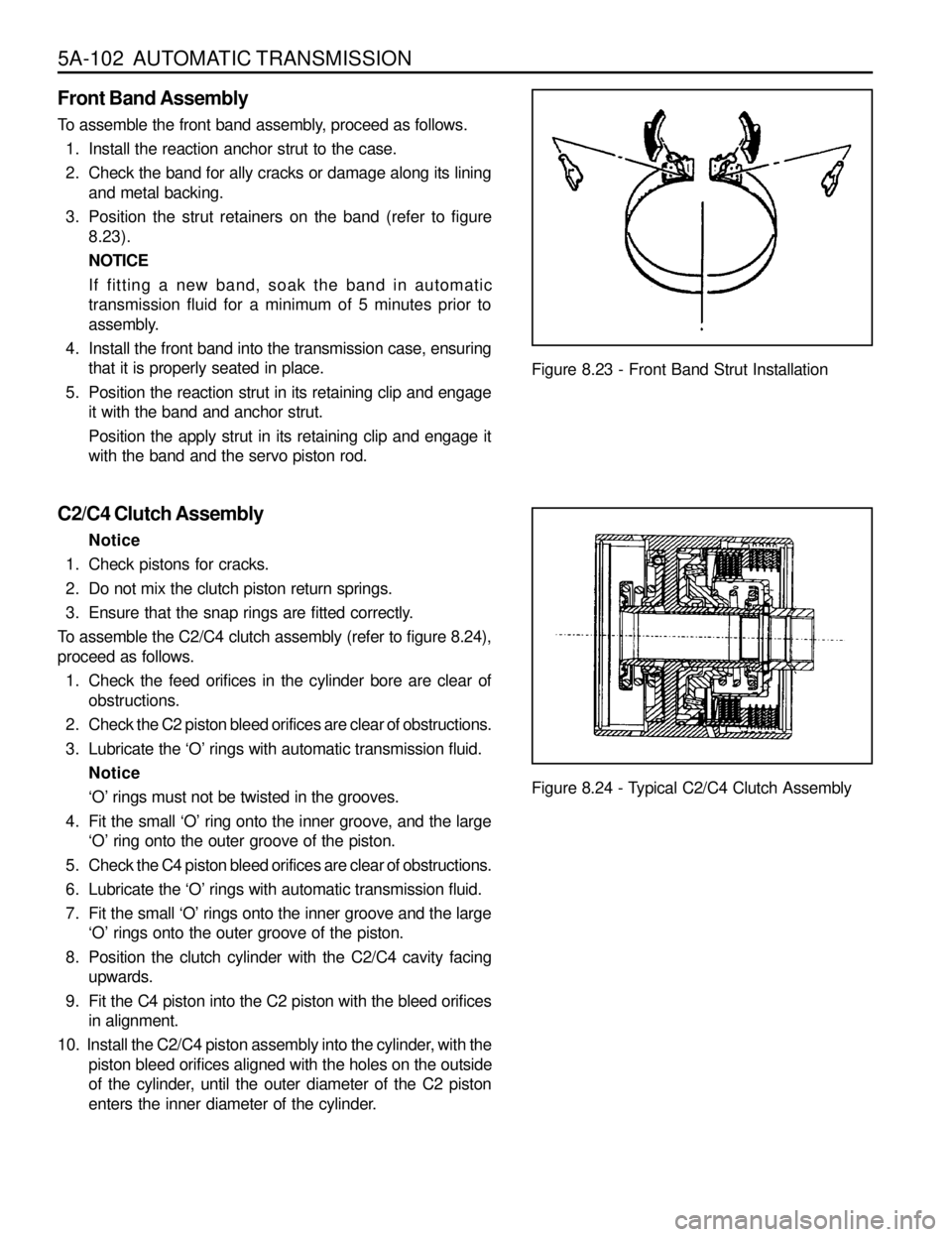

Front Band Assembly

To assemble the front band assembly, proceed as follows.

1. Install the reaction anchor strut to the case.

2. Check the band for ally cracks or damage along its lining

and metal backing.

3. Position the strut retainers on the band (refer to figure

8.23).

NOTICE

If fitting a new band, soak the band in automatic

transmission fluid for a minimum of 5 minutes prior to

assembly.

4. Install the front band into the transmission case, ensuring

that it is properly seated in place.

5. Position the reaction strut in its retaining clip and engage

it with the band and anchor strut.

Position the apply strut in its retaining clip and engage it

with the band and the servo piston rod.

C2/C4 Clutch Assembly

Notice

1. Check pistons for cracks.

2. Do not mix the clutch piston return springs.

3. Ensure that the snap rings are fitted correctly.

To assemble the C2/C4 clutch assembly (refer to figure 8.24),

proceed as follows.

1. Check the feed orifices in the cylinder bore are clear of

obstructions.

2. Check the C2 piston bleed orifices are clear of obstructions.

3. Lubricate the ‘O’ rings with automatic transmission fluid.

Notice

‘O’ rings must not be twisted in the grooves.

4. Fit the small ‘O’ ring onto the inner groove, and the large

‘O’ ring onto the outer groove of the piston.

5. Check the C4 piston bleed orifices are clear of obstructions.

6. Lubricate the ‘O’ rings with automatic transmission fluid.

7. Fit the small ‘O’ rings onto the inner groove and the large

‘O’ rings onto the outer groove of the piston.

8. Position the clutch cylinder with the C2/C4 cavity facing

upwards.

9. Fit the C4 piston into the C2 piston with the bleed orifices

in alignment.

10. Install the C2/C4 piston assembly into the cylinder, with the

piston bleed orifices aligned with the holes on the outside

of the cylinder, until the outer diameter of the C2 piston

enters the inner diameter of the cylinder.

Figure 8.23 - Front Band Strut Installation

Figure 8.24 - Typical C2/C4 Clutch Assembly