transmission fluid SSANGYONG MUSSO 1998 Workshop Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1080 of 1463

AUTOMATIC TRANSMISSION 5A-103

11. Assemble the piston return spring to the piston, and fit the

spring retainer over the spring.

Notice

The wire diameter of this spring is 4.3 mm.

12. Using special tool No. 0555-331899, compress the spring

sufficiently to enable the installation of the retaining circlip

ensuring that the circlip is firmly seated in its groove, then

remove the tool.

13. Check the C1 piston check valves are not damaged and

are free to move, and that the cylinder feed orifices are

clear of obstructions.

14. Lubricate the’0’rings with automatic transmission fluid and

fit them to their respective grooves.

Notice

‘O’ rings must not be twisted in the grooves.

15. Position the cylinder with the C1 cavity upwards. Install the

piston into the cylinder until the outer diameter of the piston

enters the inner diameter of the cylinder.

16. Install the spring and spring retainer onto the piston.

Notice

The wire diameter of this spring is 5.26 mm.

17. Using special tool No. 0555-331899, compress the spring

sufficiently to enable the installation of the retaining circlip

ensuring that the circlip is firmly seated in its groove, then

remove the tool.

18. Install the C2 wave washer into the cylinder with the crest

of one wave covering one of the bleed orifices in the C2

piston.

19. Measure and record the thickness of the flange of the C2

sleeve. Refer to figure 8.25.

20. Install the C4 clutch plates and wave washer into the C2

actuating sleeve, with the rounded edge of the steel plates

down, in the following sequence:

lSteel plate (selective)

lFriction disc

lSteel plate

lFriction disc

lSteel plate

lFriction disc

lSteel plate

lWave washer

Page 1082 of 1463

AUTOMATIC TRANSMISSION 5A-105

21. Holding the cylinder horizontal, install the sleeve and clutch

plate assembly into the cylinder, with the crest of one wave

of the washer In line with one of the holes in the outside of

the cylinder, until the sleeve contacts the C2 wave washer.

22. Check the C4 clutch pack clearance using special tool No.

0555-331900. Refer to figure 8.25.

Notice

With the C2 wave spring compressed, and the clutch Pack

supporting a 2 k9 weight, the dimension from the underside

of the C2 pressure plate to the selective steel is to be

between 1.4- 1.8 mm. If the clutch is to be gauged from

the top of the pressure plate, then the dimension is to be

the actual thickness of the pressure plate plus 1.4-1.8 mm.

23. Use selective plates to achieve the correct specification. If

new friction plates are being fitted, remove the clutch pack

and soak the friction plates in ATF for a minimum of 5

minutes prior to reassembly.

Notice

The clutch pack clearance must be taken before the

elements are soaked in Automatic Transmission Fluid

(ATF).

24. Reassemble the sleeve and clutch pack into the cylinder.

Observe the alignment of the wave washer to the hole in

the cylinder.

25. Install the C2 clutch plates in the cylinder in the following

sequence:

lFriction disc

lSteel plate

lFriction disc

lSteel plate

lSteel plate - 0574-000001, 0574-000003,

0574-000004, 0574-000005, 0574-000020,

0574-000021, or friction disc -0574-000002

lSteel plate (selective)

lFriction disc

lSteel plate (selective)

lFriction disc

Page 1084 of 1463

AUTOMATIC TRANSMISSION 5A-107

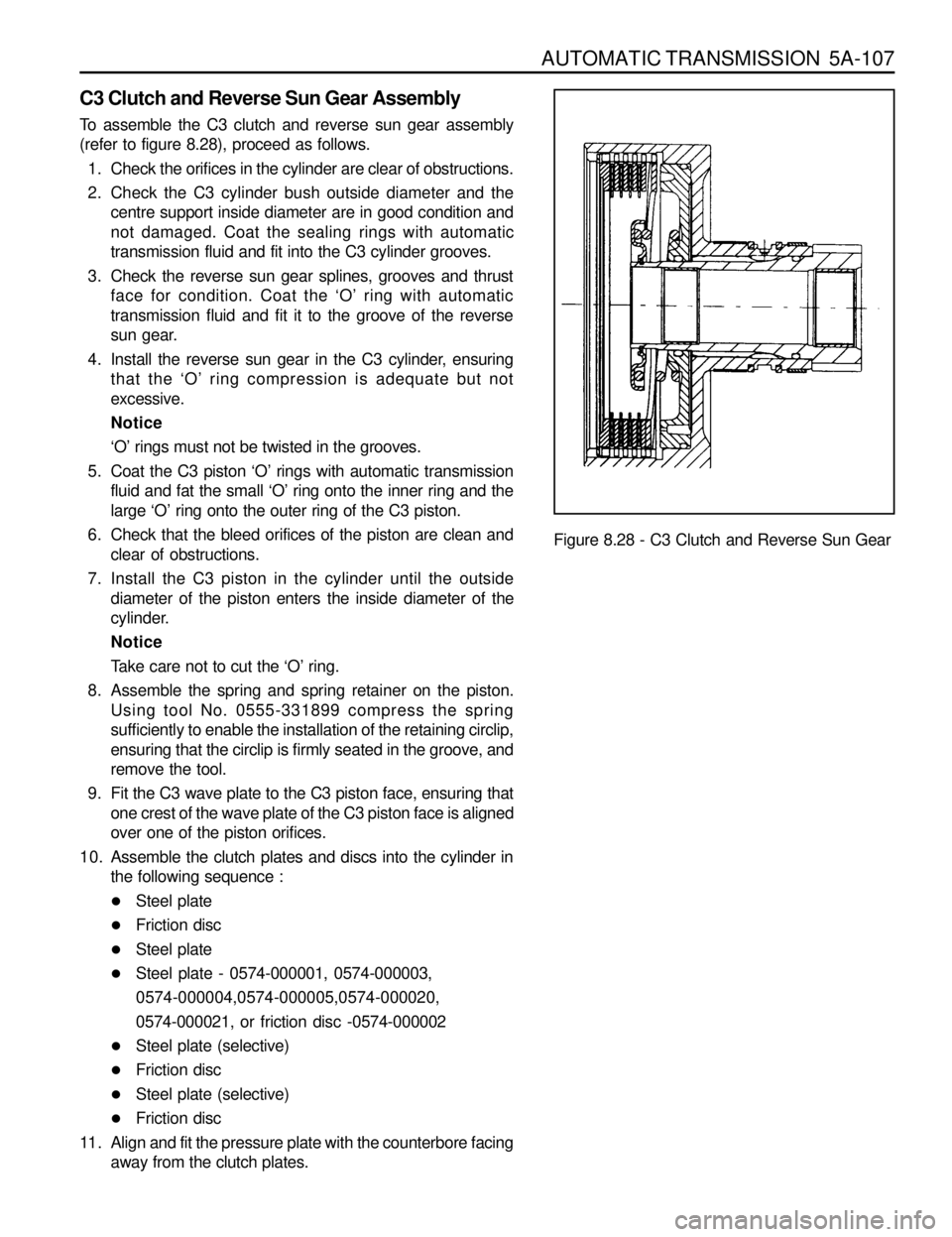

C3 Clutch and Reverse Sun Gear Assembly

To assemble the C3 clutch and reverse sun gear assembly

(refer to figure 8.28), proceed as follows.

1. Check the orifices in the cylinder are clear of obstructions.

2. Check the C3 cylinder bush outside diameter and the

centre support inside diameter are in good condition and

not damaged. Coat the sealing rings with automatic

transmission fluid and fit into the C3 cylinder grooves.

3. Check the reverse sun gear splines, grooves and thrust

face for condition. Coat the ‘O’ ring with automatic

transmission fluid and fit it to the groove of the reverse

sun gear.

4. Install the reverse sun gear in the C3 cylinder, ensuring

that the ‘O’ ring compression is adequate but not

excessive.

Notice

‘O’ rings must not be twisted in the grooves.

5. Coat the C3 piston ‘O’ rings with automatic transmission

fluid and fat the small ‘O’ ring onto the inner ring and the

large ‘O’ ring onto the outer ring of the C3 piston.

6. Check that the bleed orifices of the piston are clean and

clear of obstructions.

7. Install the C3 piston in the cylinder until the outside

diameter of the piston enters the inside diameter of the

cylinder.

Notice

Take care not to cut the ‘O’ ring.

8. Assemble the spring and spring retainer on the piston.

Using tool No. 0555-331899 compress the spring

sufficiently to enable the installation of the retaining circlip,

ensuring that the circlip is firmly seated in the groove, and

remove the tool.

9. Fit the C3 wave plate to the C3 piston face, ensuring that

one crest of the wave plate of the C3 piston face is aligned

over one of the piston orifices.

10. Assemble the clutch plates and discs into the cylinder in

the following sequence :

lSteel plate

lFriction disc

lSteel plate

lSteel plate - 0574-000001, 0574-000003,

0574-000004,0574-000005,0574-000020,

0574-000021, or friction disc -0574-000002

lSteel plate (selective)

lFriction disc

lSteel plate (selective)

lFriction disc

11. Align and fit the pressure plate with the counterbore facing

away from the clutch plates.Figure 8.28 - C3 Clutch and Reverse Sun Gear

Page 1085 of 1463

5A-108 AUTOMATIC TRANSMISSION

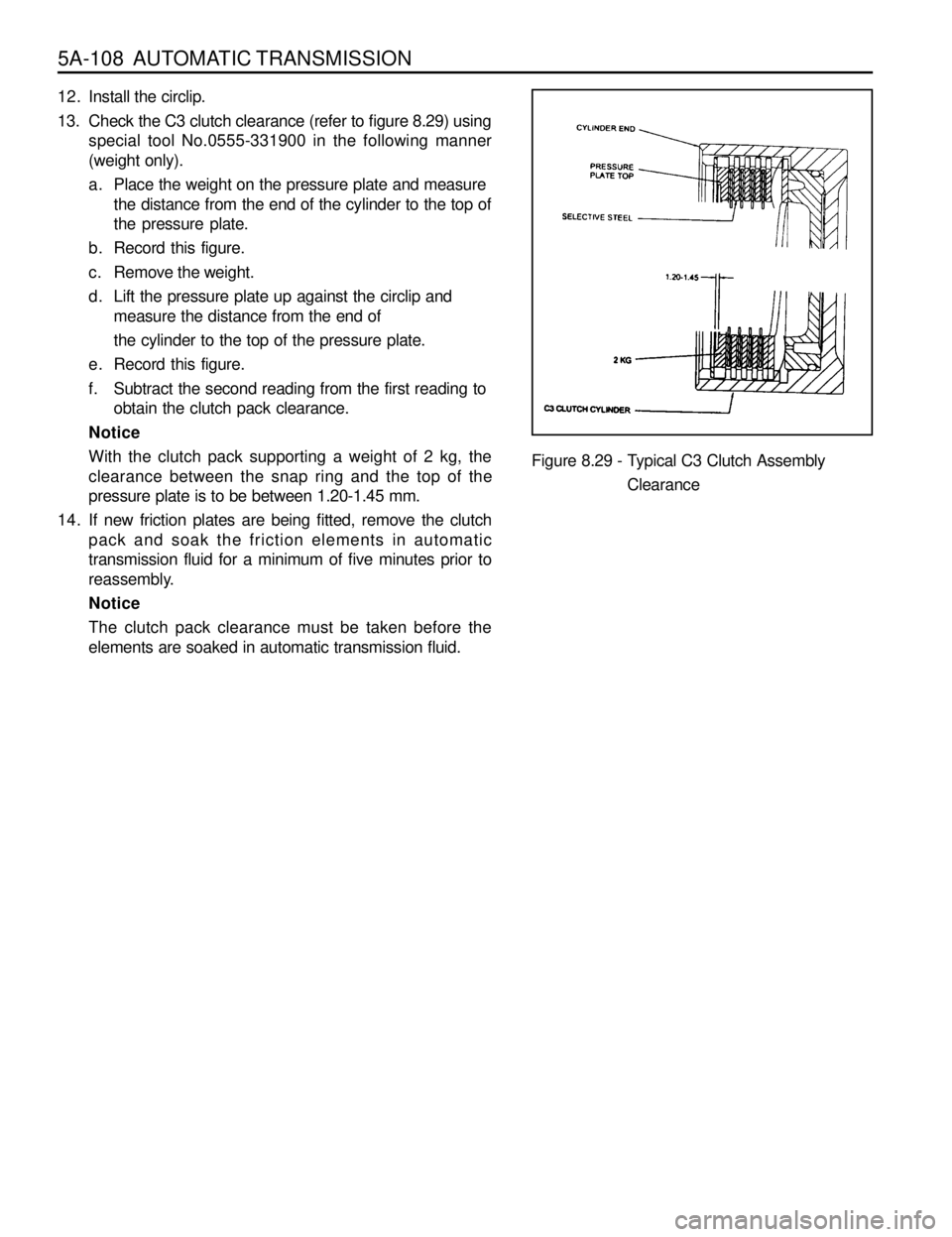

12. Install the circlip.

13. Check the C3 clutch clearance (refer to figure 8.29) using

special tool No.0555-331900 in the following manner

(weight only).

a. Place the weight on the pressure plate and measure

the distance from the end of the cylinder to the top of

the pressure plate.

b. Record this figure.

c. Remove the weight.

d. Lift the pressure plate up against the circlip and

measure the distance from the end of

the cylinder to the top of the pressure plate.

e. Record this figure.

f. Subtract the second reading from the first reading to

obtain the clutch pack clearance.

Notice

With the clutch pack supporting a weight of 2 kg, the

clearance between the snap ring and the top of the

pressure plate is to be between 1.20-1.45 mm.

14. If new friction plates are being fitted, remove the clutch

pack and soak the friction elements in automatic

transmission fluid for a minimum of five minutes prior to

reassembly.

Notice

The clutch pack clearance must be taken before the

elements are soaked in automatic transmission fluid.Figure 8.29 - Typical C3 Clutch Assembly

Clearance

Page 1087 of 1463

5A-110 AUTOMATIC TRANSMISSION

C1 Clutch Overdrive Shaft and Input Shaft

Assembly

Notice

1. Ensure that the snap rings are fitted correctly.

2. Check pistons for cracks, especially the C1 piston.

3. Do not mix clutch piston return springs.

4. If the C1/C2 clutch packs separate from the C3 clutch pack,

make sure the No. 6 bearing doesn’t drop out of the bearing

retainer.

To assemble the C1 clutch overdrive shaft and input shaft

assembly, proceed as follows:

1. Check the overdrive shaft grooves for any defect.

2. Coat the sealing rings, large and small, with petroleum jelly

and fit them to the overdrive shaft. The sealing rings may

be held in place with a small amount of petroleum jelly.

3. Assemble the clutch plate and disc into the cylinder in the

following sequence:

lsteel plate

lfriction disc

lsteel plate

lfriction disc

lsteel plate

lsteel plate - 0574-GOOGOl, 0574-000003,

0574-000004, 0574-000005, 0574-000020,

0574-000021, or friction disc -0574-000002

lsteel plate (selective)

lfriction disc

lsteel plate (selective)

lfriction disc

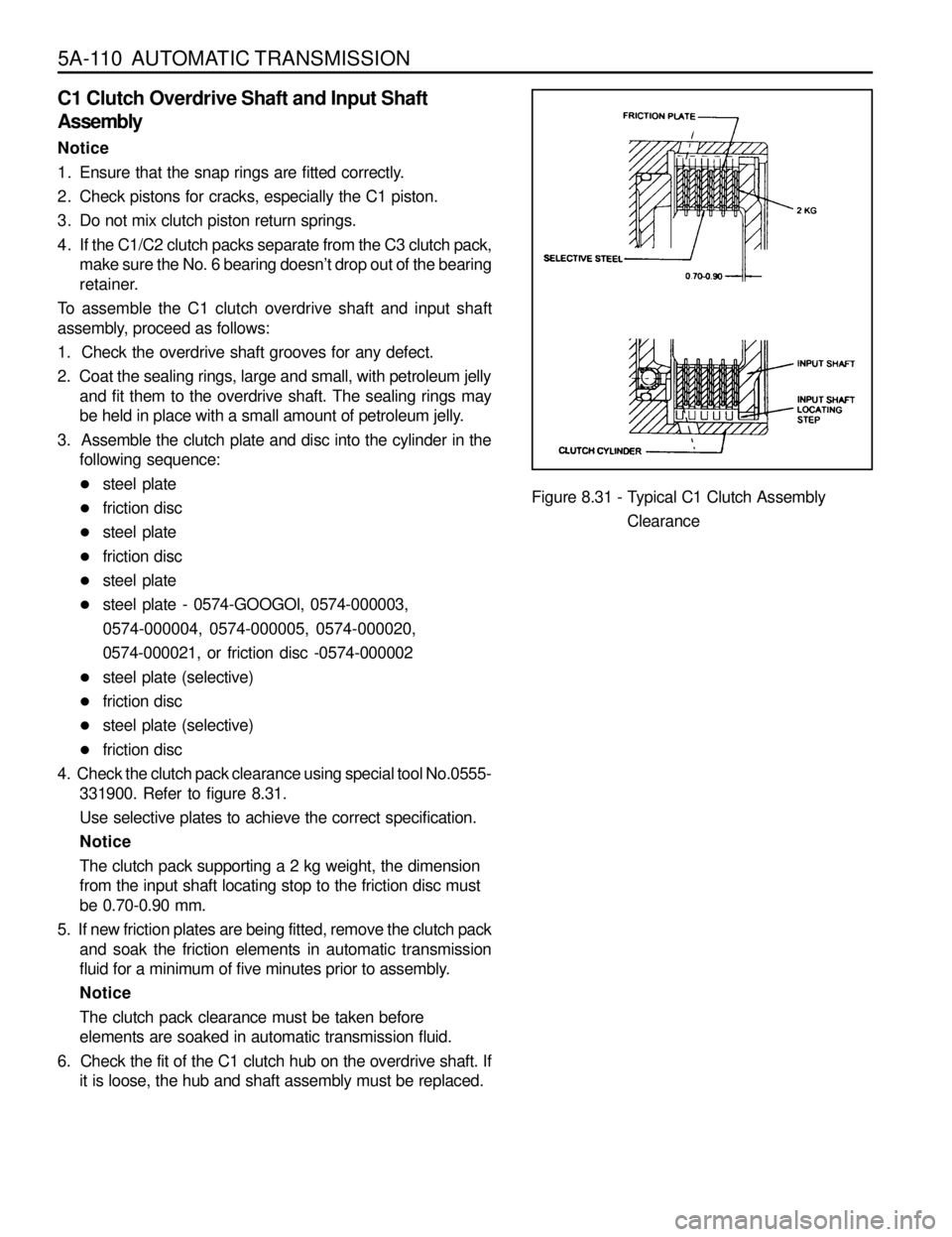

4. Check the clutch pack clearance using special tool No.0555-

331900. Refer to figure 8.31.

Use selective plates to achieve the correct specification.

Notice

The clutch pack supporting a 2 kg weight, the dimension

from the input shaft locating stop to the friction disc must

be 0.70-0.90 mm.

5. If new friction plates are being fitted, remove the clutch pack

and soak the friction elements in automatic transmission

fluid for a minimum of five minutes prior to assembly.

Notice

The clutch pack clearance must be taken before

elements are soaked in automatic transmission fluid.

6. Check the fit of the C1 clutch hub on the overdrive shaft. If

it is loose, the hub and shaft assembly must be replaced.Figure 8.31 - Typical C1 Clutch Assembly

Clearance

Page 1089 of 1463

5A-112 AUTOMATIC TRANSMISSION

Pump Cover and Converter Support

Notice

1. Do not wash the nose of solenoids in solvent.

2. Ensure that the correct ‘O’ ring is fitted for the application.

3. Do not mix up the low first blow-off and the torque converter

blow-off ball springs.

4. Be careful not to damage the needle bearings on the

assembly. Avoid any axial impact loads during assembly.

5. Check the transmission end float. This will help to detect

any missing parts or incorrect assembly.

Notice

Figure 8.35 shows the orientation of the cross- sections for

figures 8.36 to 8.42.

To assemble the pump cover and converter support

(refer to figures 8.34 and 8.35), proceed as follows.

1. Check the pump body for any damage, chips or irregularity.

Check that the bush is firmly staked in the drive gear.

2. Install the seal flush with the front face of the pump body.

3. Lubricate the pump bush, and the drive and driven gears,

with automatic transmission fluid.

4. Install the pump driven gear and the pump drive gear into

the pump body.

5. Using a straight edge and thickness gauge, check that the

clearance between pump face and gears is 0.04 - 0.018

mm.

6. Lubricate the pump body ‘O’ ring with automatic transmission

fluid and fit it to the pump body. Put the pump body to one

side.

7. Ensure that the pump cover cavities, ports and holes are

clean and free of any obstruction.

8. Lubricate all loose parts with automatic transmission fluid

prior to assembly.Figure 8.34 - Pump, Cover and Converter

Support

Figure 8.35 - Pump Cover Assembly

Page 1103 of 1463

5A-126 AUTOMATIC TRANSMISSION

Oil Filter and Pan Assembly

Notice

1. Replace the filter whenever rebuilding a transmission where a significant amount of mechanical damage has

occurred.

2. To aid the assembly of the pan gasket, use a small amount of Vaseline at the pan/gasket interface. This ensures

that the gasket remains on the pan ridge. Do not over torque pan bolts as this may distort the pan and cause

leaks.

3. Ensure that the internal line pressure plus in the valve body is fitted.

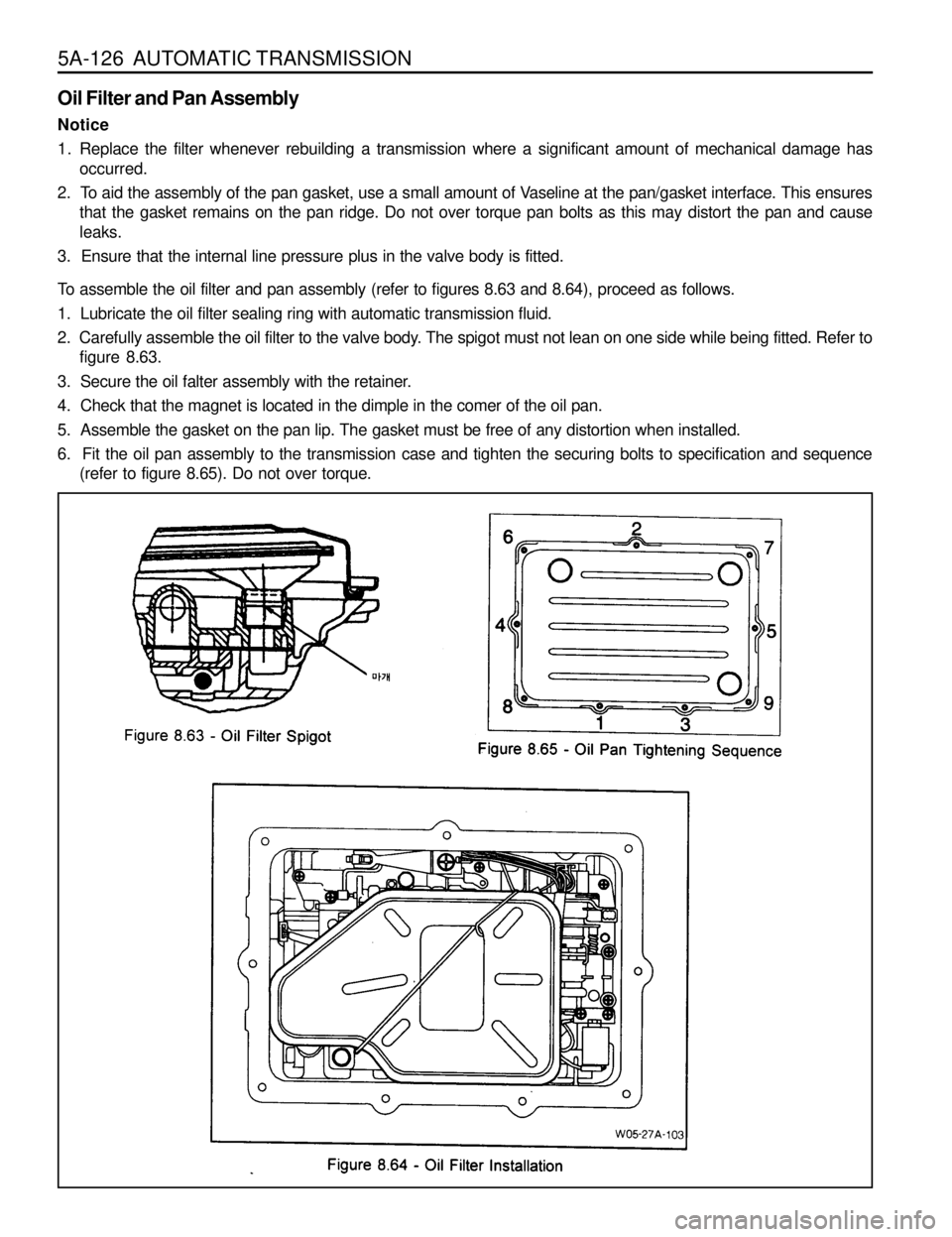

To assemble the oil filter and pan assembly (refer to figures 8.63 and 8.64), proceed as follows.

1. Lubricate the oil filter sealing ring with automatic transmission fluid.

2. Carefully assemble the oil filter to the valve body. The spigot must not lean on one side while being fitted. Refer to

figure 8.63.

3. Secure the oil falter assembly with the retainer.

4. Check that the magnet is located in the dimple in the comer of the oil pan.

5. Assemble the gasket on the pan lip. The gasket must be free of any distortion when installed.

6. Fit the oil pan assembly to the transmission case and tighten the securing bolts to specification and sequence

(refer to figure 8.65). Do not over torque.

Page 1254 of 1463

TRANSFER CASE (TOD) 5D2-47

Assembly Procedure

Assembly

Before assembly, lubricate all parts with Automatic Transmission

Fluid or equivalent.

1. If removed, drive the bearing into the front output case bore.

Drive the bearing in staight, making sure it is not cocked in

the bore. Install the internal snap ring that retains the bearing

to the front case.

2. If removed, install the front yoke to flange seal in the front

case bore.

3. If removed, install the yoke to flange seal into the mounting

adapter bore.

4 Sun Gear

5 Thrust Plate

6 Input Shaft

7 Thrust Washer

8 Bearing

9 External Snap Ring

10 Internal Snap Ring

4. If the input shaft needle bearing and bushing were removed,

install a new bearing and bushing as detailed in the following

steps:

Press a new needle bearing, then a new bushing in the

input shaft as follows:

a. Position the input shaft on Axle Bearing/Seal Plate or

equivalent, and Pinion Bearing Cone Replacer as a

spacer.

b. Press a new needle bearing into the end of the input

shaft until it seats in the input shaft.

c. Press in a new bushing.

5. The recessed face of the sun gear and the snap ring groove

on the bearing outer race should be toward the rear of the

transfer case. The stepped face of the thrust washer should

face toward the bearing.

Slide the sun gear, thrust plate and thrust washer into

position on the input shaft. Press the bearing over the input

shaft. Install the external snap ring to the input shaft.

Page 1255 of 1463

5D2-48 TRANSFER CASE (TOD)

6. Install the front planet to the sun gear and input shaft.

Install the internal snap ring to the planetary carrier.

7. Place the tanged snap ring in the case. Expand snap ring

with snap ring pliers and install planetary carrier assembly.

Check installation by holding the case and carefully tapping

the face of the input shaft against a wooden block to make

sure the snap ring is installed.

8. Remove all traces of gasket sealant from the front case

and mounting adapter mating surfaces. Install a bead of

gasket sealant on the surface of the front case.

9. Install the high-low shift fork and high-low collar as an

assembly into the front planet.

Notice

Make sure that the nylon wear pads are installed on the

shift fork and snapped securely into place.

12 Rear Output Shaft

13 Oil Strainer

14 Coupling Hose

15 Hose Clamp

16 Pump Body

10. If new pump is used, align the flat of the output shaft and

the flat of the pump. Slide the pump onto the output shaft.

lDo not disassemble oil pump. It is serviced only as an

assembly. Check the pump to make sure the pump

rotates freely.

lDo not remove the plastic insert from the bore of the

new pump. Discard it after it slides out during pump

installation to the rear output shaft.

lWhile turning the output shaft, prime the pump through

the oil filter pickup tube or housing inlet hole with clean

Automatic Transmission Fluid or equivalent.

11. Inspect the outside surfaces and bore of the oil pump. If

there is no discoloration in the pump housing, gear or cover,

and the pump bore and the lube holes of the output shaft

show evidence of oil, the pump is working.

Page 1260 of 1463

TRANSFER CASE (TOD) 5D2-53

40. Install the rear case flange on the output shaft. Install the

rubber seal, output shaft yoke washer and nut. Tighten

the nut.

Tightening Torque 137 - 196 Nm

41. Install the drainplug and tighten.

42. Fill the transfer case with 1.4 liters of Automatic

Transmission Fluid or equivalent.

Notice

Fluid level should be just below the filler plug hole.

Tightening Torque 19 - 30 Nm

Tightening Torque 19 - 30 Nm 43. Install the fill pulg and tighten.

44. Install the transfer case as outlined in removal and

Installation, transfer case in the section.

Notice

Make sure proper drain and fill plugs are installed if case

is replaced.