SSANGYONG MUSSO 1998 Workshop Owner's Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owner's Manual

Page 210 of 1463

M161 ENGINE MECHANICAL 1B2-21

ALTERNATOR

Removal & Installation Procedure

1. Remove the drive belt.

2. Remove the alternator.

3. Unscrew the alternator carrier bolts (1,2,3) and remove the

carrier (4).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

Notice

Apply 3Nm of torque when mounting the bolt (1); apply 25 ±

2.5Nm of torque when mounting the bolts (2), and (3); and

then tighten the bolt (1) with 25 ± 2.5Nm of torque.

4. Installation should follow the removal procedure in the

reverse order. 1 Bolt (M8 X 40, 3 pieces).................22.5-27.5 Nm

2 Bolt (M8 X 70, 2 pieces).................22.5-27.5 Nm3 Bolt (M8 X 85, 1 piece)...................22.5-27.5 Nm

4 Alternator Bracket

Page 211 of 1463

1B2-22 M161 ENGINE MECHANICAL

POWER STEERING PUMP AND A/C BRACKET

Preceding Work : Removal of cooling fan and shroud

Removal of drive belt

1 Nut .................................................35.2-28.8 Nm

2 Washer

3 Belt Pulley

4 Bolt (M8 X 91, 2 pieces).................22.5-27.5 Nm

5 Power Steering Pump

6 Bracket

7 Washer

8 Bolt (M8 X 20, 2 pieces).................22.5-27.5 Nm9 Washer

10 Bolt (M8 X 105,4 pieces)................22.5-27.5 Nm

11 A/C Compressor

12 Bolt (M8 X 50, 5 pieces, M8 X 80,

5 pieces)........................................22.5-27.5 Nm

13 A/C Bracket

14 Vent Hose

15 Bracket Gasket...................................... Replace

Page 212 of 1463

M161 ENGINE MECHANICAL 1B2-23

Removal & Installation Procedure

1. Remove the belt pulley after removal of poly v-belt.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley counterclockwise as shown in the

figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 217 of 1463

1B2-28 M161 ENGINE MECHANICAL

POLY V-BELT

Preceding Work : Removal of cooling fan

1 Poly V-belt (2,155 mm)

2 Belt Tensioning Pulley

Removal & Installation Procedure

1. Release the belt tension by turning the stud on the cap with

12 sided wrench or spanner counterclockwise.

2. Remove the poly v-belt.

Notice

Check the belt for damage and tensioning pulley bearing

point for wear and replace them if necessary.

3. Install the belt after prying the tensioning pulley.

3 Belt Tensioner

Page 218 of 1463

M161 ENGINE MECHANICAL 1B2-29

Poly V-belt Arrangement

1 Belt Tensioning Pulley

2 Crankshaft Belt Pulley

3 A/C Compressor Pulley5 Alternator Pulley

7 Power Steering Pump Pulley

8 Water Pump Pulley

Page 221 of 1463

1B2-32 M161 ENGINE MECHANICAL

3. Pointed rib.

4. Belt cord visible in the base of rib.

POLY V-BELT INSPECTION

lMake marks on the belt with chalk.

lRotate the engine and check the belt for damage.

Notice

If one of the following types of damages is found, replace

the belt.

1. Rubber lumps in the base of rib.

2. Dirt or grit ingrained.

Page 222 of 1463

M161 ENGINE MECHANICAL 1B2-33

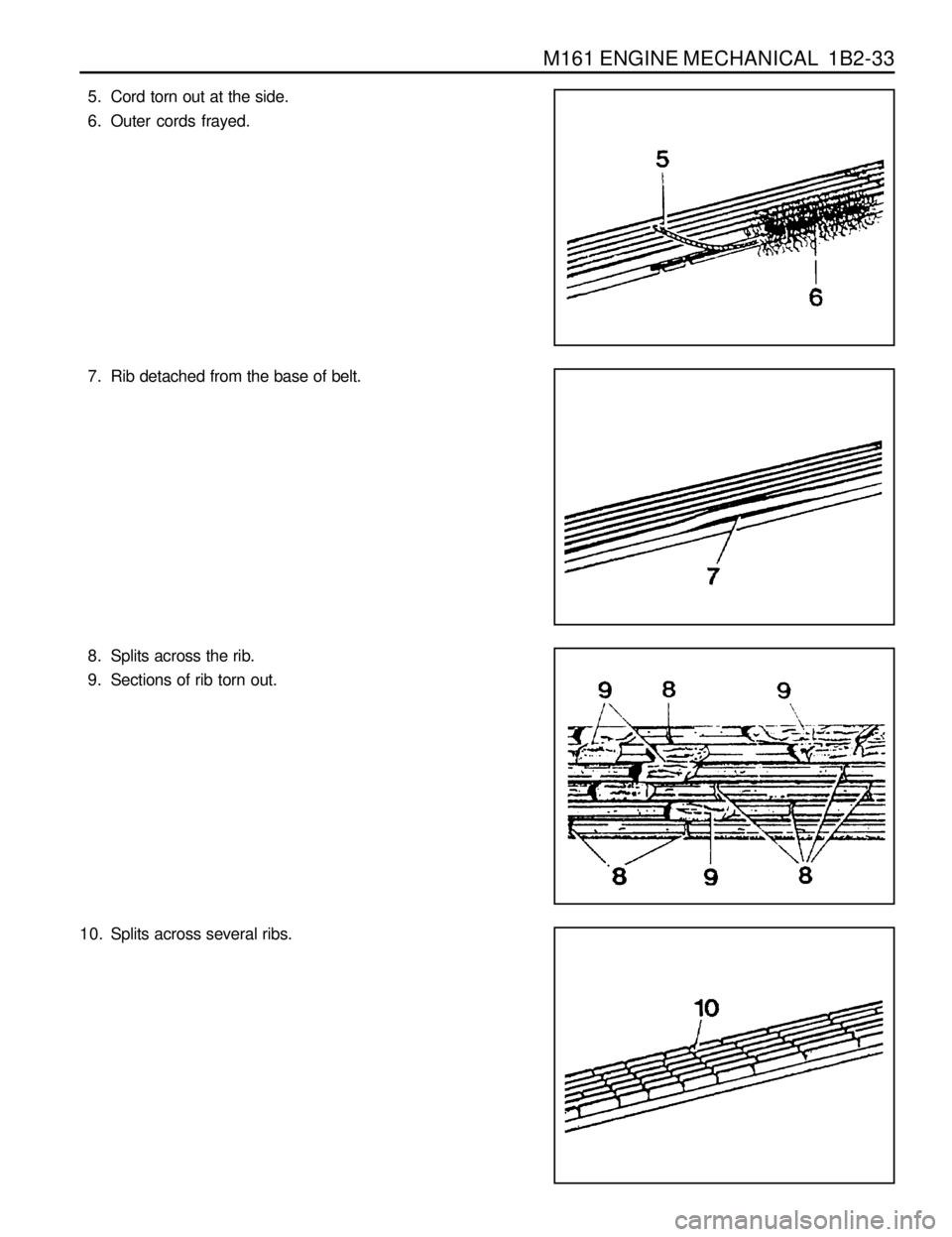

5. Cord torn out at the side.

6. Outer cords frayed.

7. Rib detached from the base of belt.

8. Splits across the rib.

9. Sections of rib torn out.

10. Splits across several ribs.

Page 223 of 1463

1B2-34 M161 ENGINE MECHANICAL

11. Splits across the back of the belt.

Page 234 of 1463

M161 ENGINE MECHANICAL 1B2-45

Tools Required

001 589 72 21 00 Torque Wrench

116 589 2 0 33 00 Sliding Hammer

116 589 01 34 00 Threaded Bolt

Removal & Installation Procedure

1. Remove the power steering belt pulley and A/C compressor

bracket.

2. Remove the oil line from power steering pump.

3. Rotate the crankshaft so that the piston of number, cylinder

is at ATDC20°

Sliding Hammer 116 589 20 33 00

Threaded Pin 116 589 02 34 00

4. Put the alignment marks (arrows) on the timing chain and

camshaft sprocket.

5. Remove the chain tensioner.

Installation Notice

Tightening Torque 78 - 88 Nm

6. Remove the intake and exhaust camshaft sprocket

(remove the camshaft adjuster assembly in E23 engine).

Installation Notice

Tightening Torque1st step 18 - 22 Nm

2nd step 85° - 95°

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

7. Remove the guide rail pin using the sliding hammer (02)

and the threaded pin (03).

Notice

Apply the sealant on guide rail pin when installation.

Page 235 of 1463

1B2-46 M161 ENGINE MECHANICAL

8. Unscrew the bolts (A).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

9. Remove the belt pulley and vibration damper.

Installation Notice (Center Bolt)

Tightening Torque1st step 180 - 220 Nm

2nd step 80° - 100°

10. Unscrew the bolts (1, 2) on timing gear case cover and

remove the timing gear case cover.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

Notice

Be careful not to damage the cylinder head gasket.

11. Remove the radial shaft seal

Notice

Installation note replace the seal with new one.

12. Clean the timing gear case cover and crankcase sealing

surface.

13. Replace the O-ring with new one and apply the sealant on

the sealing surface.

Notice

Be careful not to stain the oil chamber of chain tensioner

with the sealant.

14. Installation should follow the removal precedure in the

reverse order.

15. Warm up the engine and check for oil leaks.