belt SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 531 of 1463

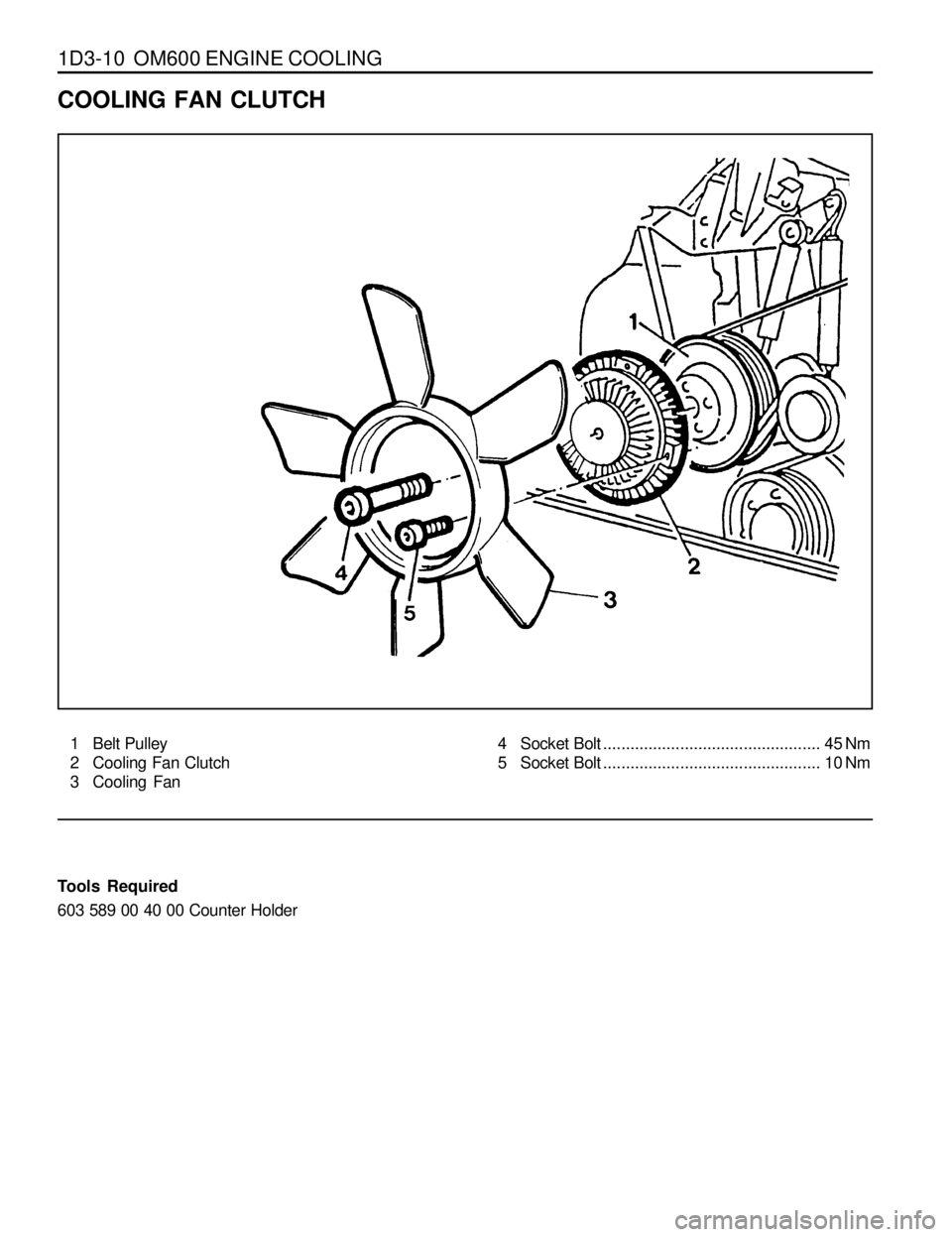

1D3-10 OM600 ENGINE COOLING

COOLING FAN CLUTCH

1 Belt Pulley

2 Cooling Fan Clutch

3 Cooling Fan4 Socket Bolt................................................ 45 Nm

5 Socket Bolt................................................ 10 Nm

Tools Required

603 589 00 40 00 Counter Holder

Page 542 of 1463

1E1-4 M162 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 554 of 1463

1E2-4 M161 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 568 of 1463

1E3-6 OM600 ENGINE ELECTRICAL

ALTERNATOR

Preceding Work : Removal of poly V-belt

1 Cooling Fan

2 Bolt............................................................45Nm

3 Bolt............................................................45Nm4 Alternator

5 Plug Connection

Page 742 of 1463

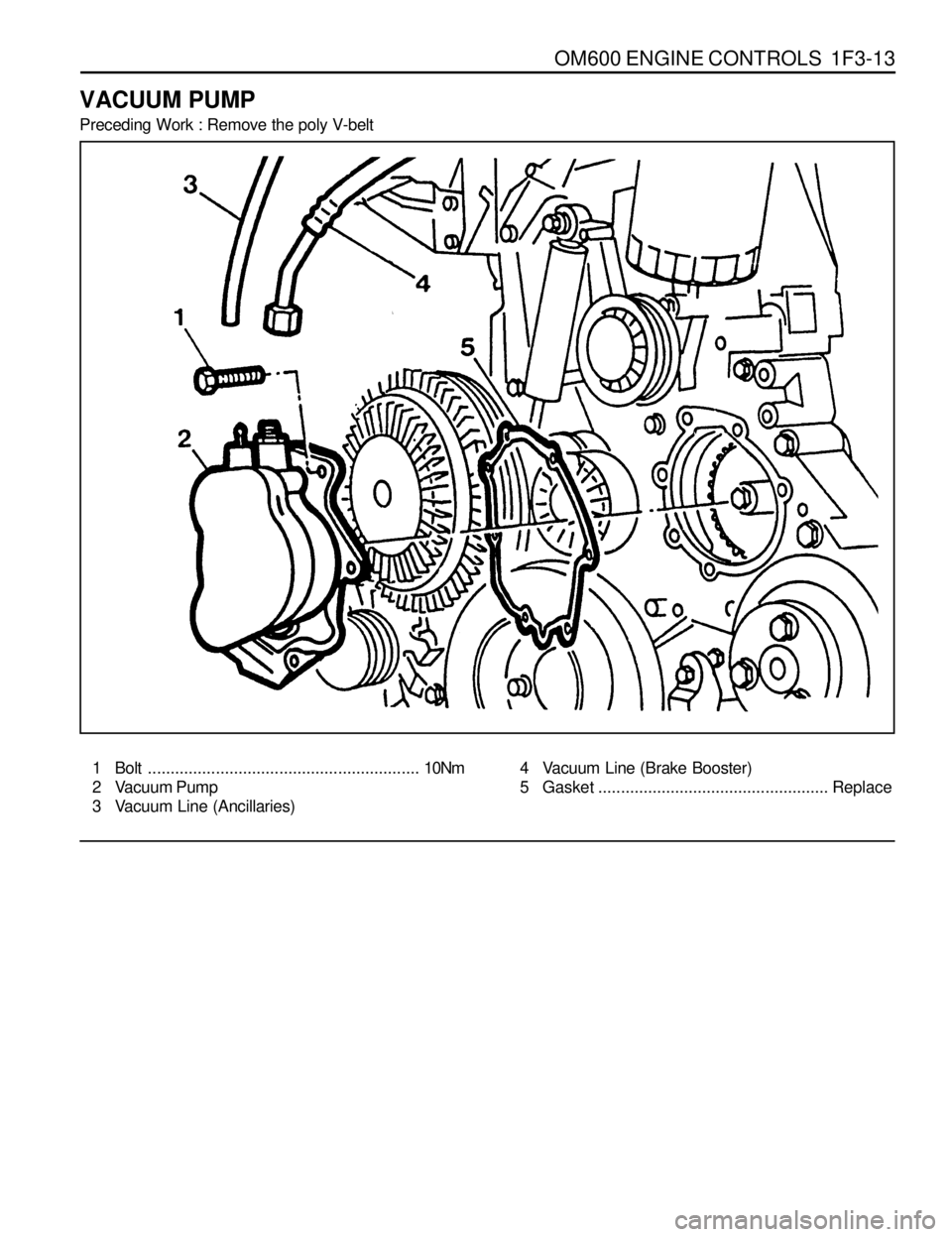

OM600 ENGINE CONTROLS 1F3-13

VACUUM PUMP

Preceding Work : Remove the poly V-belt

1 Bolt............................................................10Nm

2 Vacuum Pump

3 Vacuum Line (Ancillaries)4 Vacuum Line (Brake Booster)

5 Gasket ................................................... Replace

Page 830 of 1463

2B-2 WHEEL ALIGNMENT

DIAGNOSIS

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes.

Some of them are incorrect inflation pressures, lack of

regular rotation, poor driving habits, or improper wheel

alignment.

Rotate the tires if :

lThe front tire wear is different from the rear.

lThe left and right front tire wear is unequal.

lThe left and right rear tire wear is unequal, Check

wheel alignment if :

lThe left and right front tire wear is unequal.

lThe wear is uneven across the tread of either front

tire.

lThe front tire treads are scuffed with “feather” edges

on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built-in tread wear

indicators to show when the tires need replacement.

These indicators appear as bands when the tire tread

depth becomes shallow. Tire replacement is

recommended when the indicators appear in three or

more grooves at six locations.

Radial Tire Waddle

Waddle is side-to-side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire

or wheel.

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the

vehicle will shake from side to side or “waddle” if the

waddle tire is on the rear of the vehicle. From the driver’s

seat, it feels as though someone is pushing on the side

of the vehicle. If the faulty tire is on the front of the vehicle,

the waddle is more visual. The front sheet meld appears

to be moving back and forth, and the drivers seat feels

like the pivot point in the vehicle.

Waddle can be diagnosed using the method of

substituting known good tire and wheel assemblies on

the problem vehicle

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle in

place of those on the offending end of the problem

vehicle. If the source of the waddle is not obvious,

change the rear tires.

Page 831 of 1463

WHEEL ALIGNMENT 2B-3

3. Road test the vehicle. If there is improvement, install

the original tires to find the offending tire. If there is

no a straight improvement, install good tires in place

of all four offending tires.

4. Install original tires one at a time to find the offending

tire.

RADIAL TIRE LEAD/PULL

Lead/pull is the deviation of the vehicle from a straight

path on a level road with no pressure on the steering

wheel. Lead is usually caused by:

lIncorrect alignment.

lUneven brake adjustment.

lTire construction.

The way in which a tire is built can produce lead/pull in

the vehicle.011-center belts on radial tires can cause

the tire to develop a side force while the vehicle rolls

straight down the road. If one side of the tire has even a

little larger diameter than the diameter of the other side,

the tire will tend to roll to one side. Unequal diameters

will cause the tire to develop a side force which can

produce vehicle lead/pull.

The radial lead/pull diagnosis chart should be used to

determine whether the problem originates from an

alignment problem or from the tires. Part of the lead

diagnosis procedure calls for tire rotation that is different

from the proper tire rotation pattern. If a medium- to high-

mileage tire is moved to the other side of the vehicle, be

sure to check for ride roughness. Rear tires will not cause

lead/pull.

Page 1262 of 1463

6A-2 POWER STEERING SYSTEM

Checks

Damaged or Binding Steering Ball Joint

Improper Preload of Steering Pinion

Damaged Wheel or Tire

Faulty Suspension SystemChecks

Worn Steering Gear

Worn or Damaged Steering Ball Joint

Loosened Steering Gearbox BoltsChecks

Damaged Steering Linkage

Damaged Wheel and Tire

Faulty Brake System

Faulty Suspension SystemChecks

Lack of Lubrication

Abnormal Wear or Binding of Steering Ball Joint

Damaged or Faulty Steering Gear

Improper Preload of Steering Pinion

Faulty Steering Shaft Joint

Steering Fluid Leaks

Lack of Fluid or Air-in System

Faulty Steering Oil Pump

Damaged or Loosened Pump Drive Belt

Clogging Oil Line

Damaged Wheel or Tire

Faulty Suspension System

DIAGNOSIS

HARD STEERING

Action

Lubricate

Replace

Replace gear assembly

Adjust

Replace

Repair or replace

Replenish or bleed

Replace

Adjust or replace

Repair or replace

Repair or replace

Repair or replace

STEERING PULLS TO ONE SIDE

Action

Repair

Repair or replace

Repair or replace

Repair or replace

EXCESSIVE WHEEL PLAY

Action

Replace gear assembly

Replace

Retighten

POOR RETURN OF STEERING WHEEL

Action

Replace

Replace gear assembly

Repair or replace

Repair or replace

Page 1263 of 1463

POWER STEERING SYSTEM 6A-3

Checks

Loosened Steering Gearbox Mounting Bolt

Faulty Steering Gear

Steering Column Linterference

Loosened Steering Linkage

Damaged or Loosened Oil Pump Drive Belt

Loosened Oil Pump Bracket

Loosened Oil Pump Mounting Bolt

Air-in System

Faulty Oil PumpChecks

Damaged Steering Linkage

Loosened Steering Gearbox Mounting Bolt

Damaged or Binding Steering Ball Joint

Worn or Damaged Front Wheel Bearing

Damaged Wheel or Tire

Faulty Suspension System

STEERING WHEEL SHIMMY

Action

Replace

Retighten

Replace

Replace

Repair or replace

Repair or replace

ABNORMAL NOISE FROM STEERING SYSTEM

Action

Retighten

Replace gear assembly

Replace

Retighten

Adjust or replace

Retighten

Retighten

Bleed

Replace

Page 1295 of 1463

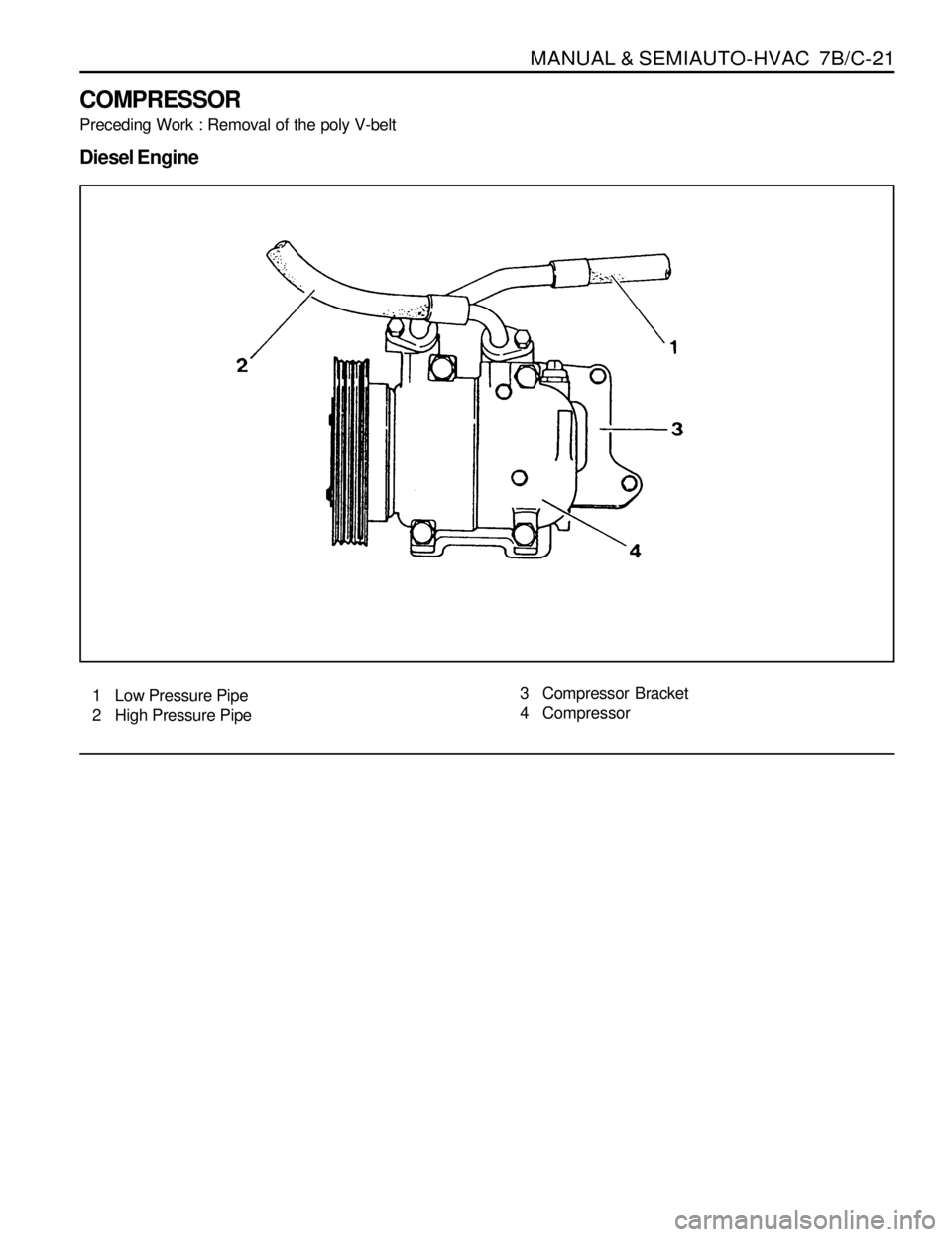

MANUAL & SEMIAUTO-HVAC 7B/C-21

COMPRESSOR

Preceding Work : Removal of the poly V-belt

Diesel Engine

1 Low Pressure Pipe

2 High Pressure Pipe3 Compressor Bracket

4 Compressor