belt SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 377 of 1463

OM600 ENGINE MECHANICAL 1B3-75

Sectional View

3 Socket Bolt

4 Crankshaft Belt Pulley

5 Vibration Damper

6 Bolt

7 Washer

8 Straight Pin

Notice

The mounting position of vibration damper is fixed by straight

pin (8).

Tools Required

602 589 00 40 00 Engine Lock

103 589 00 30 00 Puller9 Hub

11 Radial Seal

12 Timing Gear Case Cover

13 Key

14 Crankshaft Sprocket

16 Crankshaft

Page 378 of 1463

1B3-76 OM600 ENGINE MECHANICAL

Removal Procedure

1. Remove the starter motor and install the engine lock into

the wheel ring gear.

Engine Lock 602 589 00 40 00

2. Remove the poly V-belt.

3. Remove the cooling fan.

Notice

Keep the fan in vertical position.

4. Remove the cooling fan belt pulley (2).

5. Place alignment marks (arrow) on the vibration damper (5)

and crankshaft belt pulley (4).

6. Remove the timing sensor bracket.

Notice

Remove if necessary.

Page 379 of 1463

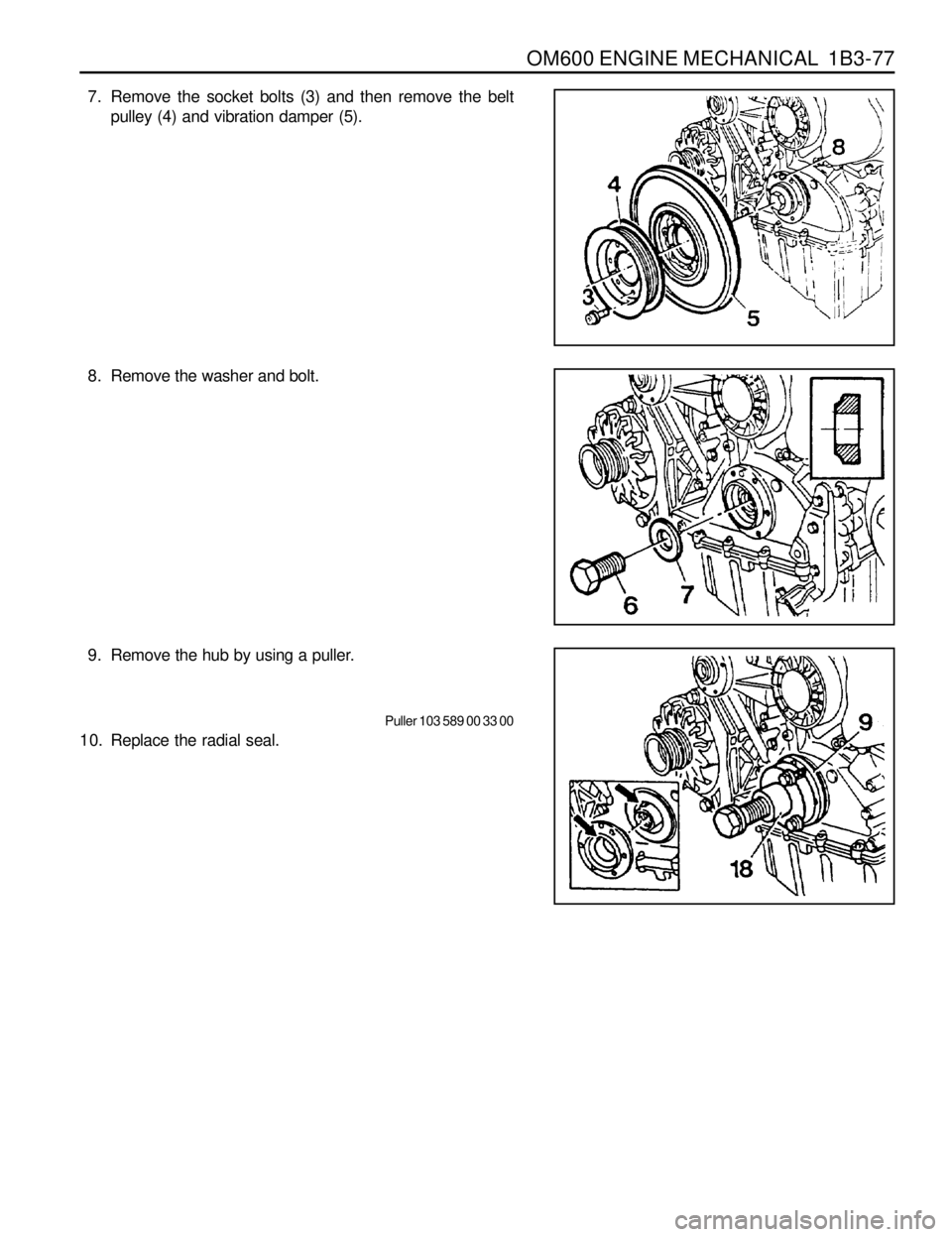

OM600 ENGINE MECHANICAL 1B3-77

7. Remove the socket bolts (3) and then remove the belt

pulley (4) and vibration damper (5).

8. Remove the washer and bolt.

9. Remove the hub by using a puller.

Puller 103 589 00 33 00

10. Replace the radial seal.

Page 380 of 1463

1B3-78 OM600 ENGINE MECHANICAL

Installation Procedure

1. Install the hub.

Notice

Exactly align the woodruff key and the groove of hub (arrow).

2. Install the washer (7) and tighten the bolt (6).

Washer (new) : 1 EA 200 Nm + 90°

3. Install the vibration damper.

Notice

Exactly align and insert onto the straight pin.

4. Install the belt pulley.

Tightening Torque 25 Nm

Notice

Align the alignment marks.

Page 381 of 1463

OM600 ENGINE MECHANICAL 1B3-79

5. Install the timing sensor bracket.

Notice

See the ‘TDC setting’.

6. Install the cooling fan pulley.

Tightening Torque 10 Nm

7. Install the cooling fan.

8. Install the fan belt.

9. Remove the engine lock.

Page 454 of 1463

1B3-152 OM600 ENGINE MECHANICAL

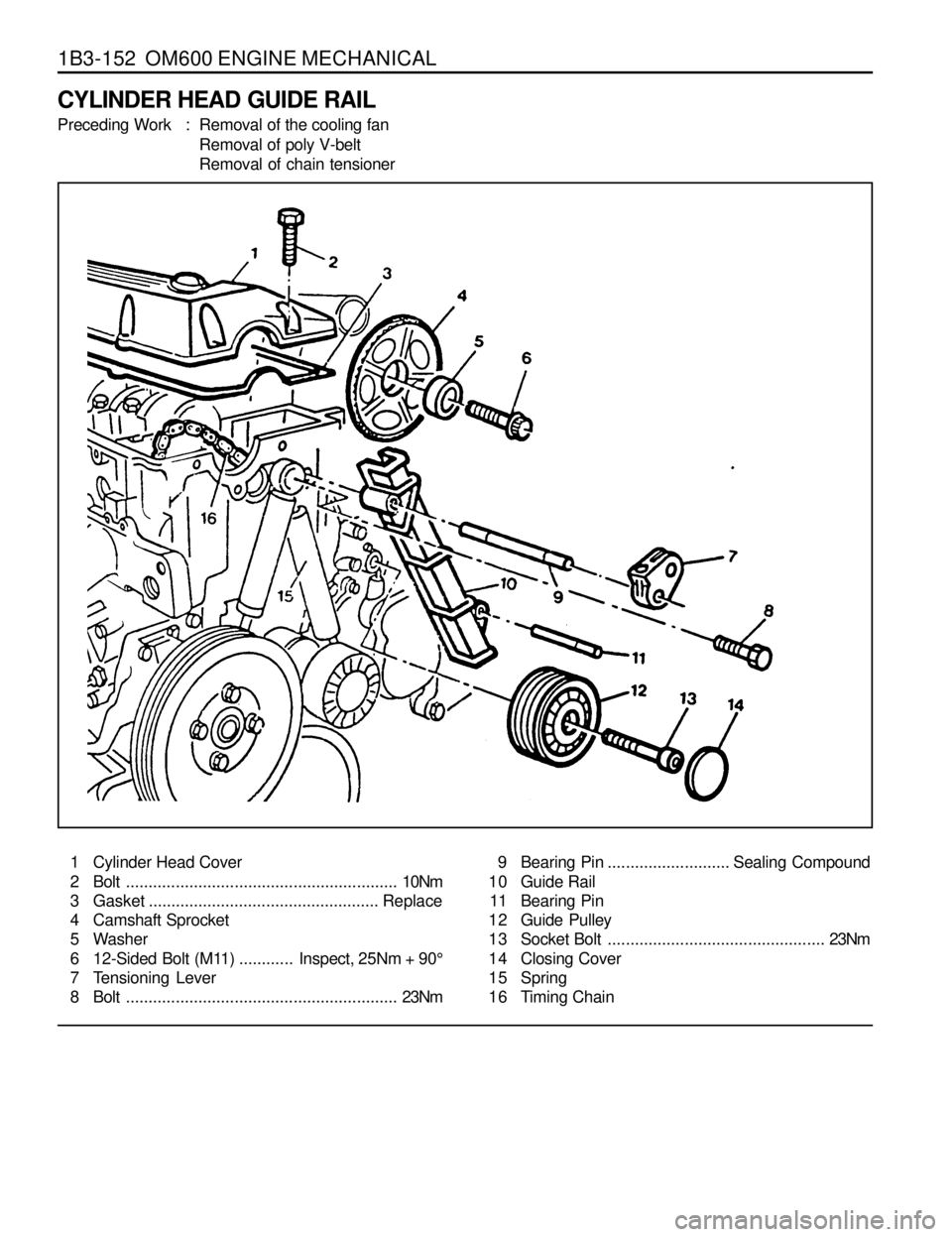

CYLINDER HEAD GUIDE RAIL

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

Removal of chain tensioner

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace

4 Camshaft Sprocket

5 Washer

6 12-Sided Bolt (M11)............Inspect, 25Nm + 90°

7 Tensioning Lever

8 Bolt............................................................23Nm9 Bearing Pin...........................Sealing Compound

10 Guide Rail

11 Bearing Pin

12 Guide Pulley

13 Socket Bolt................................................23Nm

14 Closing Cover

15 Spring

16 Timing Chain

Page 497 of 1463

1D1-8 M162 ENGINE COOLING

WATER PUMP

Preceding Work : Removal of V-belt

Removal of air admission housing

1 Air Admission Housing

2 Oil Cooler Pipe Line

3 Seal....................................................... Replace

4 Bolt........................................................9-11 Nm

5 Coolant Hose

6 Coolant Hose

7 Outlet Coolant Hose8 Coolant Hose

9 Inlet Coolant Hose

10 Coolant Pump

1 1 Bolt........................................................... 21 Nm

12 Dowel Sleeve

1 3 Seal....................................................... Replace

Page 515 of 1463

1D2-10 M161 ENGINE COOLING

Tools Required

124 589 15 21 00 Tester

Removal & Installation Procedure

1. Drain the coolant.

2. Disconnect the coolant hoses (8, 9, 10).

3. Tak off the drive belt.

4. Unscrew the four bolts (6) from coolant pump pulley and

remove the pulley (7).

Installation Notice

Tightening Torque 9 - 11 Nm

22.5 - 27.5 Nm

(1, 2, 3)

(4) Notice

Hold the pulley with special tool (603 589 00 40 00) while

removing the pulley.

Tightening Torque 9 - 11 Nm

5. Unscrew the bolts (1, 2, 3, 4) from coolant pump housing

(5) and remove the coolant pump.

Installation Notice

6. Clean the sealing surface.

7. Replace the gasket with new one.

Notice

Apply the sealant when the sealing surface of coolant pump

housing and coolant mounting area is clean.

8. Installation should follow the removal procedure in the

reverse order.

9. Check for leaks by starting the engine.

Page 522 of 1463

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1

General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2

Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Coolant

Mixing Ratio (Water : anticorrosion)

CapacityDescription

ALUTEC P- 78

50 : 50

10.5L - 11L

9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt

Belt Pulley Bolt

Coolant Pump Housing Return Pipe Bolt

Thermostat Bolt

Cooling Fan Clutch Socket Bolt (Center)

Cooling Fan Clutch Socket Bolt (Side)

Radiator Bolt

Coolant Sub-tank BoltN

· ·· ·

·m

10

10

10

10

45

10

3 - 7

3 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA

661LA

Page 527 of 1463

1D3-6 OM600 ENGINE COOLING

COOLANT PUMP

Preceding Work : Removal of cooling fan

Removal of V-belt

1 Tensioning Lever

2 Gasket ................................................... Replace

3 Bolt........................................................... 10 Nm4 Belt Pulley

5 Bolt........................................................... 10 Nm

6 Coolant Pump