SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 317 of 1463

OM600 ENGINE MECHANICAL 1B3-15

15. Remove the air-conditioner lines from the compressor.

Notice

Evacuate the refrigerant before removal.

12. Remove the hose(air cleaner to turbocharger) with blow

by hose.

13. Disconnect the air cleaner intake hose and remove the air

cleaner cover and element.

14. Disconnect the coolant hose from the water inlet.

Page 318 of 1463

1B3-16 OM600 ENGINE MECHANICAL

16. Remove the power steering pump lines.

Notice

Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the feed

pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler (2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.

Page 319 of 1463

OM600 ENGINE MECHANICAL 1B3-17

26. Disconnect the starter motor wires and remove the starter

motor.

21. Remove the fuel lines from the fuel filter and cover the

filter with plug.

22. Disconnect the brake booster hose from vacuum pump.

23. Disconnect the other vacuum lines.

24. Disconnect the ground cable.

25. Disconnect the alternator wires.

Page 320 of 1463

1B3-18 OM600 ENGINE MECHANICAL

27. Disconnect the preheating time relay sensor plug.

28. Disconnect the coolant temperature sensor plug.

29. Disconnect the accelerator cable from the control linkage.

Installation Notice

Tightening Torque 8 - 18 Nm

30. Loosen the connection of control pressure cable (an arrow)

used in auto transmission.

Page 321 of 1463

OM600 ENGINE MECHANICAL 1B3-19

33. Disconnect the exhaust pipe flange from the exhaust

manifold.

Installation Notice

35. Remove the shift control cable.

36. Remove the transmission.

Tightening TorqueAxle 70 ~ 80 Nm

T/C 81 ~ 89 Nm

Tightening Torque 20 - 34 Nm 31. Separate the exhaust pipe flange from the turbo charger.

Installation Notice

32. Loosen the installing bolt of clutch release cylinder and

remove the clutch release cylinder.

Installation Notice

Tightening Torque 30 Nm

Tightening Torque 30 Nm

34. Remove the propeller shaft from the transmission.

Installation Notice

Page 322 of 1463

1B3-20 OM600 ENGINE MECHANICAL

37. Loosen the engine mounting bracket nut.

Installation Notice

38. Remove the engine assembly from the vehicle by using a

hoist or crane.

39. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 50 - 75 Nm

Page 323 of 1463

OM600 ENGINE MECHANICAL 1B3-21

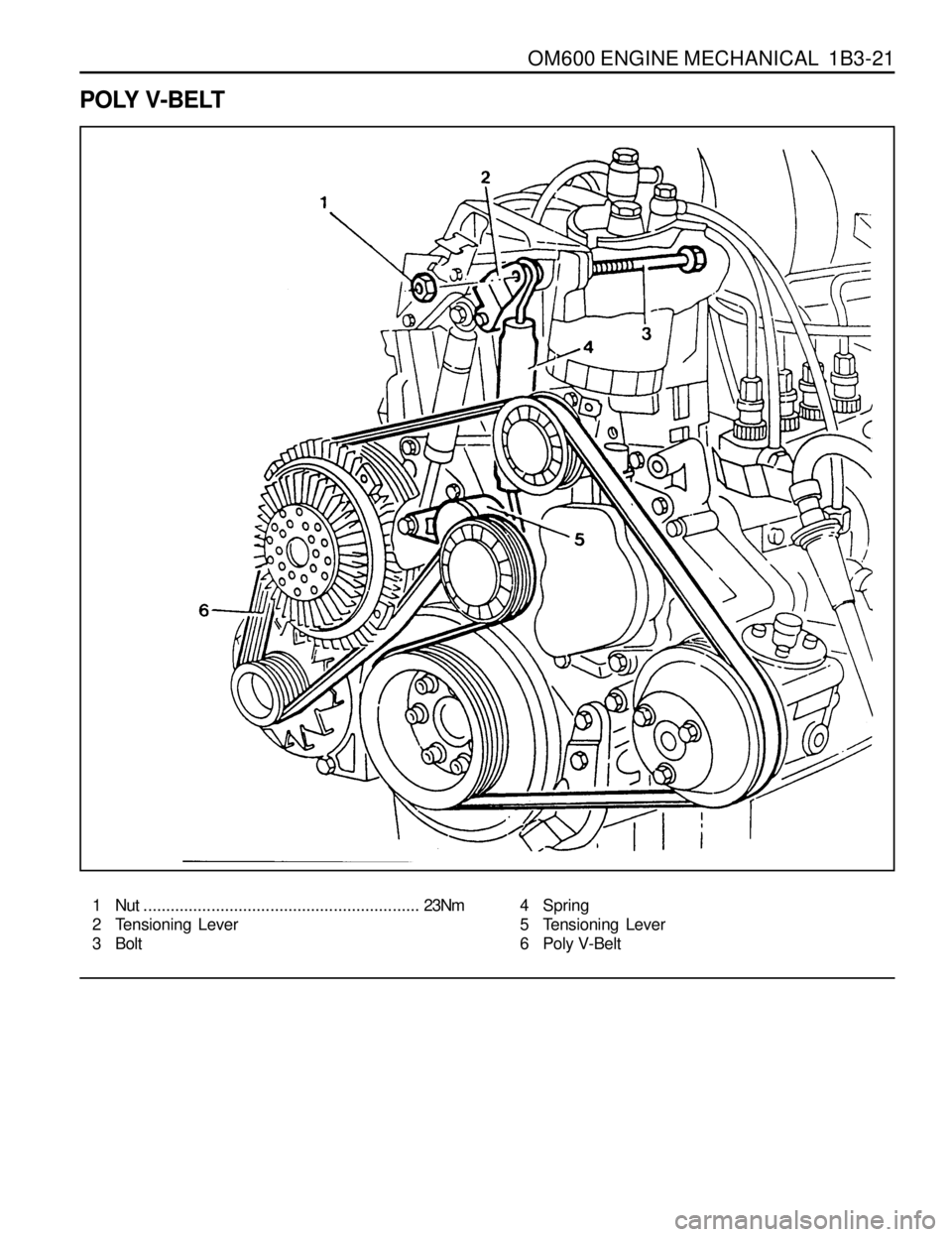

POLY V-BELT

1 Nut .............................................................23Nm

2 Tensioning Lever

3 Bolt4 Spring

5 Tensioning Lever

6 Poly V-Belt

Page 324 of 1463

1B3-22 OM600 ENGINE MECHANICAL

With Air Conditioner

Removal & Installation Procedure

1. Remove the nut.

2. Push the tensioning lever in direction of arrow with a rod

(F12 ´ 180mm) and pull out the bolt to the rear.

3. Push back the tensioning lever (arrow direction) to release

the spring tension and remove the belt.

4. Install the poly V-belt beginning at the tensioning pulley (7).

7 Tensioning Pulley

8 Crankshaft

9 Alternator

10 Coolant Pump

11 Guide Pulley

12 Power Steering Pump

13 Aircon. Compressor

Lengthe of Belt

Length (L)

Without Air Conditioner2,100 mm

2,040 mm

Page 325 of 1463

OM600 ENGINE MECHANICAL 1B3-23

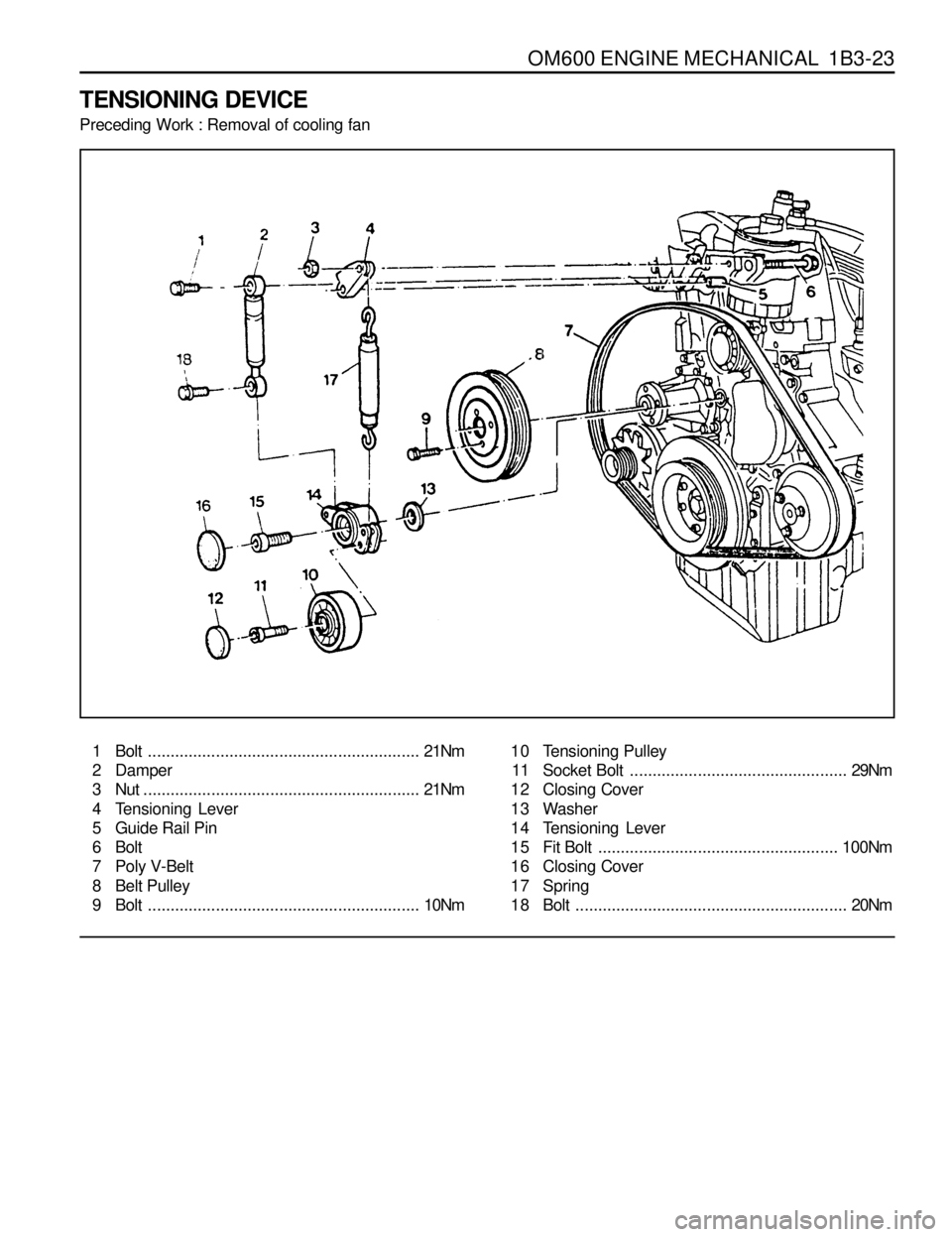

TENSIONING DEVICE

Preceding Work : Removal of cooling fan

1 Bolt............................................................21Nm

2 Damper

3 Nut .............................................................21Nm

4 Tensioning Lever

5 Guide Rail Pin

6 Bolt

7 Poly V-Belt

8 Belt Pulley

9 Bolt............................................................10Nm10 Tensioning Pulley

11 Socket Bolt................................................29Nm

12 Closing Cover

13 Washer

14 Tensioning Lever

15 Fit Bolt .....................................................100Nm

16 Closing Cover

17 Spring

1 8 Bolt............................................................20Nm

Page 326 of 1463

1B3-24 OM600 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the nut.

Installation Notice

Tightening Torque 10 Nm

2. Push the tensioning lever in direction of arrow with a rod

( F12 ´ 180mm ) and push out the bolt to the rear.

3. Push back the tensioning lever to release the spring tension

and remove the belt.

4. Remove the bolt (9) and then remove the belt pulley (8).

5. Remove the bolt (1, 18) and take off the damper (2).

Notice

Pay attention to installation position of the damper.