oil SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1293 of 1463

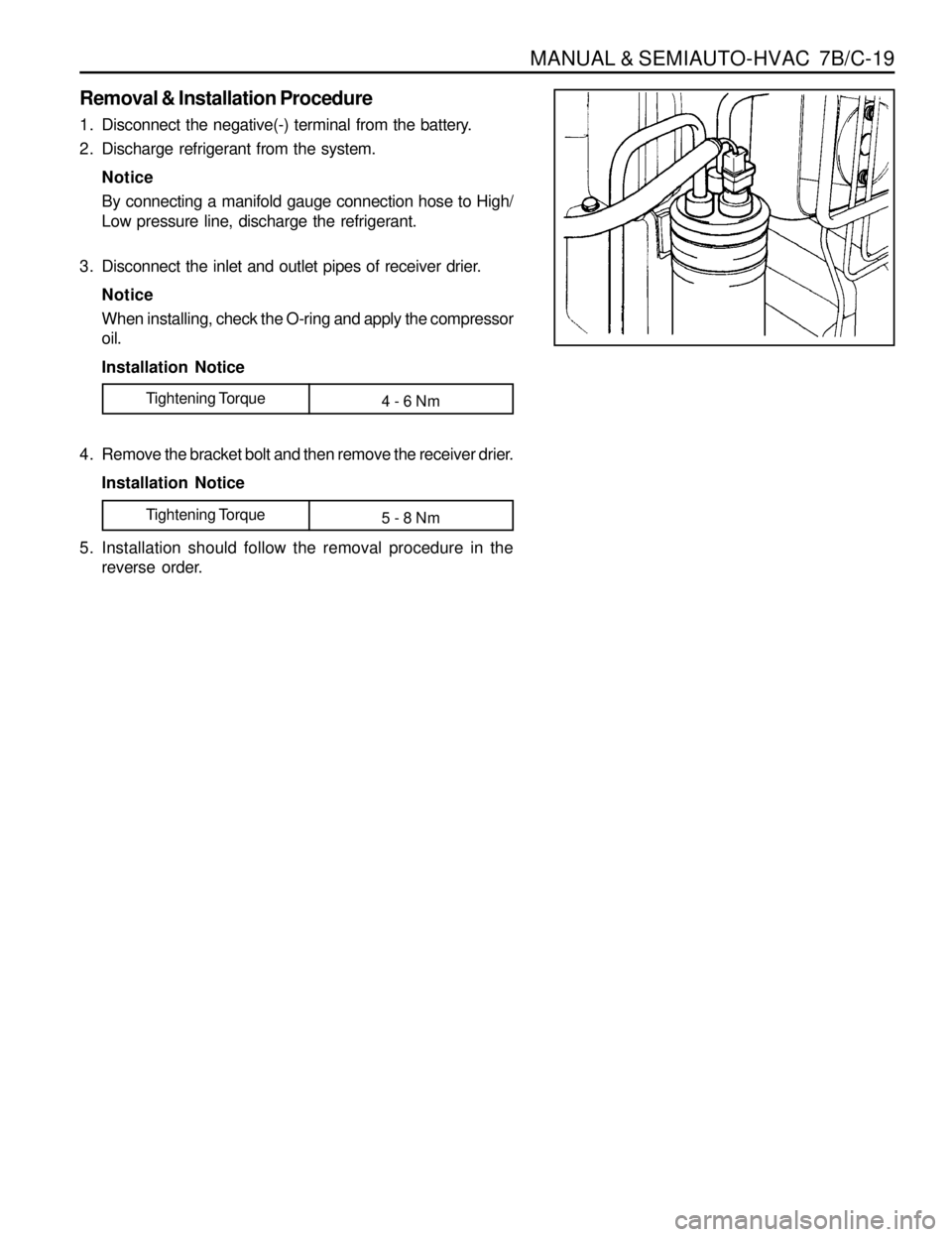

MANUAL & SEMIAUTO-HVAC 7B/C-19

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the inlet and outlet pipes of receiver drier.

Notice

When installing, check the O-ring and apply the compressor

oil.

Installation Notice

4. Remove the bracket bolt and then remove the receiver drier.

Installation Notice

Tightening Torque

4 - 6 Nm

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

5 - 8 Nm

Page 1296 of 1463

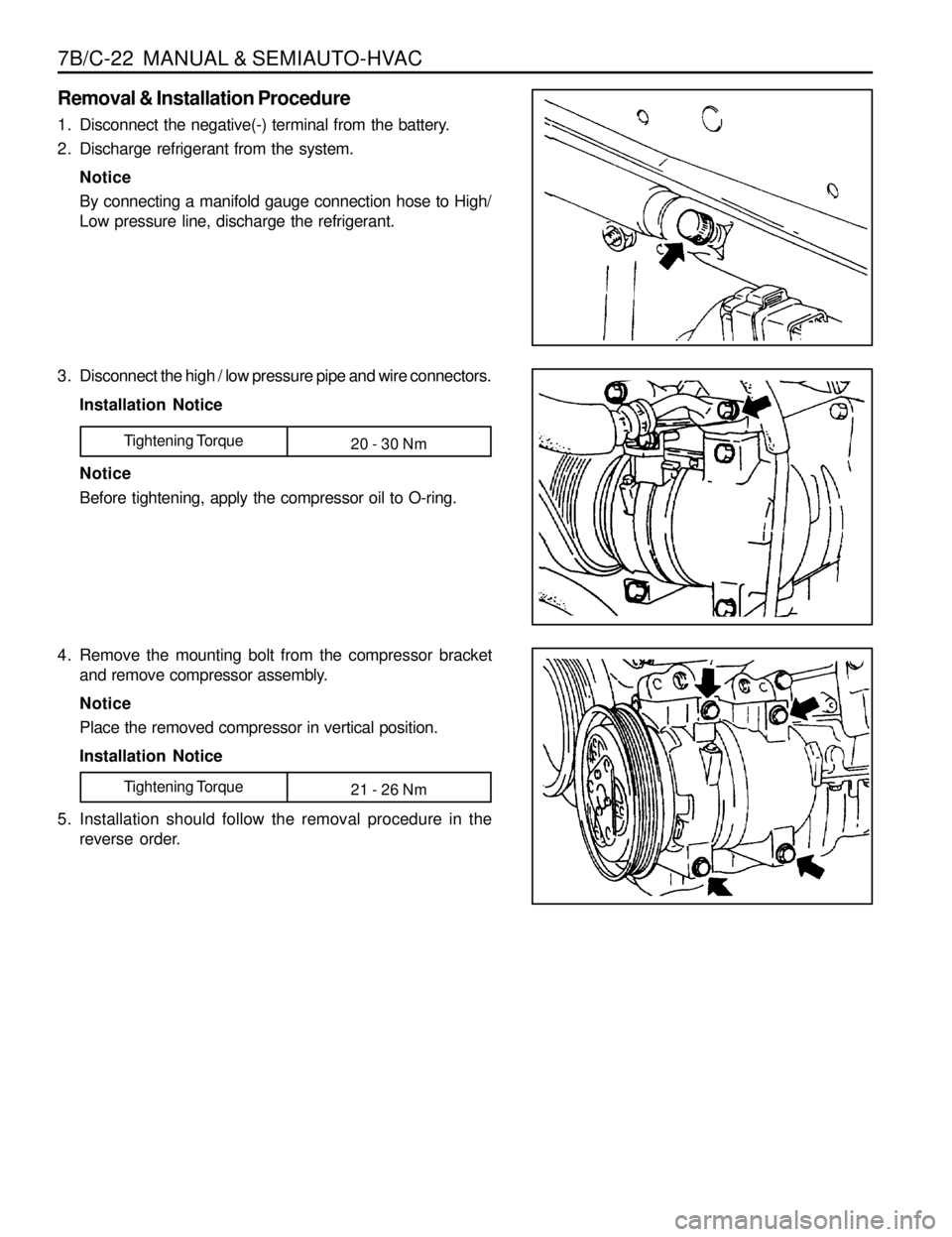

7B/C-22 MANUAL & SEMIAUTO-HVAC

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the high / low pressure pipe and wire connectors.

Installation Notice

Notice

Before tightening, apply the compressor oil to O-ring.

Tightening Torque

20 - 30 Nm

4. Remove the mounting bolt from the compressor bracket

and remove compressor assembly.

Notice

Place the removed compressor in vertical position.

Installation Notice

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

21 - 26 Nm

Page 1346 of 1463

9A-20 BODY WIRING SYSTEM

GASOLINE ENGINE (MSE)

1 ECU Main Wiring Connector

2 ECU Main Wiring Connector

3 Crankshaft Position Sensor

4 Oil Pressure Switch

5 Knock Sensor 2

6 Hot-Film Air Mass Sensor

7 Injector 6

8 Injector 5

9 Injector 4

10 Injector 3

11 Injector 2

12 Injector 1

13 Camshaft Adjustment Magnet14 Ignition Coil 3

15 Ignition Coil 2

16 Ignition Coil 1

17 Temperature Sensor (Gauge)

18 Double Sensor

19 Camshaft Position Sensor

20 Knock Sensor 1

21 Throttle Regulating Unit

22 Resonance Flap

23 Main Wiring Connector

2 4 ECU

25 ECU Engine Wiring Connector

26 ECU Engine Wiring Connector

Page 1347 of 1463

BODY WIRING SYSTEM 9A-21

GASOLINE ENGINE (HFM)

1 ECU

2 Main Wiring Connector

3 Crankshaft Position Sensor

4 Knock Sensor

5 Hot-Film Air Mass Sensor

6 Aspiration Sensor

7 Throttle Regulating Unit

8 Knock Sensor

9 Camshaft Position Sensor

10 Ignition Coil 3

11 Ignition Coil 2

12 Ignition Coil 113 Injector 6

14 Injector 5

15 Injector 4

16 Injector 3

17 Injector 2

18 Injector 1

19 Camshaft Adjustment Magnet

20 Resonance Flap

21 Temperature Sensor (Gauge)

22 Double Sensor

23 Ground

Page 1349 of 1463

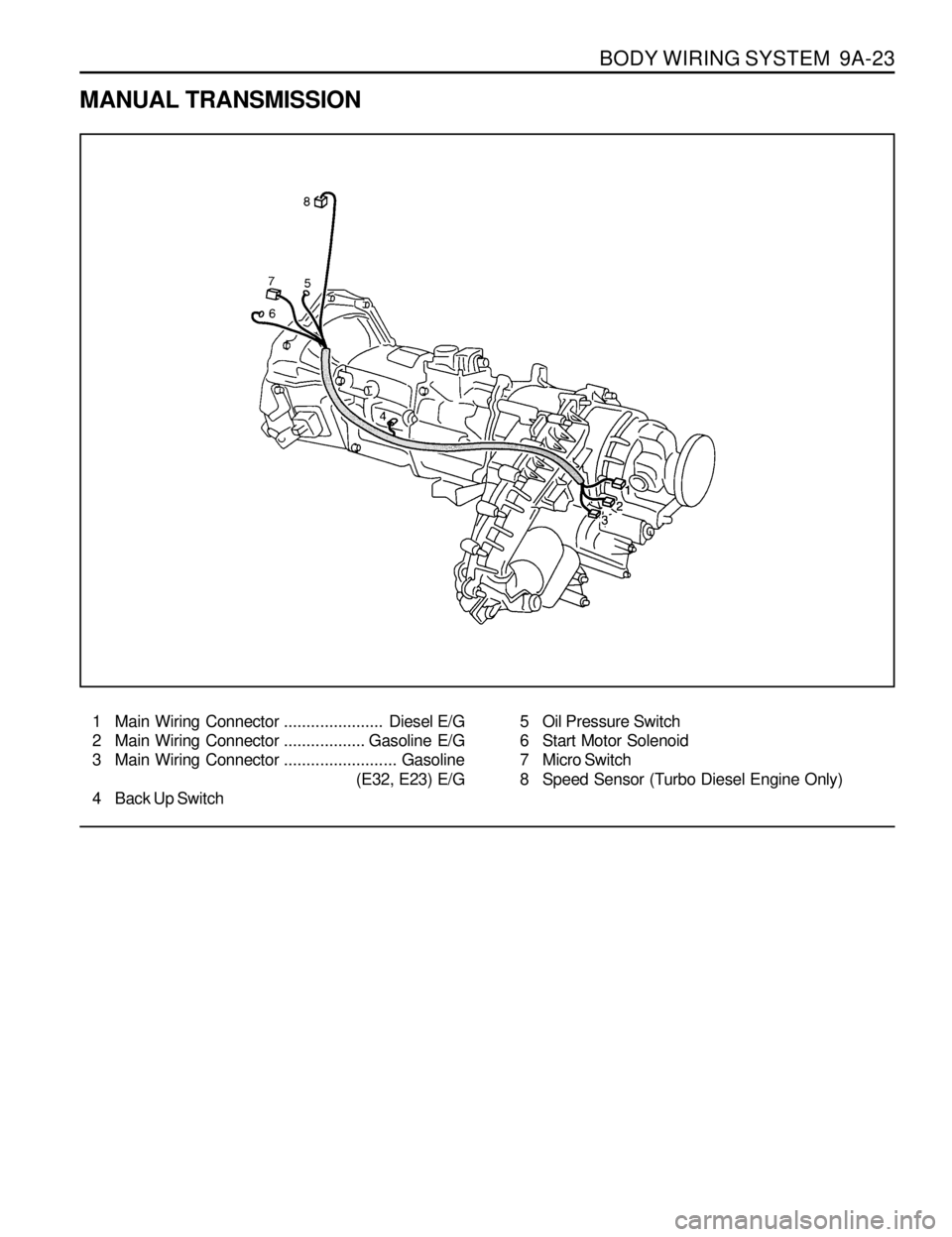

BODY WIRING SYSTEM 9A-23

MANUAL TRANSMISSION

1 Main Wiring Connector......................Diesel E/G

2 Main Wiring Connector..................Gasoline E/G

3 Main Wiring Connector.........................Gasoline

(E32, E23) E/G

4 Back Up Switch5 Oil Pressure Switch

6 Start Motor Solenoid

7 Micro Switch

8 Speed Sensor (Turbo Diesel Engine Only)

Page 1350 of 1463

9A-24 BODY WIRING SYSTEM

AUTOMATIC TRANSMISSION (BENZ)

1 Main Wiring Connector

2 Start Lock Switch

3 Automatic Transmission Change Over Valve

4 Transmission Overload

Protection Switch...........................Gasoline E/G5 Oil Pressure Switch

6 Start Solenoid

7 Micro Switch.......................................Diesel E/G

8 Speed Sensor.......................... Turbo Diesel E/G

Page 1351 of 1463

BODY WIRING SYSTEM 9A-25

AUTOMATIC TRANSMISSION (BTRA)

1 Main Wiring Connector

2 Main Wiring Connector

3 Transmission

4 Transmission Lever

5 Oil Pressure Switch............................Diesel E/G6 Start Motor Solenoid

7 Throttle Position Sensor....................Diesel E/G

8 Speed Sensor.......................... Turbo Diesel E/G

9 Inhibitor Switch

Page 1376 of 1463

INSTRUMENTATION/DRIVER INFORMATION 9E-3

COMBINATION METER

COMPONENT LOCATOR

1. Speedometer

2. Odometer

3. Trip odometer

4. Tachometer

5. Coolant temperature gauge

6. Fuel gauge

7. Low fuel level warning light

8. Turn signal indicator (left)

9. Turn signal indicator (right)

10. Outside rearview mirror & tailgate heating switch

11. Reset button

12. Auto shift indicator*

13. Door open warning light

14. TCS indicator (equipped with ABD)*

21. ABS warning light*22. EBD warning light*

23. ECS / SPORT warning light*

24. 4 - wheel warning light*

25. 4 - wheel high indicator

26. 4 - wheel low indicator

27. WINTER indicator

28. POWER indicator

29. High beam indicator

15. Alternator warning light

16. Engine oil pressure warning light

17. Brake system warning light

18. Glow indicator light (For Diesel engine)

19. Airbag warning light*

20. Seat belt reminder

Page 1395 of 1463

GLASS AND MIRRORS 9L-5

Installation of Windshield

1. Cleaning of windshield mounting flange.

lDo not reuse a gauze over 20 times.

lSaturate the gauze in solvent (lsoprophyl alcohol).

lKeep the cleaned surface to be cleaned.

lApply body primer to the cleaned and dry body flange.

lIf body flange is oiled or contaminated, primer can not

be applied.

lDuration : 3 minutes - 8 hours (reapply after 8 hours).

lIf primer is applied to the body, clean off immediately

with solvent (ethyl alcohol and ethyl acetate, 50 : 50 in

volume).

lDo not apply primers which is over its duration.

lBe careful not to contaminate other parts.

2. Installation of windshield spacer.

lInsert the spacer completely.

lAfter inserting, there should be no clearance on the body.

- To the direction of the side spacer.

- To the direction of the lower spacer.

3. Cleaning of windshield glass.

lClean the windshield glass keeping 15mm from the edge

of glass.

lDo not reuse a gauze over 20 times.

lSaturate the gauze in solvent (lsoprophyl alcohol).

lDo not touch the cleaned glass surface.

lApply glass primer to the cleaned and dry glass.

lIf glass is oiled or contaminated, primer can not be

applied.

Page 1400 of 1463

9L-10 GLASS AND MIRRORS

Installation of Tailgate Glass

1. Clean the tailgate flange.

lDo not reuse a gauze over 20 times.

lSaturate the gauze in solvent (Isoprophyl alcohol).

lKeep the cleaned surface to be cleaned.

lApply body primer to the cleaned and dry flange.

- If flange is oiled or contaminated, primer can not be

applied.

2. Apply primer after cleaning of tailgate flange.

lKeep primers in a refrigerator(-2°C - +5°C).

lUse sufficiently mixed primer in a mixer over 10 minutes.

lApply primer within 2 hours after opening.

lDo not apply primers which is over its druation.

lApply evenly to the flange.

lDuration : 3 minutes - 8 hours (reapply after 8 hours).

lIf primer is applied to the body, clean off immediately

with solvent.

lBe careful not to contaminate other parts.

3. Clean the tailgate galss.

lClean the glass keeping 15mm from the edge of glass.

lDo not reuse a gauze over 20 times.

lSaturate the gauze in solvent(Isoprophyl alcohol).

lDo not touch the cleaned galss surface.

lApply glass primer to the cleaned and dry glass surface.

If glass is oiled or contaminated, primer can not be

applied.

4. Apply primer to the tailgate glass.

lUse sufficiently mixed primer in a mixer over 10 minutes.

lBe careful not to contaminate other parts due to over

application.

lDuration : 1 minute - 24 hours(reapply after 24 hours).

lNever use the primer containing deposits or floating

materials.

lDo not use primers which is over its duration.

lDo not reuse a gauze over 20 times.

lApply evenly to glass.