ignition SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 588 of 1463

1F1-18 M162 ENGINE CONTROLS

Failure

codeItem

Þ 18.1

Checking method Test

stepRequirementSpecified

valuePossible cause

73 28 - 12 W

· ·· ·

· Camshaft

actuator:

Solenoid

resistance

Þ 21.0· ·· ·

· Purge

control

valve:

- Vacuum

control· Engine:in idling/

normal operating

temperature· Vacuum line

· Purge control valve

· Cable

· Camshaft actuator

Diagnosis

socket

Þ 19.0

73 69Engine is

unstable or

stopped· ·· ·

· Camshaft

actuator:

Mechanical

Actuation· Mechanical failure of

camshaft actuator

Þ 20.0

· Engine:in idling

34 11The purge

control valve

should be

operated after

approx.

1minute.

(refer to figure

5)· ·· ·

· Purge

control

valve:

- Operating

226,

227,

· ECU

· Cable

· Purge control valve

· Ignition:ON0.3 - 0.5 A - Current

consumption

10 34

Creating

above 50mbar

of vacuum

after approx.

1 minute

Þ 22.0

· Ignition:OFF

38 37· Data bus

· Þ 22.1

· Þ 22.2 55 - 65 W

· ·· ·

· CAN data

bus

· Ignition:OFF

· Engine:in idling

- connect the bridge

to the test box for

approx. 10 seconds

40,

41,

54,

Connect the vacuum

gauge between the

control valve and

canister

22,23,

24,26,

27,29,

30,31,

59,60,

Page 589 of 1463

M162 ENGINE CONTROLS 1F1-19

Failure

codeItem

Þ 22.1

Checking method Test

stepRequirementSpecified

valuePossible cause

38 37115 - 125 W

· ·· ·

· CAN module

resistance in

ABS, ABD,

ASR control

unit· Cable

· ABS, ABD, ASR

control unit

· Ignition:OFF

- disconnect the

coupling "No.1" from

ECU.

Þ 22.2

38 37115 - 125 W

· ·· ·

· CAN module

resistance in

ECU control

unit· ECU· Ignition:OFF

- disconnect the

coupling "No.1" from

ECU.

Þ 23.0

55811 - 14 V· ·· ·

· Diagnosis

cable

operating· ECU

· Cable

· Ignition:ON

22,23,

24,26,

27,29,

30,31,

59,60,

Page 591 of 1463

M162 ENGINE CONTROLS 1F1-21

Failure

codeItemChecking method Test

stepRequirementSpecified

valuePossible cause

10 1211 - 14V

· ·· ·

· ECU:power

supply

- terminal

30(TM.30)

Þ 2.2· ·· ·

· Power

supply:

- terminal

87(TM.87)· Ignition:ON· Power supply cable

· OVPR

IGNITION SYSTEM TEST

08,· Þ 1.1

· Þ 1.2

Þ 1.1

· Ignition:ON

10 211 - 14V· ·· ·

· Ground

cable:

- Battery

ground· Ground cable

· Ground condition

(figure 1)Diagnosis

socket

69 2

Diagnosis

socket

Þ 1.2· Ignition:ON

11211 - 14V· ·· ·

· Power

supply:

- terminal

30(TM.30)· Power supply cable

· Fuse No.8Diagnosis

socket

Þ 2.0· Ignition:ON

51111 -14V· ·· ·

· ECU:power

supply

- terminal

87(TM.87)08,· Þ 2.1

· Þ 2.2

Þ 2.1

· Ignition:ON 11 - 14V· ·· ·

· Ground

cable

- Electronic

ground· Ground cable

52

Diagnosis

socket

111

Diagnosis

socket

· Ignition:OFF

11 - 14V

< 1V

Þ 3.0· Ignition:ON

6911 - 14 V· ·· ·

· Ignition

coil(T1/1)

- No.2,5

Cylinder64,· Cable

· Ignition coil(T1/1)

· Fuse No.17

· Engine:in cranking > 10 V

Page 592 of 1463

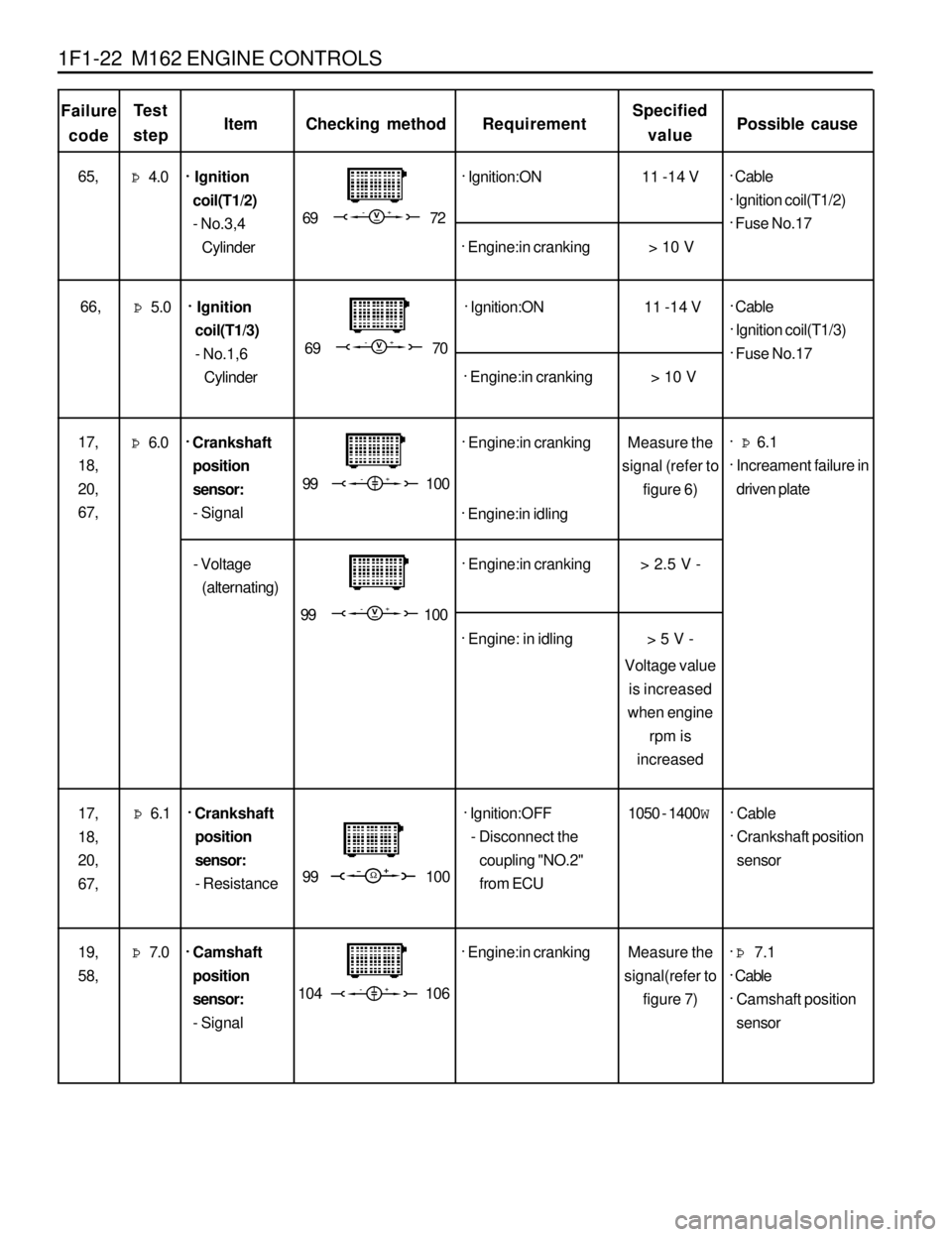

1F1-22 M162 ENGINE CONTROLS

Failure

codeItemChecking method Te s t

stepRequirementSpecified

valuePossible cause

Þ 6.1· ·· ·

· Crankshaft

position

sensor:

- Resistance· Ignition:OFF

- Disconnect the

coupling "NO.2"

from ECU· Cable

· Crankshaft position

sensor Þ 6.0

· Engine:in cranking

99 100Measure the

signal (refer to

figure 6)· ·· ·

· Crankshaft

position

sensor:

- Signal17,

18,

20,

67,· Þ 6.1

· Increament failure in

driven plate

> 5 V - 99 100

99 100

1050 - 1400W

Þ 7.0

· Engine:in cranking

104 106· Þ 7.1

· Cable

· Camshaft position

sensor Measure the

signal(refer to

figure 7)

· ·· ·

· Camshaft

position

sensor:

- Signal

Þ 4.0· Ignition:ON

69 7211 -14 V· ·· ·

· Ignition

coil(T1/2)

- No.3,4

Cylinder65,· Cable

· Ignition coil(T1/2)

· Fuse No.17

· Engine:in cranking > 10 V

· Engine:in idling

- Voltage

(alternating)

· Engine:in cranking

· Engine: in idling> 2.5 V -

19,

58,

Þ 5.0· Ignition:ON

69 7011 -14 V· ·· ·

· Ignition

coil(T1/3)

- No.1,6

Cylinder66,· Cable

· Ignition coil(T1/3)

· Fuse No.17

· Engine:in cranking > 10 V

17,

18,

20,

67,Voltage value

is increased

when engine

rpm is

increased

Page 593 of 1463

M162 ENGINE CONTROLS 1F1-23

Failure

codeItemChecking method Te s t

stepRequirementSpecified

valuePossible cause

106 11The value will

be changed in

1.2 - 1.7 V - Voltage

(alternating)

0.9 - 1.6 W 71 11

71 72

· Engine:in cranking

Þ 7.1

· Ignition:ON

- Remove the

connector from the

Camshaft position

sensor between

No.1 terminal and

No.3 terminal. 1311 -14 V· ·· ·

· Camshaft

position

sensor

(E23 only)

- Power

supply· Cable

· OVPR

· ·· ·

· Ignition

coil(T1/1)

- primary coil

voltage

(No.2 and 5

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)

· Ignition:OFF200 - 350 V

Camshaft position

sensor

64,Þ 8.0· Þ 8.1

Þ 8.1

· ·· ·

· Connecting

resistance of

ignition coil

between T1/

1 and T1/2· Cable

· Ignition coil T1/1

· Ignition coil T1/2

72 11

· ·· ·

· Ignition

coil(T1/2)

- primary coil

voltage

(No.3 and 4

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)200 - 350 V 65,Þ 9.0· Þ 9.1

0.9 - 1.6 W

72 71

· Ignition:OFFÞ 9.1· ·· ·

· Connecting

resistance of

ignition coil

between T1/

2 and T1/1· Cable

· Ignition coil T1/1

· Ignition coil T1/2 The

resistance of

ignition coil at

20°C is

approached

0.6W

The

resistance of

ignition coil at

20°C is

approached

0.6W

Page 594 of 1463

1F1-24 M162 ENGINE CONTROLS

Failure

codeItemChecking method Test

stepRequirementSpecified

valuePossible cause

8 - 20 KV· ·· ·

· Ignition coil

(T1/1, T1/2,

T1/3)

- Secondary

ignition

voltage

> 10 MW

11 7 11 8· Engine:in cranking

- Select the ignition

coil in order of T1/1,

T1/2

- Measuring range:

20KV

- Time range:100 %

· Ignition:OFF

- Disconnect the

coupling "No.2" from

ECU.Þ 12.0· ·· ·

· Knock

sensor 1

- Resistance

(cylinder

No1, 2, 3)· Connecting

condition

· Cable

· ECU Þ 11.0 64,

65,

66,

Engine tester· Þ 11.1

· Ignition plug

· ECU

· High tension cable

6 - 8.5 KW

· ·· ·

· Ignition coil

(T1/1, T1/2,

T1/3)

- Secondary

coil

resistance· Remove the high

tension cable of T1/

1, T1/2, T1/3. Þ 11.1Ignition coil

(T1/1, T1/2, T1/3)· Ignition coil T1/1

· Ignition coil T1/2

· Ignition coil T1/3TM.4a

TM.4b

56,

11

· ·· ·

· Ignition

coil(T1/3)

- primary coil

voltage

(No.1 and 6

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %200 - 350 V 66,Þ 10.0· Þ 10.1

0.9 - 1.6 W

70 72

· Ignition:OFFÞ 10.1· ·· ·

· Connecting

resistance of

ignition coil

between T1/

3 and T1/2· Cable

· Ignition coil T1/3

· Ignition coil T1/2

> 10 MW

11 4 11 5· Ignition:OFF

- Disconnect the

coupling "No.2" from

ECU.Þ 13.0· ·· ·

· Knock

sensor 2

- Resistance

(cylinder

No.4, 5, 6)· Connecting

condition

· Cable

· ECU 57,

The

resistance of

ignition coil at

20°C is

approached

0.6W

Page 596 of 1463

1F1-26 M162 ENGINE CONTROLS

IDLING CONTROL AND ELECTRONIC PEDAL SYSTEM TEST

Þ 2.1· Ignition:ON

50 512.25 - 2.75 V· ·· ·

· Pedal valve

sensor:

- Power

supply

(potentiometer 2)

· Cable

· ECU

Failure

codeItem

Þ 1.0

Checking method

· Ignition:ON

· Position of

accelerator pedal:

- Closed throttle

position

- Full throttle with kick

down

Test

stepRequirement

Specified

valuePossible cause

31 47

0.3 - 0.7 V

· ·· ·

· Pedal valve

sensor:

- Signal

(potentiometer 1)

160,

161,

164,

167,

4.3 - 4.8 V

· Þ 1.1

· Cable

· Pedal valve sensor

Þ 1.1

· Ignition:ON

31 324.75 - 5.25 V· ·· ·

· Pedal valve

sensor:

- Power

supply

(potentiometer 1)

· Cable

· ECU

Þ 2.0

· Ignition:ON

· Position of

accelerator pedal:

- Closed throttle

position

- Full throttle with kick

down 50 48

0.1 - 0.4 V

· ·· ·

· Pedal valve

sensor:

- Signal

(potentiometer 2)

162,

163,

164,

167,

2.1 - 2.5 V· Þ 2.1

· Cable

· Pedal valve sensor

Þ 3.0

· Engine:in idling

84 87

0.3 - 0.9 V· ·· ·

· Throttle

valve

actuator:

- Signal

Throttle valve

potentiometer 1104,

105,

108,

109,

116,

119,

185,

4.0 - 4.6 V· Þ 3.1

· Cable

· E-GAS actuator

· Position of

accelerator pedal:

- Closed throttle

position

- Full throttle with kick

down

Page 597 of 1463

M162 ENGINE CONTROLS 1F1-27

Failure

codeItem

Checking method Test

stepRequirementSpecified

valuePossible cause

Þ 3.1· Ignition:ON

84 1124.75 - 5.25 V· ·· ·

· Throttle

valve

actuator:

- Power

supply(5V)· Cable

· ECU

Þ 4.0

· Ignition:ON

68 670.8 - 2.3 V

The value will

be changed in

1.0 - 2.5V.· ·· ·

· Throttle

valve

actuator:

- Signal

Throttle valve

actuator

motor voltage

supply104,

105,

108,

109,

116,

119,

185,· ECU

· Cable

· E-GAS actuator

· Engine:in idling

- Coolant

temperature:

>70 °C 84 85

4.0 - 4.6 V Throttle valve

potentiometer 2

0.3 - 0.9 V

· Position of

accelerator pedal:

- Closed throttle

position

- Full throttle with

kick down

Throttle valve

potentiometer

1+2

· Ignition:OFF

< 10 W

Throttle valve

actuator

motor

resistance68 67

Page 599 of 1463

M162 ENGINE CONTROLS 1F1-29

FUEL PRESSURE AND INTERNAL LEAKAGE TEST

01 Pressure Tester

02 Pressure Hose

03 Measuring Beaker

Preparation

Connection of the Equipment

1. Turn the ignition switch to "OFF" position.

2. Remove the air cleaner cross pipe.

3. Remove the cap on fuel pressure test plug and connect the

pressure hose and pressure tester.

4. Prepare the beaker for measuring the amount of fuel.

Tools Required

103 589 00 21 00 Pressure Tester

119 589 04 63 00 Pressure Hose

Page 601 of 1463

M162 ENGINE CONTROLS 1F1-31

FUEL PUMP TEST

Preparation

1 ECU

2 Test Coupling(No.1-60)

3 Test Coupling(No.61-120)

4 Stop Watch

5 Measuring Beaker

Connection of the Equipment

1. Turn the ignition switch to "OFF" position.

2. Connect the test box to the ECU.0 3 Test Box

04 ECU Test Cable

Tools Required

103 589 00 21 00 Pressure Tester

210 589 00 99 00 Adaptor Line

129 589 00 21 00 Test Box

210 589 08 63 00 Ecu Test Cable