SSANGYONG MUSSO 1998 Workshop Manual PDF

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Manual PDF

Page 350 of 1463

1B3-48 OM600 ENGINE MECHANICAL

38. Remove the camshaft bearing cap bolts according to the

numerical sequence.

Notice

Remove the No.1 bolts first and then remove the No. 2

bolts. Do not remove the bolts at a time completely but

remove them step by step evenly or camshaft can be

seriously damaged.

OM662LA

39. Remove the bearing caps and then pull out the

camshaft(20) upward.

Notice

Be careful not to miss the locking washer.

40. Remove the locking washer.

Notice

Check the locking washer and replace if necessary.

OM661LA

Page 357 of 1463

OM600 ENGINE MECHANICAL 1B3-55

12. Install the idle pulley and fit the closing cover.

Tightening Torque 25 Nm

13. Insert the tensioning lever(31) and install the spring.

14. Install the damper.

Tightening Torque 23 Nm

Notice

Insert the tensioning lever bolts onto the mounting hole.

15. Insert the locking washer.

16. Inspect the valve tappet and check that the tappet moves

smoothly.

Page 359 of 1463

OM600 ENGINE MECHANICAL 1B3-57

21. Position the camshaft on marking and install the camshaft

sprocket.

Notice

Align the alignment marks on the chain and sprocket.

23. Install the camshaft sprocket bolt. 22. Check the TDC position of the crankshaft.

Tightening Torque 25 Nm + 90°

Page 372 of 1463

1B3-70 OM600 ENGINE MECHANICAL

15. Install the guide pulley (22) and fit the closing cover (20).

16. Replace the gasket (3) and install the cylinder head cover

(2).

17. Install the cooling fan belt pulley and fan clutch.

18. Install the belt tensioning device and then install the belt.

19. Install the cooling fan.

20. Fill the engine oil and check oil leaks by running the engine.

Tightening Torque 23 Nm

Tightening Torque 10 Nm

Page 393 of 1463

OM600 ENGINE MECHANICAL 1B3-91

Notice

If the max. length of bolts(L) exceed 63.8mm, replace them.

19. Coat the new crankshaft with engine oil and place it on the

crankcase.

20. Install the crankshaft bearing caps according to marking

and tighten the bolts.

Tightening Torque 55 Nm + 90°

Notice

Install from No. 1 cap.

22. Rotate the crankshaft with hand and check whether it

rotates smoothly.

23. Measure crankshaft bearing axial clearance.

Clearance 0.100 - 0.245mm

Notice

If the clearance is out of standard, adjust the axial clearance

of crankshaft bearing by replacing the thrust washers.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

Page 394 of 1463

1B3-92 OM600 ENGINE MECHANICAL

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether it rotates

smoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve.

- clean the oil pump and oil filter housing carefully and

replace the hose if necessary.

Notice

After assembling the engine, check the camshaft timing,

adjust the start of fuel injection and check the TDC sensor

bracket setting.

32. Fill oil and run the engine and then check the oil pressure

and oil level.

Notice

Install the original oil filter element and then change the

engine oil and oil filter element after 1,000 - 1,500km. 27. Measure the radial clearance (L) of the connecting rod

bearing.

Example)Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L’ 0.026 - 0.068mm

Notice

If the clearance is out of standard, adjust the radial

clearance of connecting rod bearing by replacing the

connecting rod bearing shells. 26. Measure connecting rod bearing journal diameter (K).

Notice

Refer to measurement of the crankshaft bearing journal

diameter.

24. Insert the new connecting rod bearing shells into the

connecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

25. Measure inner diameter of connecting rod bearing.

Tightening Torque 40 Nm + 90°

Page 395 of 1463

OM600 ENGINE MECHANICAL 1B3-93

FLYWHEEL

Preceding Work : Removal of the transmission

Removal of the clutch

1 Oil Pan

2 Straight Pin

3 Flywheel4 12-Sided Stretch Bolt............Check, 45Nm + 90°

5 Drive Plate (Automatic Transmission)

6 Flywheel (Automatic Transmission)

Page 403 of 1463

OM600 ENGINE MECHANICAL 1B3-101

HYDRAULIC VALVE CLEARANCE COMPENSATION ELEMENT CHECK

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace4 Valve Tappet

5 Cylinder Head

Page 404 of 1463

1B3-102 OM600 ENGINE MECHANICAL

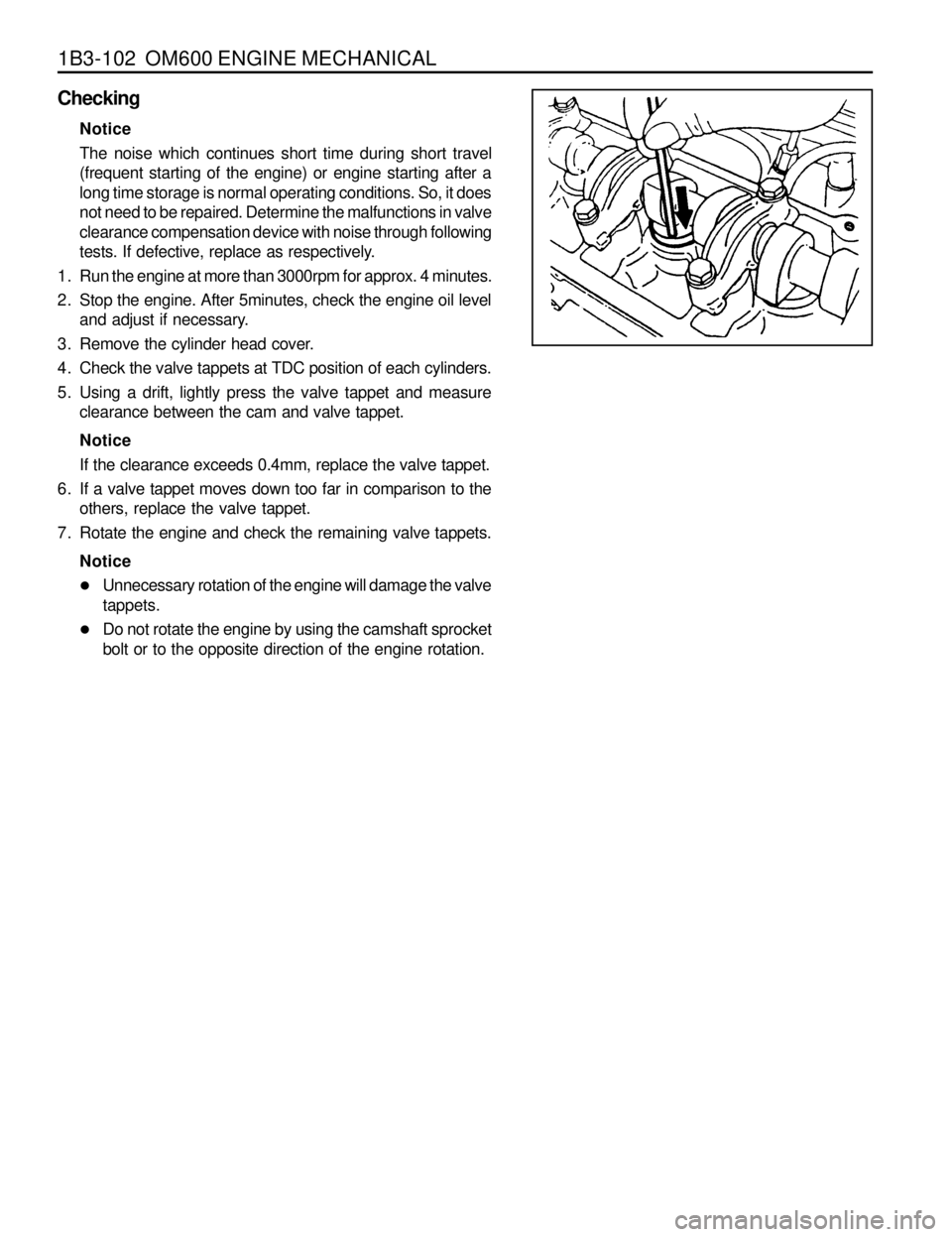

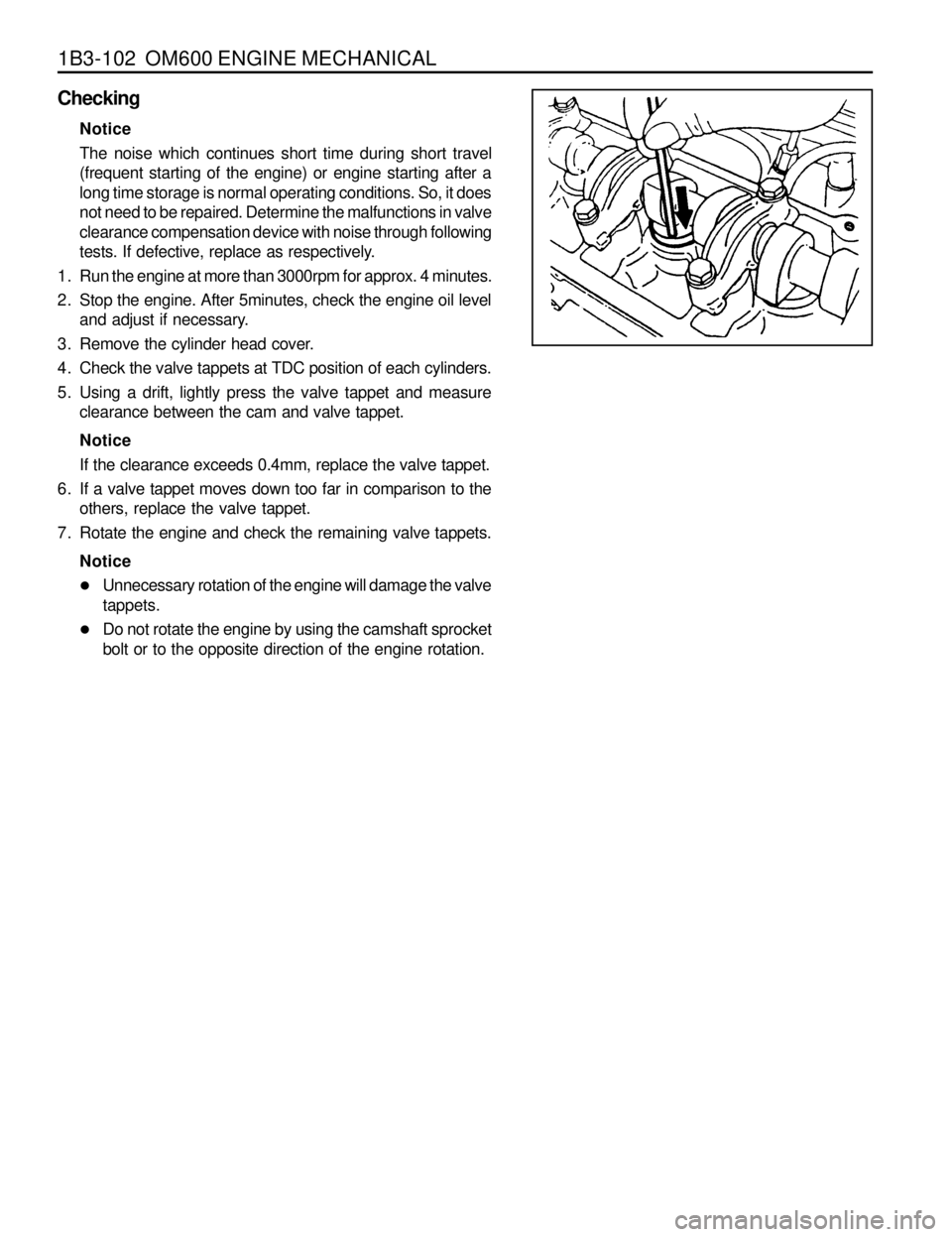

Checking

Notice

The noise which continues short time during short travel

(frequent starting of the engine) or engine starting after a

long time storage is normal operating conditions. So, it does

not need to be repaired. Determine the malfunctions in valve

clearance compensation device with noise through following

tests. If defective, replace as respectively.

1. Run the engine at more than 3000rpm for approx. 4 minutes.

2. Stop the engine. After 5minutes, check the engine oil level

and adjust if necessary.

3. Remove the cylinder head cover.

4. Check the valve tappets at TDC position of each cylinders.

5. Using a drift, lightly press the valve tappet and measure

clearance between the cam and valve tappet.

Notice

If the clearance exceeds 0.4mm, replace the valve tappet.

6. If a valve tappet moves down too far in comparison to the

others, replace the valve tappet.

7. Rotate the engine and check the remaining valve tappets.

Notice

lUnnecessary rotation of the engine will damage the valve

tappets.

lDo not rotate the engine by using the camshaft sprocket

bolt or to the opposite direction of the engine rotation.

Page 406 of 1463

1B3-104 OM600 ENGINE MECHANICAL

Replacement Procedure

1. Pull out the valve tappet (1).

Magnetic Bar 102 589 03 40 00

2. Remove the plug (5) and blow compressed air into the oil

gallery (3). At this time, check that the outlet bores(arrow)

at the seat of the valve tappet are clear.

3. Replace the seal (4) and tighten the plug (5).

4. Insert the new valve tappet.

Notice

Coat the valve tappet with oil.