check engine SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 281 of 1463

1B2-92 M161 ENGINE MECHANICAL

1. Check the piston ring gap and apply the engine oil to the

piston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by pressing in

the piston pin (6) and install the snap ring to the groove.

3. Clean the cylinder bore, connecting rod bearing journal,

connecting rod bearing shell and the piston and coat them

with engine oil.

4. Install the piston ring using the tensioning strap(000 589

04 14 00).

5. Install the piston so that the arrow on the piston head faces

to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap mark

(// or a number), tighten the bolts.

Installation Notice

Tightening Torque1st step 35 - 45 Nm

2nd step90°+5°

Apply the engine oil to the bearing cap upper and lower

bearing shells.

7. Check if the crankshaft rotates without any trouble by rotating

it.

Page 283 of 1463

1B2-94 M161 ENGINE MECHANICAL

Inspection

1. Measure the basic bore of the connecting rod bearing.

Notice

If the basic bore exceeds the value of 51.614mm, replace

the bearing or check the connecting rod.

2. Check connecting rod bolts.

3. Check the assembly mark(indication//or number:arrow) of

the connecting rods and the bearing cap when installing.

Notice

lMake sure it doesn’t exceed over 4g with other

connecting rods when replacing the connecting rods.

lCheck if the connecting rod and the bearing cap are

accurately seated on the groove when replacing the

bearing. Notice

If the length exceeds max. length, replace it.

Length When New (L)

Max. Length (L)

Tightening Torque51.7 - 52 mm

52.9 mm

1st step 40 + 5 Nm

2nd step 90°+10°

Page 286 of 1463

M161 ENGINE MECHANICAL 1B2-97

OIL PAN

1 Bolt

2 Bolt

3 Bolt

4 Bolt

1. Remove the drain plug and drain the oil completely.

2. Unscrew the bolts and remove the oil pan and gasket.

Notice

Arrange the bolts according to each size.

3. Clean the inside of oil pan and sealing surface, then apply

the sealant.

4. Replace the gasket with new one.

5. Install the oil pan with gasket, and tighten each bolt in

specified torque.

6. Check for oil leaks while running the engine.

M8 X 40, 4 pieces

M6 X 35, 1 pieces

M6 X 100, 2 piece

M6 X 85, 3 pieces

M6 X 20, 20 pieces

5 Bolt

6 Oil Pan

7 Gasket

u

Page 289 of 1463

1B2-100 M161 ENGINE MECHANICAL

9. Fill up engine oil through the engine oil filler opening.

10. Check for oil leaks at normal engine temperature after

starting the engine.

11. Stop the engine and wait 5 minutes.

Check the oil level and fill up as specified if necessary. 4. Remove the drain plug (1) and drain the engine oil.

Notice

Leave the oil filler cap (3) open to ease the engine oil

discharge.

5. Tighten the engine oil drain plug after cleaning it.

Installation Notice Tools Required

103 589 02 09 00 Oil Filter Socket Wrench

Replacement Procedure

1. Install the socket wrench”7” (special tool : 103 589 02 09

00) on the oil filter cover (2).

Notice

Make the screw cover removable by tightening the bolt at

the side of the socket wrench (special tool).

2. Install the wrench to the upper bolt in the socket wrench

and remove the oil cover by turning it.

3. Remove the oil filter element.

Notice

Work with a cloth under the vehicle when removing the oil

filter element to not drain the oil.

Replace the seal washer with new one.

6. Replace the O-ring(5) in the oil filter cover with new one.

Notice

Apply the engine oil to the O-ring.

7. Insert new oil filter element into the oil filter housing.

Tightening Torque 25 Nm

8. Temporarily tighten the oil filter cover (2). Install the socket

wrench “7” (special tool : 103 589 02 09 00), and then

completely tighten it.

Installation Notice

2 Oil Filter Cover

5 O-ring

6 Oil Filter Element

7 Special Tool (Socket Wrench)

Tightening Torque 25 Nm

Page 294 of 1463

M161 ENGINE MECHANICAL 1B2-105

OIL DIPSTICK GUIDE TUBE

1 Oil Dipstick Level Gauge

2 Oil Dipstick Guide Tube

3 O-ring

Removal & Installation Procedure

1. Pull out the oil dipstick level gauge (1).

2. Unscrew the bolt (4) and remove the oil dipstick guide

tube (2).

Installation Notice4 Bolt (M6 X 16, 1 piece)........................... 9-11 Nm

5 Clamp

Tightening Torque 9 - 11 Nm

It is very hard to remove the oil dipstick guide tube without

special tool. If it is not necessary, do not remove the guide

tube.

3. Installation should follow the removal procedure in the

reverse order.

4. Check for leaks by starting the engine.

Page 296 of 1463

M161 ENGINE MECHANICAL 1B2-107

Tools Required

102 589 00 15 00 Drift

Replacement Procedure

1. Remove the intake and exhaust manifolds.

2. Pull back the core plug until the end of one side comes out

using the screw driver.

3. Pull out the plug carefully using a pliers.

5. Press in new plug using a drift.

Notice

Wait for about 45minutes before filling the coolant so that

the Loctite 241 hardens.

6. Warm up the engine and check the coolant for leaks. 4. Clean the sealing surface and apply Loctite 241.

Page 302 of 1463

M161 ENGINE MECHANICAL 1B2-113

Measurement of Mating Surface

1. Measure the height (H) of the cylinder head (refer to Service

data standard

).

2. Check the mating surface of the cylinder head.

3. Mill the sharp edge of the combustion chamber.

4. Re-measure the height (H) of the cylinder head.

5. Seal the intake and exhaust valves.

6. Measure the dimension (T) between the camshaft bearing

and the valve system (refer to

Service data standard).

7. Mill the cylinder head valve seat (refer to

Service data

standard

).

Universal Tool

Surface Grinding MachineSceledum, Type RTY

Roaro

Schio/Italy

Page 303 of 1463

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2

Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of

Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface . . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 329 of 1463

OM600 ENGINE MECHANICAL 1B3-27

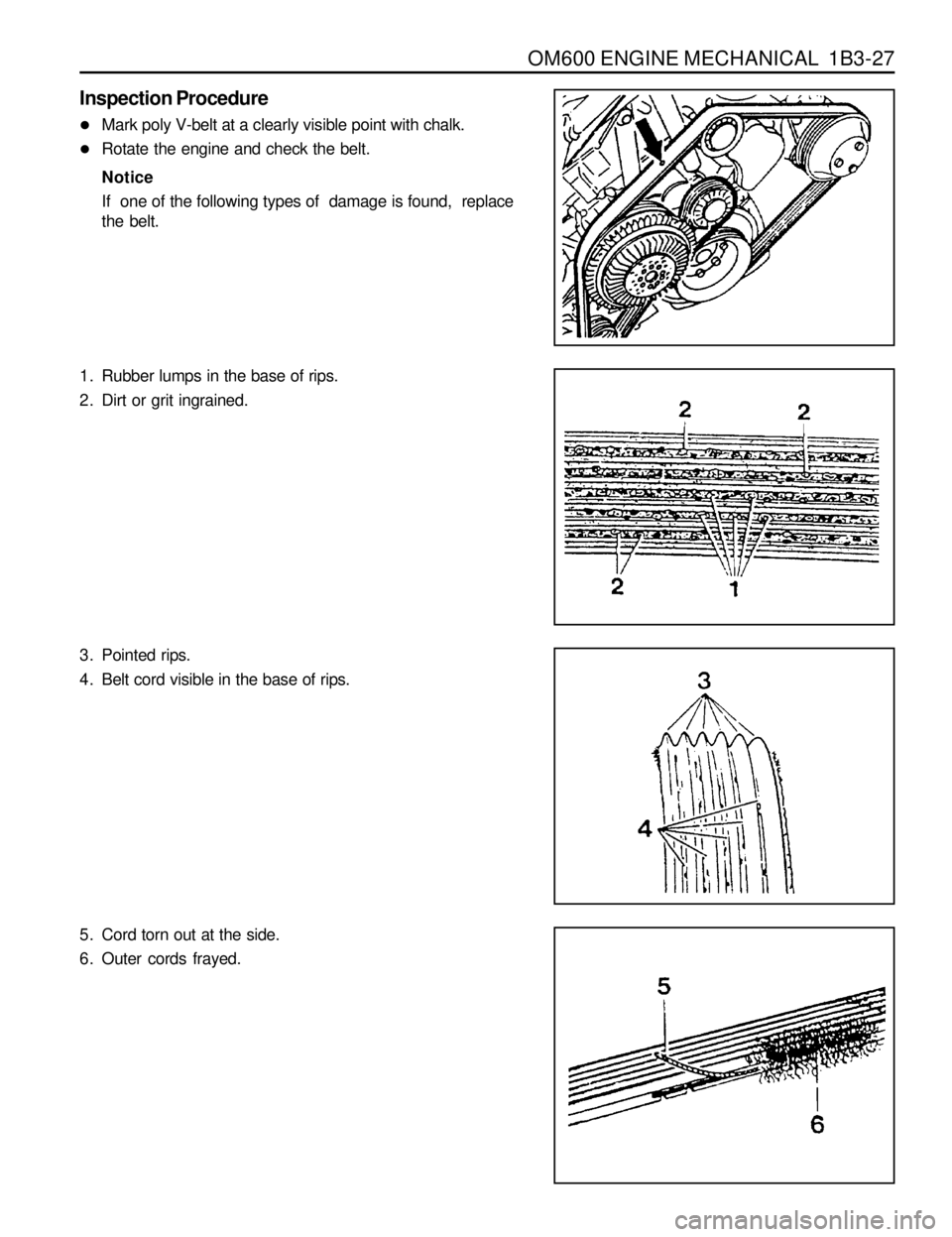

Inspection Procedure

lMark poly V-belt at a clearly visible point with chalk.

lRotate the engine and check the belt.

Notice

If one of the following types of damage is found, replace

the belt.

1. Rubber lumps in the base of rips.

2. Dirt or grit ingrained.

5. Cord torn out at the side.

6. Outer cords frayed. 3. Pointed rips.

4. Belt cord visible in the base of rips.

Page 339 of 1463

OM600 ENGINE MECHANICAL 1B3-37

CYLINDER HEAD

1 Fuel Injection Pipe.....................................18Nm

2 Cylinder Head

3 Gasket ................................................... Replace

4 Bolt............................................................25Nm

5 Washer

6 Clamp

7 Heater Feed Pipe

8 Bolt

9 Washer

1 0 Bolt

11 Nozzle Washer....................................... Replace

12 Fuel Injection Nozzle............................35-40 Nm

13 Hexagon Socket Bolt................................. 25 Nm

14 Washer

1 5 Bolt........................................................... 25 Nm

16 Cylinder Head Bolt..............................See Table

17 Cylinder Head Cover

1 8 Bolt........................................................... 10 Nm

19 Gasket

2 0 Camshaft21 Camshaft Drive Sprocket....................... Replace

22 Washer

23 Bolt(12-Sided) ..................................25Nm + 90°

24 Sliding Rail

25 Sliding Rail Pin

26 Sliding Rail Pin

27 Chain Tensioner....................................... 80 Nm

28 Gasket ................................................... Replace

29 Cooling Fan.............................................. Check

30 Hexagon Socket Bolt................................. 45 Nm

31 Tensioning Lever

3 2 Bolt........................................................... 25 Nm

3 3 Bolt

34 Nut ............................................................ 23 Nm

35 Fuel Filter

36 Turbo Charger

37 Intake Duct

38 Gasket ................................................... Replace

39 Intake Manifold