engine SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1056 of 1463

AUTOMATIC TRANSMISSION 5A-79

ADJUSTMENTS

HYDRAULIC SYSTEM

The procedures detailed below should be followed in the event that the self test procedure detailed in section 6, or a

defect symptom, indicates that there is a fault in the hydraulic system.

When making adjustments to the transmission, select the appropriate procedures from the following preliminary

checks.

lConduct a transmission fluid test procedure, refer to section 7.2.

lCheck the manual linkage adjustment (refer to the vehicle workshop manual).

lCheck engine idle speed (refer to Section 7.3).

lConduct a stall test (it is outside the scope of this publication to detail this procedure)

lconduct a road test (it is outside the scope of this publication to detail this procedure).

TRANSMISSION FLUID TEST PROCEDURE

Checking Transmission Fluid Level

This procedure is to be used when checking a concern with the fluid level in a vehicle. A low fluid level will result in

gearshift loss or delay if driven when the vehicle is cold.

The vehicle is first checked for transmission diagnostic messages (refer to section 6). If the vehicle has a speedo fault

it is possible for the oil level to be low.

The vehicle is to be test driven to determine if there is an abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low oil level is a momentary loss of drive when driving the vehicle around a comer. Also when

the transmission fluid level is low, a loss of drive may occur when the transmission oil temperature is low.

If there is no loss of drive when the vehicle is driven warm and a speedo fault is registered, then fluid should be added

to the transmission.

Checking, Adding Fluid and Filling

When adding or changing transmission oil use only Castrol TQ 95 automatic transmission fluid (ATF) or other approved

fluids. The use of incorrect oil will cause the performance and durability of the transmission to be severely degraded.

Do not underfill the transmission. Incorrect tilling may cause damage to the transmission. The fluid level setting

procedure is detailed below.

Notice

When a transmission is at operating temperature hot transmission fluid may come out of the case if the fill plug is

removed. 9 the transmission is at operating temperature allow two hours for cooling prior to removing the plug.

1. If the vehicle is at operating temperature allow the vehicle to cool down for two, but no greater than four hours

before adding transmission fluid (this will allow the transmission to be within the correct temperature

range).

While hot the ATF level is higher and removing the plug may result in oil being expelled from the filler hole. This

will result in the level being low.

2. The transmission selector is to be in Park.

Switch the engine off.

3. Raise the vehicle on a hoist (or leave over a service pit).

4. Clean all dirt from around the service fill plug prior to removing the plug. Remove the oil service fill plug.

Clean the fill plug and check that there is no damage to the ‘O’ ring.

Install the filler pump into the filler hole.

5. Lower the vehicle with the filler pump still connected and partially fill the transmission.

Start the vehicle in Park with the Parking brake and foot brake applied with the engine idling, cycle the transmission

gear selector through all positions, adding ATF until gear application is felt.

Page 1057 of 1463

5A-80 AUTOMATIC TRANSMISSION

6. Switch off the engine and raise the vehicle on the hoist, if applicable, ensuring that the vehicle is level.

7. Three minutes after the engine has stopped, but no longer than one hour, remove the filler pump, The correct

level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATF to the correct level.

8. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle.

9. Tighten the transmission filler plug to specification.

Checking, Adding Fluid and Filling - Drained or Dry Transmission

To set the correct fluid level proceed as follows.

1. Set the transmission selector to Park and switch the engine off.

2. Raise the vehicle on a hoist (or leave over a service pit).

3. Clean all dirt from around the service fill plug prior to removing the plug, Remove the oil service fill plug. Clean the

fill plug and check that there is no damage to the ‘O’ ring. Install the filler pump into the filler hole.

4. Lower the vehicle with the filler pump still connected and partially fill the transmission. This typically requires

approximately :

a. If the transmission torque converter is empty:

9.0 litres - 4WD

9.0 litres - RWD

b. If the transmission torque converter is full:

4.5 litres - 4WD

4.5 litres - RWD

5. Start the vehicle in Park with the Parking brake and foot brake applied with the engine idling, cycle the transmission

gear selector through all positions, adding ATF until gear application is felt.

6. Then add an additional 0.5 litres of ATF.

7. Switch off the engine and raise the vehicle on the hoist. Remove the filler pump and replace the filler plug. The

plug shall be tightened to specification.

8. The vehicle is then to be driven between 3.5 and 4.5 kilometers at light throttle so that the engine does not

exceed 2500 rpm. This should result in the transmission temperature being in the range 50 to 60°C.

9. With the engine idling, cycle the transmission selector through all gear positions with the brake applied.

10. Stop the engine. Raise the vehicle on the hoist, if applicable ensuring the vehicle is level.

11. Three minutes after the engine has stopped, but no longer than one hour, remove the filler plug. The correct

level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATP to the correct level.

12. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle. Tighten the

transmission Filler plug to specification.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustment

Carry out the adjustments to the idle speed as detailed in the workshop manual.

Throttle Position Calibration

Should the throttle position data stored in the TCU be lost or be out of specification, as indicated by a diagnostic

trouble message, it may be re-established by the following procedure.

lCheck that the hot engine idle speed is within specification.

lAllow the engine to idle in ‘Drive’ for 60 seconds with the air conditioner (if fitted) turned off. The closed throttle

reference point in the TCU has now been set.

Switch the engine off but leave the ignition on. Hold the accelerator pedal on the floor for 60 seconds. The wide open

throttle reference point in the TCU has now been set.

Page 1058 of 1463

AUTOMATIC TRANSMISSION 5A-81

Throttle Clearing

The leant throttle clearing routine uses the mode switch and gear lever. Carry out the following steps to complete the

automated throttle clearing procedure:

1. Switch ignition ‘ON’ with handbrake applied and engine ‘OFF’.

2. Select ‘M1’ and ‘WINTER’ mode.

3. Move the T-bar to ‘M2’ and then select ‘NORMAL’ or ‘POWER’ mode.

4. Move the T-bar to ‘M3’ and then select ‘WINTER’ mode.

Vehicle Coding

The vehicle coding is integrated as part of the diagnostic software. The coding applies to the following vehicle

models:

1. 4WD Gasoline E32.

2. 4WD Gasoline 523

3. 4WD Gasoline 520.

4. 4WD Diesel D29NA.

5. 4WD Diesel D29LA.

6. 4WD Diesel D23LA.

7. RWD E20.

8. RWD E23.

Page 1060 of 1463

AUTOMATIC TRANSMISSION 5A-83

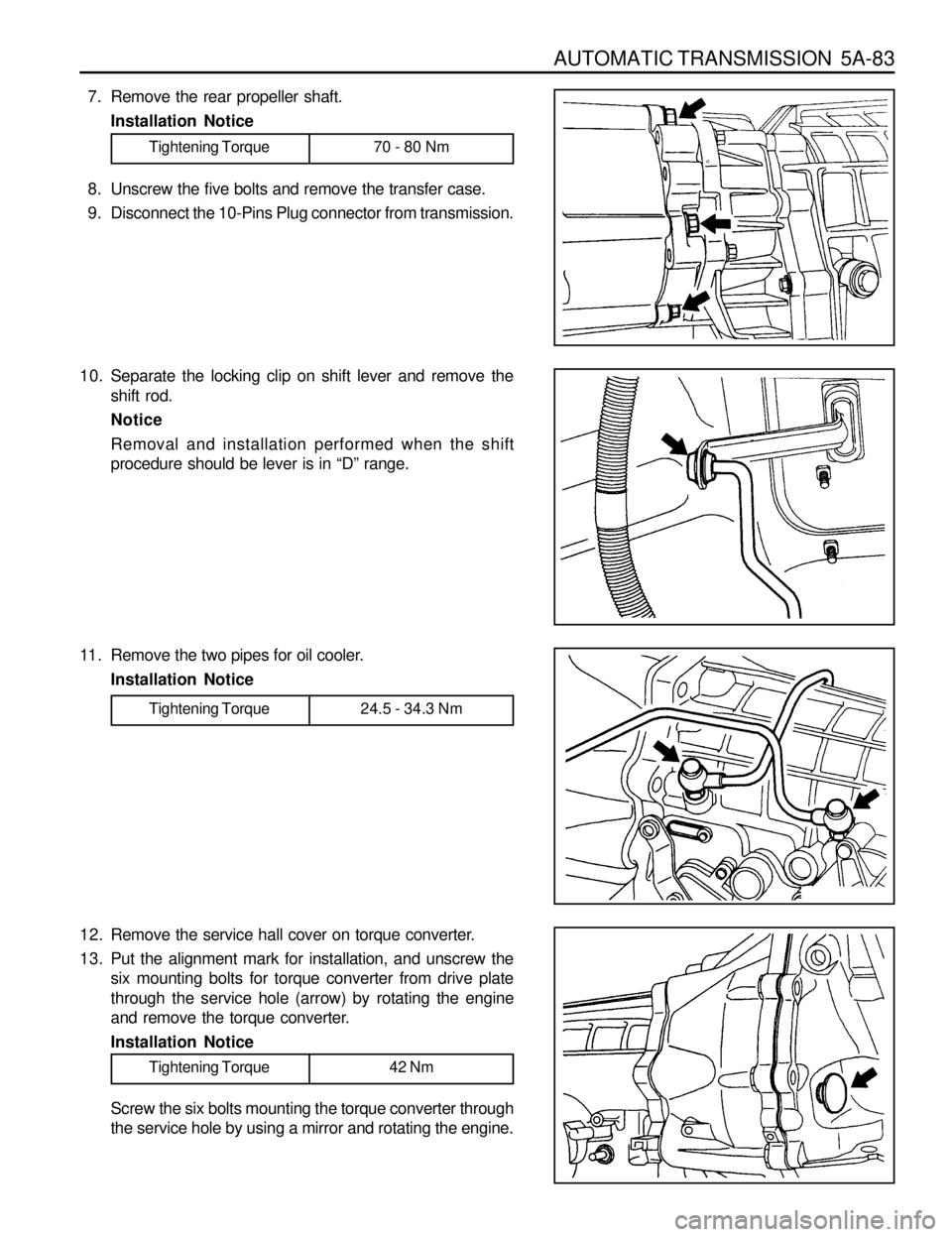

Tightening Torque 70 - 80 Nm

11. Remove the two pipes for oil cooler.

Installation Notice

Tightening Torque24.5 - 34.3 Nm

12. Remove the service hall cover on torque converter.

13. Put the alignment mark for installation, and unscrew the

six mounting bolts for torque converter from drive plate

through the service hole (arrow) by rotating the engine

and remove the torque converter.

Installation Notice

Tightening Torque 42 Nm

7. Remove the rear propeller shaft.

Installation Notice

8. Unscrew the five bolts and remove the transfer case.

9. Disconnect the 10-Pins Plug connector from transmission.

10. Separate the locking clip on shift lever and remove the

shift rod.

Notice

Removal and installation performed when the shift

procedure should be lever is in “D” range.

Screw the six bolts mounting the torque converter through

the service hole by using a mirror and rotating the engine.

Page 1112 of 1463

MANUAL TRANSMISSION 5B-5

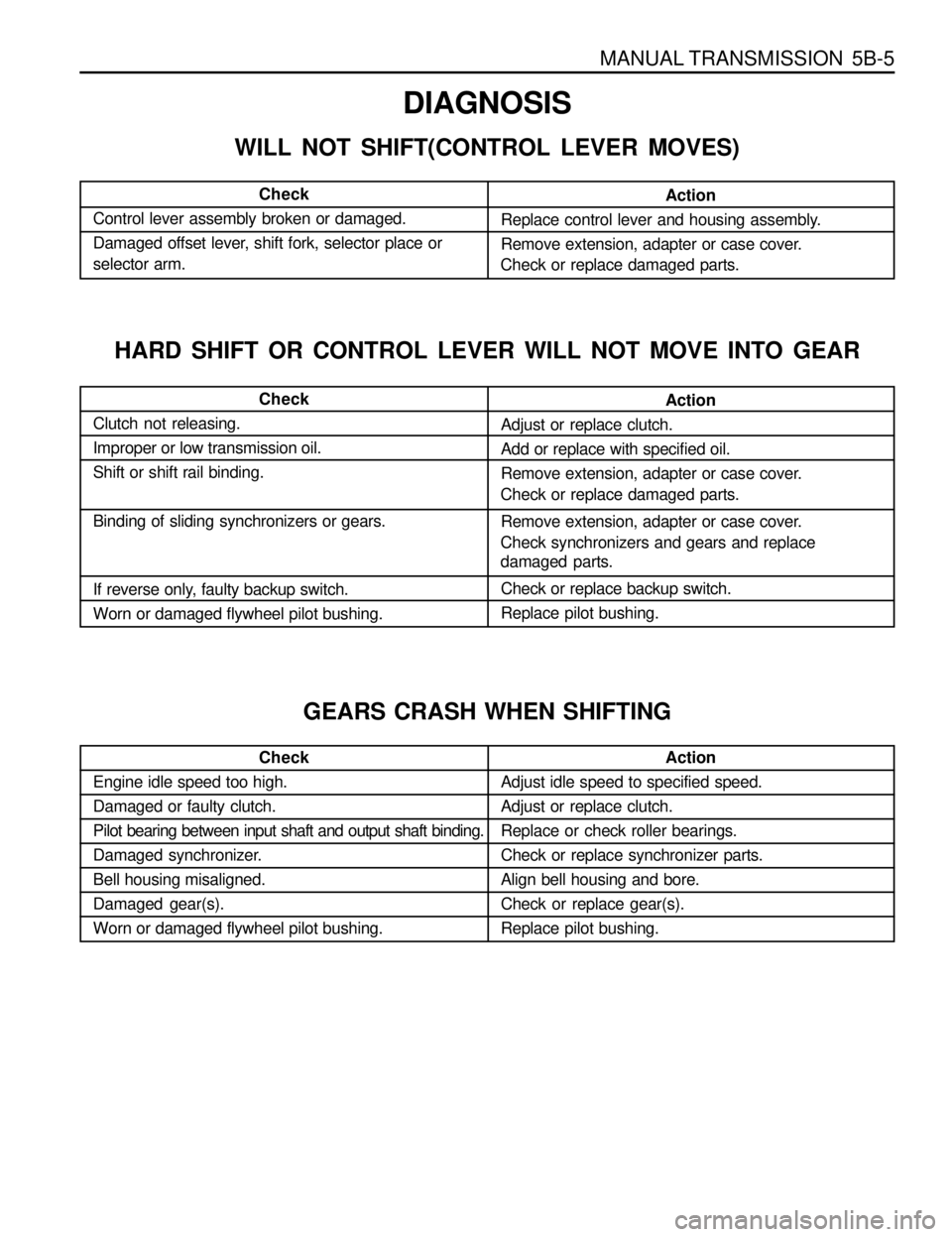

Check

Clutch not releasing.

Improper or low transmission oil.

Shift or shift rail binding.

Binding of sliding synchronizers or gears.

If reverse only, faulty backup switch.

Worn or damaged flywheel pilot bushing.Check

Control lever assembly broken or damaged.

Damaged offset lever, shift fork, selector place or

selector arm.

DIAGNOSIS

WILL NOT SHIFT(CONTROL LEVER MOVES)

Action

Replace control lever and housing assembly.

Remove extension, adapter or case cover.

Check or replace damaged parts.

HARD SHIFT OR CONTROL LEVER WILL NOT MOVE INTO GEAR

Action

Adjust or replace clutch.

Add or replace with specified oil.

Remove extension, adapter or case cover.

Check or replace damaged parts.

Remove extension, adapter or case cover.

Check synchronizers and gears and replace

damaged parts.

Check or replace backup switch.

Replace pilot bushing.

GEARS CRASH WHEN SHIFTING

Check

Engine idle speed too high.

Damaged or faulty clutch.

Pilot bearing between input shaft and output shaft binding.

Damaged synchronizer.

Bell housing misaligned.

Damaged gear(s).

Worn or damaged flywheel pilot bushing.Action

Adjust idle speed to specified speed.

Adjust or replace clutch.

Replace or check roller bearings.

Check or replace synchronizer parts.

Align bell housing and bore.

Check or replace gear(s).

Replace pilot bushing.

Page 1113 of 1463

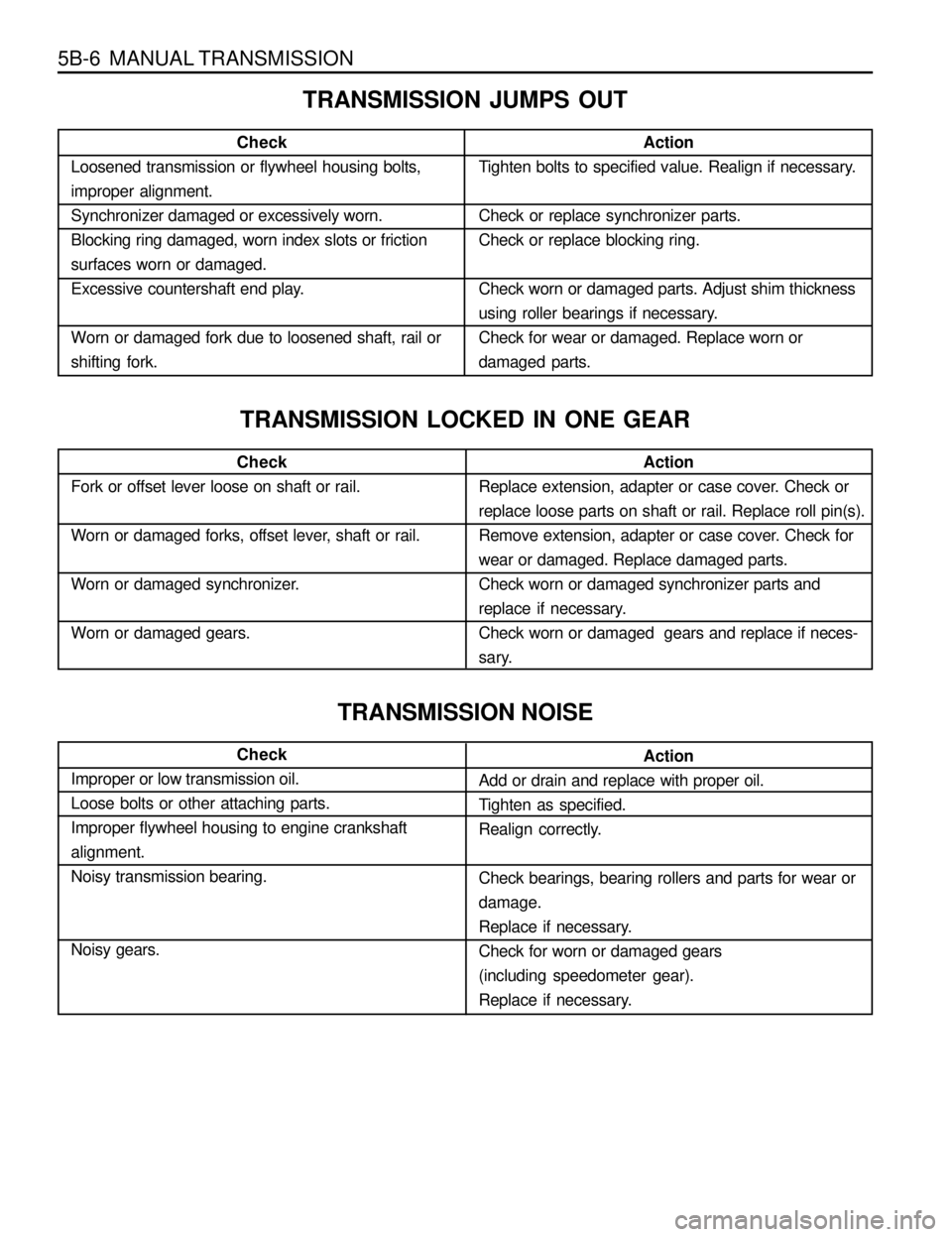

5B-6 MANUAL TRANSMISSION

Check

Loosened transmission or flywheel housing bolts,

improper alignment.

Synchronizer damaged or excessively worn.

Blocking ring damaged, worn index slots or friction

surfaces worn or damaged.

Excessive countershaft end play.

Worn or damaged fork due to loosened shaft, rail or

shifting fork.

TRANSMISSION JUMPS OUT

Action

Tighten bolts to specified value. Realign if necessary.

Check or replace synchronizer parts.

Check or replace blocking ring.

Check worn or damaged parts. Adjust shim thickness

using roller bearings if necessary.

Check for wear or damaged. Replace worn or

damaged parts.

Check

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever, shaft or rail.

Worn or damaged synchronizer.

Worn or damaged gears.

TRANSMISSION LOCKED IN ONE GEAR

Action

Replace extension, adapter or case cover. Check or

replace loose parts on shaft or rail. Replace roll pin(s).

Remove extension, adapter or case cover. Check for

wear or damaged. Replace damaged parts.

Check worn or damaged synchronizer parts and

replace if necessary.

Check worn or damaged gears and replace if neces-

sary.

Check

Improper or low transmission oil.

Loose bolts or other attaching parts.

Improper flywheel housing to engine crankshaft

alignment.

Noisy transmission bearing.

Noisy gears.

TRANSMISSION NOISE

Action

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly.

Check bearings, bearing rollers and parts for wear or

damage.

Replace if necessary.

Check for worn or damaged gears

(including speedometer gear).

Replace if necessary.

Page 1123 of 1463

5B-16 MANUAL TRANSMISSION

7. Remove the front and rear propeller shafts from the

transfercase.

Installation Notice

Tightening Torque81 - 89 Nm

70 - 90 NmFront

Rear

8. Support the transmission on an suitable jack.

Unscrew the center mounting nuts and each sides

mounting bolts and remove the cross member.

Installation Notice

9. Remove the transmission mounting bolts.

Installation Notice

Tightening Torque (1)

Tightening Torque (2)21 - 35 Nm

62 - 93 Nm

10. Move the transmission jack backward careful and

disengage the transmission input shaft from the engine.

Remove the transmission.

11. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 77 - 87 Nm

Page 1153 of 1463

5B-46 MANUAL TRANSMISSION

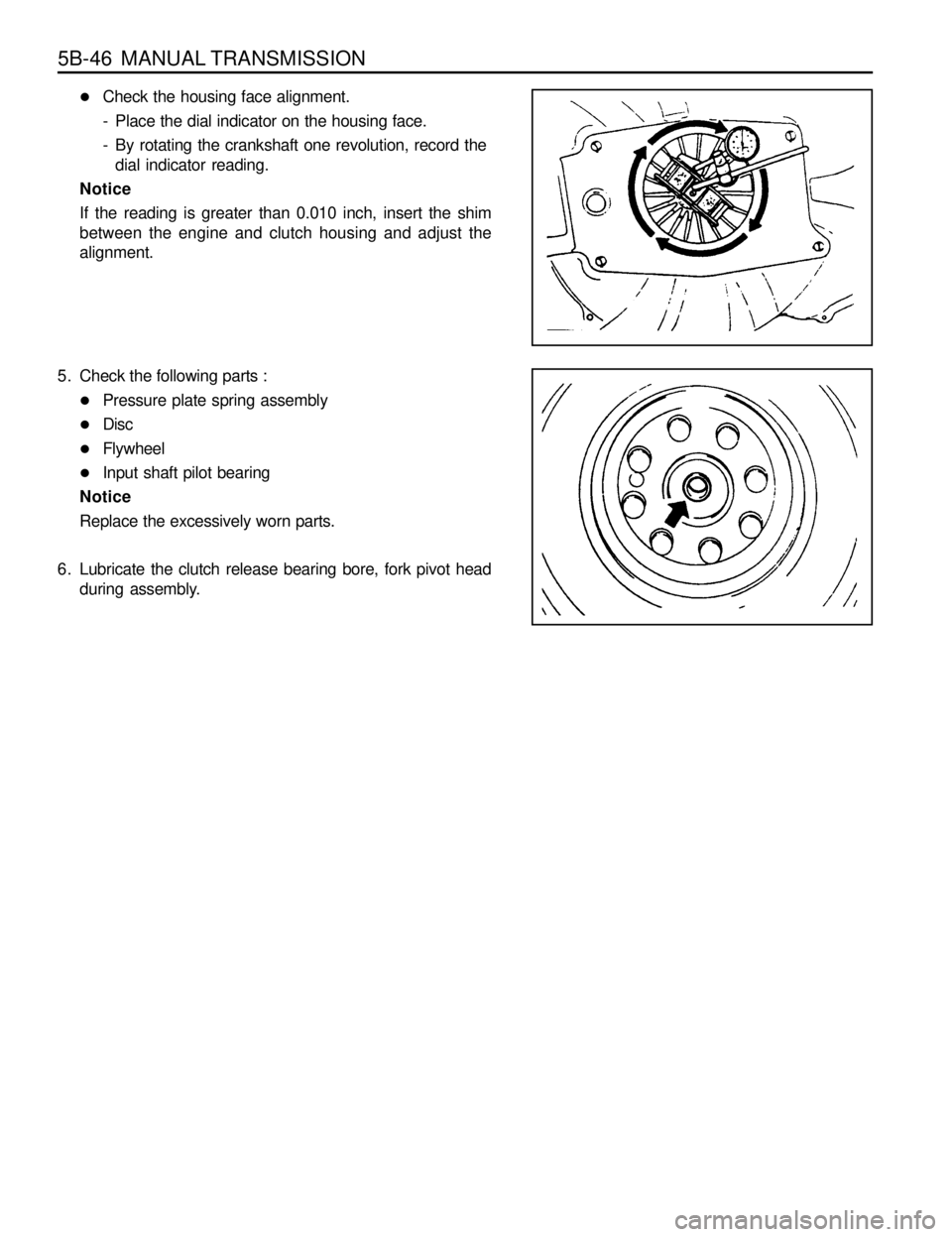

lCheck the housing face alignment.

- Place the dial indicator on the housing face.

- By rotating the crankshaft one revolution, record the

dial indicator reading.

Notice

If the reading is greater than 0.010 inch, insert the shim

between the engine and clutch housing and adjust the

alignment.

5. Check the following parts :

lPressure plate spring assembly

lDisc

lFlywheel

lInput shaft pilot bearing

Notice

Replace the excessively worn parts.

6. Lubricate the clutch release bearing bore, fork pivot head

during assembly.

Page 1156 of 1463

CLUTCH 5C-3

SPECIAL TOOLS

SPECIAL TOOLS TABLE

602 589 00 40 00

Engine Lock661 589 00 15 00

Centering Pin

Page 1157 of 1463

5C-4 CLUTCH

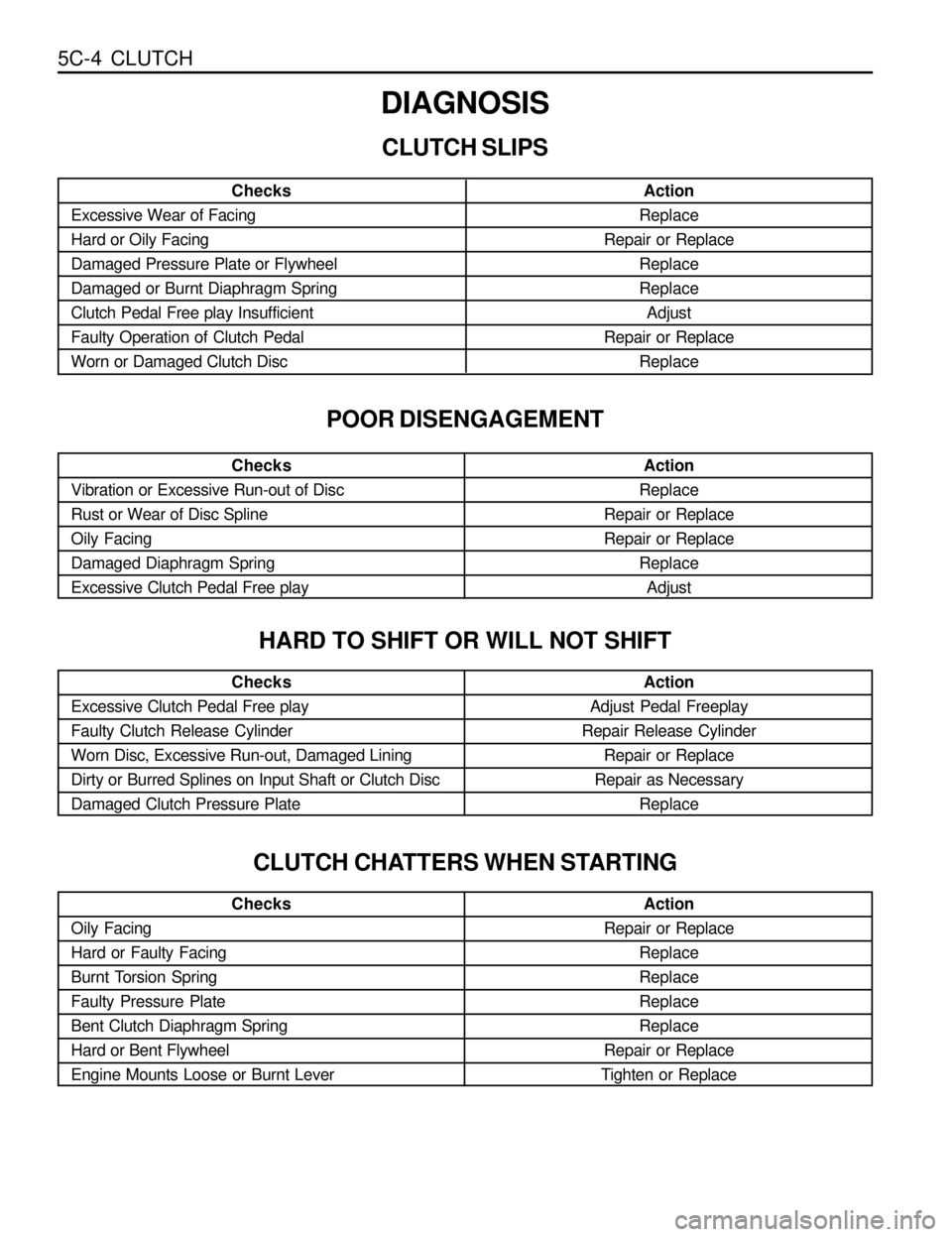

Checks

Oily Facing

Hard or Faulty Facing

Burnt Torsion Spring

Faulty Pressure Plate

Bent Clutch Diaphragm Spring

Hard or Bent Flywheel

Engine Mounts Loose or Burnt LeverAction

Adjust Pedal Freeplay

Repair Release Cylinder

Repair or Replace

Repair as Necessary

Replace Checks

Excessive Clutch Pedal Free play

Faulty Clutch Release Cylinder

Worn Disc, Excessive Run-out, Damaged Lining

Dirty or Burred Splines on Input Shaft or Clutch Disc

Damaged Clutch Pressure PlateChecks

Vibration or Excessive Run-out of Disc

Rust or Wear of Disc Spline

Oily Facing

Damaged Diaphragm Spring

Excessive Clutch Pedal Free play

DIAGNOSIS

CLUTCH SLIPS

Checks

Excessive Wear of Facing

Hard or Oily Facing

Damaged Pressure Plate or Flywheel

Damaged or Burnt Diaphragm Spring

Clutch Pedal Free play Insufficient

Faulty Operation of Clutch Pedal

Worn or Damaged Clutch DiscAction

Replace

Repair or Replace

Replace

Replace

Adjust

Repair or Replace

Replace

POOR DISENGAGEMENT

Action

Replace

Repair or Replace

Repair or Replace

Replace

Adjust

HARD TO SHIFT OR WILL NOT SHIFT

CLUTCH CHATTERS WHEN STARTING

Action

Repair or Replace

Replace

Replace

Replace

Replace

Repair or Replace

Tighten or Replace