filler SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 25 of 1463

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are

removed for rotation. Inspect the lines and the hoses

for proper hookup, binding, leaks, cracks, chafing, etc.

Inspect the disc brake pads for wear. Inspect the rotors

for surface condition. Inspect other brake parts, the

parking brake, etc., at the same time. Inspect the brakes

more often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the exhaust

system. Look for broken, damaged, missing, or out-of-

position parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper

tension. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the

secondary latch. It should keep the hood from opening

all the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be

securely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive

materials used for ice and snow removal and dust control.

At least every spring clean the underbody. First, loosen

the sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection,

corrosion protection and engine operating temperature.

Inspect the hoses. Replace the cracked, swollen, or

deteriorated hoses. Tighten the clamps. Clean the

outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help

ensure proper operation.

Page 42 of 1463

GENERAL ENGINE INFORMATION 1A1-11

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap

4 Vibration Damper

Permissible Pressure Leakage

6 Cylinder Pressure Leakage Tester with

Connecting Hose

Universal Tool

At Whole Engine

At Valve and Cylinder Head Gasket

At Piston and Piston RingMax. 25 %

Max. 10 %

Max. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC Mark

Cylinder Numberb (240°)

3, 4a (120°)

2, 5 OT (TDC)

1, 6

Cylinder Pressure Leakage Tester

Bosch, EFAW 210A

Sun, CLT 228

Page 43 of 1463

1A1-12 GENERAL ENGINE INFORMATION

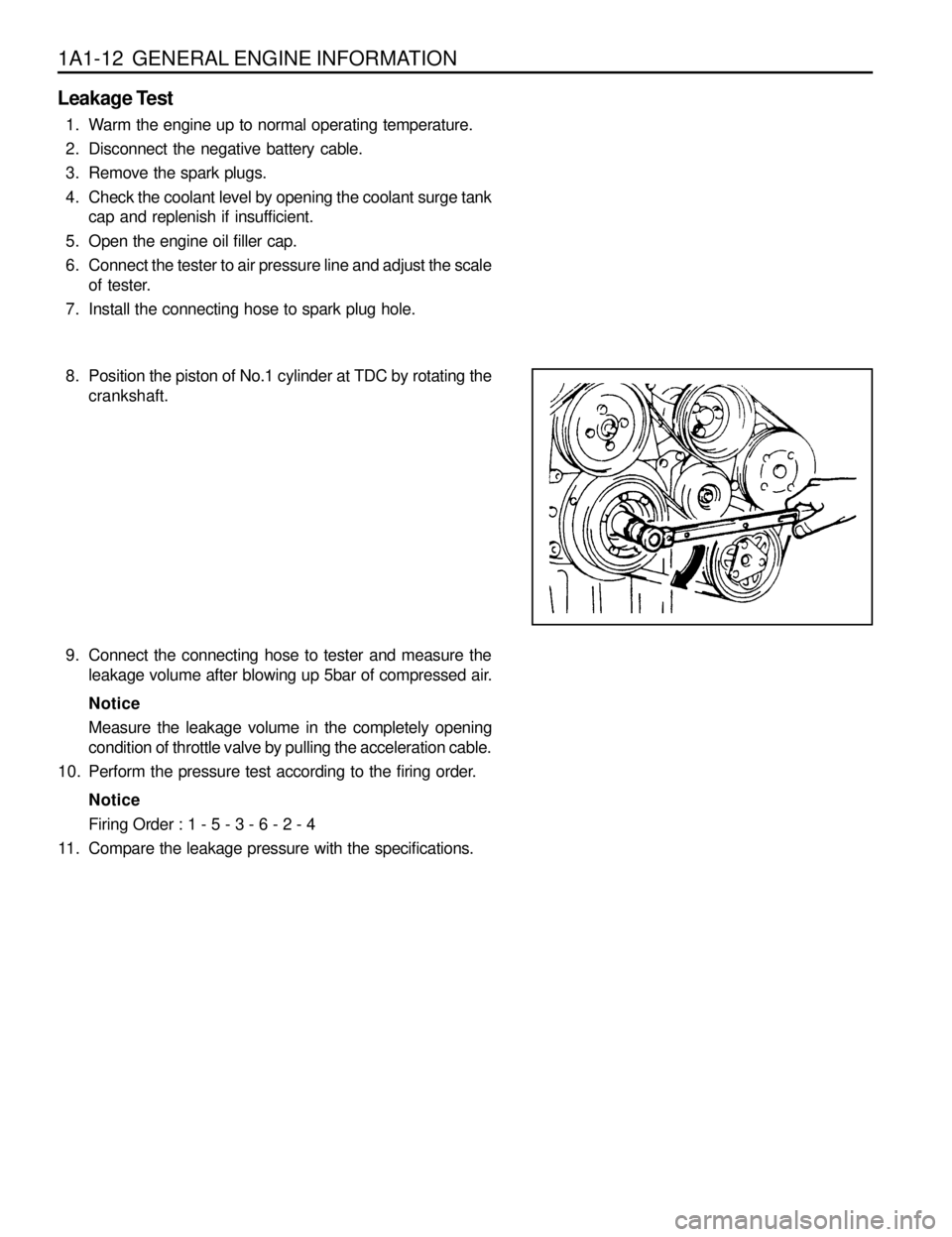

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 5 - 3 - 6 - 2 - 4

11. Compare the leakage pressure with the specifications.8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

Page 48 of 1463

1A2-4 GENERAL ENGINE INFORMATION

23 Camshaft Adjuster

24 Oil Filler Cap

25 Engine Hanger Bracket

26 Cooling Fan and Viscous Clutch

27 Oil Filter

28 Timing Chain29 Oil Pump Drive Chain

30 Oil Strainer

31 Oil Pump

32 Ring Gear and Flywheel of Drive Plate

33 Piston

SIDE VIEW

Page 56 of 1463

1A2-12 GENERAL ENGINE INFORMATION

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap

5 Vibration Damper

Permissible Pressure Leakage

6 Cylinder Pressure Leakage Tester with

Connecting Hose

Universal Tool

At Whole Engine

At Valve and Cylinder Head Gasket

At Piston and Piston RingMax. 25 %

Max. 10 %

Max. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC Mark

Cylinder NumberUT (BDC : 180°)

2, 3OT (TDC)

1, 4

Cylinder Pressure Leakage Tester Bosch EF AW 210A

Sun, CLT 228

Page 57 of 1463

GENERAL ENGINE INFORMATION 1A2-13

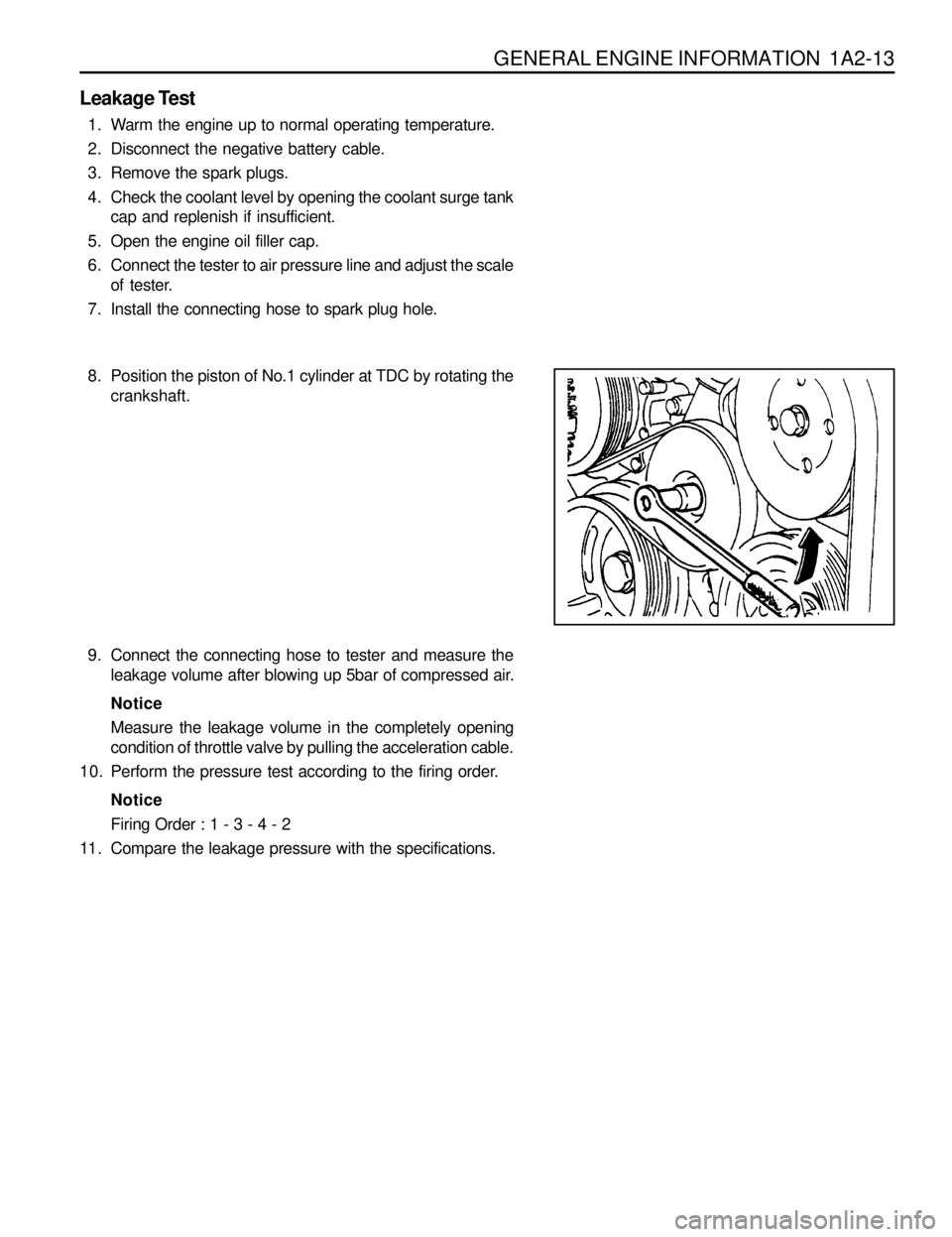

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 3 - 4 - 2

11. Compare the leakage pressure with the specifications.8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

Page 72 of 1463

1A3-14 GENERAL ENGINE INFORMATION

Leakage Test

1. Run the engine to be the coolant temperature 80°C.

2. Remove the fuel injection nozzle.

3. Open the coolant subtank cap.

4. Check the coolant level and replenish if necessary.

5. Open the oil filler cap.

6. Remove the air cleaner cover and element.

7. Position the piston at TDC.

8. Install the connector (1) and connection piece (2).

9. Calibrate the tester and connect the connection hose

(3)

10. Pressurize with compressed air and compare the

pressure changes with permissible pressure leakage.

11. If permissible pressure leakage is out of standard, check

followings :

- Intake and exhaust lines.

- Sounds in oil filler area.

- Air bubbles in radiator coolant.

12. Do pressure leakage test for the remaining cylinders

according to the firing order.

lOM 662LA Engine : 1-2-4-5-3

lOM 661LA Engine : 1-3-4-2

13. Remove the tester.

14. Close the coolant pressure cap and oil filler cap.

15. Install the air cleaner element and cover.

16. Install the fuel injection nozzle.

Page 145 of 1463

1B1-72 M162 ENGINE MECHANICAL

CHAIN TENSIONER

1 Screw Plug................................................ 40 Nm

2 Seal

3 Filler Pin

4 Compression Spring5 Snap Ring

6 Thrust Pin

7 Chain Tensioner Housing.....................72-88 Nm

8 Seal

Removal Procedure

1. Position the No.1 cylinder to TDC (OT).

Notice

Remove the oil filler cap at adjustment position, and check

whether the intake camshaft cam’s lobe (arrow) stays in the

upper side.

2. Cover the alternator with a clean cloth.

3. Release the tension by unscrewing the screw plug once.

Notice

In case that the tension is reduced by unscrewing the screw

plug, reinstall after completely removing the chain tensioner.

If the chain tensioner is tightened again without completely

reducing its tension, then the detent spring doesn’t return

to the original position and the tension gets excedded.

Page 146 of 1463

M162 ENGINE MECHANICAL 1B1-73

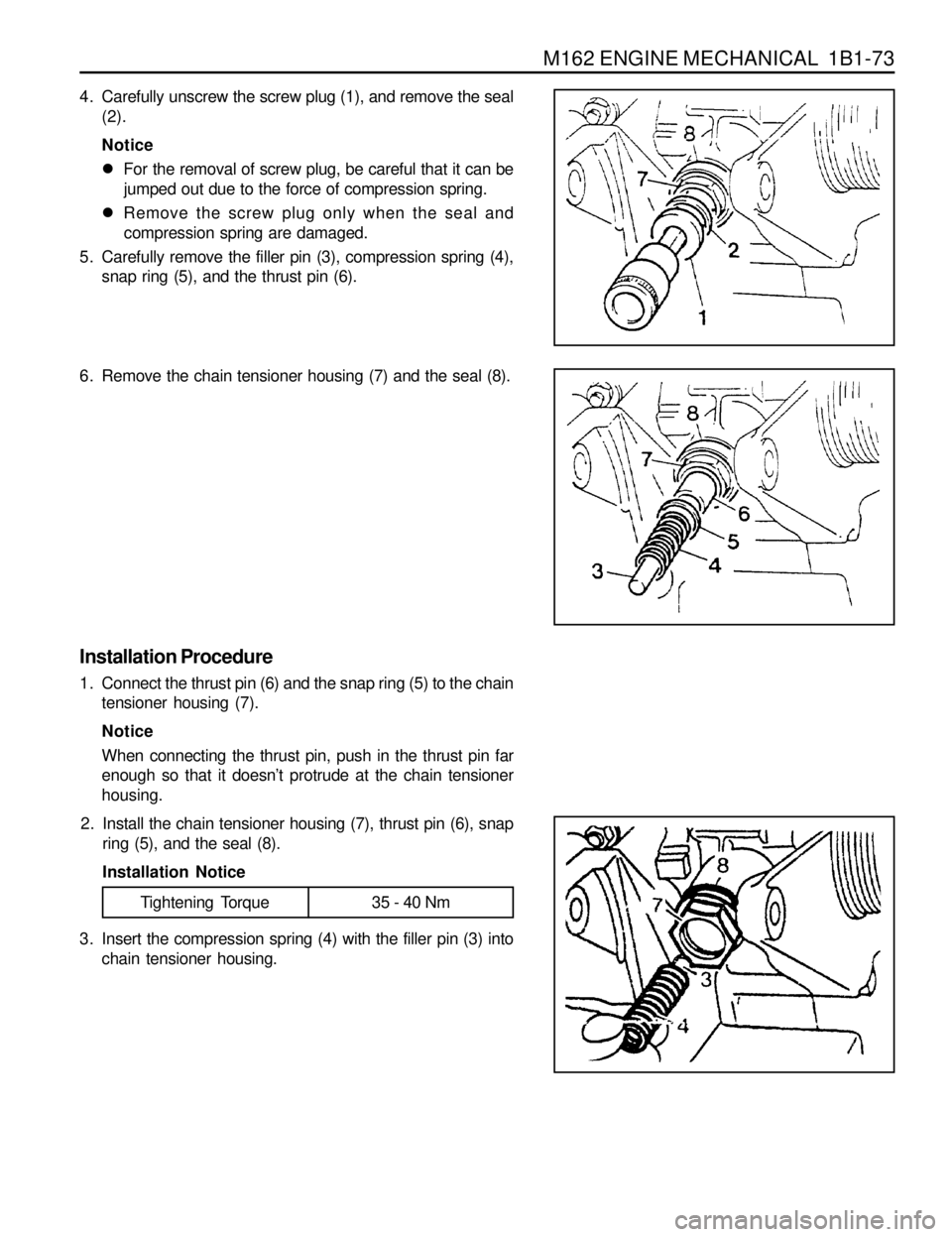

Installation Procedure

1. Connect the thrust pin (6) and the snap ring (5) to the chain

tensioner housing (7).

Notice

When connecting the thrust pin, push in the thrust pin far

enough so that it doesn’t protrude at the chain tensioner

housing. 4. Carefully unscrew the screw plug (1), and remove the seal

(2).

Notice

lFor the removal of screw plug, be careful that it can be

jumped out due to the force of compression spring.

lRemove the screw plug only when the seal and

compression spring are damaged.

5. Carefully remove the filler pin (3), compression spring (4),

snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal (8).

3. Insert the compression spring (4) with the filler pin (3) into

chain tensioner housing. 2. Install the chain tensioner housing (7), thrust pin (6), snap

ring (5), and the seal (8).

Installation Notice

Tightening Torque 35 - 40 Nm

Page 147 of 1463

1B1-74 M162 ENGINE MECHANICAL

4. Lightly apply the grease to the seal (2) and install the screw

plug (1).

Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

1 4 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole 5. Check for leaks by operating the engine.

Tightening Torque 40 Nm