clock SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 93 of 1463

1B1-20 M162 ENGINE MECHANICAL

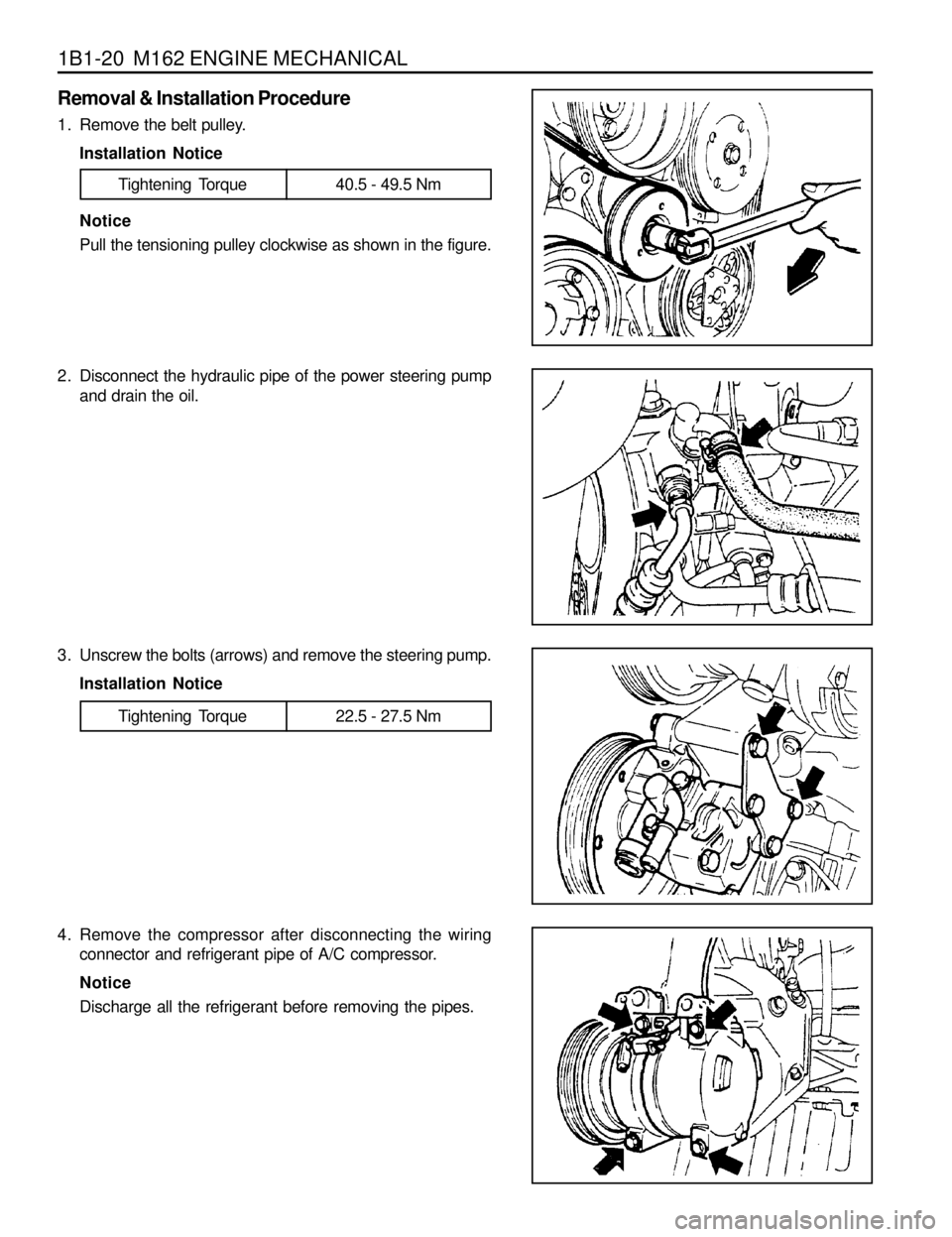

Removal & Installation Procedure

1. Remove the belt pulley.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley clockwise as shown in the figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 98 of 1463

M162 ENGINE MECHANICAL 1B1-25

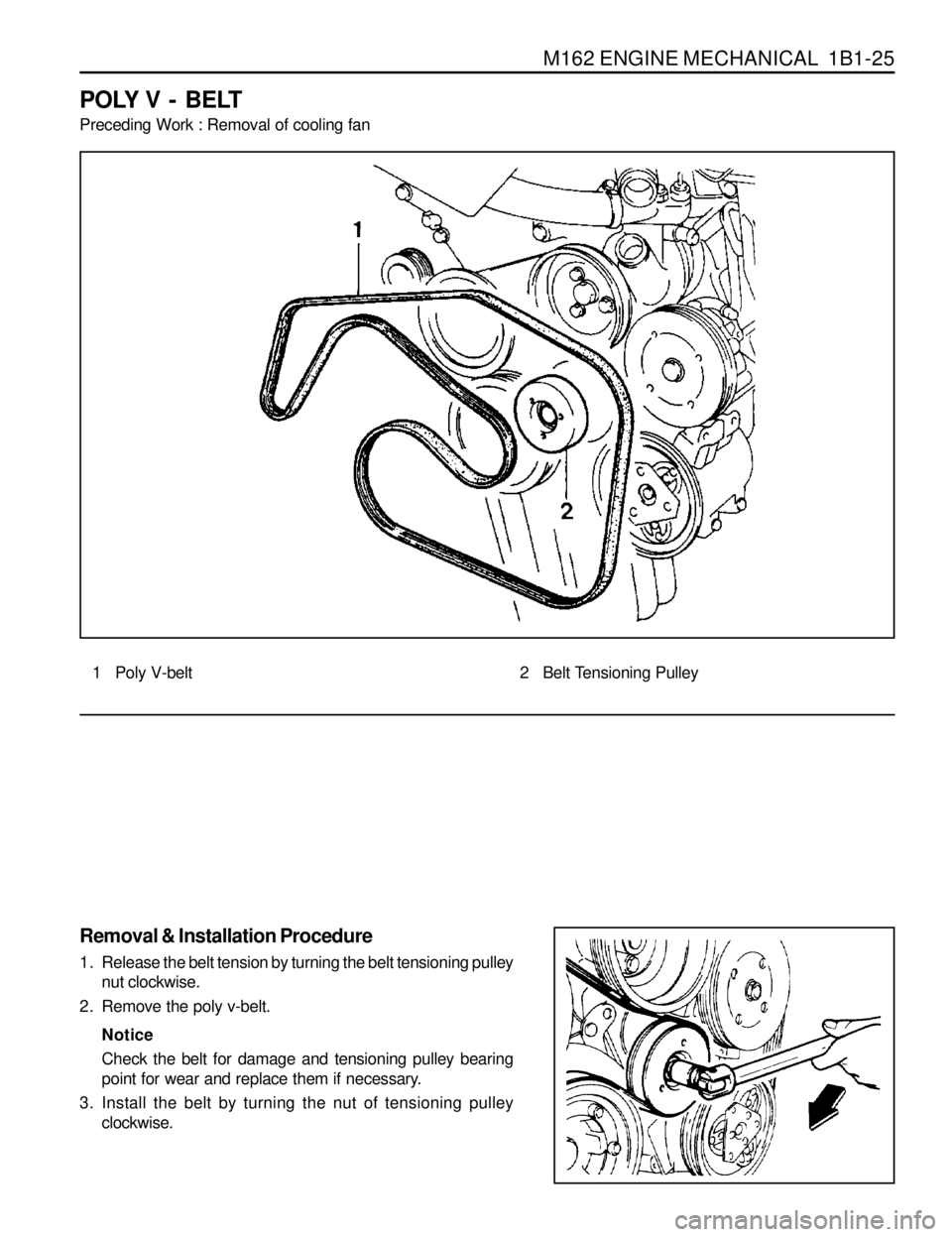

POLY V - BELT

Preceding Work : Removal of cooling fan

1 Poly V-belt

Removal & Installation Procedure

1. Release the belt tension by turning the belt tensioning pulley

nut clockwise.

2. Remove the poly v-belt.

Notice

Check the belt for damage and tensioning pulley bearing

point for wear and replace them if necessary.

3. Install the belt by turning the nut of tensioning pulley

clockwise.

2 Belt Tensioning Pulley

Page 100 of 1463

M162 ENGINE MECHANICAL 1B1-27

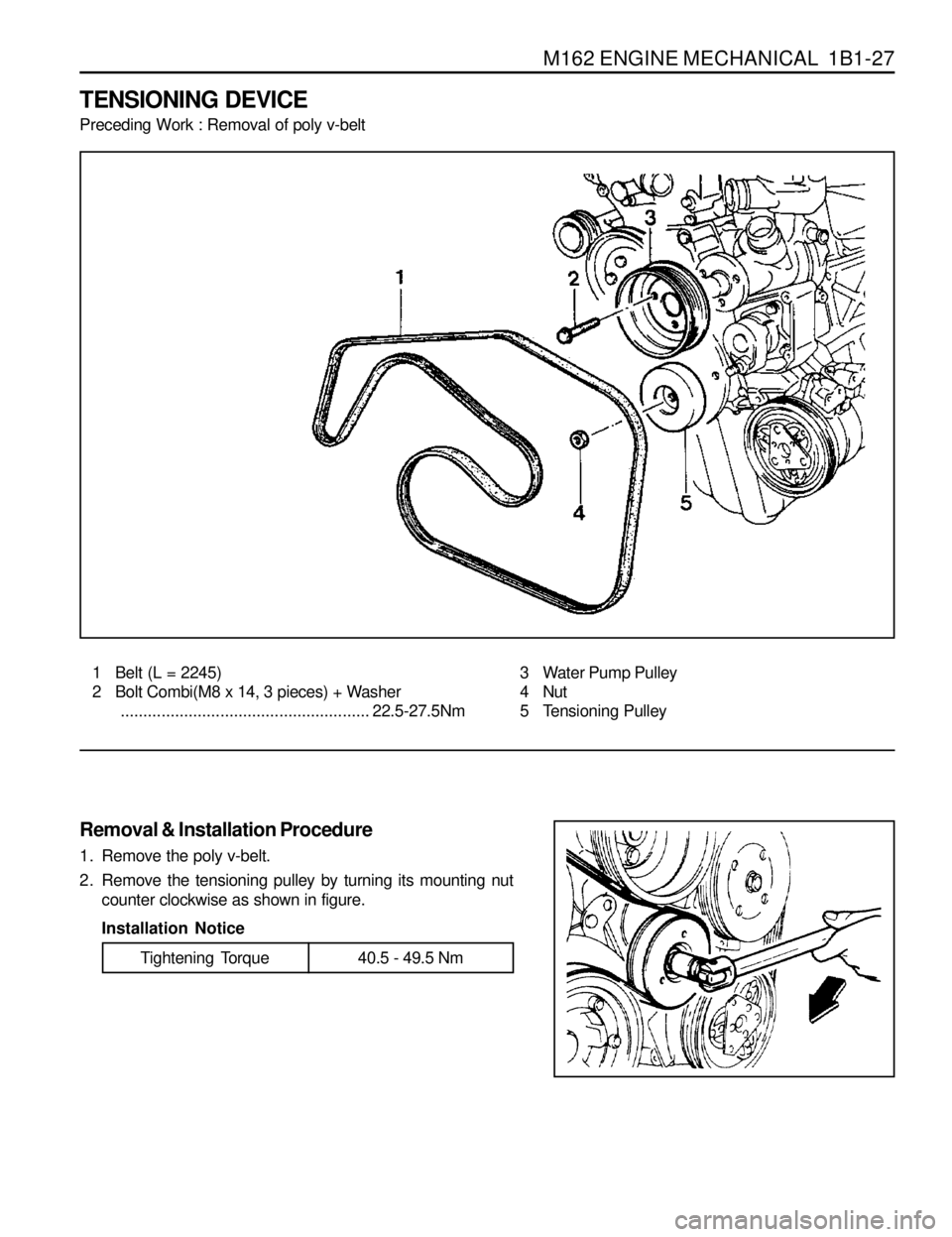

TENSIONING DEVICE

Preceding Work : Removal of poly v-belt

1 Belt (L = 2245)

2 Bolt Combi(M8 x 14, 3 pieces) + Washer

.......................................................22.5-27.5Nm

Removal & Installation Procedure

1. Remove the poly v-belt.

2. Remove the tensioning pulley by turning its mounting nut

counter clockwise as shown in figure.

Installation Notice3 Water Pump Pulley

4 Nut

5 Tensioning Pulley

Tightening Torque 40.5 - 49.5 Nm

Page 134 of 1463

M162 ENGINE MECHANICAL 1B1-61

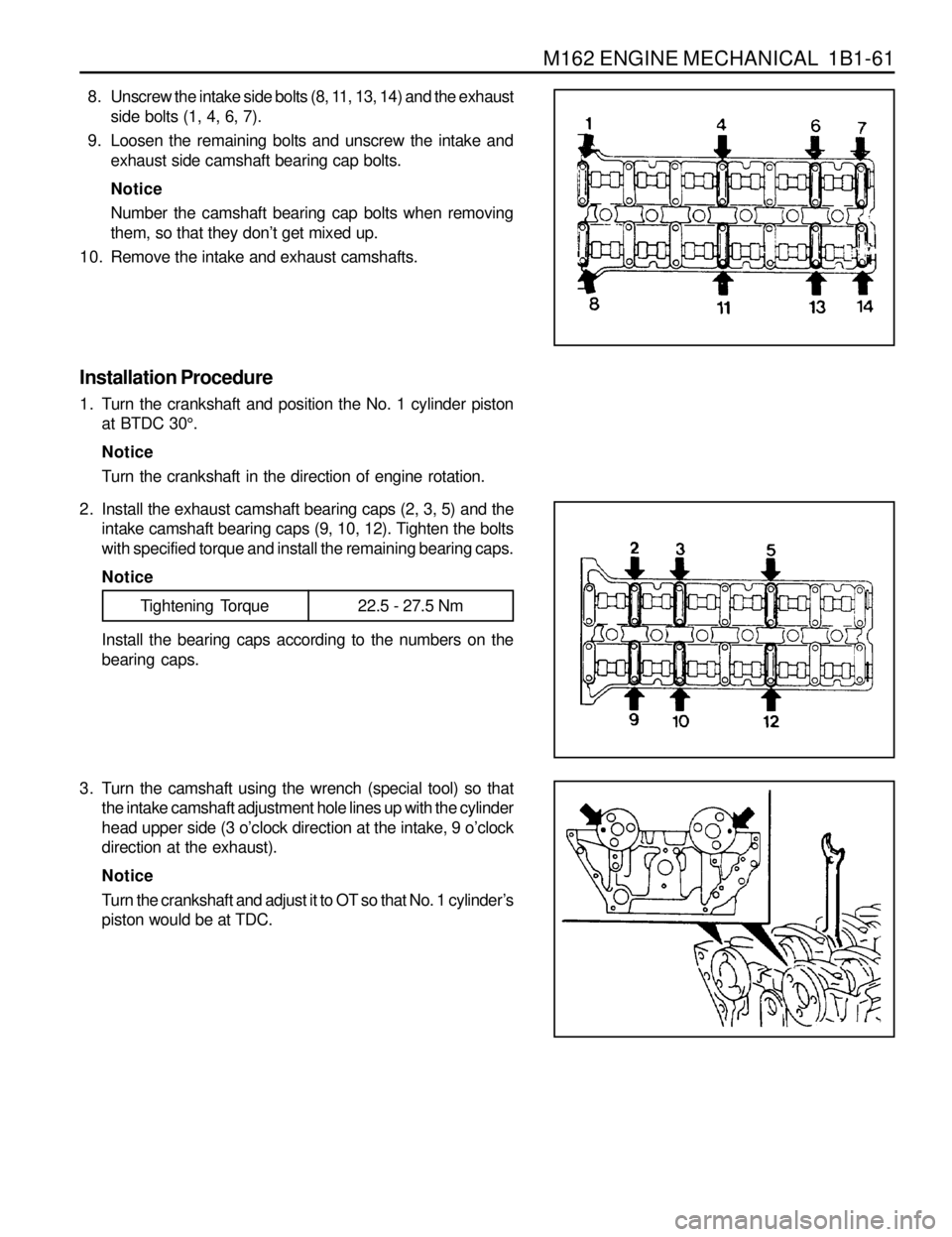

8 . Unscrew the intake side bolts (8, 11, 13, 14) and the exhaust

side bolts (1, 4, 6, 7).

9. Loosen the remaining bolts and unscrew the intake and

exhaust side camshaft bearing cap bolts.

Notice

Number the camshaft bearing cap bolts when removing

them, so that they don’t get mixed up.

10. Remove the intake and exhaust camshafts.

Installation Procedure

1. Turn the crankshaft and position the No. 1 cylinder piston

at BTDC 30°.

Notice

Turn the crankshaft in the direction of engine rotation.

3. Turn the camshaft using the wrench (special tool) so that

the intake camshaft adjustment hole lines up with the cylinder

head upper side (3 o’clock direction at the intake, 9 o’clock

direction at the exhaust).

Notice

Turn the crankshaft and adjust it to OT so that No. 1 cylinder’s

piston would be at TDC. Install the bearing caps according to the numbers on the

bearing caps.

Tightening Torque 22.5 - 27.5 Nm 2. Install the exhaust camshaft bearing caps (2, 3, 5) and the

intake camshaft bearing caps (9, 10, 12). Tighten the bolts

with specified torque and install the remaining bearing caps.

Notice

Page 138 of 1463

M162 ENGINE MECHANICAL 1B1-65

Adjustment Procedure

1. Position the No.1 cylinder to BTDC 30° .

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

4. Align the intake and exhaust camshaft flange hole with the

cylinder head upper surface.

lIntake Side : 3 o’clock direction

lExhaust Side : 9 o’clock direction

5. Secure the intake and exhaust camshaft.

6. Position the piston of No.1 cylinder at TDC (OT) by turning

the crankshaft.

7. Turn the camshaft adjuster of the intake camshaft to the

left as much as possible (cam adjuster ‘retarded’ position).

8. Install the chain to the intake camshaft sprocket.

Notice

Timing chain must be placed on the guide rail in gear case

cover. Tools Required

104 589 01 01 00Spanner

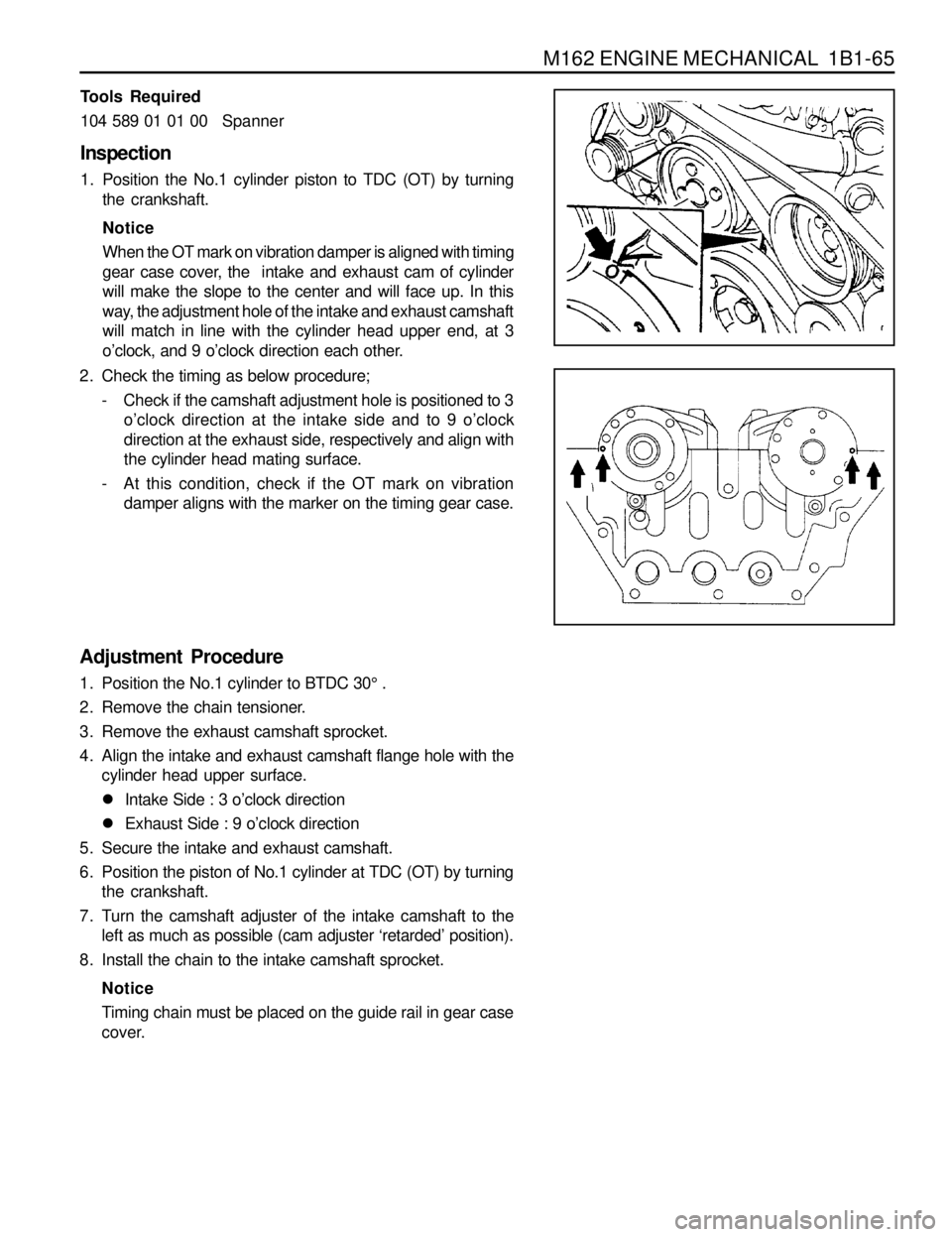

Inspection

1. Position the No.1 cylinder piston to TDC (OT) by turning

the crankshaft.

Notice

When the OT mark on vibration damper is aligned with timing

gear case cover, the intake and exhaust cam of cylinder

will make the slope to the center and will face up. In this

way, the adjustment hole of the intake and exhaust camshaft

will match in line with the cylinder head upper end, at 3

o’clock, and 9 o’clock direction each other.

2. Check the timing as below procedure;

- Check if the camshaft adjustment hole is positioned to 3

o’clock direction at the intake side and to 9 o’clock

direction at the exhaust side, respectively and align with

the cylinder head mating surface.

- At this condition, check if the OT mark on vibration

damper aligns with the marker on the timing gear case.

Page 212 of 1463

M161 ENGINE MECHANICAL 1B2-23

Removal & Installation Procedure

1. Remove the belt pulley after removal of poly v-belt.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley counterclockwise as shown in the

figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 217 of 1463

1B2-28 M161 ENGINE MECHANICAL

POLY V-BELT

Preceding Work : Removal of cooling fan

1 Poly V-belt (2,155 mm)

2 Belt Tensioning Pulley

Removal & Installation Procedure

1. Release the belt tension by turning the stud on the cap with

12 sided wrench or spanner counterclockwise.

2. Remove the poly v-belt.

Notice

Check the belt for damage and tensioning pulley bearing

point for wear and replace them if necessary.

3. Install the belt after prying the tensioning pulley.

3 Belt Tensioner

Page 219 of 1463

1B2-30 M161 ENGINE MECHANICAL

TENSIONING DEVICE

Preceding Work : Removal of tensioning device shock absorber

1 Bolt (M8 x 75, 2 pieces) +

Washer ..........................................22.5-27.5 Nm

2 Bolt (M8 x 25, 1 pieces) +

Washer ..........................................22.5-27.5 Nm

Removal & Installation Procedure

1. Turn the stud bolt to counterclockwise.

2. Insert the pin (111 589 01 15 00) into the hole in tensioning

arm.

3. Unscrew the bolts (1, 2) and remove the tensioning device.

Installation Notice

4. Installation should follow the removal procedure in the

reverse order.3 Tensioning Device

4 Stud bolt

5 Tensioning Arm

Tightening Torque 22.5 - 27.5 Nm

Page 338 of 1463

1B3-36 OM600 ENGINE MECHANICAL

Setting (with cylinder head installed)

1. Remove the prechamber of No. 1 cylinder.

2. Position the piston of No.1 cylinder at BTDC 10.

3. Install the measuring device into the prechamber bore and

position the dial gauge with a preload of 5mm.

Dial Gauge 001 589 53 21 00

Depth Gauge 601 589 07 21 00

4. Slowly rotate the crankshaft in the direction of engine rotation

until the large pointer on the dial gauge stops (TDC position).

Notice

The position of TDC is when the large pointer on the dial

gauge is stopped before moving back.

5. remove the reinstall the measuring device and position the

dial gauge scale at ‘0’.

6. Slowly rotate the crankshaft in the direction of engine rotation

until the dial gauge has moved back (counterclockwise) by

3.65mm.

7. Insert fixing device into the sensor bracket.

Notice

The pin on the vibration damper must engage into the slot

of the fixing device.

Fixing Device 667 589 01 21 00

8. If the pin does not engage, adjust the setting of the sensor

bracket by removing and tightening of the sensor bracket

bolts.

Tightening Torque 10 Nm

Notice

The timing mark on the damper must be positioned at ATDC

20.

Page 732 of 1463

OM600 ENGINE CONTROLS 1F3-3

FUEL INJECTION PUMP CODING

Model Code

PES 4M 55C 320 RS 167

PES 5M 55C 320 RS 168

Fuel Injection Pump Code

Example)PES 5M 55C 320 RS 168

P Pump

E Self-Driven

S End Flange Mounting

5 Number of Cylinders (5EA)

M Pump Size

55 Element Diameter

C Modification Letter

320 Assembly Number

R Direction of Rotation (clockwise)

S188 Special Version

RSF Governor

R Governor

S Coil Spring

F Drive Governor

Component Location

1. Fuel Injection Pump

2. Vacuum Unit (Stop Unit)

3. Control Lever

4. PLA Vacuum Unit (Idle Speed Adjustment)

5. Governor

6. Fuel Pump

OM661 LA Engine

OM662 LA Engine