lock SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 851 of 1574

4F-22 ANTILOCK BRAKE SYSTEM Pressure Decreased

1 Master Cylinder

2 Hydraulic Unit

3 Damping Chamber

4 Return Pump

5 Return Pump Motor6 Accumulator Chamber

7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Front Wheel

10 Rear Wheel

Page 852 of 1574

ANTILOCK BRAKE SYSTEM 4F-23

Pressure Maintained

1 Master Cylinder

2 Hydraulic Unit

3 Damping Chamber

4 Return Pump

5 Return Pump Motor6 Accumulator Chamber

7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Front Wheel

10 Rear Wheel

Page 853 of 1574

4F-24 ANTILOCK BRAKE SYSTEM ABS/ABD 5.3 Pressure Increased

1 Master Cylinder

2 Hydraulic Unit

3 Damping Chamber

4 Return Pump

5 Return Pump Motor

6 Accumulator Chamber7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve (ASV) 11 Pilot Valve (USV)

12 Check V alve

13 ISD (Integrated Suction Damper)

Page 854 of 1574

ANTILOCK BRAKE SYSTEM 4F-25

Pressure Decreased

1 Master Cylinder

2 Hydraulic Unit

3 Damping Chamber

4 Return Pump

5 Return Pump Motor

6 Accumulator Chamber7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve (ASV) 11 Pilot Valve (USV)

12 Check V alve

13 ISD (Integrated Suction Damper)

Page 855 of 1574

4F-26 ANTILOCK BRAKE SYSTEM Pressure Maintained (Hold)

1 Master Cylinder

2 Hydraulic Unit

3 Damping Chamber

4 Return Pump

5 Return Pump Motor

6 Accumulator Chamber7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve (ASV) 11 Pilot Valve (USV)

12 Check V alve

13 ISD (Integrated Suction Damper)

Page 856 of 1574

SECTION 4G

PARKING BRAKE

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4G-1General Specifications . . . . . . . . . . . . . . . . . . 4G-1

Fastener Tightening Specifications . . . . . . . . . 4G-1

Component Locator . . . . . . . . . . . . . . . . . . . 4G-2 TABLE OF CONTENTS

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . 4G-2

Maintenance and Repair . . . . . . . . . . . . . . . 4G-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4G-3 Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . 4G-3

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting thiscable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCKunless otherwise noted.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Parking Brake Lever Bolt Cable Mounting Bracket Bolt

N

m

8 - 18 8 - 18

FASTENER TIGHTENING SPECIFICATIONS

Application

Type

Operating Type

Description

Mechanically Operated Rear Wheel Expansion Manual

Page 860 of 1574

SECTION 5A

AUTOMATIC TRANSMISSION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

Model Part Numbers and Applications . . . . . . 5A-2

Model Specifications . . . . . . . . . . . . . . . . . . . . 5A-2

Clutch Pack Details . . . . . . . . . . . . . . . . . . . . . 5A-3

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 5A-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5A-4

Schematic and Routing Diagrams . . . . . . . . 5A-5

TCU Circuit (Diesel) . . . . . . . . . . . . . . . . . . . . 5A-5

TCU Circuit (Gasoline) . . . . . . . . . . . . . . . . . . 5A-6

Shift Pattern Diagram . . . . . . . . . . . . . . . . . 5A-7

661LA Normal Mode . . . . . . . . . . . . . . . . . . . . 5A-7

661LA Power Mode . . . . . . . . . . . . . . . . . . . . 5A-8

662LA Normal Mode . . . . . . . . . . . . . . . . . . . . 5A-9

662LA Power Mode . . . . . . . . . . . . . . . . . . . 5A-10

662LA Low Mode . . . . . . . . . . . . . . . . . . . . . 5A-11

E32 Power Mode . . . . . . . . . . . . . . . . . . . . . 5A-12

E32 Normal Mode . . . . . . . . . . . . . . . . . . . . . 5A-13

E32 Low Mode . . . . . . . . . . . . . . . . . . . . . . . 5A-14

E23 Power Mode . . . . . . . . . . . . . . . . . . . . . 5A-15

E23 Normal Mode . . . . . . . . . . . . . . . . . . . . . 5A-16

E23 Low Mode . . . . . . . . . . . . . . . . . . . . . . . 5A-17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 5A-18

Operator Interfaces . . . . . . . . . . . . . . . . . . 5A-20

Gear Select Lever Operation . . . . . . . . . . . . 5A-20

Driving Mode Selector . . . . . . . . . . . . . . . . . 5A-21

Control Systems . . . . . . . . . . . . . . . . . . . . . 5A-22

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

Electronic Control System . . . . . . . . . . . . . . . 5A-22

Hydraulic Control System . . . . . . . . . . . . . . . 5A-31

Power Train System . . . . . . . . . . . . . . . . . . 5A-42

Torque Converter . . . . . . . . . . . . . . . . . . . . . 5A-43

Clutch Packs . . . . . . . . . . . . . . . . . . . . . . . . . 5A-44Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-45

One Way Clutches . . . . . . . . . . . . . . . . . . . .

5A-45

Planetary Gear Set . . . . . . . . . . . . . . . . . . . . 5A-45

Parking Mechanism . . . . . . . . . . . . . . . . . . . 5A-46

Power Flows . . . . . . . . . . . . . . . . . . . . . . . . 5A-47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-47

Power Flow - Park and Neutral . . . . . . . . . . . 5A-48

Power Flow - Reverse . . . . . . . . . . . . . . . . . . 5A-49

Power Flow - Manual 1 . . . . . . . . . . . . . . . . . 5A-50

Power Flow - Drive 1 . . . . . . . . . . . . . . . . . . . 5A-51

Power Flow - Drive 2 and Manual 2 . . . . . . . 5A-52

Power Flow - Drive 3 and Manual 3 . . . . . . . 5A-54

Power Flow - Drive 3 Lock Up and Manual

3 Lock Up . . . . . . . . . . . . . . . . 5A-56

Power Flow - Drive 4 (Overdrive) . . . . . . . . . 5A-57

Power Flow - Drive 4 Lock Up . . . . . . . . . . . . 5A-59

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-60

Diagnostic System . . . . . . . . . . . . . . . . . . . . 5A-60

Mechanical Tests . . . . . . . . . . . . . . . . . . . . . 5A-69

Self Diagnosis Test . . . . . . . . . . . . . . . . . . 5A-75

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 5A-79

Hydraulic System . . . . . . . . . . . . . . . . . . . . . 5A-79

Transmission Fluid Test Procedure . . . . . . . . 5A-79

Electronic Adjustments . . . . . . . . . . . . . . . . . 5A-80

Maintenance and Repair . . . . . . . . . . . . . . 5A-82

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 5A-82

Removal and Installation of Transmission . . . 5A-82

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 5A-85

Rebuild Warnings . . . . . . . . . . . . . . . . . . . . . 5A-85

Disassembly Procedure . . . . . . . . . . . . . . . . 5A-85

Assembly Procedure . . . . . . . . . . . . . . . . . . . 5A-94

Front and Rear Band Adjustment . . . . . . . . 5A-128

Page 863 of 1574

5A-4 AUTOMATIC TRANSMISSIONSPECIAL TOOLS

SPECIAL TOOLS TABLE

Part Number

0555 - 332083 0555 - 3360460555 - 3362560555 - 3362570555 - 336258 0555 - 336259 0555 - 3362600555 - 3362610555 - 3362620555 - 336263 0555 - 336264 0555 - 3362650555 - 3362660555 - 3362670555 - 336268 0555 - 336269 0555 - 3362700555 - 332895Description

Solenoid / Thermistor, Electronic Tester

Solenoid, Bench Tester

Transmission Bench Cradle Pump Puller

Pin Remover / Installer Tool (Cross Shaft / Detent Lever)Clutch Spring CompressorClutch Pack Clearance Kit

Seal Removal Tool (Cross - Shaft) Oil Seal Dolly (Cross - Shaft)Assembly BulletSeal CompressorPin Press Seal Dolly

Alignment ToolPump Seal DollyEnd Float AdaptorEnd Float Shaft

Locknut Crimping Tool (W-Car Only)

Page 877 of 1574

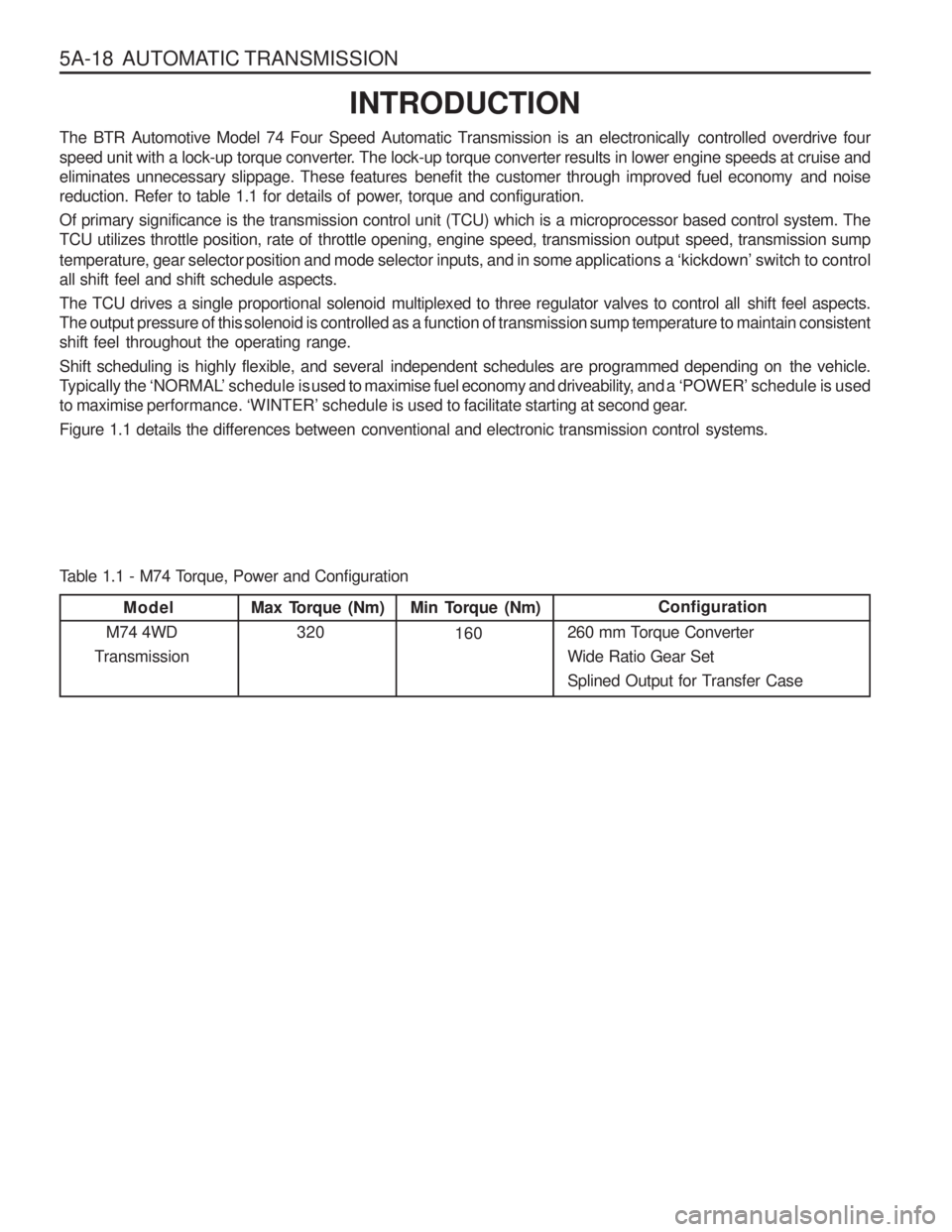

5A-18 AUTOMATIC TRANSMISSIONINTRODUCTION

The BTR Automotive Model 74 Four Speed Automatic Transmission is an electronically controlled overdrive four

speed unit with a lock-up torque converter. The lock-up torque converter results in lower engine speeds at cruise and

eliminates unnecessary slippage. These features benefit the customer through improved fuel economy and noise

reduction. Refer to table 1.1 for details of power, torque and configuration.

Of primary significance is the transmission control unit (TCU) which is a microprocessor based control system. The

TCU utilizes throttle position, rate of throttle opening, engine speed, transmission output speed, transmission sump

temperature, gear selector position and mode selector inputs, and in some applications a ‘kickdown’ switch to control

all shift feel and shift schedule aspects.

The TCU drives a single proportional solenoid multiplexed to three regulator valves to control all shift feel aspects.

The output pressure of this solenoid is controlled as a function of transmission sump temperature to maintain consistent

shift feel throughout the operating range.

Shift scheduling is highly flexible, and several independent schedules are programmed depending on the vehicle.

Typically the ‘NORMAL’ schedule is used to maximise fuel economy and driveability, and a ‘POWER’ schedule is used

to maximise performance. ‘WINTER’ schedule is used to facilitate starting at second gear.

Figure 1.1 details the differences between conventional and electronic transmission control systems.

Max Torque (Nm)

320 Configuration

260 mm Torque Converter Wide Ratio Gear Set

Splined Output for Transfer CaseMin Torque (Nm) 160

Model

M74 4WD

Transmission

Table 1.1 - M74 Torque, Power and Configuration

Page 880 of 1574

AUTOMATIC TRANSMISSION 5A-21

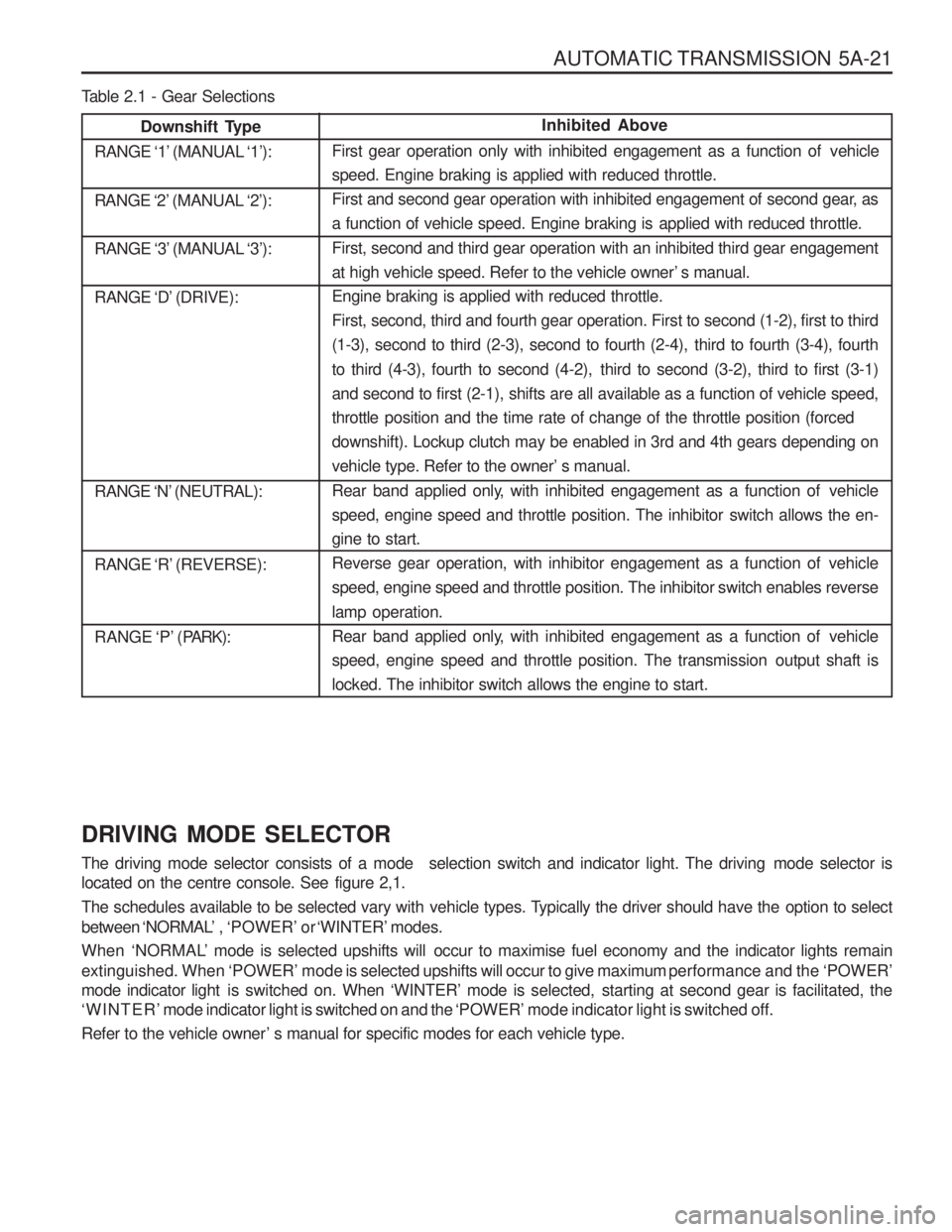

Downshift Type

RANGE ‘1’ (MANUAL ‘1’):

RANGE ‘2’ (MANUAL ‘2’):

RANGE ‘3’ (MANUAL ‘3’):

RANGE ‘D’ (DRIVE):

RANGE ‘N’ (NEUTRAL):

RANGE ‘R’ (REVERSE):

RANGE ‘P’ (P ARK):Inhibited Above

First gear operation only with inhibited engagement as a function of vehicle speed. Engine braking is applied with reduced throttle.

First and second gear operation with inhibited engagement of second gear, as

a function of vehicle speed. Engine braking is applied with reduced throttle.

First, second and third gear operation with an inhibited third gear engagement

at high vehicle speed. Refer to the vehicle owner’ s manual.Engine braking is applied with reduced throttle.

First, second, third and fourth gear operation. First to second (1-2), first to third

(1-3), second to third (2-3), second to fourth (2-4), third to fourth (3-4), fourth

to third (4-3), fourth to second (4-2), third to second (3-2), third to first (3-1)

and second to first (2-1), shifts are all available as a function of vehicle speed,throttle position and the time rate of change of the throttle position (forced

downshift). Lockup clutch may be enabled in 3rd and 4th gears depending on

vehicle type. Refer to the owner’ s manual.

Rear band applied only, with inhibited engagement as a function of vehicle

speed, engine speed and throttle position. The inhibitor switch allows the en-gine to start.

Reverse gear operation, with inhibitor engagement as a function of vehicle

speed, engine speed and throttle position. The inhibitor switch enables reverse lamp operation.

Rear band applied only, with inhibited engagement as a function of vehicle

speed, engine speed and throttle position. The transmission output shaft is

locked. The inhibitor switch allows the engine to start.

Table 2.1 - Gear Selections DRIVING MODE SELECTOR

The driving mode selector consists of a mode selection switch and indicator light. The driving mode selector is

located on the centre console. See figure 2,1.

The schedules available to be selected vary with vehicle types. Typically the driver should have the option to select

between ‘NORMAL’ , ‘POWER’ or ‘WINTER’ modes.

When ‘NORMAL’ mode is selected upshifts will occur to maximise fuel economy and the indicator lights remain

extinguished. When ‘POWER’ mode is selected upshifts will occur to give maximum performance and the ‘POWER’

mode indicator light is swi tched on. When ‘WINTER’ mode is selected, starting at second gear is facilitated, the

‘WINTER’ mode indicator light is switched on and the ‘POWER’ mode indicator light is switched off.

Refer to the vehicle owner ’ s manual for specific modes for each vehicle type.