sensor SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1315 of 1574

MUSSO-SPORTS 1A-3

SUPPLEMENT

HUBER EGR

SYSTEM DESCRIPTION The following chart shows the relationship between the input and the output in Huber EGR control unit. Compared to traditional system that only operates theEGR valve with RPM sensor and Micro switch, the HuberEGR control unit bring big differences that of traditionalsystem on the functions.

Input Signal

RPM sensor (CPS)

EGR valve lift sensor

Throttle position sensor (TPS) - M/T

Shift lever position

Throttle position sensor (TPS)

Vehicle speed sensor(VSS) Basic input signal for EGR operation Engine cold or hot signal

Position signal of EGR valve that is triggered by vacuum modulator 1 Transfer the engine load signal to the control unit directly (manual transmission)

TCU (A/T)

EGR

Control

Unit

Coolant temperature sensor (CTS)

Solenoid valve (Control forvacuum modulator 2)

If the control unit determines it is in no-load sharp accel- eration mode after analyzing the input signals, this conver- sion type switch reduces the fuel consumption by cutting off the intake air pressure from

fuel injection ALDA and gen- erating the vacuum pressure. In no-load sharp acceleration

mode, Duty Control ( continu- ous precise control) is acti- vated according to the varia- tions of the input signals when the solenoid valve generates the vacuum pressure in ALDA.

Vacuum modulator 2

The opening value of the modulator is precisely con- trolled by input signals and programmed MAP, and the opening value of EGR valve is also changed by the varia- tions of vacuum pressure to EGR valve. The changed opening value is transferred to the control unit as input signal.

Vacuum modulator 1

TCU in automatic transmission equipped vehicle transfers the information such as driving conditions and speeds into the EGR control unit. EGR control unit uses the shift lever position and vehicle speed as important information for operating the solenoid valve during no-load sharp acceleration mode. In manual transmission, the signal of vehicle speed is transferred into the EGR control unit directly.

Clutch switch

In manual transmission, the clutch switch is the one of core elements to determine driving condition. Output Signal

EGR Control Unit

Page 1317 of 1574

MUSSO-SPORTS 1A-5

SUPPLEMENT

KAA5A020

KAA5A020

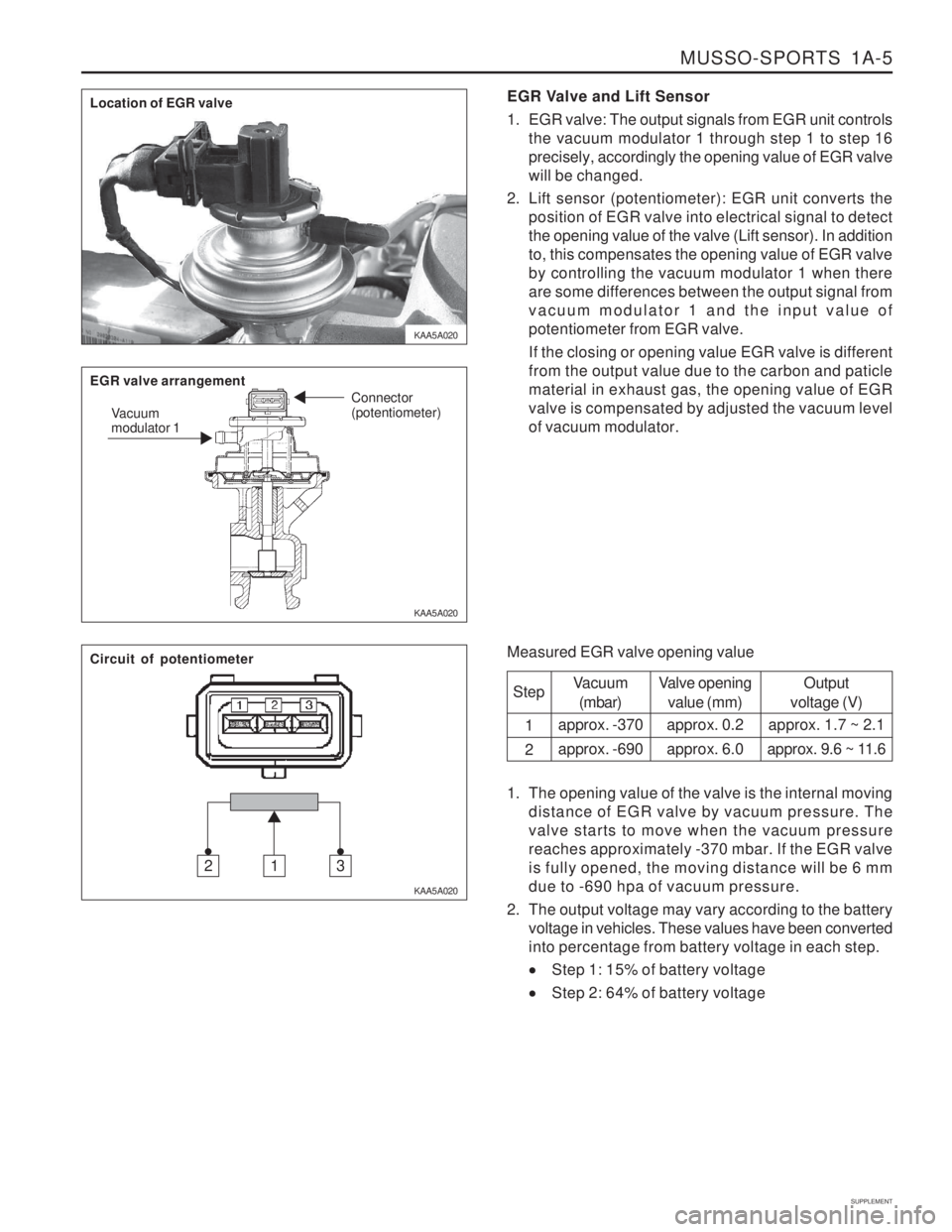

KAA5A020EGR Valve and Lift Sensor

1. EGR valve: The output signals from EGR unit controls

the vacuum modulator 1 through step 1 to step 16 precisely, accordingly the opening value of EGR valvewill be changed.

2. Lift sensor (potentiometer): EGR unit converts the position of EGR valve into electrical signal to detectthe opening value of the valve (Lift sensor). In additionto, this compensates the opening value of EGR valveby controlling the vacuum modulator 1 when thereare some differences between the output signal fromvacuum modulator 1 and the input value ofpotentiometer from EGR valve. If the closing or opening value EGR valve is different from the output value due to the carbon and paticlematerial in exhaust gas, the opening value of EGRvalve is compensated by adjusted the vacuum levelof vacuum modulator.

Measured EGR valve opening value Step 1 2

Vacuum(mbar)

approx. -370 approx. -690 Valve opening

value (mm)

approx. 0.2approx. 6.0 Output

voltage (V)

approx. 1.7 ~ 2.1

approx. 9.6 ~ 11.6

1. The opening value of the valve is the internal moving distance of EGR valve by vacuum pressure. The valve starts to move when the vacuum pressurereaches approximately -370 mbar. If the EGR valveis fully opened, the moving distance will be 6 mmdue to -690 hpa of vacuum pressure.

2. The output voltage may vary according to the battery voltage in vehicles. These values have been convertedinto percentage from battery voltage in each step.

Step 1: 15% of battery voltage

Step 2: 64% of battery voltage

Location of EGR valve EGR valve arrangement

Vacuum modulator 1 Connector (potentiometer)

Circuit of potentiometer

312

Page 1318 of 1574

1A-6 MUSSO-SPORTS

SUPPLEMENT

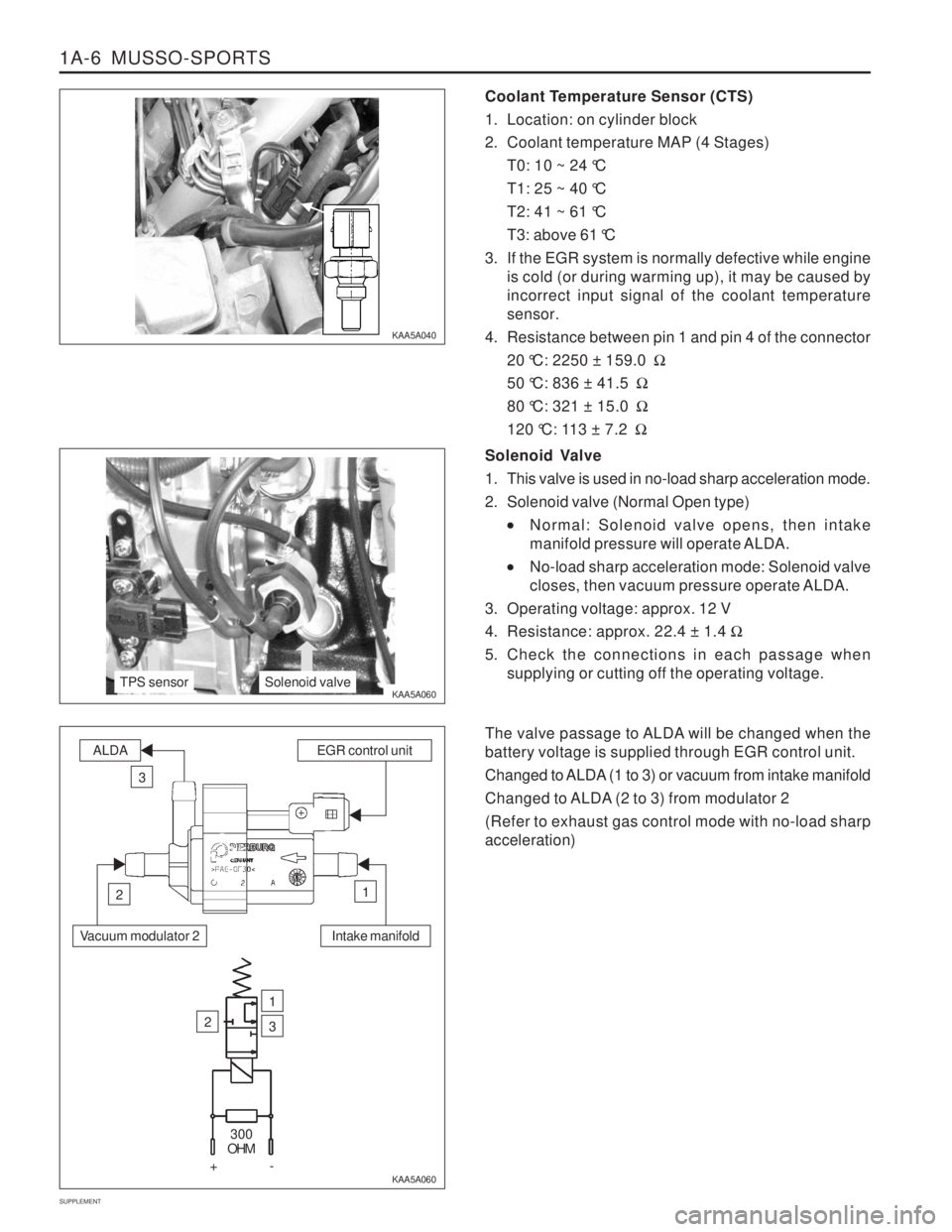

Coolant Temperature Sensor (CTS)

1. Location: on cylinder block

2. Coolant temperature MAP (4 Stages) T0: 10 ~ 24 °C

T1: 25 ~ 40 °C

T2: 41 ~ 61 °C

T3: above 61 °C

3. If the EGR system is normally defective while engine is cold (or during warming up), it may be caused by incorrect input signal of the coolant temperaturesensor.

4. Resistance between pin 1 and pin 4 of the connector 20 °C: 2250 ± 159.0 �

50 °C: 836 ± 41.5 �

80 °C: 321 ± 15.0 �

120 °C: 113 ± 7.2 �

KAA5A040 KAA5A060

KAA5A060Solenoid Valve

1. This valve is used in no-load sharp acceleration mode.

2. Solenoid valve (Normal Open type)

Normal: Solenoid valve opens, then intake

manifold pressure will operate ALDA.

No-load sharp acceleration mode: Solenoid valve

closes, then vacuum pressure operate ALDA.

3. Operating voltage: approx. 12 V

4. Resistance: approx. 22.4 ± 1.4 �

5. Check the connections in each passage when supplying or cutting off the operating voltage.

The valve passage to ALDA will be changed when the battery voltage is supplied through EGR control unit.

Changed to ALDA (1 to 3) or vacuum from intake manifold

Changed to ALDA (2 to 3) from modulator 2 (Refer to exhaust gas control mode with no-load sharp acceleration)

TPS sensorSolenoid valve

Intake manifold

ALDAEGR control unit

3

12

Vacuum modulator 2

2

1

3

300

OHM

+-

Page 1319 of 1574

MUSSO-SPORTS 1A-7

SUPPLEMENT

Throttle Position Sensor (TPS)

1. EGR unit receives TPS signal from TCU (A/T) or input

signal from pin 61 of EGR unit (M/T). The load value of engine is important signal because Huber EGRsystem make EGR valve operate in extended rangeexcept no-load sharp acceleration mode.

2. Resistance check

Disconnect the TPS sensor connector from fuelinjection pump and measure the entire resistancebetween pin 1 and pin 4. Specified value: 5 k � ± 20 %

Measure the resistance between pin 1 and pin 2 at no-load and full-load. Approx. 10 ~ 20 % of full resistance at no-load Approx. 70 ~ 85 % of full resistance at full-load

3. Voltage check

The supplied voltage to TPS from EGR unit (for

M/T) or TCU (for A/T) is approx. 5 V. 0.60 ± 0.2 V at no-load 3.85 ± 0.3 V at full-load

VACUUM LINE Installation of modulator and vacuum line (on-vehicle)

E GR n

Page 1324 of 1574

1A-12 MUSSO-SPORTS

SUPPLEMENT

KAA5A020

KAA5A020

KAA5A020 EXHAUST GAS RECIRCULATION MODULE Removal and Installation Procedure

1. After releasing fixing screw of door scuff to the

passenger seat , remove the door scuff.

KAA5A020 2. After releasing fixing bolt of cowl side trim, remove

cowl side trim.

3. Remove pin of connector from the EGR module.

4. After releasing the fixing nut(3ea) of EGR module, remove the the EGR module.

5. Installation should follow the removal procedure in the reverse order.

THROTTLE POSITION SENSOR Removal Procedure 1. Disconnect the TPS connector from the TPS.

2. After releasing the fixing bolt, remove the TPS. Installation Procedure

1. Install temporary fixing bolt of TPS.

2. Install connector of TPS on the TPS.

3. Check the voltage of TPS by using SCAN-100.

4. Install completely fixing bolt of TPS.

Page 1325 of 1574

MUSSO-SPORTS 1A-13

SUPPLEMENT

KAA5A020

KAA5A020

KAA5A020VACUUM MODULATOR 1, 2 Removal and Installation Procedure

1. Disconnect vacuum hose and connector from vacuum

module.

2. After releasing fixing bolt from bracket of intake manifold, and then remove vacuum modulator.

3. Installation should follow the removal procedures in the reverse order.

KAA5A020 EGR VALVE AND LIFT SENSOR Removal and Installation Procedure

1. Disconnect vacuum hose and connector from the

EGR valve.

2. After releasing the clamping bolt/nut of EGR Valve pipe and then remove the clamp.

3. After releasing fixing bolt of EGR Valve of Intake Manifold, remove the EGR Valve assembly.

4. Installation should follow the removal procedure in the reverse order.

COOLANT TEMPERATURE SENSOR Removal and Installation Procedure

1. Disconnect the coolant temperature sensor from the coolant temperature sensor.

2. After releasing the coolant temperature sensor from cylinder block and then remove the coolant tempera- ture sensor.

3. Installation should follow the removal procedure in the reverse order.

SOLENOID VALVE Removal and Installation Procedure

1. Disconnect vacuum hose(3ea) and connector from the solenoid valve.

2. Remove the solenoid valve from the fixing bracket of injection pump.

3. Installation should follow the removal procedure in the reverse order.

Page 1346 of 1574

1A-34 MUSSO-SPORTS

SUPPLEMENT

15 IGN1

31

* ( ) : A/T

* A/T TPS, RPM Signal : TCU A5

30

GND

F24

LW A/T

TCU A5 Clutch SW

"1" TPSM/T

41 2

2 RPM Sensor

S201

1 3

LW GrW HUBER EGR ECU (K2004) BG

C R G BrB BrWLRG

10A

BAT+

F17

RY RY 3 9 28 62 61 81 10 29

1

4 6 0798 05 675 4 324 3 332 3 736

WR W WB BrW GR

WR W WB BrW GR BG BrG GL LG YL LB

WR Lift Sensor

EGR Valve Water Sensor

Temp EGR Modulator Exhanst Gas

RecirculationModulator Sol Valve

W WB BrW GR BG BrG GL LG YL LB

S201

8

12 10A

213 7 8

B

13(11) 14(12) 11(9) 12(10) 9(7) (10)8

C901 (C902)

C901

C108

C105

C104

G204

Ef 2 Ef 8

80A60A

C103

2

56 7 2 1

16 15 1411 10

4. HUBER EGR CIRCUIT(MUSSO SPORT)

Page 1367 of 1574

USAGE AND CAPACITY OF FUSES IN FUSE BOX 4-3

2. I/P FUSE BLOCK

1) POSITION OF RELAY AND FUSE 2) USAGE OF FUSE IN PASSENGER ROOM FUSE BOX

* 30 : BAT(+) Power Supply Through Ef1.

15A10A

10A15A10A

20A10A10A

10AST F110AIG1 F210AIG1 F3

ACC10AF4 B+30AF5

B+

(1) F6

F13

IG1

F20

15AF730AF1410AF21

F8F15F22

20AF915AF1610AF23

F10

B+

(2)

F17

F24

20AF1115AF1810A 15A

20AF1210AIG2 F19

30A

F25 F26

F27

85

87a3087

86

85

-3087

86

BE

L

85-

30

87

86

2) RELAY BOX

FRONT WIPERRELAY DEFOGGER

RELAY TURN SIGNAL

RELAY GSL : FUEL PUMP RELAYDSL : CIGAR LIGHTER, P/SOCKET RELAY A/T SHIFT LOCK

RELAY

8730

8685

8730

8685

8730

8685

8730

8685

A/T:PNP RELAY M/T:CLUTCH INTER LOCK RELAY SUNROOF

RELAY 'B' S/W

INTERLOCK RELAY POWER WINDER

RELAY 10A 10A10A10A30A15A15A10A20A20A20A20A30A15A15A10A 15A 10A10A10A10A10A10A10A15A30A

F1F2F3F4F5F6F7F8F9

F10 F11F12F14F15F16F17 F18 F19F20F21F22F23F24F25F26F27

Fuse No Capacity Usage

Starter Motor Relay Air BagABS/ABDOutside Mirror, AudioCigar Lighter, Power SocketStop LampHazard SwitchInteriorFuel Pump (Only GSL)TCCU/TOD, Power seatOVPR 1 (Only GSL)OVPR 4 (Only GSL)Heated GlassSun RoofRear Fog Lamp, Power ANT., ECSDLCFront Wiper & WasherRear Wiper & WasherTCCU/TCMBack Up Lamp, Turn Signal LampHead Lamp, Cluster OVPR 3 (Only GSL) Speed Sensor, Unit, Relay CoilNot UsedNot UsedNot Used

Power Supply

30 BAT(+)

ACC (15C) IGN2 (15A)

30 BAT (+)

IGN1 (15)

IGN1 (15)

SPARE

8730

8685

8730

8685

ECS

RELAY ABS WARNING

LAMP RELAY

8730

8685

Page 1369 of 1574

CONTENTS

1. STARTING & CHARGING CIRCUIT ........................................................................................... 5-8

1) GSL E23 MB A/T ............................................................................................................... ...................................... 5-8

2) GSL BTRE A/T, GSL E32 MB A/T ................................................................................................. ........................5-10

3) DSL NA BTRE A/T, M/T ......................................................................................................... .................................5-12

4) DSL LA BTRE A/T, M/T ......................................................................................................... .................................5-14

2. PREHEAT'G UNIT CIRCUIT ...................................................................................................... 5-16

3. EGR CONTROL CIRCUIT.......................................................................................................... 5-18

4. ECM (E23, MSE) ............................................................................................................... .......... 5-20

1) OVPR, FUEL PUMP, CCP SOLENOID CIRCUIT ........................................................................................ ....... 5-20

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-20

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-22

2) IGNITION COIL, SENSOR (CAM SHAFT, MAP, CKP), CAM SHAFT ACTUATOR, CPS CIRCUIT .............. 5-24 (1) W/O EURO III ............................................................................................................... ..................................................................... 5-24

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-26

SECTION 5

ELECTRICAL WIRING DIAGRAMS

Page 1370 of 1574

3) PEDAL MODULE, THROTTLE MOTOR & SENSOR, CTS, SENSOR(KNOCK, INTAKE AIR TEMP',HEATED O 2) CIRCUIT ...................................................................................................................... ......................5-28

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-28

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-30

4) VSS, CLUTCH SWITCH, IMMOBILIZER CIRCUIT ...................................................................................... .........5-32

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-32

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-34

5. ECM (E32, MSE) ............................................................................................................... .......... 5-36

1) OVPR, FUEL PUMP, CCP SOLENOID CIRCUIT ........................................................................................ ....... 5-36

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-36

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-38

2) IGNITION COIL, SENSOR (CAM SHAFT POSITION, HFM, CKP), CAM SHAFT ACTUATOR, RESONANCE FLAP CIRCUIT ............................................................................................................................... . 5-40

3) PEDAL MODULE, THROTTLE MOTOR & SENSOR, SENSOR(KNOCK, ECT, HEATED O 2) CIRCUIT ....... 5-42

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-42

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-44

4) VSS, CLUTCH SWITCH, IMMOBILIZER CIRCUIT ...................................................................................... ....... 5-46

5) HEATED O 2 SENSOR(1,2,3,4) ............................................................................................................... ............... 5-48

6. ECM (E20, HFM).............................................................................................................. ........... 5-50

1) INJECTOR, OVPR, IGNITION COIL, FUEL PUMP CIRCUIT ............................................................................ 5-50

2) CCP SOLENOID, SENSOR (MAF, CKP) CIRCUIT ...................................................................................... ...... 5-52

3) THROTTLE MOTOR & SENSOR, ECT SENSOR, VSS, HEATED O 2 SENSOR CIRCUIT ............................ 5-54

7. ECM(E23, HFM) ............................................................................................................... ........... 5-56

1) INJECTOR, OVPR, IGNITION COIL, FUEL PUMP CIRCUIT(W/ IMMOBILIZER) ........................................... 5-56

2) INJECTOR, OVPR, IGNITION COIL, FUEL PUMP CIRCUIT(W/O IMMOBILIZER) ........................................ 5-58

3) SENSOR (CKP, CMP, KNOCK, MAF), CAM SHAFT ACTUATOR CIRCUIT ...................................................... 5-60

4) THROTTLE MOTOR & SENSOR, ECT SENSOR, VSS, HEATED O 2, SENSOR CIRCUIT ............................. 5-62