ignition SSANGYONG MUSSO 2003 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 484 of 1574

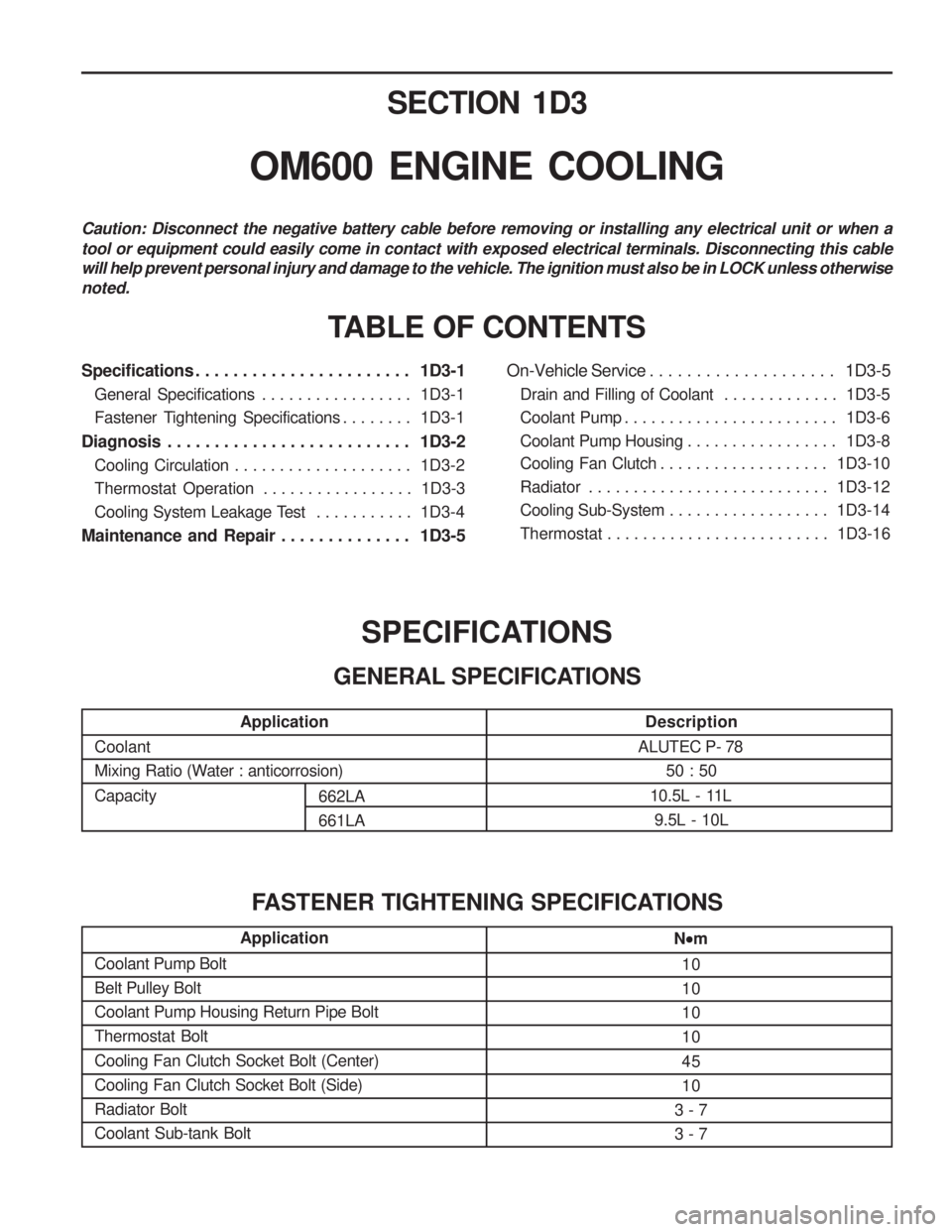

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2 Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5 On-Vehicle Service . . . . . . . . . . . . . . . . . . . .

1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Application

Coolant

Mixing Ratio (Water : anticorrosion) Capacity

Description

ALUTEC P- 78 50 : 50

10.5L - 11L 9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt Belt Pulley BoltCoolant Pump Housing Return Pipe BoltThermostat Bolt Cooling Fan Clutch Socket Bolt (Center) Cooling Fan Clutch Socket Bolt (Side)Radiator BoltCoolant Sub-tank BoltN

m

10 101010 45 10

3 - 73 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA 661LA

Page 501 of 1574

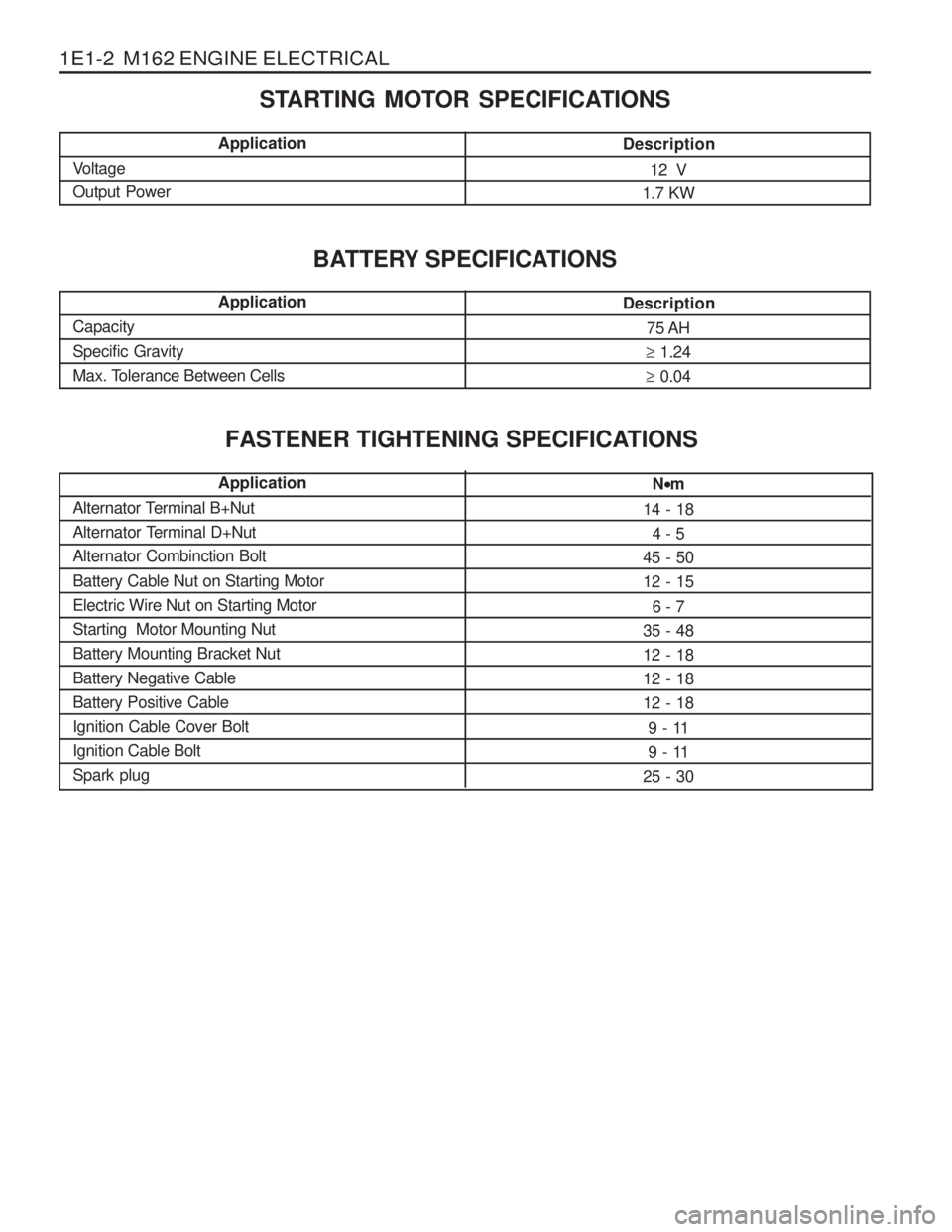

SECTION 1E1

M162 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E1-1Alternator Specifications . . . . . . . . . . . . . . . . 1E1-1

Starting Motor Specifications . . . . . . . . . . . . 1E1-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E1-2

Fastener Tightening Specifications . . . . . . . . 1E1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E1-3 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E1-3

Maintenance and Repair . . . . . . . . . . . . . . 1E1-4 On-Vehicle Service . . . . . . . . . . . . . . . . . . . . .

1E1-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E1-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E1-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E1-12 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E1-12

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cablewill help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

TABLE OF CONTENTS

Application

Output Voltage CurrentResistance Between Rotor Core and Slip Ring Description

12 - 14 V115 A� �

Page 502 of 1574

1E1-2 M162 ENGINE ELECTRICALNm

14 - 18 4 - 5

45 - 50 12 - 15

6 - 7

35 - 4812 - 1812 - 1812 - 18

9 - 11

9 - 11

25 - 30

STARTING MOTOR SPECIFICATIONS

Application

Voltage Output Power Description

12 V

1.7 KW

BATTERY SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Capacity Specific Gravity

Max. Tolerance Between Cells Description

75 AH

� 1.24

� 0.04

Application

Alternator Terminal B+Nut

Alternator Terminal D+NutAlternator Combinction Bolt Battery Cable Nut on Starting Motor Electric Wire Nut on Starting MotorStarting Motor Mounting NutBattery Mounting Bracket Nut Battery Negative Cable Battery Positive CableIgnition Cable Cover BoltIgnition Cable BoltSpark plug

Page 507 of 1574

M162 ENGINE ELECTRICAL 1E1-7

1 Ignition Coil Cable Cover

2 Bolt (M6 X 60, 7 pieces)......................... 9-11 Nm

3 Spark Plug

SPARK PLUG Preceding Work : Removal of intake air ductT1/1

Ignition Coil : Cylinder 2 and 5

T1/2 Ignition Coil : Cylinder 3 and 4

T1/3 Ignition Coil : Cylinder 1 and 6

Page 508 of 1574

1E1-8 M162 ENGINE ELECTRICAL

Tools Required 120 589 09 00 Spark Plug Wrench Replacement Procedure

1. Remove the seven bolts (2) and remove the ignition cablecover. Installation Notice

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 11 Nm

2. Remove the two bolts (M6 X 25) from each ignition cableand remove the ignition cable. Installation Notice

3. Remove the spark plug using the special tool. Installation Notice

Spark Plug Wrench 120 589 02 09 00

Page 509 of 1574

M162 ENGINE ELECTRICAL 1E1-9

IGNITION CABLE Preceding Work : Removal of intake air duct

1 Control Cable Connection

2 Ignition Cable

3 Spark Plug Connector

4 Coupling Plug5a, 5b Secondary Voltage Connection

E Iron Core

L1 Secondary Ignition Coil

L2 Primary Ignition Coil

Page 510 of 1574

1E1-10 M162 ENGINE ELECTRICAL Functions

1. Firing order : 1-5-3-6-2-4

2. The ignition cables are located on the cylinder head cover.Each ignition coil provides the high voltage to two spark

plugs simultaneously.

- T1/1 : cylinder 2 and 5

- T1/2 : cylinder 3 and 4

- T1/3 : cylinder 1 and 6

Removal & Installation Procedure

1. Disconnect the negative battery cable (1).

2. Remove the ignition cable connector from the ignition cable.

3. Disconnect the secondary spark plug connectors from the each spark plugs and remove the ignition cable. Installation Notice

3. The secondary output voltage (5a) is supplied to the No.2

cylinder spark plug through the spark plug connector. The secondary output voltage (5b) is supplied to the No.5 cylinderspark plug through the ignition cable. The guide pin (W)acts as a ground while the ignition cable is operated.

� Make sure that the ignition cables are correctly routed.

� Exactly install the ignition cable guide pin into the vehicle

to be grounded.

4. Installation should follow the removal procedure in the reverse order.

Tightening Torque 9 - 11 Nm

Page 511 of 1574

M162 ENGINE ELECTRICAL 1E1-11

Circuit Diagram

Inspection & Maintenance Procedure (for MSE)

1. While the ignition switch is in 'OFF' position, remove thewiring connectors (1 and 15) from ignition coil and measure the primary resistance between terminal No.1 and No.15.

2. During engine cranking, measure primary voltage (T1/1) between ECU terminal No. 71 and No. 69.

Notice If out of specified value, replace the ignition coil.

Specified Value

0.9 - 1.6 � (20 °C)

Specified Value 200 - 350 V

Notice

� Measure remaining cables.

- T1/2 : No. 72 and 69.

- T1/3 : No. 70 and 69.

� If out of specified value, check ignition cable and ECU.

3. Using a multi-tester, measure the secondary coil resistance between 5a and 5b.

Specified Value 6 - 8.5 k�

Page 513 of 1574

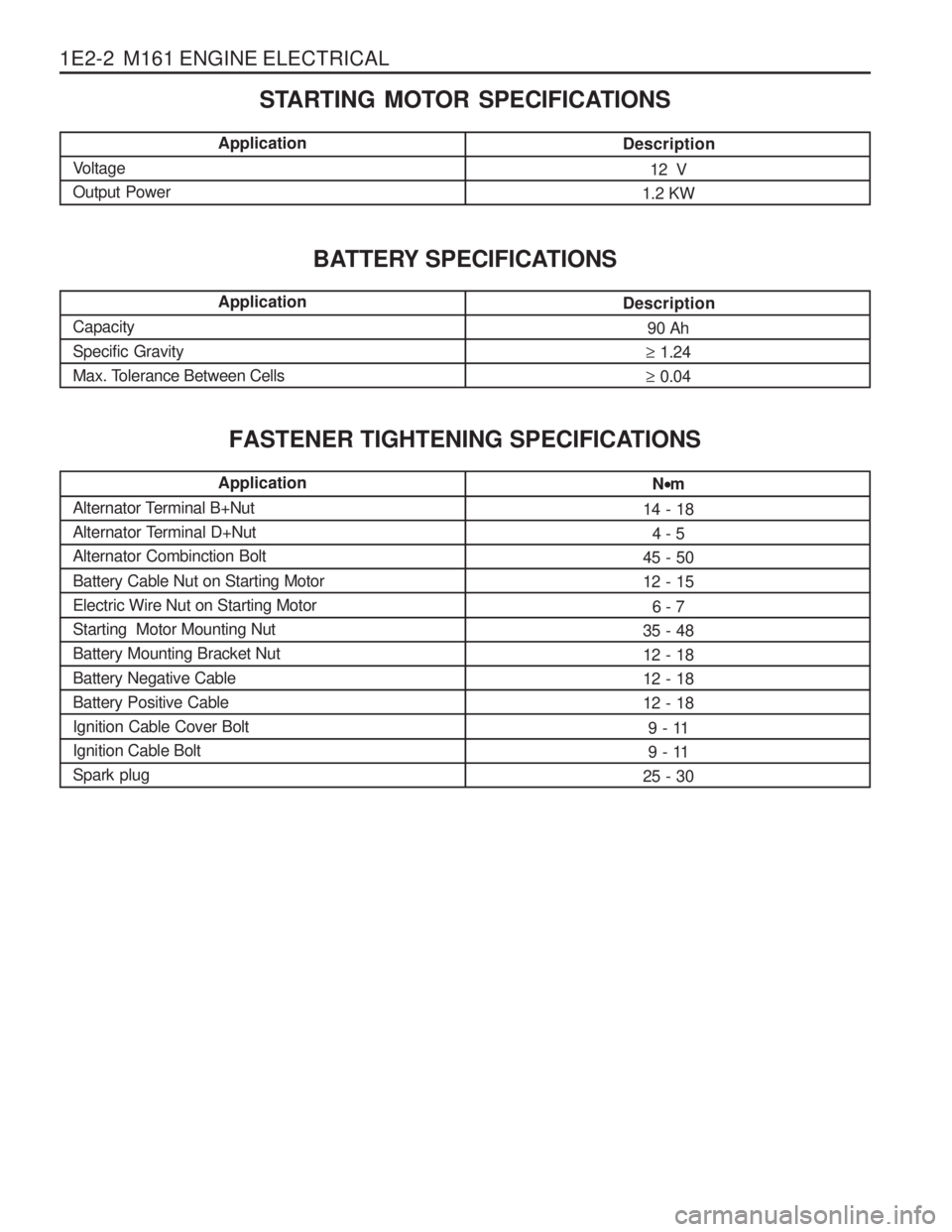

SECTION 1E2

M161 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E2-1Alternator Specifications . . . . . . . . . . . . . . . . 1E2-1

Starting Motor Specifications . . . . . . . . . . . . 1E2-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E2-2

Fastener Tightening Specifications . . . . . . . . 1E2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E2-3 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E2-3

Maintenance and Repair . . . . . . . . . . . . . . 1E2-4 On-Vehicle Service . . . . . . . . . . . . . . . . . . . . .

1E2-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E2-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E2-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cablewill help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

TABLE OF CONTENTS

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

Application

Output Voltage Current Resistance Between Rotor Core and Slip Ring Description

12 - 14 V115 A

� �

Page 514 of 1574

1E2-2 M161 ENGINE ELECTRICALNm

14 - 18 4 - 5

45 - 50 12 - 15

6 - 7

35 - 4812 - 1812 - 1812 - 18

9 - 11

9 - 11

25 - 30

STARTING MOTOR SPECIFICATIONS

Application

Voltage Output Power Description

12 V

1.2 KW

BATTERY SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Capacity Specific Gravity

Max. Tolerance Between Cells Description

90 Ah

� 1.24

� 0.04

Application

Alternator Terminal B+Nut

Alternator Terminal D+NutAlternator Combinction Bolt Battery Cable Nut on Starting Motor Electric Wire Nut on Starting MotorStarting Motor Mounting NutBattery Mounting Bracket Nut Battery Negative Cable Battery Positive CableIgnition Cable Cover BoltIgnition Cable BoltSpark plug