power steering SSANGYONG MUSSO 2003 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 287 of 1574

1B3-22 OM600 ENGINE MECHANICALWith Air Conditioner

Removal & Installation Procedure

1. Remove the nut.

2. Push the tensioning lever in direction of arrow with a rod

(F12 ´ 180mm) and pull out the bolt to the rear.

3. Push back the tensioning lever (arrow direction) to release the spring tension and remove the belt.

4. Install the poly V-belt beginning at the tensioning pulley (7). 7 Tensioning Pulley

8 Crankshaft

9 Alternator

10 Coolant Pump 11 Guide Pulley

12 Power Steering Pump

13 Aircon. Compressor

Lengthe of Belt

Length (L)

Without Air Conditioner 2,100 mm 2,040 mm

Page 328 of 1574

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fanRmoval of the V-belt tensioning device Removal of the vibration damper and hub Removal of the alternator

1 Bolt............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm 10 Power Steering Pump

11 Bolt

12 Belt Pulley 13 Bolt

............................................................ 32Nm

14 Timing Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 330 of 1574

OM600 ENGINE MECHANICAL 1B3-65

11. Remove the alternator bracket (16).

9. Disconnect the pipes of power steering pump and removethe belt pulley. Notice

Be careful not to lose the key.

10. Remove the nut and pull out the bolt and then remove the power steering pump.

12. Remove the fuel filter.

Page 334 of 1574

OM600 ENGINE MECHANICAL 1B3-69

10. Install the fuel filter.

11. Install the vacuum pump.

12. Install the power steering pump.

13. Install the power steering pump pulley.

Tightening Torque 25 Nm

Tightening Torque 10 Nm

Tightening Torque 23 Nm

Tightening Torque 32 Nm

14. Install the guide pulley bracket.

Tightening Torque 9 Nm

Page 700 of 1574

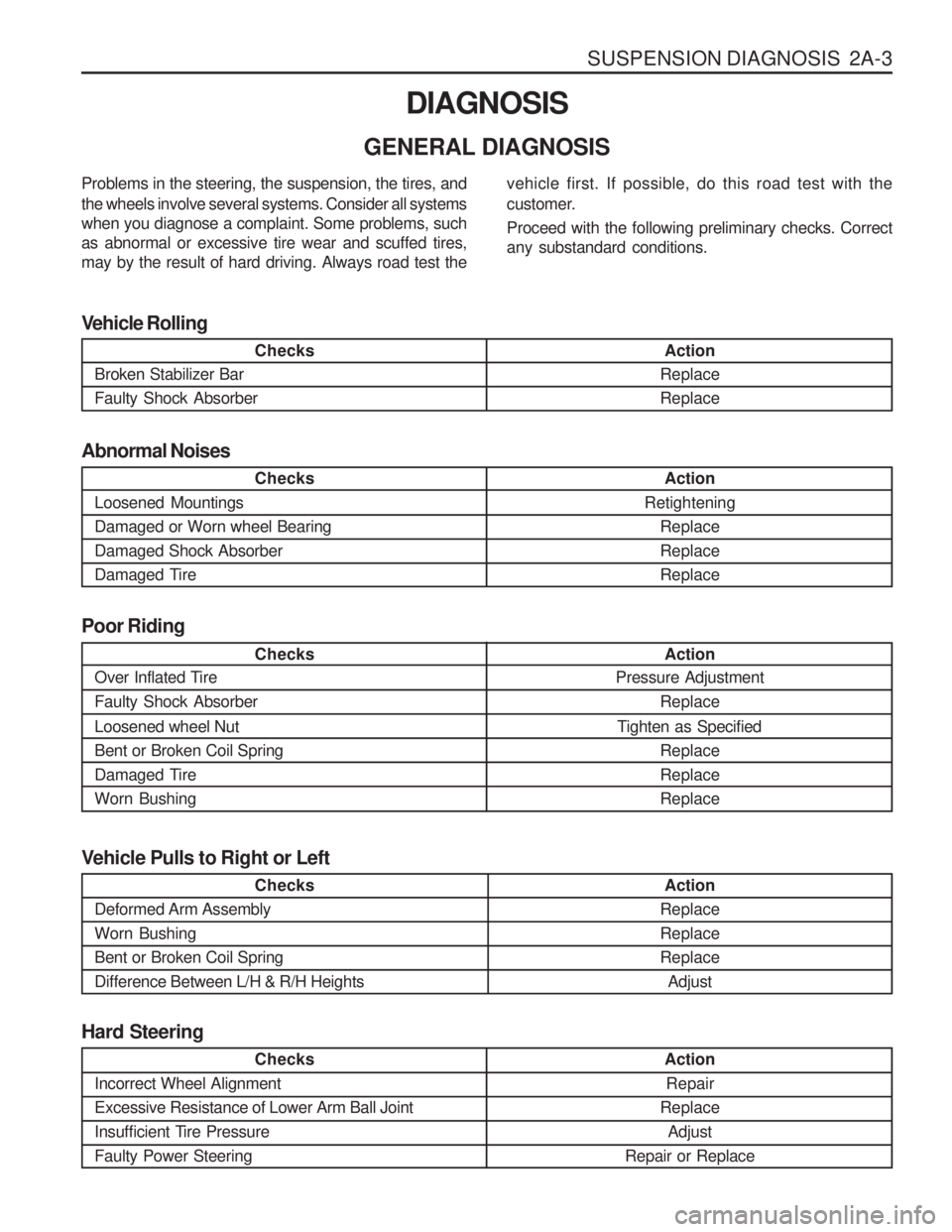

SUSPENSION DIAGNOSIS 2A-3

DIAGNOSIS

GENERAL DIAGNOSIS

Checks

Loosened Mountings Damaged or Worn wheel BearingDamaged Shock Absorber

Damaged Tire Action

Retightening ReplaceReplaceReplace

Abnormal Noises

Checks

Broken Stabilizer Bar Faulty Shock Absorber Action

ReplaceReplace

Vehicle Rolling

Checks

Over Inflated Tire Faulty Shock Absorber Loosened wheel Nut Bent or Broken Coil Spring

Damaged TireWorn Bushing Action

Pressure Adjustment

Replace

Tighten as Specified ReplaceReplaceReplace

Poor Riding

Problems in the steering, the suspension, the tires, and the wheels involve several systems. Consider all systems when you diagnose a complaint. Some problems, suchas abnormal or excessive tire wear and scuffed tires,may by the result of hard driving. Always road test the

vehicle first. If possible, do this road test with the

customer. Proceed with the following preliminary checks. Correct any substandard conditions.

Checks

Incorrect Wheel Alignment Excessive Resistance of Lower Arm Ball Joint

Insufficient Tire PressureFaulty Power Steering

Action Repair

Replace Adjust

Repair or Replace

Hard Steering

Checks

Deformed Arm Assembly Worn BushingBent or Broken Coil SpringDifference Between L/H & R/H Heights Action

ReplaceReplaceReplace Adjust

Vehicle Pulls to Right or Left

Page 1143 of 1574

Application

Steering Wheel Steering Gear Box Oil Pump Steering Column

Minmum Turning Radius Oil SECTION 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 6A-1

General Specifications . . . . . . . . . . . . . . . . . . 6A-1

Fastener Tightening Specifications . . . . . . . . . 6A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Hard Steering . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Steering Pulls to One Side . . . . . . . . . . . . . . . 6A-2

Excessive Wheel Play . . . . . . . . . . . . . . . . . . . 6A-2

Poor Return of Steering Wheel . . . . . . . . . . . . 6A-2

Steering Wheel Shimmy . . . . . . . . . . . . . . . . . 6A-3

SPECIFICATIONS

GENERAL SPECIFICATIONS Abnormal Noise From Steering System . . . . . 6A-3

Component Locator . . . . . . . . . . . . . . . . . . . 6A-4

Steering System . . . . . . . . . . . . . . . . . . . . . . . 6A-4

Maintenance and Repair . . . . . . . . . . . . . . . 6A-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 6A-5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-5

Oil Pump Pressure Check . . . . . . . . . . . . . . . . 6A-6

Bleeding of Power Steering System . . . . . . . . 6A-6

Steering Gear Box . . . . . . . . . . . . . . . . . . . . . 6A-7

Number of Spoke Outer Diameter

Type Gear Ratio Inner Steering AngleOuter Steering Angle

TypeMaximum Pressure

Upper Tilting Angle

Lower Tilting Angle

Type Capacity Change Interval

Description

4

396 mm

Rack and Pinion

�

33°37'

31°50' Vane

75-82 kg/cm 2

4.646° 6.969°

5.25m

ATF DEXRON II

1 L

Every 24,000 km

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Shaft Bolt Pressure Hose BoltReturn Pipe Nut Slotted Nut Steering Gearbox Bolt

N �m

30 - 40 12 - 1812 - 1835 - 45 35 - 45

Page 1144 of 1574

6A-2 POWER STEERING SYSTEMChecks

Damaged or Binding Steering Ball Joint Improper Preload of Steering Pinion

Damaged Wheel or TireFaulty Suspension System Checks

Worn Steering Gear Worn or Damaged Steering Ball Joint Loosened Steering Gearbox Bolts Checks

Damaged Steering Linkage

Damaged Wheel and Tire Faulty Brake System Faulty Suspension System Checks

Lack of Lubrication Abnormal Wear or Binding of Steering Ball Joint Damaged or Faulty Steering GearImproper Preload of Steering PinionFaulty Steering Shaft JointSteering Fluid Leaks Lack of Fluid or Air-in System Faulty Steering Oil PumpDamaged or Loosened Pump Drive BeltClogging Oil Line

Damaged Wheel or Tire Faulty Suspension System DIAGNOSIS

HARD STEERING

Action

Lubricate

Replace

Replace gear assembly

Adjust

Replace

Repair or replace

Replenish or bleed Replace

Adjust or replace

Repair or replace Repair or replace Repair or replace

STEERING PULLS TO ONE SIDE

Action Repair

Repair or replace Repair or replace Repair or replace

EXCESSIVE WHEEL PLAY

Action

Replace gear assembly

Replace

Retighten

POOR RETURN OF STEERING WHEEL

Action

Replace

Replace gear assembly Repair or replace Repair or replace

Page 1145 of 1574

POWER STEERING SYSTEM 6A-3

Checks

Loosened Steering Gearbox Mounting Bolt Faulty Steering Gear Steering Column LinterferenceLoosened Steering LinkageDamaged or Loosened Oil Pump Drive BeltLoosened Oil Pump Bracket Loosened Oil Pump Mounting Bolt Air-in SystemFaulty Oil Pump Checks

Damaged Steering LinkageLoosened Steering Gearbox Mounting Bolt Damaged or Binding Steering Ball Joint Worn or Damaged Front Wheel Bearing

Damaged Wheel or TireFaulty Suspension System STEERING WHEEL SHIMMY

Action

Replace

Retighten

Replace Replace

Repair or replaceRepair or replace

ABNORMAL NOISE FROM STEERING SYSTEM

Action

Retighten

Replace gear assembly Replace

Retighten

Adjust or replace Retighten RetightenBleed

Replace

Page 1146 of 1574

6A-4 POWER STEERING SYSTEM

1 Steering Wheel

2 Steering Column Shaft

3 Steering Gear Box

4 End Ass'y - Tie RodCOMPONENT LOCATOR

STEERING SYSTEM5 Lower Shaft

6 Oil Reservoir

7 Oil Pump

8 Steering Knuckle

Page 1147 of 1574

POWER STEERING SYSTEM 6A-5

MAINTENANCE AND REPAIR ON-VEHICLE SERVICE INSPECTION Steering Wheel Freeplay Inspection Procedure

1. Start the engine and set the wheels in straight ahead position.

2. Slightly move the steering wheel to the left and right andmeasure steering wheel free play when the front wheel is

start to move. Notice

If exceeds specification, the steering column shaft

connections and steering linkage .clearance. Replace orrepair if necessary.

Steering Angle Inspection Procedure

1. Place the front wheel on a measuring tool.

2. Rotate steering wheel all the way right and left and measure steering angle Notice If out of standard, check or adjust toe-in.

Standard 33°37'

31°50'Inner

Outer

Steering Effort Inspection Procedure

1 Place a vehicle on the paved flat ground with front wheels in a straight ahead position.

2 Start the engine and run it at 1,000rpm.

3 Using a scale, measure the steering effort in both directions.

NoticeThe difference in steering effort of left and right should be within 0.6 kg.

Standard Max. 3.0kg

StandardMax. 30mm