electric SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 4 of 1574

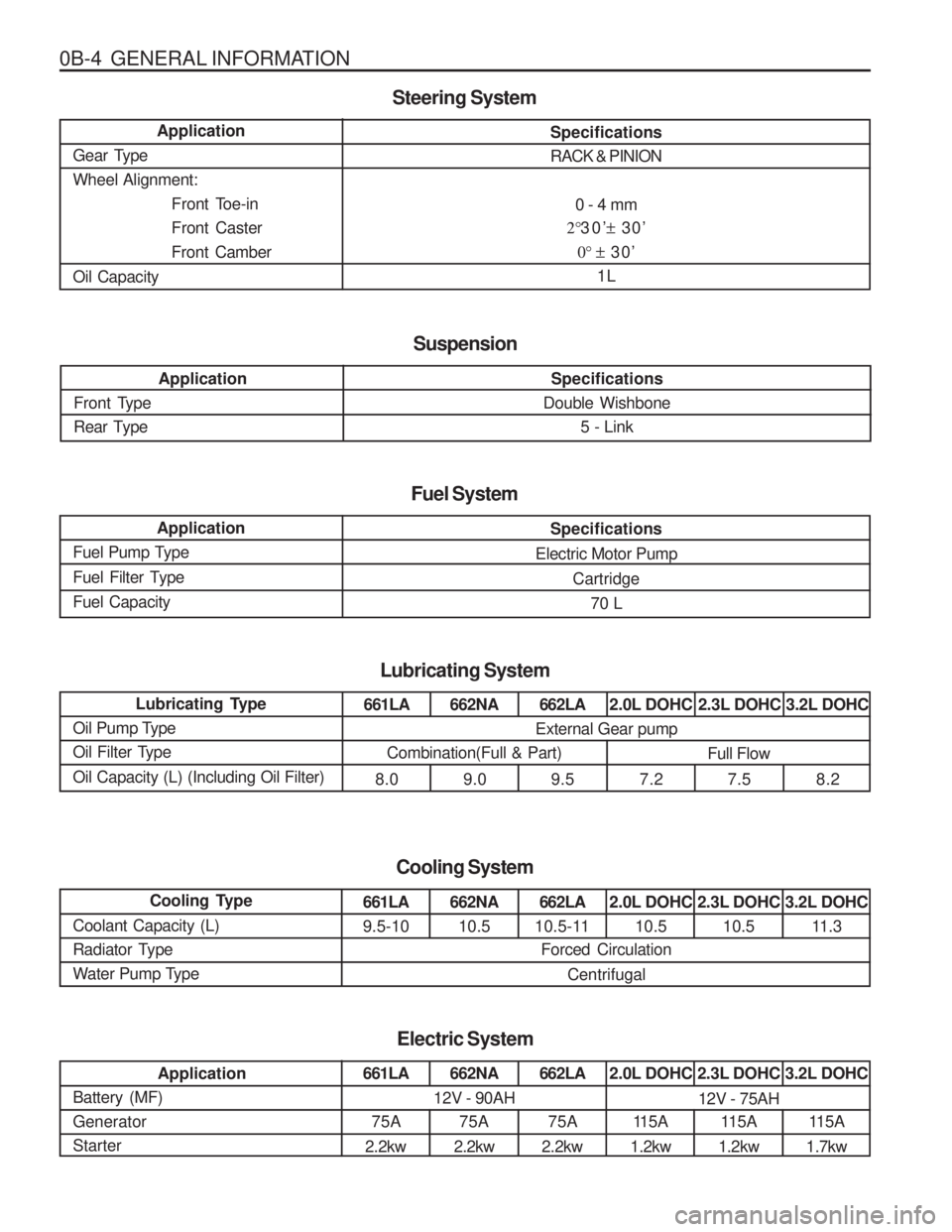

0B-4 GENERAL INFORMATIONSpecifications RACK & PINION0 - 4 mm

2° 30’ ± 30’

0° ± 30’

1L

Application

Gear TypeWheel Alignment: Front Toe-inFront CasterFront Camber

Oil Capacity

Steering System

Application

Front Type

Rear Type

Suspension

Specifications

Double Wishbone

5 - Link

Application

Fuel Pump Type

Fuel Filter TypeFuel Capacity

Specifications

Electric Motor Pump Cartridge70 L

Fuel System

Lubricating Type

Oil Pump Type

Oil Filter Type Oil Capacity (L) (Including Oil Filter)

Lubricating System

661LA

8.0662NA 9.0 662LA

9.5 2.0L DOHC

7.2 2.3L DOHC

7.5 3.2L DOHC

8.2

External Gear pump

Combination(Full & Part) Full Flow

Cooling Type

Coolant Capacity (L)

Radiator Type

Water Pump Type

Cooling System

661LA 9.5-10662NA 10.5 662LA

10.5-11 2.0L DOHC

10.5 2.3L DOHC

10.5 3.2L DOHC

11.3

Forced Circulation

Centrifugal

Application

Battery (MF) GeneratorStarter

Electric System

661LA

75A

2.2kw662NA

75A

2.2kw 662LA

75A

2.2kw 2.0L DOHC

11 5 A

1.2kw 2.3L DOHC

115A

1.2kw 3.2L DOHC

115A

1.7kw

12V - 90AH12V - 75AH

Page 32 of 1574

GENERAL ENGINE INFORMATION 1A1-13

GENERAL INFORMATION

CLEANLINESS AND CARE An automobile engine is a combination of many machined, honed, polished and lapped surfaces withtolerances that are measured in the ten-thousanths ofan inch. When any internal engine parts are serviced,care and cleanliness are important. A liberal coating of enigne oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on initialoperation. Proper cleaning and protection of machinedsurfaces and friction areas is part of the repairprocedure. This is considered standard shop practice even if not specifically stated. Whenever valve train components are removed for

service, they should be kept in order. They should beinstalled in the same locations, and with the same matingsurfaces, as when they were removed. Battery cables should be disconnected before any majorwork is performed on the engine. Failure to disconnectcables may result in damage to wire harness or other electrical parts. ON-ENGINE SERVICE Caution: Disconnect the negative battery cable before removing or installing any electrical unit, or when a tool or equipment could easily come in contact with exposed electrical terminals.Disconnecting this cable will help prevent personalinjury and damage to the vehicle. The ignition mustalso be in LOCK unless otherwise noted. Notice:

Any time the air cleaner is removed, the intake

opening should be covered. This will protect against accidental entrance of foreign material, which could follow the intake passage into the cylinder and cause extensive damage when the engine is started.

Page 37 of 1574

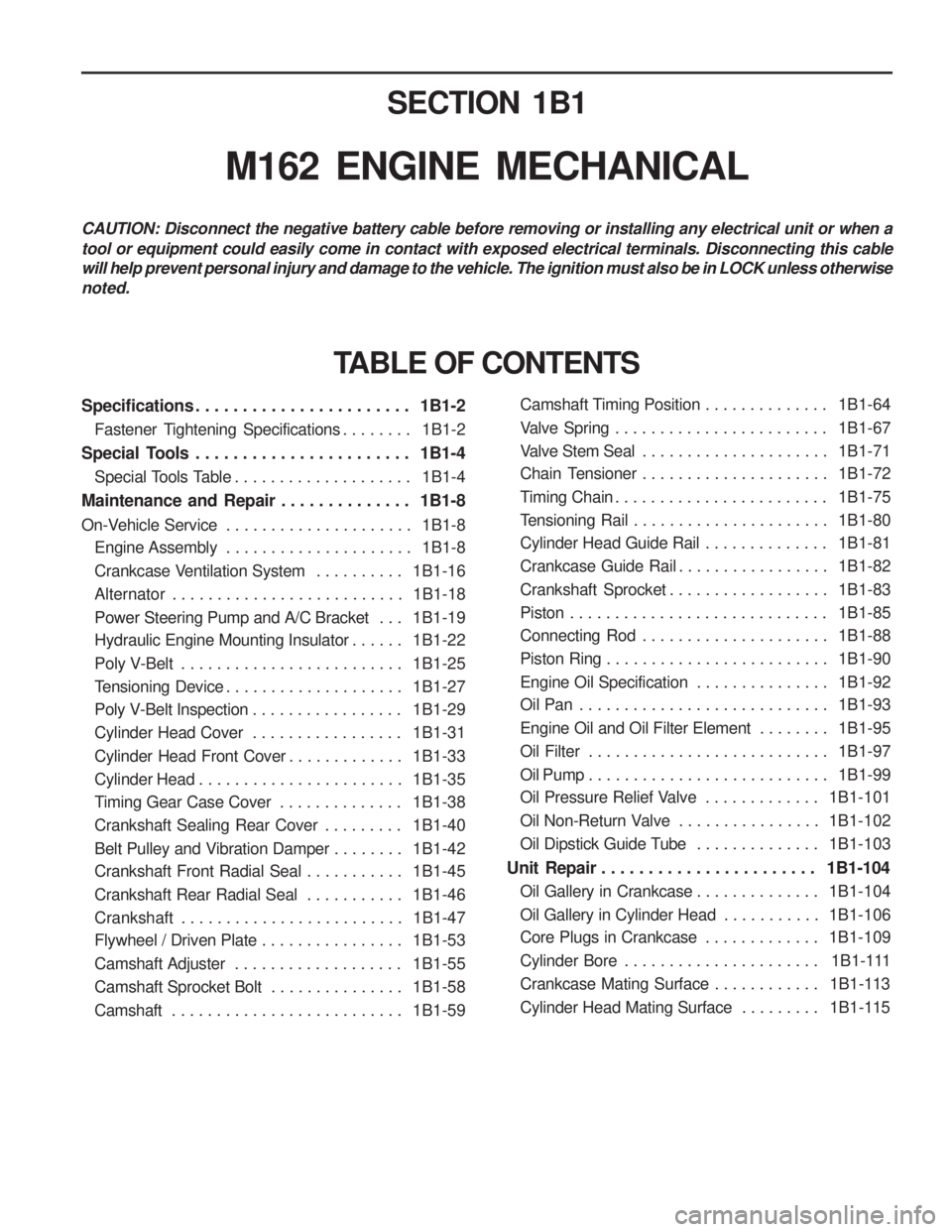

SECTION 1B1

M162 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B1-2Fastener Tightening Specifications . . . . . . . . 1B1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B1-4 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B1-4

Maintenance and Repair . . . . . . . . . . . . . . 1B1-8

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1B1-8

Engine Assembly . . . . . . . . . . . . . . . . . . . . . 1B1-8

Crankcase Ventilation System . . . . . . . . . . 1B1-16

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-18

Power Steering Pump and A/C Bracket . . . 1B1-19

Hydraulic Engine Mounting Insulator . . . . . . 1B1-22

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-25

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B1-27

Poly V-Belt Inspection . . . . . . . . . . . . . . . . . 1B1-29

Cylinder Head Cover . . . . . . . . . . . . . . . . . 1B1-31

Cylinder Head Front Cover . . . . . . . . . . . . . 1B1-33

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B1-35

Timing Gear Case Cover . . . . . . . . . . . . . . 1B1-38

Crankshaft Sealing Rear Cover . . . . . . . . . 1B1-40

Belt Pulley and Vibration Damper . . . . . . . . 1B1-42

Crankshaft Front Radial Seal . . . . . . . . . . . 1B1-45

Crankshaft Rear Radial Seal . . . . . . . . . . . 1B1-46

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-47

Flywheel / Driven Plate . . . . . . . . . . . . . . . . 1B1-53

Camshaft Adjuster . . . . . . . . . . . . . . . . . . . 1B1-55

Camshaft Sprocket Bolt . . . . . . . . . . . . . . . 1B1-58

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-59

TABLE OF CONTENTS

Camshaft Timing Position . . . . . . . . . . . . . . 1B1-64

Valve Spring . . . . . . . . . . . . . . . . . . . . . . . . 1B1-67

Valve Stem Seal . . . . . . . . . . . . . . . . . . . . . 1B1-71

Chain Tensioner . . . . . . . . . . . . . . . . . . . . . 1B1-72

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . 1B1-75

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . . 1B1-80

Cylinder Head Guide Rail . . . . . . . . . . . . . . 1B1-81

Crankcase Guide Rail . . . . . . . . . . . . . . . . . 1B1-82

Crankshaft Sprocket . . . . . . . . . . . . . . . . . . 1B1-83

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-85

Connecting Rod . . . . . . . . . . . . . . . . . . . . . 1B1-88

Piston Ring . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-90

Engine Oil Specification . . . . . . . . . . . . . . . 1B1-92

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-93

Engine Oil and Oil Filter Element . . . . . . . . 1B1-95

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-97

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-99

Oil Pressure Relief Valve . . . . . . . . . . . . . 1B1-101

Oil Non-Return Valve . . . . . . . . . . . . . . . . 1B1-102

Oil Dipstick Guide Tube . . . . . . . . . . . . . . 1B1-103

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B1-104 Oil Gallery in Crankcase . . . . . . . . . . . . . . 1B1-104

Oil Gallery in Cylinder Head . . . . . . . . . . . 1B1-106

Core Plugs in Crankcase . . . . . . . . . . . . . 1B1-109

Cylinder Bore . . . . . . . . . . . . . . . . . . . . . . 1B1-111

Crankcase Mating Surface . . . . . . . . . . . . 1B1-113

Cylinder Head Mating Surface . . . . . . . . . 1B1-115

Page 129 of 1574

M162 ENGINE MECHANICAL 1B1-93

OIL PAN

1 Gasket ................................................... Replace

2 Bolt (M6 x 22, 6 pieces)............................ 10 Nm

3 Drain Plug (M6 x 20) ................................. 25 Nm

4 Bolt (M6 x 20, 22 pieces) .......................... 10 Nm 5 Bolt (M6 x 85)

............................................ 10 Nm

6 Bolt (M8 x 40) ............................................ 25 Nm

7 Bolt (M10) ................................................. 40 Nm

8 Oil Pan

Removal & Installation Procedure

1. Remove the drain plug and drain the oil completely.

2. Disconnect the electric connector from oil level switch.

3. Unscrew the bolts (10) for oil level switch and check the O- ring (11) for wear or damage. And replace it if necessary.

4. Unscrew the bolts and remove the oil pan and gasket.

NoticeArrange the bolts according to each size.

5. Clean the inside of oil pan and sealing surface, then apply the sealant.

6. Replace the gasket with new one.

7. Install the oil pan with gasket, and tighten each bolt in specified torque.

8. Check for oil leaks while running the engine.

M8 X 40, 4 pieces M6 X 85, 3 piecesM6 X 35, 3 piecesM6 X 20, 28 pieces

the rest

Page 153 of 1574

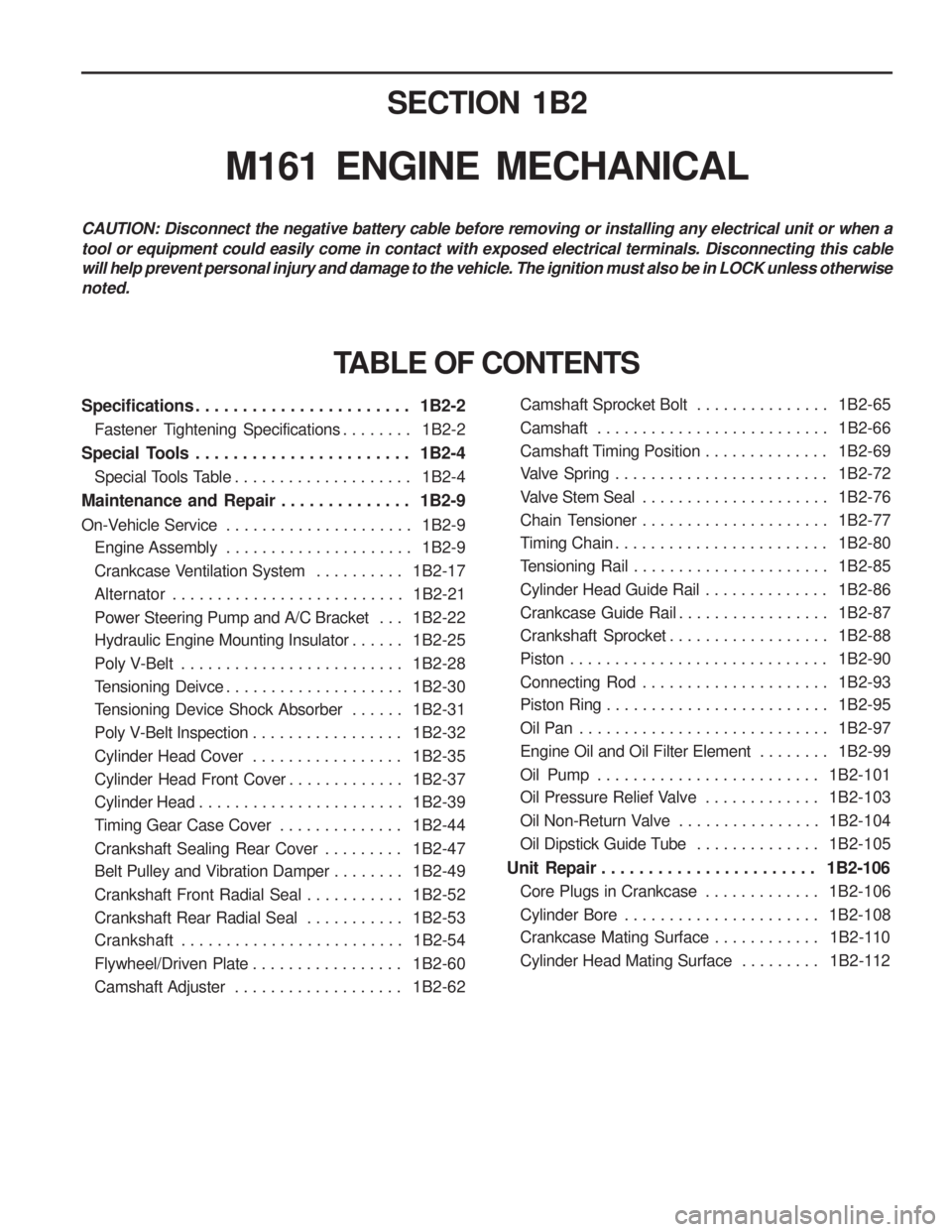

SECTION 1B2

M161 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B2-2Fastener Tightening Specifications . . . . . . . . 1B2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B2-4 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B2-4

Maintenance and Repair . . . . . . . . . . . . . . 1B2-9

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1B2-9

Engine Assembly . . . . . . . . . . . . . . . . . . . . . 1B2-9

Crankcase Ventilation System . . . . . . . . . . 1B2-17

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-21

Power Steering Pump and A/C Bracket . . . 1B2-22

Hydraulic Engine Mounting Insulator . . . . . . 1B2-25

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-28

Tensioning Deivce . . . . . . . . . . . . . . . . . . . . 1B2-30

Tensioning Device Shock Absorber . . . . . . 1B2-31

Poly V-Belt Inspection . . . . . . . . . . . . . . . . . 1B2-32

Cylinder Head Cover . . . . . . . . . . . . . . . . . 1B2-35

Cylinder Head Front Cover . . . . . . . . . . . . . 1B2-37

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B2-39

Timing Gear Case Cover . . . . . . . . . . . . . . 1B2-44

Crankshaft Sealing Rear Cover . . . . . . . . . 1B2-47

Belt Pulley and Vibration Damper . . . . . . . . 1B2-49

Crankshaft Front Radial Seal . . . . . . . . . . . 1B2-52

Crankshaft Rear Radial Seal . . . . . . . . . . . 1B2-53

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-54

Flywheel/Driven Plate . . . . . . . . . . . . . . . . . 1B2-60

Camshaft Adjuster . . . . . . . . . . . . . . . . . . . 1B2-62

TABLE OF CONTENTS

Camshaft Sprocket Bolt . . . . . . . . . . . . . . . 1B2-65

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-66

Camshaft Timing Position . . . . . . . . . . . . . . 1B2-69

Valve Spring . . . . . . . . . . . . . . . . . . . . . . . . 1B2-72

Valve Stem Seal . . . . . . . . . . . . . . . . . . . . . 1B2-76

Chain Tensioner . . . . . . . . . . . . . . . . . . . . . 1B2-77

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . 1B2-80

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . . 1B2-85

Cylinder Head Guide Rail . . . . . . . . . . . . . . 1B2-86

Crankcase Guide Rail . . . . . . . . . . . . . . . . . 1B2-87

Crankshaft Sprocket . . . . . . . . . . . . . . . . . . 1B2-88

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-90

Connecting Rod . . . . . . . . . . . . . . . . . . . . . 1B2-93

Piston Ring . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-95

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-97

Engine Oil and Oil Filter Element . . . . . . . . 1B2-99

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-101

Oil Pressure Relief Valve . . . . . . . . . . . . . 1B2-103

Oil Non-Return Valve . . . . . . . . . . . . . . . . 1B2-104

Oil Dipstick Guide Tube . . . . . . . . . . . . . . 1B2-105

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B2-106 Core Plugs in Crankcase . . . . . . . . . . . . . 1B2-106

Cylinder Bore . . . . . . . . . . . . . . . . . . . . . . 1B2-108

Crankcase Mating Surface . . . . . . . . . . . . 1B2-110

Cylinder Head Mating Surface . . . . . . . . . 1B2-112

Page 266 of 1574

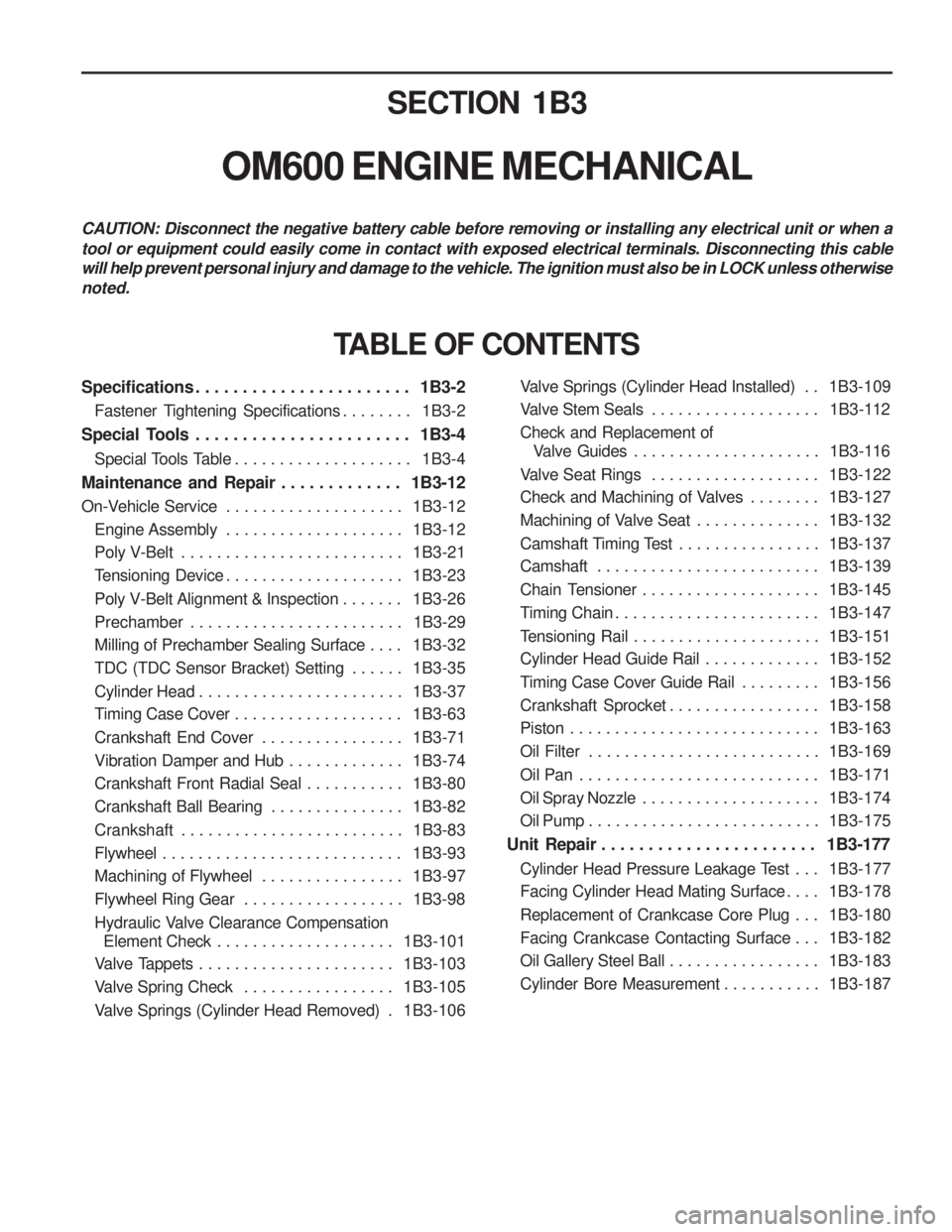

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface . . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 388 of 1574

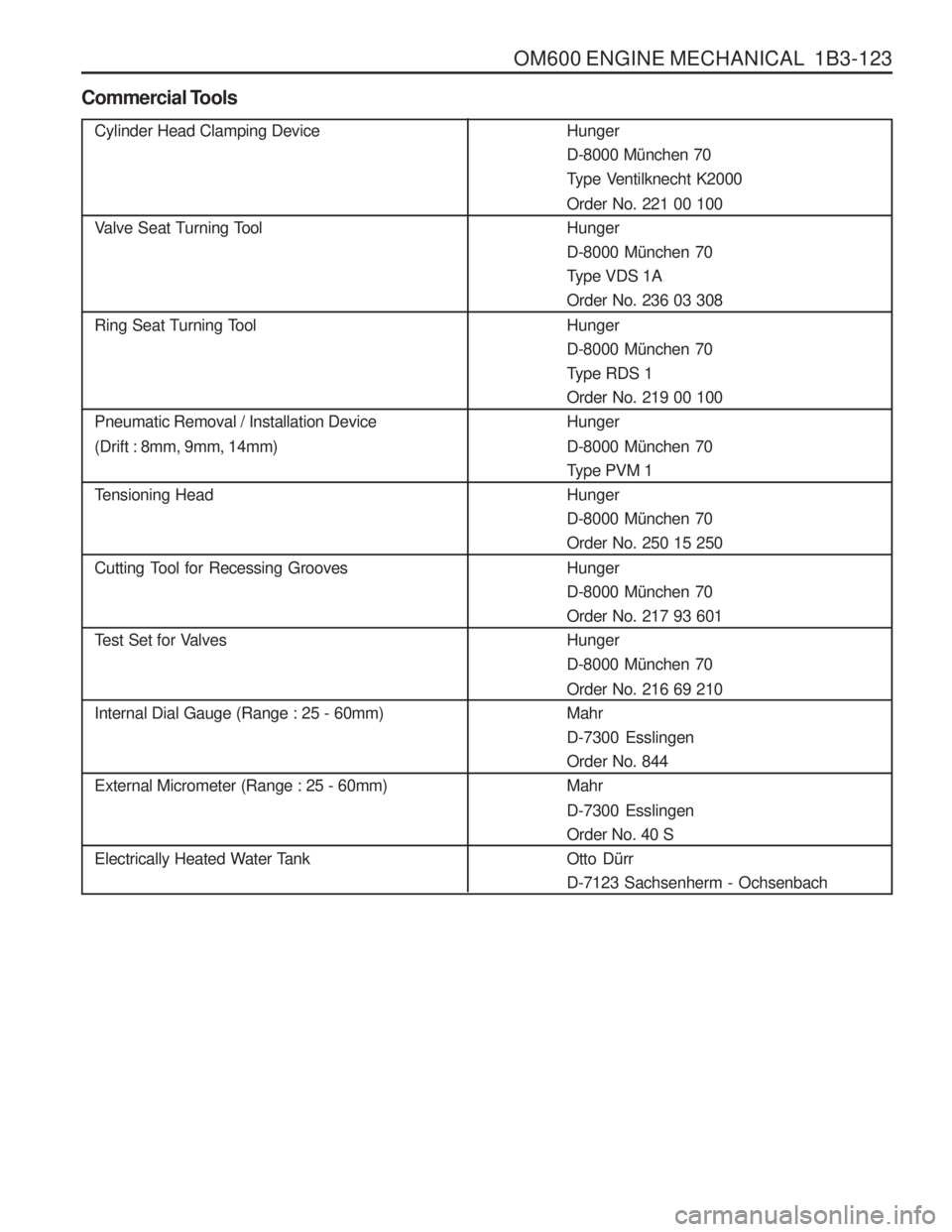

OM600 ENGINE MECHANICAL 1B3-123

Cylinder Head Clamping Device

Valve Seat Turning Tool

Ring Seat Turning Tool Pneumatic Removal / Installation Device (Drift : 8mm, 9mm, 14mm)

Tensioning Head

Cutting Tool for Recessing Grooves

Test Set for Valves Internal Dial Gauge (Range : 25 - 60mm) External Micrometer (Range : 25 - 60mm)

Electrically Heated Water Tank

Commercial ToolsHunger D-8000 M

ünchen 70

Type Ventilknecht K2000 Order No. 221 00 100 HungerD-8000 M ünchen 70

Type VDS 1AOrder No. 236 03 308 Hunger D-8000 M ünchen 70

Type RDS 1Order No. 219 00 100Hunger D-8000 M ünchen 70

Type PVM 1 HungerD-8000 M ünchen 70

Order No. 250 15 250 Hunger D-8000 M ünchen 70

Order No. 217 93 601HungerD-8000 M ünchen 70

Order No. 216 69 210MahrD-7300 EsslingenOrder No. 844Mahr D-7300 Esslingen Order No. 40 SOtto D ürr

D-7123 Sachsenherm - Ochsenbach

Page 452 of 1574

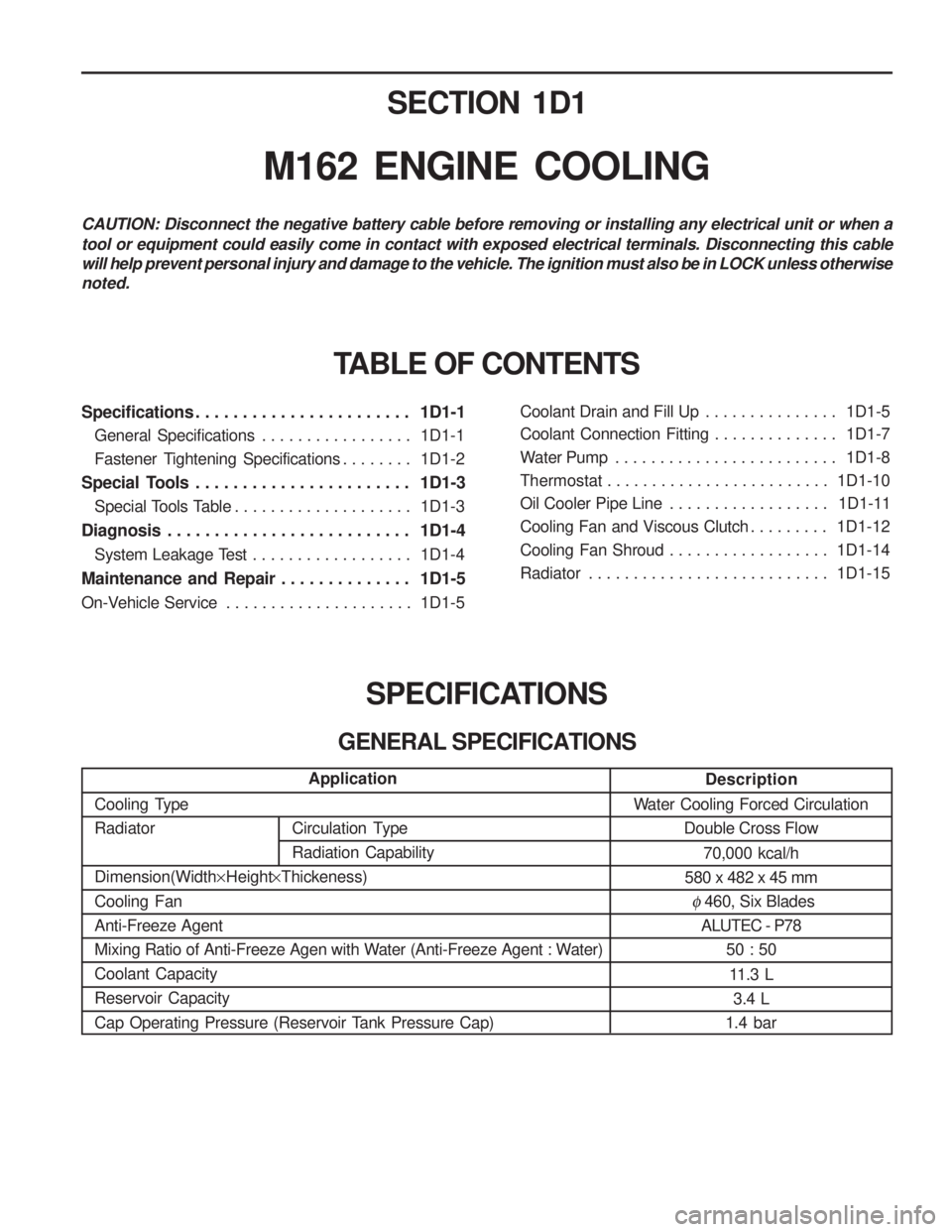

SECTION 1D1

M162 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D1-1General Specifications . . . . . . . . . . . . . . . . . 1D1-1

Fastener Tightening Specifications . . . . . . . . 1D1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D1-3 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D1-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-4 System Leakage Test . . . . . . . . . . . . . . . . . . 1D1-4

Maintenance and Repair . . . . . . . . . . . . . . 1D1-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D1-5Coolant Drain and Fill Up . . . . . . . . . . . . . . .

1D1-5

Coolant Connection Fitting . . . . . . . . . . . . . . 1D1-7

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-8

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-10

Oil Cooler Pipe Line . . . . . . . . . . . . . . . . . . 1D1-11

Cooling Fan and Viscous Clutch . . . . . . . . . 1D1-12

Cooling Fan Shroud . . . . . . . . . . . . . . . . . . 1D1-14

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation Double Cross Flow

70,000 kcal/h

580 x 482 x 45 mm

� 460, Six Blades

ALUTEC - P78

50 : 50

11.3 L 3.4 L

1.4 bar

Application

Cooling Type Radiator Dimension(Width ×Height ×Thickeness)

Cooling Fan Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water)Coolant CapacityReservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Circulation Type Radiation Capability

Page 468 of 1574

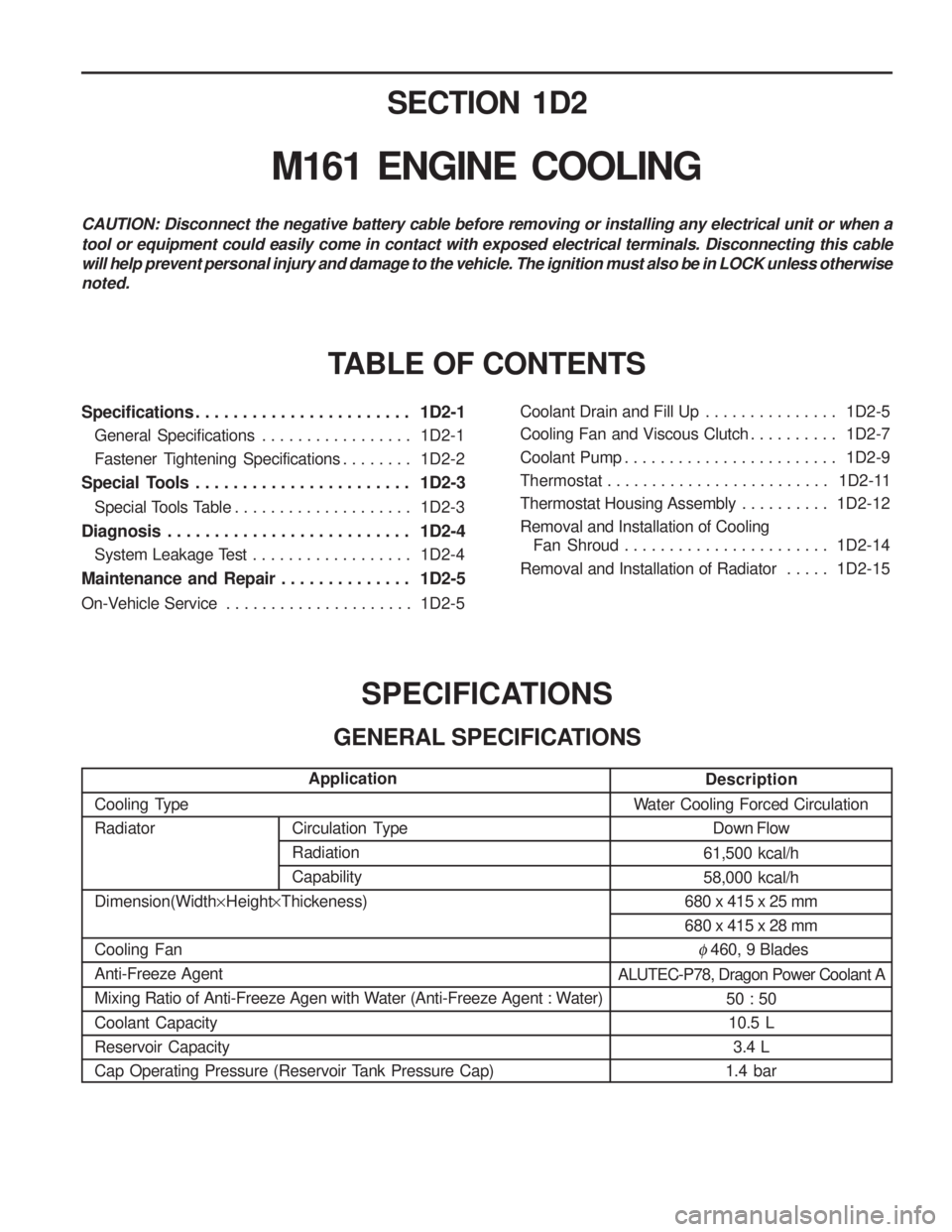

Circulation Type RadiationCapabilitySECTION 1D2

M161 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D2-1

General Specifications . . . . . . . . . . . . . . . . . 1D2-1

Fastener Tightening Specifications . . . . . . . . 1D2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D2-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-4 System Leakage Test . . . . . . . . . . . . . . . . . . 1D2-4

Maintenance and Repair . . . . . . . . . . . . . . 1D2-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D2-5Coolant Drain and Fill Up . . . . . . . . . . . . . . .

1D2-5

Cooling Fan and Viscous Clutch . . . . . . . . . . 1D2-7

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D2-9

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-11

Thermostat Housing Assembly . . . . . . . . . . 1D2-12

Removal and Installation of Cooling Fan Shroud . . . . . . . . . . . . . . . . . . . . . . . 1D2-14

Removal and Installation of Radiator . . . . . 1D2-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation Down Flow

61,500 kcal/h 58,000 kcal/h

680 x 415 x 25 mm680 x 415 x 28 mm

� 460, 9 Blades

ALUTEC-P78, Dragon Power Coolant A 50 : 5010.5 L 3.4 L

1.4 bar

Application

Cooling TypeRadiator Dimension(Width ×Height ×Thickeness)

Cooling Fan Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water) Coolant Capacity Reservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Page 484 of 1574

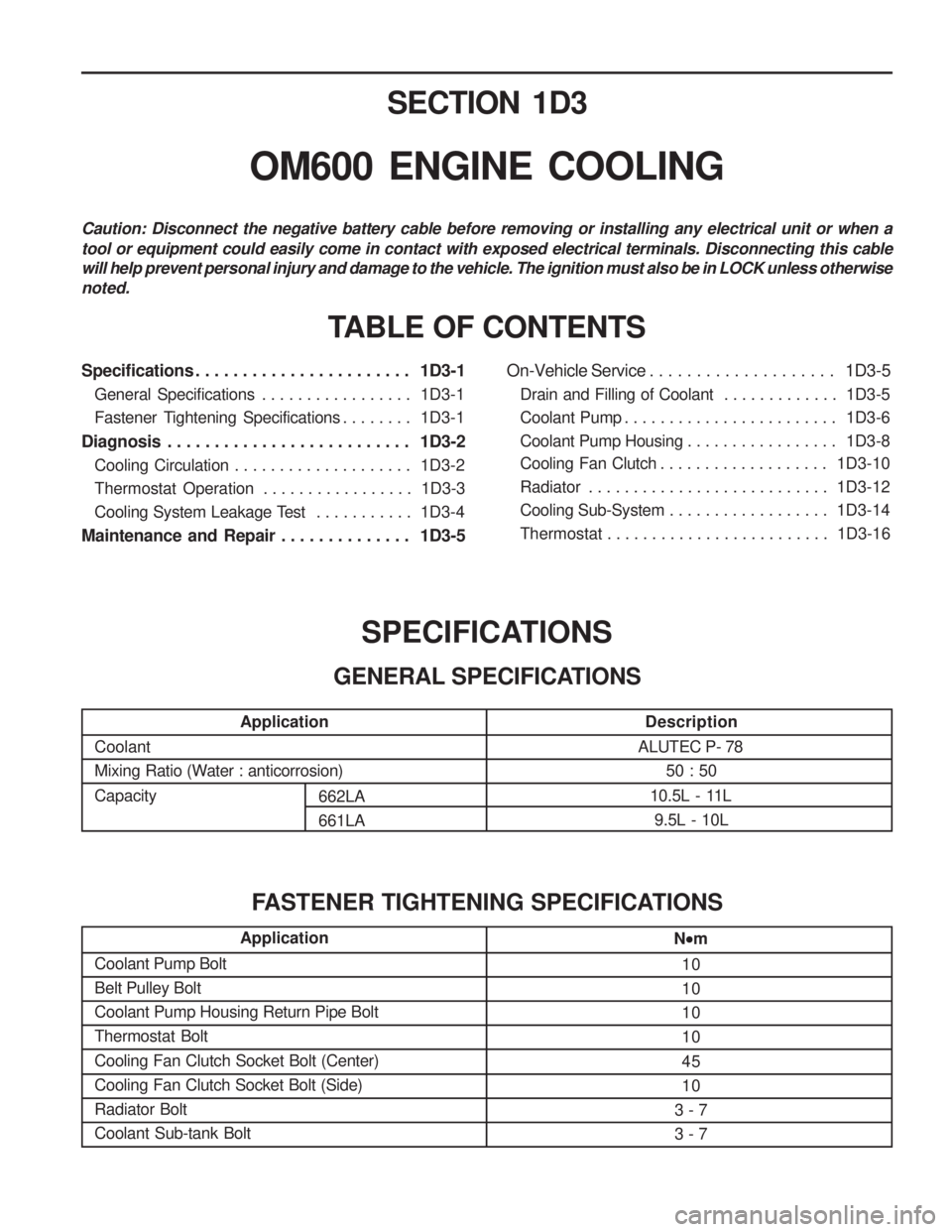

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2 Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5 On-Vehicle Service . . . . . . . . . . . . . . . . . . . .

1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Application

Coolant

Mixing Ratio (Water : anticorrosion) Capacity

Description

ALUTEC P- 78 50 : 50

10.5L - 11L 9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt Belt Pulley BoltCoolant Pump Housing Return Pipe BoltThermostat Bolt Cooling Fan Clutch Socket Bolt (Center) Cooling Fan Clutch Socket Bolt (Side)Radiator BoltCoolant Sub-tank BoltN

m

10 101010 45 10

3 - 73 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA 661LA