electric SSANGYONG MUSSO 2003 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 531 of 1574

OM600 ENGINE ELECTRICAL 1E3-7

Removal & Installation Procedure

1. Disconnect the negative terminal of the battery.

2. Disconnect the plug connection (5).

3. OM 662 EngineAlign the groove of cooling fan with bolt (2) (arrow).

4. Remove the bolts (2, 3) and take out the alternator.

5. Installation should follow the removal procedure in the reverse order.

Tightening Torque 45 Nm

Page 532 of 1574

1E3-8 OM600 ENGINE ELECTRICAL

STARTER MOTOR

1 Starter Motor

2 Washer3 Nut .............................................................

15Nm

4 Bolt ............................................................ 48Nm

Removal & Installation Procedure

1. Disconnect the battery terminals.

2. Disconnect the starter motor cable harnesses.

3. Remove the bolts and then remove the starter motor.

4. Installation should follow the removal procedure in the

reverse order.

Page 533 of 1574

SECTION 1F1

M162 ENGINE CONTROLS

TABLE OF CONTENTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cablewill help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F1-2

Fastener Tightening Specifications . . . . . . . . 1F1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1F1-3 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1F1-3

Schematic and Routing Diagrams . . . . . . . 1F1-4 E32 ECU (HFM) . . . . . . . . . . . . . . . . . . . . . . 1F1-4

E32 ECU (MSE) . . . . . . . . . . . . . . . . . . . . . . 1F1-5

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Socket Pin Numbers andDescriptions . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Failure Code . . . . . . . . . . . . . 1F1-7

Test Box Connection . . . . . . . . . . . . . . . . . . 1F1-10

Fuel Injection System Test (MSE3.62) . . . . . 1F1-11

Ignition System Test . . . . . . . . . . . . . . . . . . 1F1-21

Idling Control and Electronic Pedal System Test . . . . . . . . . . . . . . . . . . . . . . . 1F1-26

Air Conditioner Control System Test . . . . . . 1F1-28

Fuel Pressure and Internal Leakage Test . . 1F1-29

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F1-31Injector Test . . . . . . . . . . . . . . . . . . . . . . . .

1F1-33

Maintenance and Repair . . . . . . . . . . . . . 1F1-35

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F1-35

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-35

Fuel Pressure Regulator . . . . . . . . . . . . . . 1F1-46

Fuel Distributor . . . . . . . . . . . . . . . . . . . . . . 1F1-50

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-54

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-57

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-58

Purge Switchover Valve . . . . . . . . . . . . . . . 1F1-62

Vacuum System . . . . . . . . . . . . . . . . . . . . . 1F1-64

Crankshaft Position Sensor . . . . . . . . . . . . 1F1-65

Camshaft Position Sensor . . . . . . . . . . . . . 1F1-67

Hot Film Air Mass (HFM) Sensor . . . . . . . . . 1F1-69

Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . 1F1-72

Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . 1F1-74

Coolant Temperature Sensor . . . . . . . . . . . 1F1-75

Accelerator Pedal Module . . . . . . . . . . . . . . 1F1-78

Page 604 of 1574

1F1-72 M162 ENGINE CONTROLS

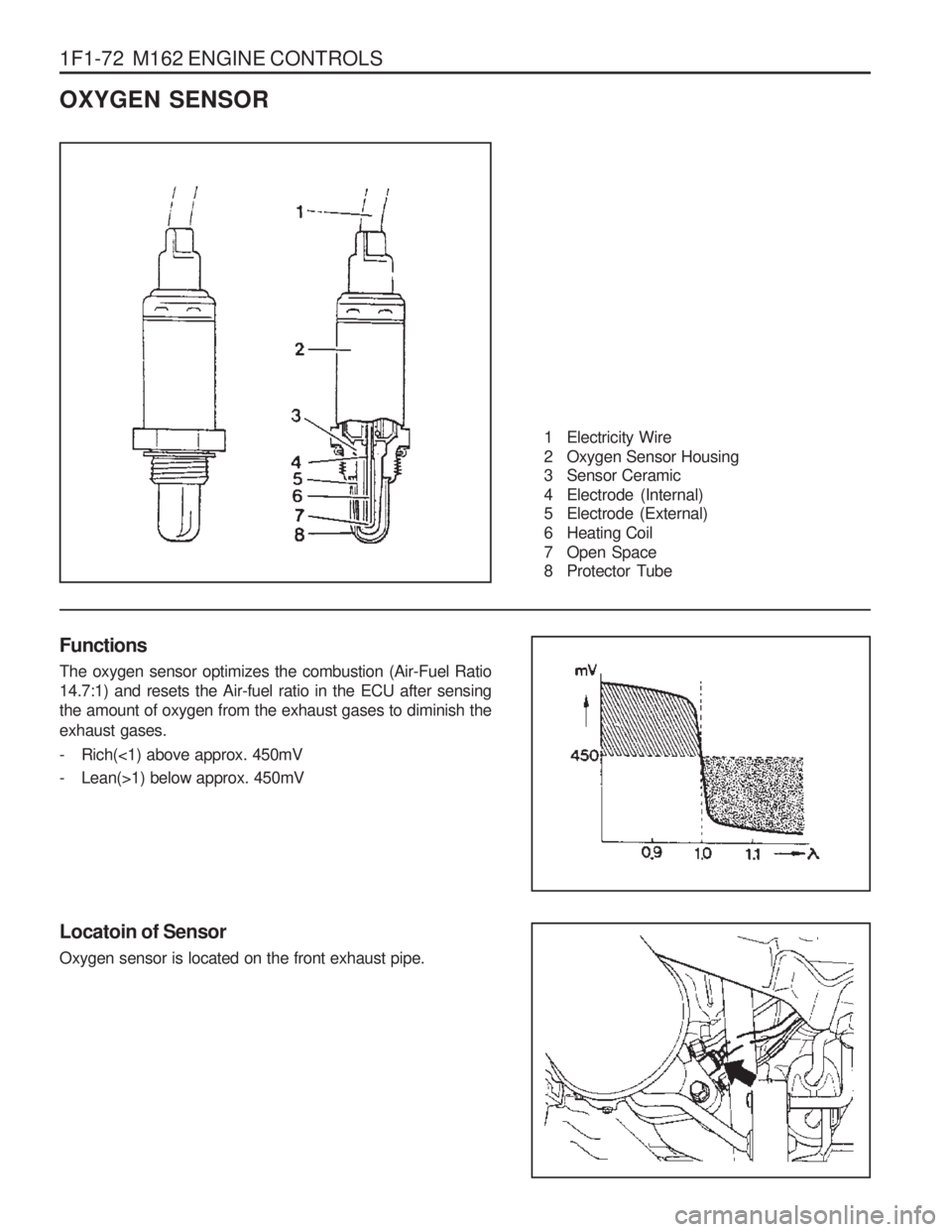

OXYGEN SENSOR

1 Electricity Wire

2 Oxygen Sensor Housing

3 Sensor Ceramic

4 Electrode (Internal)

5 Electrode (External)

6 Heating Coil

7 Open Space

8 Protector Tube

Functions The oxygen sensor optimizes the combustion (Air-Fuel Ratio 14.7:1) and resets the Air-fuel ratio in the ECU after sensingthe amount of oxygen from the exhaust gases to diminish the exhaust gases.

- Rich(<1) above approx. 450mV

- Lean(>1) below approx. 450mV

Locatoin of Sensor Oxygen sensor is located on the front exhaust pipe.

Page 612 of 1574

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . .

1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test (Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut Fuel Pump Pressure Line Fuel Injection NozzleFuel Injection Pipe

Nozzle Tensioning NutScrew Plug Left-Hand Thread Bolt

N· m

28 - 47 13

35 - 40 18 8030 46

Page 666 of 1574

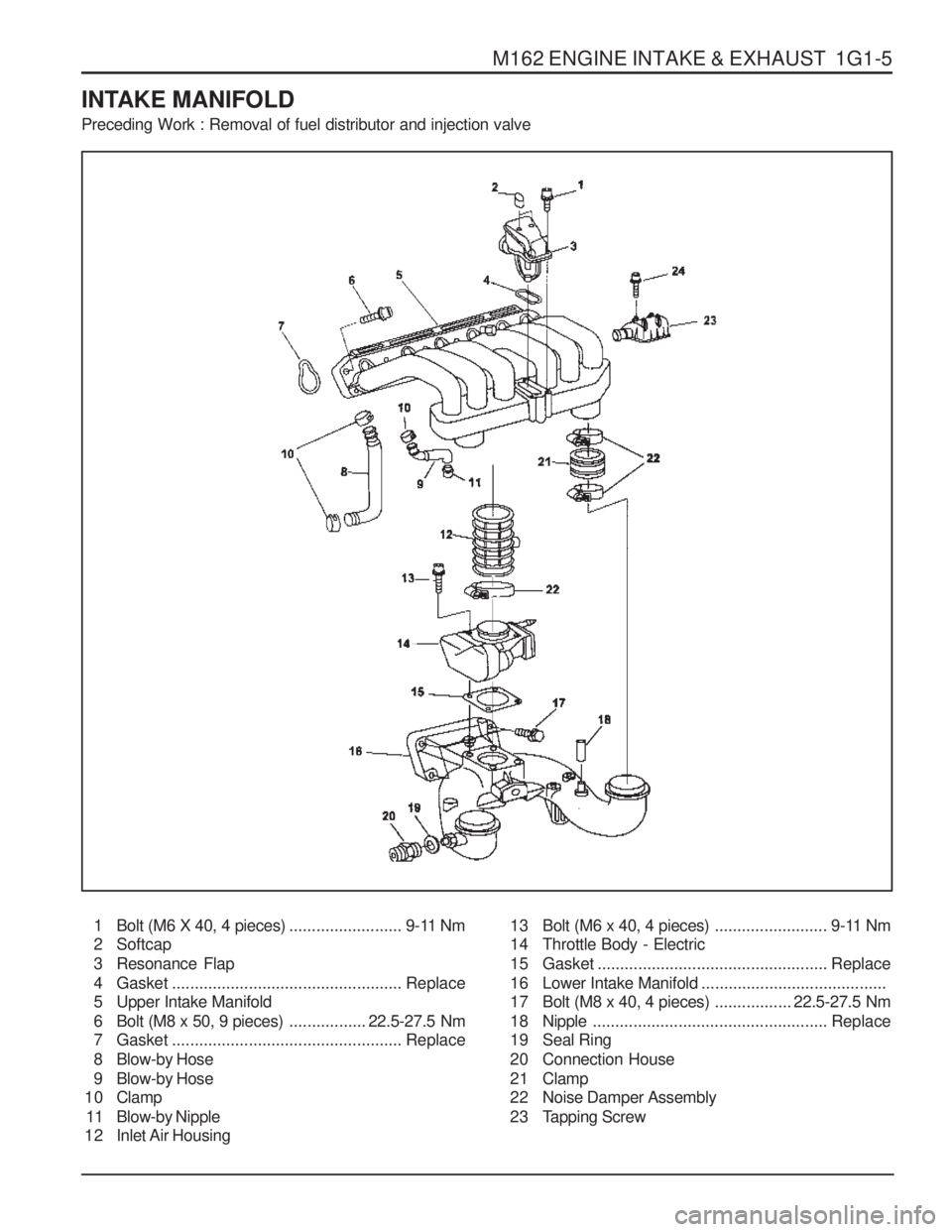

M162 ENGINE INTAKE & EXHAUST 1G1-5

INTAKE MANIFOLD Preceding Work : Removal of fuel distributor and injection valve

1 Bolt (M6 X 40, 4 pieces)......................... 9-11 Nm

2 Softcap

3 Resonance Flap

4 Gasket ................................................... Replace

5 Upper Intake Manifold

6 Bolt (M8 x 50, 9 pieces) .................22.5-27.5 Nm

7 Gasket ................................................... Replace

8 Blow-by Hose

9 Blow-by Hose

1 0 Clamp

11 Blow-by Nipple

12 Inlet Air Housing 13 Bolt (M6 x 40, 4 pieces)

......................... 9-11 Nm

14 Throttle Body - Electric

15 Gasket ................................................... Replace

16 Lower Intake Manifold .........................................

17 Bolt (M8 x 40, 4 pieces) .................22.5-27.5 Nm

1 8 Nipple .................................................... Replace

19 Seal Ring

20 Connection House

2 1 Clamp

22 Noise Damper Assembly

23 Tapping Screw

Page 684 of 1574

SECTION 1G3

OM600 ENGINE INTAKE & EXHAUST

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G3-1Fastener Tightening Specifications . . . . . . . . 1G3-1

Schematic and Routing Diagrams . . . . . . . 1G3-2 EGR Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-2

Maintenance and Repair . . . . . . . . . . . . . . 1G3-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1G3-3 TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Air Cleaner Housing Cover Nut Intake Manifold Bolt (M8 x 20)Intake Manifold Bolt (M8)Exhaust Mainfold Stud BoltExhaust Pipe Nut (Engine) Exhaust Pipe Bolt

N

m

9 - 11

22.5 - 27.5 22.5 - 27.5 9.5 - 12.5 15 - 2828 - 47

Air Cleaner and Inlet Duct & Hose . . . . . . . . 1G3-3

Intake and Exhaust Manifold . . . . . . . . . . . . . 1G3-5

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . 1G3-8

Charge Air System Diagram . . . . . . . . . . . . . 1G3-8

Intercooler . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-9

Turbocharger Assembly . . . . . . . . . . . . . . . 1G3-11

Page 798 of 1574

SECTION 4A

HYDRAULIC BRAKES

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4A-1

General Specifications . . . . . . . . . . . . . . . . . . 4A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Noise or Vehicle Vibration When Applied

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Pulls to One Side When Braking . . . . . . . . . . . 4A-2

Poor Braking . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2Increasing Pedal Stroke (Pedal Goes to

Floor) or Brake Dragging . . . . . . . . . . . . . . . 4A-3

Poor Braking of Parking Brake . . . . . . . . . . . . 4A-3 TABLE OF CONTENTS

Component Locator . . . . . . . . . . . . . . . . . . . 4A-4

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-4

ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-5

Non-ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . 4A-6

Maintenance and Repair . . . . . . . . . . . . . . . 4A-7

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4A-7

Bleeding the Brakes . . . . . . . . . . . . . . . . . . . . 4A-7

Brake Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-9

LCRV (Load Conscious Reducing Valve) . . . 4A-12

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting thiscable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCKunless otherwise noted.

Type

Pedal Ratio

Pedal Stroke

Pedal Freeplay Type

Inner Diameter Type

Ratio

Type

I.D. of Caliper Cylinder

Thickness of Brake Pad Thickness of Disc Plate Type

I.D. of Caliper Cylinder

Thickness of Brake Pad Thickness of Disc Plate

Type

Operation

Specification PBR Brake

4.3 : 1

132 mm

�23.81 mm

5.0 : 1

�60.4 mm

�

�40.5 mm

9.5 mm

�

Suspended

1 - 4 mm

Tandem Type with Lever Sensor

Vacuum Booster Type

Ventilated Disc 10 mm 24 mm

Rear Wheel Internal Expansion Type Mechanical

SAE J1703, DOT3

SPECIFICATIONS

GENERAL SPECIFICATIONS

Brake Pedal

Master Cylinder Brake Booster Front Brake

Rear Brake

Parking Brake Brake Fluid MANDO Brake

4.3 : 1

138 mm

�25.4 mm

5.6 : 1

�60 mm

Solid Disc

�38.2 mm

10.0 mm 10.4 mm

Application

Page 830 of 1574

FrontRear

Front Rear

SECTION 4F

ANTILOCK BRAKE SYSTEM

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting thiscable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCKunless otherwise noted.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application Model

ECUNumber of Pins

Operating TemperatureMotor Operating CurrentSolenoid Coil Resistance External Resistance Air Gap

Number of teeth Description

ABS 5.3 31

-40 ~ +120 °C

Below MAX 40A

1.28K � - 1.92K �

0.35 - 1.60 mm 0.15 - 1.20 mm 52 52 ABS/ABD 5.3

83

-40 ~ +85 °C

Below MAX 45A

8.04 - 9.04 � except AV,

HSV 4.04 - 4.54 �

1.28K � - 1.92K �

0.35 - 1.60 mm 0.15 - 1.20 mm

52 52

Hydraulic System

Wheel Speed Sensor Impulse Ring

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4F-1

General Specifications . . . . . . . . . . . . . . . . . . 4F-1

Schematic and Routing Diagrams . . . . . . . . 4F-2 ABS 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4F-2

ABS/ABD 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . 4F-3

ABS 5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4F-4

ABS/ABD 5.3 . . . . . . . . . . . . . . . . . . . . . . . . . 4F-5

Component Locator . . . . . . . . . . . . . . . . . . . 4F-6 ABS, ABS/ABD . . . . . . . . . . . . . . . . . . . . . . . . 4F-6

ABD System Description . . . . . . . . . . . . . . . 4F-7 Self Diagnosis . . . . . . . . . . . . . . . . . . . . . . . 4F-9

ABS, ABS/ABD 5.3 . . . . . . . . . . . . . . . . . . . . . 4F-9

ABS, ABS/ABD 5.0 . . . . . . . . . . . . . . . . . . . . 4F-11

Defect Codes . . . . . . . . . . . . . . . . . . . . . . . . 4F-13

Maintenance and Repair . . . . . . . . . . . . . . 4F-19

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 4F-19

Wheel Speed Sensor . . . . . . . . . . . . . . . . . . 4F-19

Hydraulic Circuit . . . . . . . . . . . . . . . . . . . . 4F-21 ABS 5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4F-21

ABS/ABD 5.3 . . . . . . . . . . . . . . . . . . . . . . . . 4F-24

Page 856 of 1574

SECTION 4G

PARKING BRAKE

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4G-1General Specifications . . . . . . . . . . . . . . . . . . 4G-1

Fastener Tightening Specifications . . . . . . . . . 4G-1

Component Locator . . . . . . . . . . . . . . . . . . . 4G-2 TABLE OF CONTENTS

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . 4G-2

Maintenance and Repair . . . . . . . . . . . . . . . 4G-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4G-3 Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . 4G-3

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting thiscable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCKunless otherwise noted.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Parking Brake Lever Bolt Cable Mounting Bracket Bolt

N

m

8 - 18 8 - 18

FASTENER TIGHTENING SPECIFICATIONS

Application

Type

Operating Type

Description

Mechanically Operated Rear Wheel Expansion Manual