window SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 27 of 828

1)

2) SB2~SB4, SB7~SB11, Ef3, POWER WINDOW RELAY SB5, SB6, Ef4, Ef5, Ef11, EF16, EF17, HORN RELAY, HEAD LAMP RELAY (LO)

Page 38 of 828

3

4

5

8

11

1461-00/2820-00/1491-00/8210-00/3110-00/3410-00/4892-00/8810-00/8010-00/7410-100/8510-00/8710-00/8510-00/8610-00/

8730-00/7340-00/7632-00/8310-00/8610-00/8510-00/8320-00/8410-00/8210-00/8310-00/4810-00/7770-00/8910-00/8790-00/6810-00

ENGINE1461-00 STARTING / CHARGING.................

1413-00 GLOW CONTROL UNIT...................

1491-00 ECU (ENGINE CONTROL

UNIT - D20DTR EU-V).....................

1490-00 ECU (ENGINE CONTROL

UNIT - GSL G23)............................

8210-00 DIAGNOSIS CIRCUIT.....................CHASSIS3110-00 TCU (6-A/T)...................................

3410-00 TCCU............................................

4892-00 ABS/ESP........................................8730-00 IMMOBILIZER CIRCUIT................

7340-00 SUNROOF CIRCUIT.......................

7632-00 CIGAR LIGHTER / POWER

OUTLET CIRCUIT........................

8310-00 HEAD LAMP CIRCUIT..................

8610-00 DRL (DAY TIME RUNNING

LIGHT) UNIT CIRCUIT.................

8510-00 HLLD (HEAD LAMP LEVEL G

DEVICE) CIRCUIT.........................

8320-00 TAIL LAMP CIRCUIT....................

8410-00 TURN SIGNAL / HAZARD

LAMP CIRCUIT.............................

8210-00 TRAILER LAMP CIRCUIT.............

8310-00 FOG LAMP CIRCUIT.....................

4810-00 STOP / BACK-UP

LAMP CIRCUIT.............................

7770-00 INTERIOR LAMP CIRCUIT............

7770-00 AUTO DIMMING ROOM

MIRROR CIRCUT.........................

8910-00 AUDIO / CLOCK CIRCUIT..............

8790-00 PARKING AID CIRCUIT..................

6810-00 PTC HEATER (POSITIVE

TEMPERATURE COEFFICIENT).....

6810-00 FATC (FULL AUTO TEMP.

CONTROL) CIRCUIT....................

6810-00 AIR-CON (MANUAL) CIRCUIT......... 12

14

1533

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

52

'

ELECTRIC8810-00 AIR-BAG.......................................

8010-00 CLUSTER......................................

7410-00 POWER SEAT - DRIVER................

7410-00 POWER SEAT - PASSENGER.......

8510-00 ELECTRIC OUTSIDE MIRROR........

8510-00 SEAT WARMER.............................

8710-00 STICS.............................................

8510-00 POWER WINDOW CIRCUIT...........

8610-00 HORN............................................17

18

20

21

22

23

24

31

32

Page 63 of 828

3) TAIL LAMP, HAZARD, POWER WINDOW

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION (1) CONNECTOR INFORMATION

Page 324 of 828

15-210000-00

(7) Knocking Control

A. Resetting the pilot injection

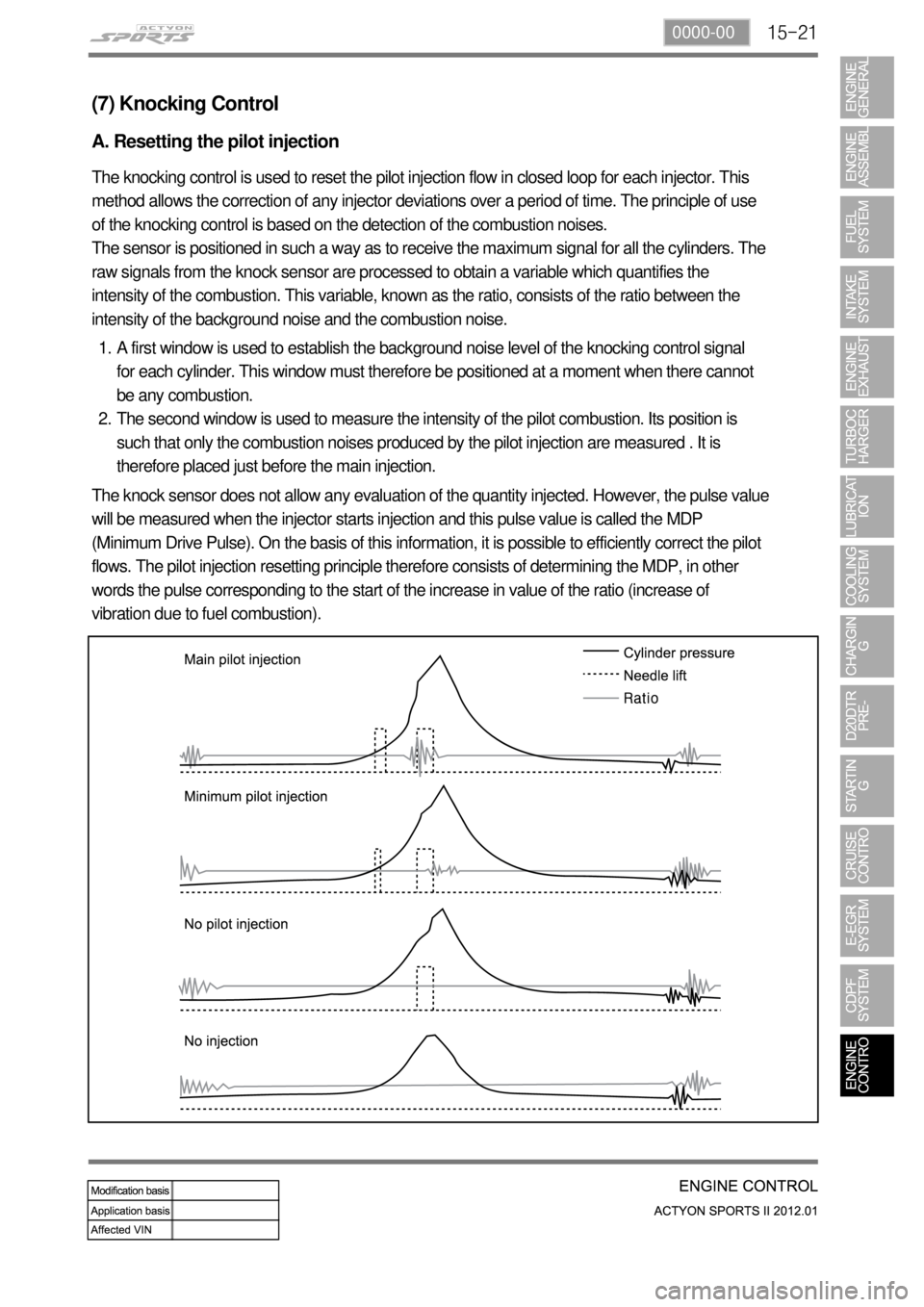

The knocking control is used to reset the pilot injection flow in closed loop for each injector. This

method allows the correction of any injector deviations over a period of time. The principle of use

of the knocking control is based on the detection of the combustion noises.

The sensor is positioned in such a way as to receive the maximum signal for all the cylinders. The

raw signals from the knock sensor are processed to obtain a variable which quantifies the

intensity of the combustion. This variable, known as the ratio, consists of the ratio between the

intensity of the background noise and the combustion noise.

A first window is used to establish the background noise level of the knocking control signal

for each cylinder. This window must therefore be positioned at a moment when there cannot

be any combustion.

The second window is used to measure the intensity of the pilot combustion. Its position is

such that only the combustion noises produced by the pilot injection are measured . It is

therefore placed just before the main injection. 1.

2.

The knock sensor does not allow any evaluation of the quantity injected. However, the pulse value

will be measured when the injector starts injection and this pulse value is called the MDP

(Minimum Drive Pulse). On the basis of this information, it is possible to efficiently correct the pilot

flows. The pilot injection resetting principle therefore consists of determining the MDP, in other

words the pulse corresponding to the start of the increase in value of the ratio (increase of

vibration due to fuel combustion).

Page 325 of 828

15-22

This is done periodically under certain operating conditions. When the resetting is finished, the

new minimum pulse value replaces the value obtained during the previous resetting. The first MDP

value is provided by the C3I. Each resetting then allows the closed loop of the MDP to be updated

according to the deviation of the injector.

B. Detection of leaks in the cylinders

The accelerometer is also used to detect any injector which may have stuck open. The detection

principle is based on monitoring the ratio. If there is a leak in the cylinder, the accumulated fuel

self-ignites as soon as the temperature and pressure conditions are favorable (high engine

speed, high load and small leak).

This combustion is set off at about 20 degrees before TDC and before main injection.

The ratio therefore increases considerably in the detection window. It is this increase which allows

the leaks to be detected. The threshold beyond which a fault is signaled is a percentage of the

maximum possible value of the ratio.

Because of the severity of the recovery process (engine shut-down), the etection must be

extremely robust.

An increase in the ratio can be the consequence of various causes:

Pilot injection too much

Main combustion offset

Fuel leak in the cylinder -

-

-

If the ratio becomes too high, the strategy initially restricts the pilot injection flow and retards the

main injection. If the ratio remains high despite these interventions, this shows that a real leak is

present, a fault is signaled and the engine is shut down.

C. Detection of an accelerometer fault

This strategy permits the detection of a fault in the sensor or in the wiring loom connecting the

sensor to the ECU.

It is based on detection of the combustion. When the engine is idling, the detection window is set

too low for the combustion caused by the main injection. If the ratio increases, this shows that the

knock sensor is working properly, but otherwise a fault is signaled to indicate a sensor failure.

The recovery modes associated with this fault consist of inhibition of the pilot injection and

discharge through the injectors.

Page 417 of 828

02-38710-01

1. PERFORMANCE AND SPECIFICATIONS

1) Rated Load & Input Signals

Rated Load ▶

NO. Item Rated Load

1 Chime bell / Buzzer DC 12V 350 mA (Inductive load)

2 Front room lamp DC 12V 16W (Lamp load)

3 Rear room lamp DC 12V 8W (Lamp load)

4 Ignition key illumination DC 12V 1.2W (Lamp load)

5 Seat belt indicator DC 12V 1.2W (Lamp load)

6 Parking brake warning lamp DC 12V 1.2W (Lamp load)

7 Door ajar warning lamp DC 12V 1.2W (Lamp load)

8 Door lock relay DC 12V 200 mA (Inductive load)

9 Door unlock relay DC 12V 200 mA (Inductive load)

10 Horn relay DC 12V 260 mA

11 Tail lamp relay DC 12V 200 mA (Inductive load)

12 Hazard warning lamp relay DC 12V 200 mA (Inductive load)

13 Power window relay DC 12V 200 mA (Inductive load)

14 Rear defogger relay DC 12V 200 mA (Inductive load)

15 Wiper LOW relay DC 12V 200 mA (Inductive load)

16 Wiper HIGH relay DC 12V 200 mA (Inductive load)

17 Front washer motor DC 12V 1.5A

18 Head lamp relay DC 12V 750 mA (Inductive load)

19 Front defogger relay DC 12V 200 mA (Inductive load)

20 Mirror lock relay DC 12V 200 mA (Inductive load)

21 Mirror unlock relay DC 12V 200 mA (Inductive load)

Page 449 of 828

02-358710-01

The defogger system uses the heated glass to remove the moisture and frost on the windows,

which can disturb safe driving.

The defogger (including de-icer) activates the corresponding switch and the STICS controls the

operating time.

Tailgate and outside rearview mirror heate

d

glass switch

Pressing switch activates tailgate and

outside rearview mirror heated glass for

approx. 12 minutes

Windshield heated glass (de-icer) switch

Pressing switch activates windshield heated

glass for approx. 12 minutes

Page 458 of 828

02-44

▶Time Lag Power Window Control

The power window relay output is "ON" when turning on the ignition switch.

The power window relay output is "ON" for 30 seconds when turning off the ignition

switch.

The power window relay output is "OFF" when opening the driver's door or the

passenger's door.

The power window relay is turned "OFF" when receiving the remote control key lock signal

(armed mode) during its extended operation period of 30 seconds. 1.

2.

3.

Page 518 of 828

06-4

1. OVERVIEW

TRIP/RESET Switch

The mode is changed each time this button is

pressed as follows: TRIP A -> TRIP B -> DTE ->

Driving time -> Average fuel economy -> Instant

fuel consumption -> Tail lamp illumination level.Windshield de-icer switch

Pressing switch activates

windshield heated glass for

approx. 12 minutes

The main switch which allows the

driver to control all door windows,

door lock and window lock from

the driver seat. Tailgate and outside

rearview mirror heated

glass switch

Pressing switch

activates tailgate and

outside rearview mirror

heated glass for

approx. 12 minutes

Driver power window switchESP ON/OFF switch

Pressing this switch deactivates the ESP

(Electronic Stability Program) system and

turns on the ESP OFF indicator on the

instrument cluster. Pressing this switch

again turns off the ESP OFF indicator and

activates the ESP system.

Outside rearview mirror folding/unfolding

switch

Press the FOLD/UNFOLD switch to fold

the outside rearview mirror and press the

switch again to unfold the mirror.

Page 546 of 828

10-6

2. SWITCH

No. Name and Function

1 RDS setup

2 AF/TA selection

3 Start call

4 USB, AUX, CD selection

5 Power (ON/OFF), Mute, Volume

6 Preset key #1, Intro SCAN

7 Preset key #2, RPT

8 Preset key #3, Random

9 Preset key #4, folder down

10 Preset key #5, folder up

11 Preset key #6, File guide

12 AST, SCAN, TUNE UP/DOWN

13 Eject

14 End call

15 Set

16 Band

17 LCD window