change time SSANGYONG NEW ACTYON SPORTS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 518 of 828

06-4

1. OVERVIEW

TRIP/RESET Switch

The mode is changed each time this button is

pressed as follows: TRIP A -> TRIP B -> DTE ->

Driving time -> Average fuel economy -> Instant

fuel consumption -> Tail lamp illumination level.Windshield de-icer switch

Pressing switch activates

windshield heated glass for

approx. 12 minutes

The main switch which allows the

driver to control all door windows,

door lock and window lock from

the driver seat. Tailgate and outside

rearview mirror heated

glass switch

Pressing switch

activates tailgate and

outside rearview mirror

heated glass for

approx. 12 minutes

Driver power window switchESP ON/OFF switch

Pressing this switch deactivates the ESP

(Electronic Stability Program) system and

turns on the ESP OFF indicator on the

instrument cluster. Pressing this switch

again turns off the ESP OFF indicator and

activates the ESP system.

Outside rearview mirror folding/unfolding

switch

Press the FOLD/UNFOLD switch to fold

the outside rearview mirror and press the

switch again to unfold the mirror.

Page 521 of 828

07-4

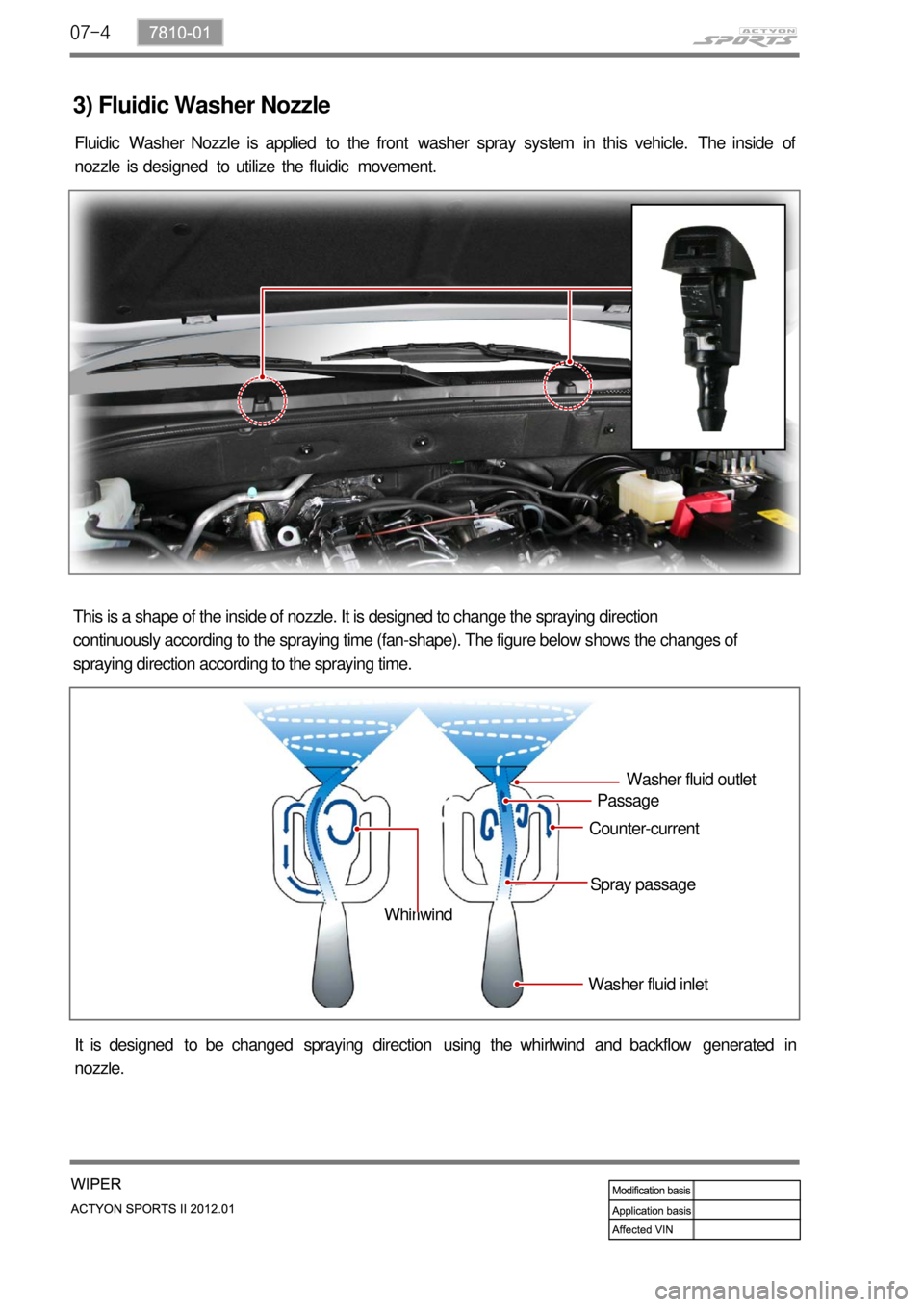

3) Fluidic Washer Nozzle

Fluidic Washer Nozzle is applied to the front washer spray system in this vehicle. The inside of

nozzle is designed to utilize the fluidic movement.

This is a shape of the inside of nozzle. It is designed to change the spraying direction

continuously according to the spraying time (fan-shape). The figure below shows the changes of

spraying direction according to the spraying time.

It is designed to be changed spraying direction using the whirlwind and backflow generated in

nozzle.Washer fluid inletSpray passage Counter-currentPassageWasher fluid outlet

Whirlwind

Page 549 of 828

01-53680-01

2. FEATURES AND SPECIFICATIONS

1) Specifications

Description DSI M78 (6-speed) Remarks

Gear ratio1st 3.53:1

2nd 2.14:1

3rd 1.48:1

4th 1.16:1

5th 0.87:1

6th 0.68:1

Reverse 3.09:1

Transmission flui

dFluid Fuchs FES 209-3292 ATF

Capacity Approx. 9.5 L

Change interval Check the fluid at every

30,000 km or 1 year, and

change it if necessary.Under the severe driving

conditions, change the fluid

at every 60,000 km.

Resistance of oil

temperature

sensor-20 430.7 ~ 533.9 kΩ

0 146.8 ~ 175.7 kΩ

20 56.74 ~ 65.86 kΩ

100 3.201 ~ 3.399 kΩ

Gear position

sensor1 -

2 -

3 -

D 2.686 kΩ ± 8%

N 5.036 kΩ ± 8%

R 8.953 kΩ ± 8%

P 16.786 kΩ ± 8%

Severe driving conditions? *

Towing a trailer or off-road driving (Inspect the

leak of fl uid at any time, occasionlly)

Taxi, patrol service or delivery service

(extended idling and excessive driving with low

speed)

Frequent stop-and-go traffi c, extended idling,

short driving distance -

-

-Driving in a hilly or mountainous terrain,

sandy, or dusty area

Driving frequently at high speed over 170

km/hour

Driving frequently in area where heavy

traffi c under the ambient temperature

above 32°C -

-

-

Page 564 of 828

01-20

3) Transmission Control Monitoring System

TCU monitors all input and output signals to identify possible failures. If a fault is detected, TCU

<0088008a009b0090009d0088009b008c009a0047009b008f008c0047009a0088008d008c009b00a0004700940096008b008c0047009b009600470092008c008c00970047009b008f008c0047008b00990090009d008c009902c5009a0047009a0088008d00

8c009b00a0004700880095008b0047009b008f008c00470093>ife span of transmission.

Monitoring the Supply Voltage ▶

Monitoring the Supply Voltage to Solenoid ▶

Monitoring the Gear Ratio ▶

Monitoring the Torque Converter ▶ If the battery voltage is too high or too low, the TCU sets the DTC.

TCU monitors the circuits for open or short to ground or supply. The monitoring function

evaluates the voltage characteristics while the switch is ON.

TCU monitors the gear is engaged properly in the allowed time.

TCU checks if the torque converter can be locked up properly. If it is failed, TCU releases the

torque converter clutch to activate the fail-safe operation.

4) Shift Energy Management

This function involves reducing or increasing the engine output torque during shifting. This

reduces the energy which is dissipated in the friction elements of the transmission during up-

shift. This is done by reducing the engine torque during the gear ratio change without interrupting

the tractive drive.

This function is used for:

Increasing the life span of transmission by shortening the slipping time

Improving the shift comfort by reducing the step changes due to gearshift

Transferring a higher engine power -

-

-

Real-time control of engine torque is required to maintain the proper shift operations and the

durability of transmission. TCU controls the engine torque during the gearshift by synchronizing

the operation of transmission clutches.

Page 593 of 828

02-33170-01

Description Specification

Gear ratio 1st 4.489 : 1

2nd 2.337 : 1

3rd 1.350 : 1

4th 1.000 : 1

5th 0.784 : 1

6th 0.679 : 1

Reverse 4.253 : 1

Synchronizer

ring type1st T: Triple-cone

2nd T: Triple-cone

3rd T: Triple-cone

4th S: Single-cone

5th D: Double-cone

6th S: Single-cone

Reverse T: Triple-cone

Shifting Type Floor change type

Gear selector

lever position

Transmission

fluidType HD MTF 75W/85 (SHELL) or HK MTF 75W/85(SK)

Capacity

Sercive interval Inspect and replenish every 60000 km or 3 years (under

severe driving conditions, change every 120,000 km)

1. SPECIFICATION

Reversing:

High-force type

What’s the severe conditions?

Towing a trailer or off-road driving (Inspect

the leak of fluid at any time, occasionlly)

Taxi, patrol service or delivery service

(extended idling and excessive driving with

low speed)

Frequent stop-and-go traffic, extended

idling, short driving distance -

-

-Driving in a hilly or mountainous terrain,

sandy, or dusty area

Driving frequently at high speed over 170

km/hour

Driving frequently in area where heavy

traffic under the ambient temperature

above 30°C -

-

-

Page 619 of 828

04-4

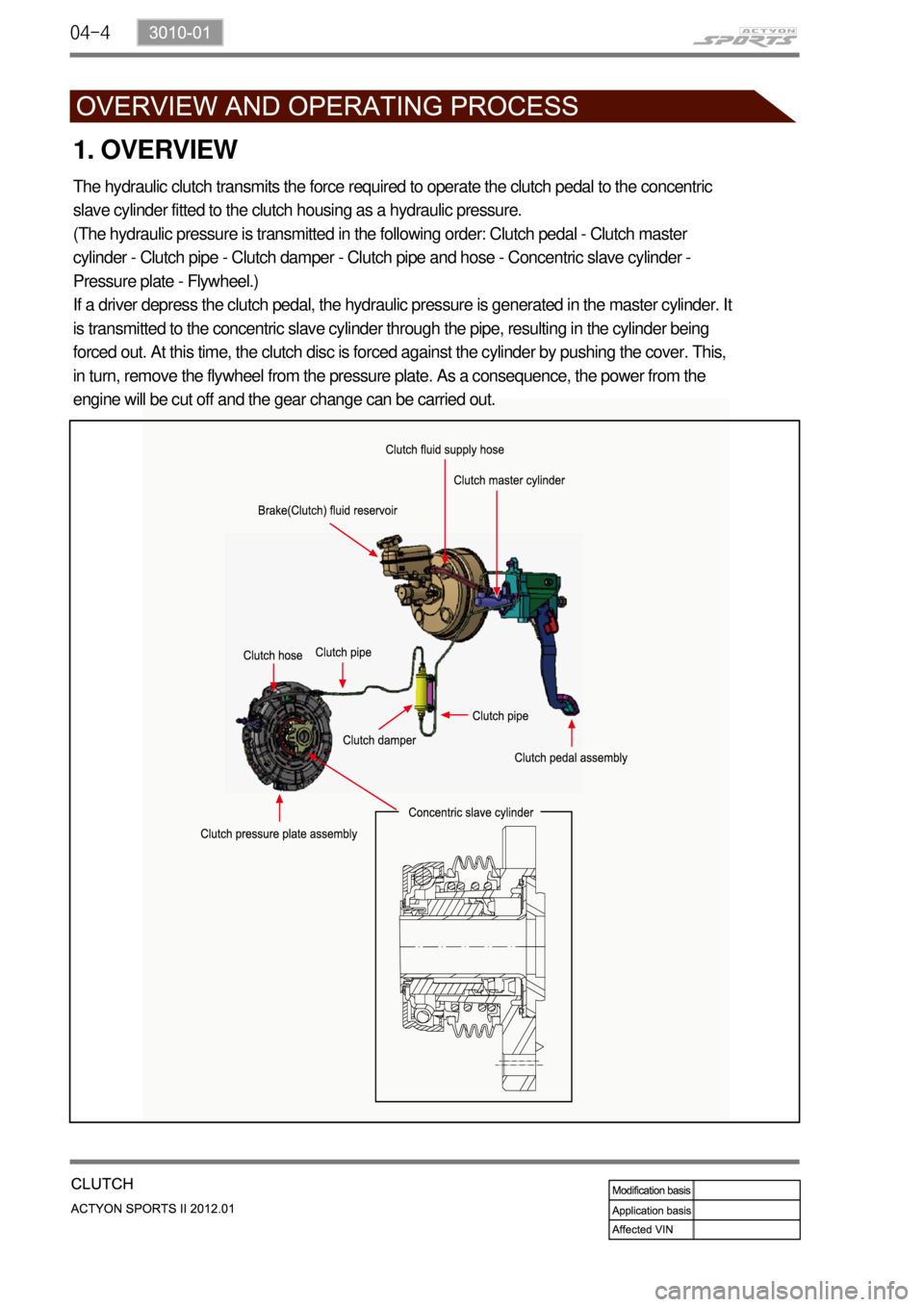

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric

slave cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master

cylinder - Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder -

Pressure plate - Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It

is transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being

forced out. At this time, the clutch disc is forced against the cylinder by pushing the cover. This,

in turn, remove the flywheel from the pressure plate. As a consequence, the power from the

engine will be cut off and the gear change can be carried out.

Page 664 of 828

09-16

Let the engine run for 1 to 2 minutes and

stop it. If the brake pedal stroke is

shortened as pumping the brake pedal,

the system is normal. If not, the system is

defective.

Depress the brake pedal several times

with engine off. If the brake goes down

when starting engine with pedal

depressed, the system is normal. If not,

the system is defective.

Depress the brake pedal when the engine

is running. If the pedal height is not

changed for 30 seconds after stopping

the engine, the system is normal. If not,

the system is defective. 1.

2.

3.

If the above three checks are OK, the system

is normal. If any condition is not met, check

the valve, vacuum hose and brake booster. Brake Booster ▶

Page 710 of 828

11-94890-10

3. PRECAUTIONS

The warning lamp flashes and warning beep sounds when the ESP is operating

When the ESP operates during vehicle movement, the ESP warning lamp on the instrument

panel flashes and beep comes on every 0.1 second. The ESP system is only a

supplementary device for comfortable driving. When the vehicle exceeds its physical limits, it

cannot be controlled.

Do not rely on the system. Keep on the safe driving.

Feeling when ESP is working

When the ESP system activates, the feeling can be different depending on vehicle driving

conditions.

For example, you will feel differently when the ESP system is activated during the ABS is

operating with the brakes applied and when the brakes are not applied on a curve.

If the ESP system operates when the brake is applied, the brake pressure will be increased on

the corresponding wheel which already has braking pressure for the ESP controls.

ARP Operation

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus,

stronger engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the

driver must take caution for the vehicle may drift away from the lane.

Noise and vibration that driver feels when ESP system is operating

The ESP system may transfer noise and vibration to the driver due to the pressure changes

caused by the motor and valve operations in a very short period of time. And, keep in mind

that the output and vehicle speed could be decreased without rpm increase due to the ASR

function that controls the engine power.

Page 720 of 828

11-194890-10

Circuit description ▶

When compared to the vehicle equipped with ABS/EBD only, the internal hydraulic circuit has a

normally-open separation valve and a shuttle valve in primary circuit and in secondary circuit.

When the vehicle brakes are not applied during engine running or when applying the non-ABS

operating brakes, the normally-open separation valve and the inlet valve are open, whereas the

normally-closed shuttle valve and the outlet valve are closed.

When the ESP system is operating, the normally-open separation valve will be closed by the

solenoid valve operation and the hydraulic circuit will be established by the shuttle valve. Then,

the inlet and outlet valves will be closed or open depending on the braking pressure RISE, HOLD

or DUMP conditions.

Flashing warning lamp and warning sound during ESP operation ▶

When the ESP operates while the vehicle is moving, the ESP warning lamp on the instrument

panel flickers and the buzzer sounds at every 0.1 second. The ESP lamp operation is to inform a

driver that the vehicle is extremely unstable.

The ESP system is just a supplementary system for the vehicle and it cannot control the vehicle

over the physical limit. Do not solely rely on the system but be advised to drive the vehicle safely.

Drive feeling during ESP operation ▶

When the ESP system activates, the driving feeling can be different depending on vehicle driving

conditions. For example, it will feel different when the ESP system is activated while the ABS is

operated by depressing the brake pedal and when the ESP system is in control without the brake

pedal depressed on the same curve.

If the ESP system operates with the brake applied, the brake pressure will be increased on the

corresponding wheel which already has braking pressure for the ESP controls. In other words, the

ESP system would make the driver feel more abruptly braked compared to the situation that the

braking pressure is applied to wheel which had no braking force.

Noise and vibration that driver senses during ESP operation ▶

The ESP system may transfer noise and vibration to a driver due to the pressure changes caused

by the motor and valve operations in a very short period of time.

Extreme cornering will trigger the ESP operation and this will make the driver sense noise and

vibration due to sudden brake application.

Also, the ESP system controls the engine power. Therefore, the driver may notice the engine

power decreases even when the accelerator pedal is depressed.

Page 737 of 828

12-114610-01

Oil Change ▶

Open the power fluid reservoir cap and

drain the fluid completely with oil suction

device. To make it easy, turn the steering

wheel to its both ends several times.

Fill up the specified fluid into fluid reservoir

and bleed air from the steering system. 1.

2. Oil Level Check ▶

Place the vehicle on a level ground and

start the engine and let it run at idle speed.

Turn the steering wheel several times so

that the oil temperature reaches to normal

operating level (75~85˚C).

Place the steering wheel at straight ahead

direction.

Check the oil level in the power steering oil

reservoir. Adjust the oil level between MAX

and MIN. 1.

2.

3.

4.

If the difference between two

measurements is below 5 mm and the level

is between MAX and MIN level, it's normal.

If it is over 5 mm, bleed air from the

system. Check the fluid level on a level ground with

the engine turned off. The fluid level should

be between the MIN and MAX marks on the

reservoir cap gauge.

below 5 mm

Engine idling Engine running

Oil typeATF Dexron II or III

Capacityapprox. 1ℓ (including

reservoir)