check engine SSANGYONG NEW ACTYON SPORTS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 193 of 828

03-10

(3) DI Engine Fuel System Check Procedure

If several DTCs are output simultaneously, check the electric wiring for open or short circuit.

Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities.

Carry out the high pressure fuel system check.

Page 195 of 828

03-12

(5) High Pressure System Pressure Test

Fuel rail pressure test ▶

Disconnect the fuel rail pressure sensor

connector and then IMV connector. 1.

Connect the pressure tester to the fuel rail

pressure sensor connector. 2.

Crank the engine 2 times for 5 seconds. 3.

Read the highest pressure value

displayed on the tester display.

If the highest pressure value is 1,050 bar

or less, refer to the section "Fuel System

Check Process". -

-

Page 196 of 828

03-132210-01

How To Use Pressure Tester ▶

Press the "TEST" button on the tester to

check if the message "TEST?" is

displayed.

If the button is pressed again at 4 seconds

after starting engine cranking, the highest

pressure is displayed on the tester. 1.

2.

The fuel rail pressure value can be checked using a diagnostic device.

Page 197 of 828

03-14

(6) Low Pressure System Pressure Test

Inspection procedure ▶

All wirings/connectors and fuel lines should

be connected and the engine should work

properly.

Prepare a special tool for low pressure test

and clean it thoroughly to prevent foreign

materials from entering. 1.

2.

Disconnect the key connector for fuel filter connection, and connect both connectors to the

fuel filter and hose. 3.

Start the engine and check visually for clogged low pressure fuel system, excessive air or air

entry.

If the fuel flow is not sufficient or air is in the fuel, repair the leak area. 4.

5.

Page 198 of 828

03-152210-01

Static test for backleak of injector ▶

Disconnect the injector return hose and cover

the openings with caps shaped screw

(included in the special tool). 1.

Connect the hose of the container for

measuring backleak to the return nipple of

the injector.

(prevent air entry to the low pressure line) 2.

Disconnect the IMV connector of the

high pressure pump and then fuel

pressure sensor connector. 3.

The connector of the injector can be easily

contaminated. Always keep it clean.

Crank the engine 2 times for 5 seconds.

Check the time for flow if injector backleak

and confirm that it is within the specified

range. 4.

5.

If the value is out of the specified range,

replace the injector.

SpecificationBelow 20 sec.

Page 199 of 828

03-16

Dynamic test for backleak of injector ▶

Warm up the engine so that the engine

coolant temperature be over 80℃ and star

the engine again.

Disconnect the injector return hose and

cover the openings with caps shaped

screw (included in the special tool).. 1.

2.

Connect the hose of the container for

measuring backleak to the return nipple of

the injector.

Start the engine again and let the engine

idle for 30 seconds.

Perform backleak test of fuel system with a

diagnostic device after 30 seconds. 3.

4.

5.

This test consists of 4 cycles, and the engine

rpm reaches 3,500 rpm for 18 seconds in each

cycle.

Check the amount of backleak collected

into the container and confirm that it is

within the specified range. 6.

Specification38 ml or less

Page 201 of 828

03-18

3. CAUTIONS FOR DI ENGINE

1) Cautions for DI Engine

This chapter describes the cautions for DI engine equipped vehicle. This includes the water

separation from engine, warning lights, symptoms when engine malfunctioning, causes and

actions.

DI Engine 1.

Comparatively conventional diesel engines, DI engine controls the fuel injection and timing

electrically, delivers high power and reduces less emission..

System Safety Mode 2.

When a severe failure has been occurred in a vehicle, the system safety mode is activated to

protect the system. It reduces the driving force, restricts the engine speed (rpm) and stops

engine operation. Refer to "Diagnosis" section in this manual.

Engine CHECK Warning Lamp 3.

The Engine CHECK warning lamp on the instrument cluster comes on when the

fuel or major electronic systems of the engine are not working properly. As a result,

<009b008f008c0047008c0095008e00900095008c02c5009a004700970096009e008c009900470096009c009b0097009c009b00470094008800a00047008b008c008a0099008c0088009a008c0047009600990047009b008f008c0047008c0095008e009000

95008c00470094008800a00047009a009b0088009300930055>

Water Separator Warning Lamp 4.

When the water level inside water separator in fuel filter exceeds a certain level

(approx. 45 cc), this warning light comes on and buzzer sounds.

Also, the driving force of the vehicle decreases (torque reduction). If these

conditions occur, immediately drain the water from fuel filter.

Page 203 of 828

03-20

(2) Di engine and its expected problems and remedies can be caused by

water in fuel

System supplement against paraffin separation ▶

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and

then can stick on the fuel filter blocking fuel flow and causing difficult starting finally. Oil

companies supply summer fuel and winter fuel by differentiating mixing ratio of kerosene and

other elements by region and season. However, above phenomenon can be happened if stations

have poor facilities or sell improper fuel for the season. In case of DI engine, purity of fuel is very

important factor to keep internal preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal

clogging due to paraffin separation, SYMC is using fuel line that high pressure and temperature

fuel injected by injector returns through fuel filter to have an effect of built-in heater (see fuel

system).

System supplement and remedy against water in fuel ▶

As mentioned above, some gas stations supply fuel with excessive than specified water. In the

conventional IDI engine, excessive water in the fuel only causes dropping engine power or engine

hunting. However, fuel system in the DI engine consists of precise components so water in the

fuel can cause malfunctions of HP pump due to poor lubrication of pump caused by poor coating

film during high speed pumping and bacterization (under long period parking). To prevent

problems can be caused by excessive water in fuel, water separator is installed inside of fuel

filter. When fuel is passing filter, water that has relatively bigger specific gravity is accumulated on

the bottom of the filter.

Water drain from water separator ▶

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump

with fuel, so the engine ECU turns on warning lamp on the meter cluster and buzzer if water level

is higher than a certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a

customer checks in to change engine oil, be sure to perform water drain from fuel filter.

Water

separator

To separate the water from the fuel filter,

remove the fuel filter assembly first.

Page 211 of 828

04-4

2. INSPECTION

1) Troubleshooting

When Abnormal Noises are Heard from the Engine Room ▶

For the vehicle equipped with DI engine, if a learning noise occurs in each range or other

noises occur, the major cause of it is a faulty turbocharger assembly. But an interference issue,

poor tightness or loose in the intake and exhaust system also can cause those noises. This is

mainly because the operator didn't follow the instruction exactly when reconnecting the intake

hoses and pipes which were disconnected to check the system or replace the air cleaner. If the

intake system is free of any faults, check the EGR and PCV oil separator connected to the

intake system.

The figure may be different from the actual engine. Therefore, read thoroughly below before

replacing the parts.

2) Abnormal Noise Caused by Poor Tightness of Intake System

When the DI engine is running, the air entered into the engine flows in the sequence as shown

above. If high intake pressure is applied to the loose or damaged part, a whistling noise may

occur, the intake air volume is measured incorrectly or the engine power is derated.

Page 212 of 828

04-51719-00

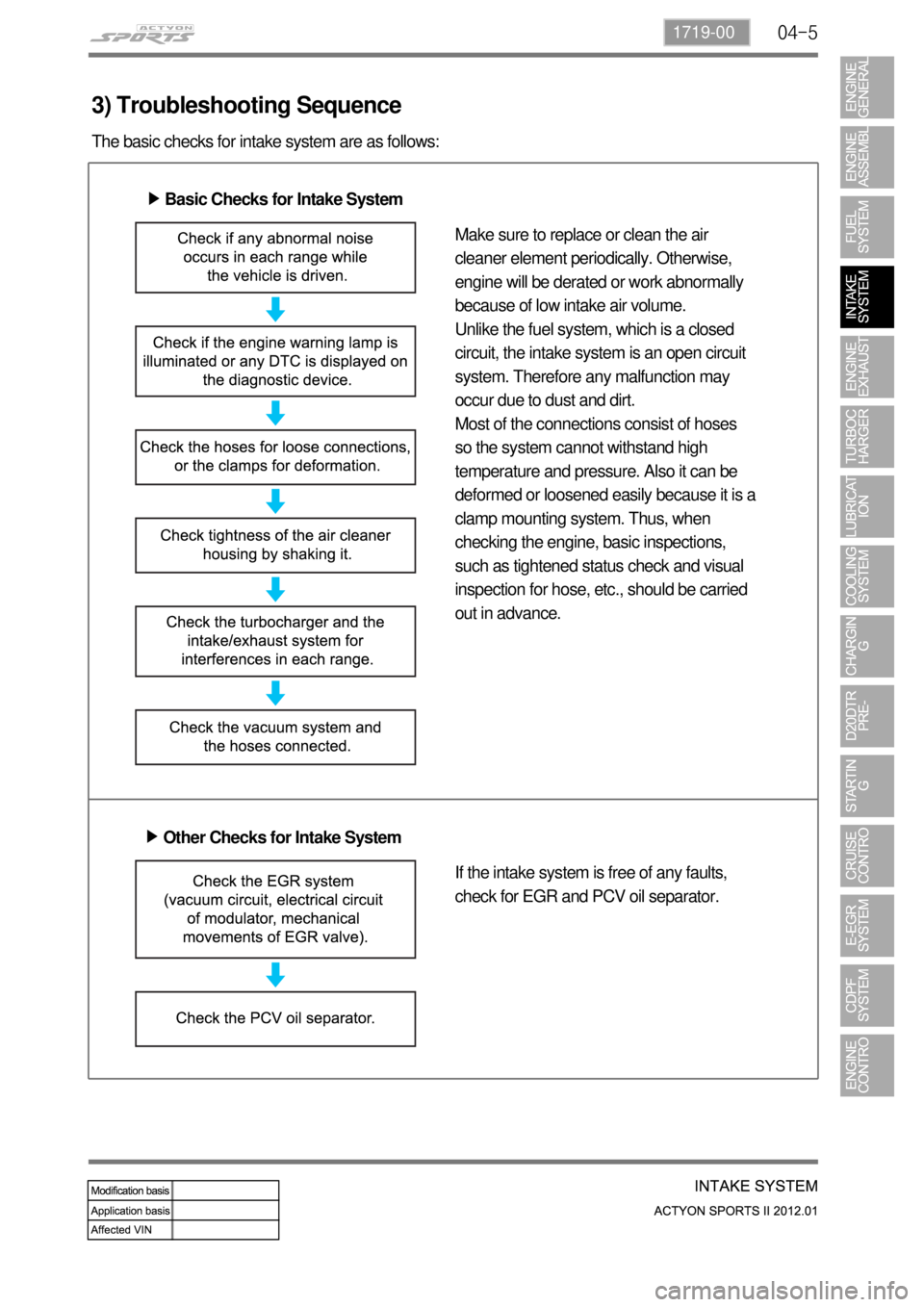

3) Troubleshooting Sequence

The basic checks for intake system are as follows:

Basic Checks for Intake System ▶

Make sure to replace or clean the air

cleaner element periodically. Otherwise,

engine will be derated or work abnormally

because of low intake air volume.

Unlike the fuel system, which is a closed

circuit, the intake system is an open circuit

system. Therefore any malfunction may

occur due to dust and dirt.

Most of the connections consist of hoses

so the system cannot withstand high

temperature and pressure. Also it can be

deformed or loosened easily because it is a

clamp mounting system. Thus, when

checking the engine, basic inspections,

such as tightened status check and visual

inspection for hose, etc., should be carried

out in advance.

Other Checks for Intake System ▶

If the intake system is free of any faults,

check for EGR and PCV oil separator.