check engine SSANGYONG NEW ACTYON SPORTS 2012 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 497 of 828

04-6

Connector Pin Arrangement ▶

The connector pin sections illustrated below are viewed from the front of the instrument

cluster. The arrangement of the pins is the same for both the main connector and the sub

connector.

Main connector - 20-pin (white)

Sub connector - 20-pin (gray)

1. -

2. Hood open

3. Seat belt - passenger's seat

4. -

5. -

6. Front fog lamp

7. -

8. Engine CHECK warning light

9. Charge

10. IGN 2

11. -

12. Air bag

13. Seat belt - driver's seat

14. High beam (-)

15. Right turn signal lamp (+)

16. High beam (+)

17. Left turn signal lamp (+)

18. Oil pressure

19. Parking brake signal input (STICS)

20. - 1. -

2. -

3. 4P output

4. Buzzer output

5. Illumination (+)

6. -

7. -

8. Door open

9. -

10. Battery

11. -

12. Fuel input signal

13. TRIP mode/reset switch

14. Manual transmission N (neutral)

input

15. Manual transmission R (reverse)

input

16. CAN LOW

17. CAN HIGH

18. AGND (fuel -)

19. MICOM ground

20. IGN 1

Page 499 of 828

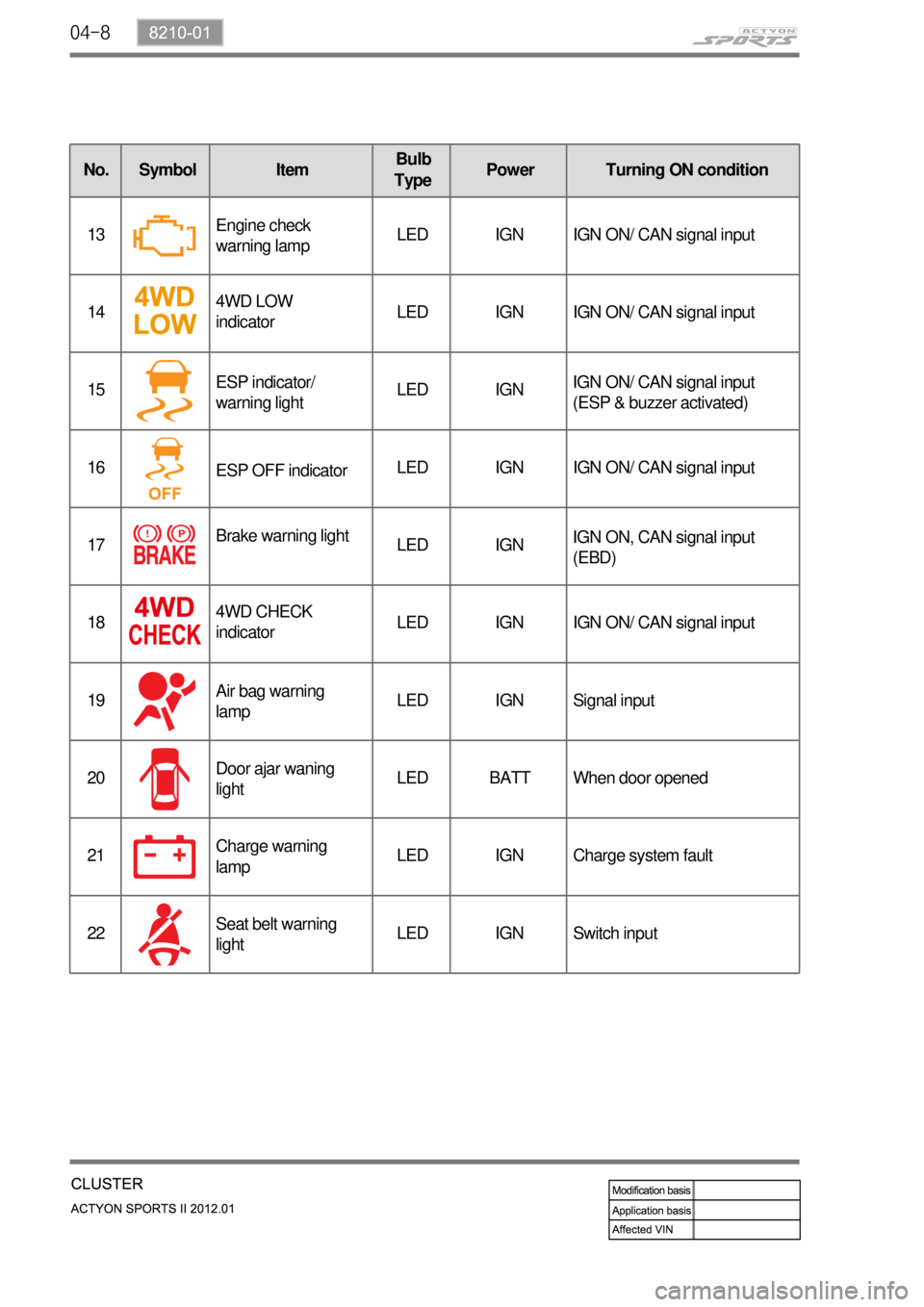

04-8

No. Symbol ItemBulb

TypePower Turning ON condition

13Engine check

warning lampLED IGN IGN ON/ CAN signal input

144WD LOW

indicatorLED IGN IGN ON/ CAN signal input

15ESP indicator/

warning lightLED IGNIGN ON/ CAN signal input

(ESP & buzzer activated)

16

ESP OFF indicatorLED IGN IGN ON/ CAN signal input

17Brake warning light

LED IGNIGN ON, CAN signal input

(EBD)

184WD CHECK

indicatorLED IGN IGN ON/ CAN signal input

19Air bag warning

lampLED IGN Signal input

20Door ajar waning

lightLED BATT When door opened

21Charge warning

lampLED IGN Charge system fault

22Seat belt warning

lightLED IGN Switch input

Page 501 of 828

04-10

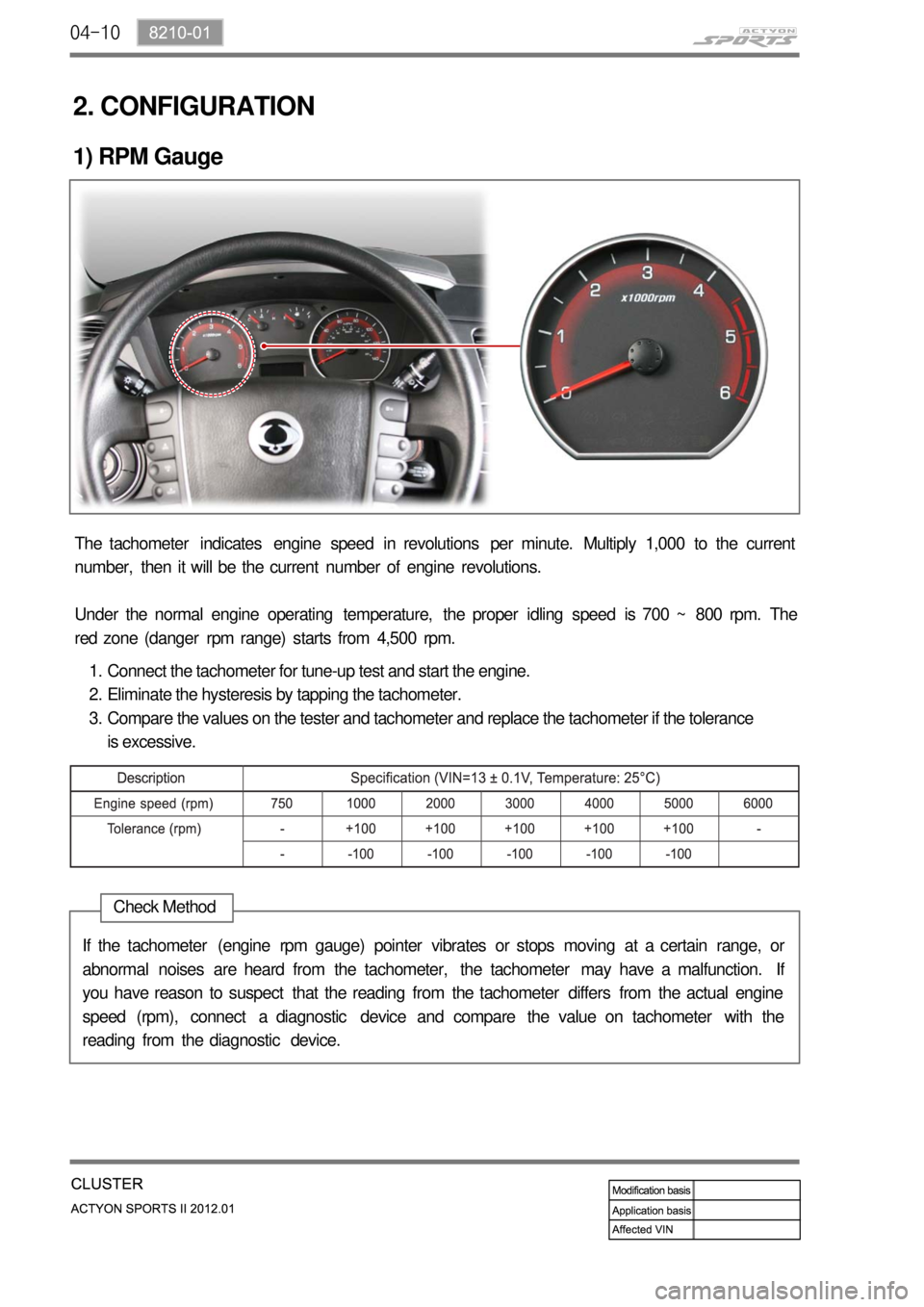

2. CONFIGURATION

1) RPM Gauge

The tachometer indicates engine speed in revolutions per minute. Multiply 1,000 to the current

number, then it will be the current number of engine revolutions.

Under the normal engine operating temperature, the proper idling speed is 700 ~ 800 rpm. The

red zone (danger rpm range) starts from 4,500 rpm.

Connect the tachometer for tune-up test and start the engine.

Eliminate the hysteresis by tapping the tachometer.

Compare the values on the tester and tachometer and replace the tachometer if the tolerance

is excessive. 1.

2.

3.

If the tachometer (engine rpm gauge) pointer vibrates or stops moving at a certain range, or

abnormal noises are heard from the tachometer, the tachometer may have a malfunction. If

you have reason to suspect that the reading from the tachometer differs from the actual engine

speed (rpm), connect a diagnostic device and compare the value on tachometer with the

reading from the diagnostic device.

Check Method

Page 511 of 828

04-20

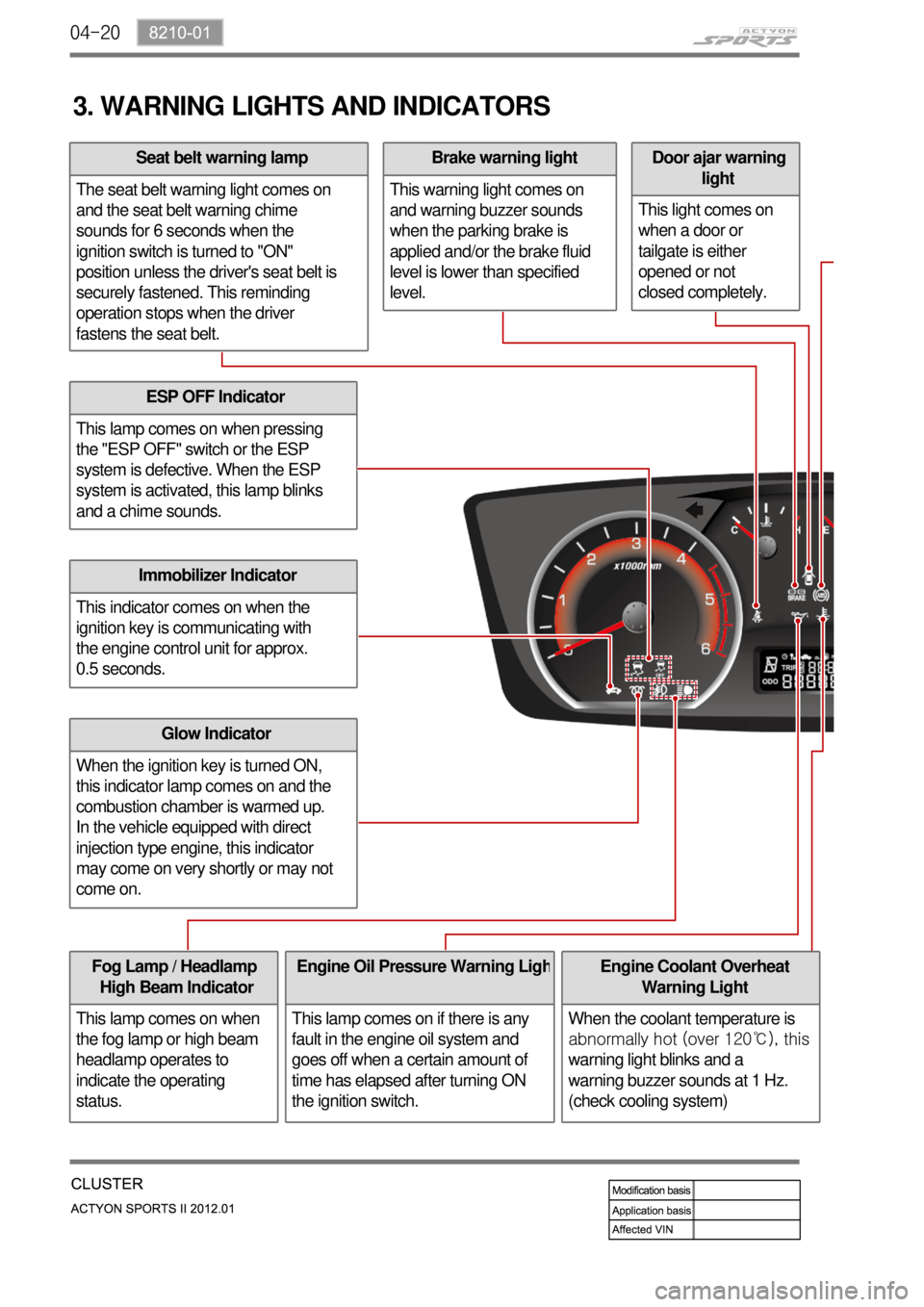

3. WARNING LIGHTS AND INDICATORS

ESP OFF Indicator

This lamp comes on when pressing

the "ESP OFF" switch or the ESP

system is defective. When the ESP

system is activated, this lamp blinks

and a chime sounds.

Immobilizer Indicator

This indicator comes on when the

ignition key is communicating with

the engine control unit for approx.

0.5 seconds.

Glow Indicator

When the ignition key is turned ON,

this indicator lamp comes on and the

combustion chamber is warmed up.

In the vehicle equipped with direct

injection type engine, this indicator

may come on very shortly or may not

come on.

Fog Lamp / Headlamp

High Beam Indicator

This lamp comes on when

the fog lamp or high beam

headlamp operates to

indicate the operating

status.Engine Oil Pressure Warning Ligh

This lamp comes on if there is any

fault in the engine oil system and

goes off when a certain amount of

time has elapsed after turning ON

the ignition switch.

Door ajar warning

light

This light comes on

when a door or

tailgate is either

opened or not

closed completely.Brake warning light

This warning light comes on

and warning buzzer sounds

when the parking brake is

applied and/or the brake fluid

level is lower than specified

level.Seat belt warning lamp

The seat belt warning light comes on

and the seat belt warning chime

sounds for 6 seconds when the

ignition switch is turned to "ON"

position unless the driver's seat belt is

securely fastened. This reminding

operation stops when the driver

fastens the seat belt.

Engine Coolant Overheat

Warning Light

When the coolant temperature is

abnormally hot (over 120℃), this

warning light blinks and a

warning buzzer sounds at 1 Hz.

(check cooling system)

Page 512 of 828

04-218210-01

ABS Warning Light

This warning light comes on

when the ignition switch is

turned to "ON" position and

should go out if the system is

normal.

The vehicle with ABS performs

self-diagnosis. During this

diagnosis, brake pedal

vibration and noise may be

apparent when the driving

motors discharges the

hydraulic pressure from the

internal hydraulic device.4WD IndicatorLow Fuel Level

Warnig Light

This warning light

comes on when the

fuel will soon be

exhausted. The time

it takes turn on,

however, varies

according to the

gradient of the

vehicle.

4WD HIGH Indicator

The lamp blinks momentarily during

the change of driving mode.

4WD LOW Indicator

The lamp blinks momentarily during

the change of driving mode.

4WD CHECK Warning Light

This indicates that there is

something wrong in the transfer

case system. (check the system) -

-

-

Auto Cruise Control

Indicator

Operating the cruise

control switch turns on

the indicator lamp to

indicate the cruise

control system is

activated.

Water Separator Warning Light

This lamp comes on to warn the driver of

water in the fuel tank which causes the

loss of engine power. When a certain

amount of water is accumulated, the lamp

comes on and a chime sounds.

Engine CHECK Warning Light

This warning light comes on when

the ignition switch is turned to "ON"

position and should go out if the

system related to engine control is

normal.

This comes on when different

sensors and devices related to

engine control are defective.

Winter Mode

Indicator

Pressing the "W" side of the

automatic transmission mode

selector switch switches the

driving mode to winter mode and

turns on the indicator lamp.

Use this mode to drive off

smoothly on icy and slippery

roads.

Charge Warning Light

This warning light comes on when the

ignition switch is turned on and go off

when the engine is started.

If this light doesn't go off after engine

starting, it means there is a malfunction in

the system.

Engine Hood Open Warning Light

When the engine hood is open, this light

comes on to inform the driver.

Page 513 of 828

04-22

How to enter self-diagnosis mode ▶

Turn the ignition ON with the TRIP switch pressed.

Press and hold the TRIP switch for 5 to 10 sec. with the ignition ON.

Press and hold the TRIP switch for less than 10 sec. and then cycle the switch between ON

and OFF 5 times within 3 sec.

Confirm that the self-diagnosis mode is activated through the instrument cluster. 1.

2.

3.

4.

4. SELF-DIAGNOSIS CHECK

Self-diagnosis OFF ▶

If the engine speed increases to 396 rpm or more while the engine is cranking or the ignition key

is turned OFF in self-diagnosis mode, the self-diagnosis mode is turned OFF automatically.

Operating process ▶

Speed gauge: changes from 0 to 220 km

RPM gauge: changes from 0 to 6,000 rpm

Fuel gauge: changes from E to F

Temperature gauge: changes from C to H

Warning/Indicator lamps: All indicator/warning lamps controlled by MICOM are turned ON.

Dimming: Illuminates at the highest lighting level.

LCD display: All elements are activated. 1.

2.

3.

4.

5.

6.

7.

Page 564 of 828

01-20

3) Transmission Control Monitoring System

TCU monitors all input and output signals to identify possible failures. If a fault is detected, TCU

<0088008a009b0090009d0088009b008c009a0047009b008f008c0047009a0088008d008c009b00a0004700940096008b008c0047009b009600470092008c008c00970047009b008f008c0047008b00990090009d008c009902c5009a0047009a0088008d00

8c009b00a0004700880095008b0047009b008f008c00470093>ife span of transmission.

Monitoring the Supply Voltage ▶

Monitoring the Supply Voltage to Solenoid ▶

Monitoring the Gear Ratio ▶

Monitoring the Torque Converter ▶ If the battery voltage is too high or too low, the TCU sets the DTC.

TCU monitors the circuits for open or short to ground or supply. The monitoring function

evaluates the voltage characteristics while the switch is ON.

TCU monitors the gear is engaged properly in the allowed time.

TCU checks if the torque converter can be locked up properly. If it is failed, TCU releases the

torque converter clutch to activate the fail-safe operation.

4) Shift Energy Management

This function involves reducing or increasing the engine output torque during shifting. This

reduces the energy which is dissipated in the friction elements of the transmission during up-

shift. This is done by reducing the engine torque during the gear ratio change without interrupting

the tractive drive.

This function is used for:

Increasing the life span of transmission by shortening the slipping time

Improving the shift comfort by reducing the step changes due to gearshift

Transferring a higher engine power -

-

-

Real-time control of engine torque is required to maintain the proper shift operations and the

durability of transmission. TCU controls the engine torque during the gearshift by synchronizing

the operation of transmission clutches.

Page 661 of 828

09-134850-01

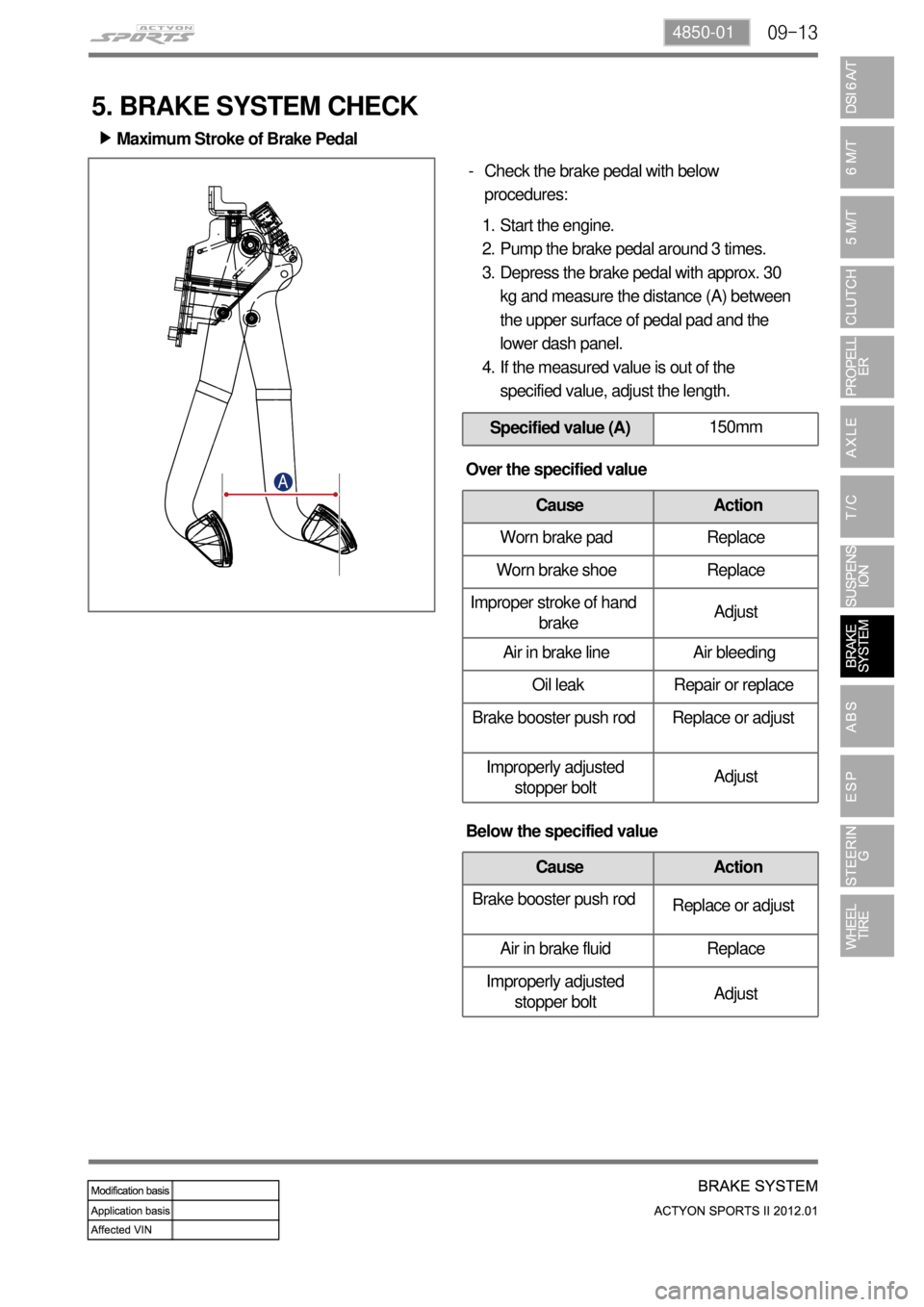

Maximum Stroke of Brake Pedal ▶

Check the brake pedal with below

procedures: -

Start the engine.

Pump the brake pedal around 3 times.

Depress the brake pedal with approx. 30

kg and measure the distance (A) between

the upper surface of pedal pad and the

lower dash panel.

If the measured value is out of the

specified value, adjust the length. 1.

2.

3.

4.

Specified value (A)150mm

5. BRAKE SYSTEM CHECK

Over the specified value

Cause Action

Worn brake pad Replace

Worn brake shoe Replace

Improper stroke of hand

brakeAdjust

Air in brake line Air bleeding

Oil leak Repair or replace

Brake booster push rod Replace or adjust

Improperly adjusted

stopper boltAdjust

Below the specified value

Cause Action

Brake booster push rod

Replace or adjust

Air in brake fluid Replace

Improperly adjusted

stopper boltAdjust

Page 662 of 828

09-14

Specified value (B)155mm

Push rod

Stop lamp

switch Pedal Height ▶

Check the pedal height with below

procedures: -

Start the engine and measure the length

(A) between floor mat and pedal.

If the measured value is out of the

specified value, adjust the length. 1.

2.

Adjust the pedal height with below

procedures: -

Disconnect the stop lamp switch connector.

Unscrew the lock nut and remove the stop

lamp switch assembly.

Loosen the lock nut on the pedal push rod.

Turn the pedal push rod to adjust the pedal

height.

Tighten the lock nut.

Install the stop lamp switch assembly.

Connect the stop lamp switch connector.

Check if the stop lamps come on when

pressing the brake pedal around 5 mm.

If the stop lamp dpes not come on, adjust

the stop lamp switch assembly again.

If the stop lamps come on, tighten the lock

nut and measure the pedal height again. 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Page 663 of 828

09-154850-01

Specified value (A)3 ~ 10mm

Connect the multimeter to stop lamp

switch connector and check if the

continuity exists when pushing in the

plunger. If the continuity doesn't exist, the

stop lamp switch is normal. - Pedal Free Play ▶

Stop Lamp Switch ▶Check the pedal free play with below

procedures: -

Stop the engine.

Depress the brake pedal several times to

discharge the vacuum pressure of the brake

booster.

Depress the brake pedal until you feel the

resistance, and measure the movement (A). 1.

2.

3.

Below the specified value: Check if the

distance between the outer case of stop

lamp switch and the brake pedal.

Over the specified value: It may be caused

by bigger clearance between the clevis pin

and the brake pedal arm. Replace the

components if necessary. -

-