cooling SSANGYONG NEW ACTYON SPORTS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 341 of 828

15-38

C. Input/Output for cooling fan and A/C compressor

Page 342 of 828

15-390000-00

D. Cooling fan and A/C compressor control

Conditions for cooling fan ▶

The cooling fan module controls the cooling fan relay, high speed relay and low speed relay. The

cooling fan is controlled by the series and parallel circuits.

A/C switch Cooling fanCoolant temperature Refrigerant pressure

A/C compressor

OFF OFF Coolant temp. < 90℃ -

LO 90℃ ≤ Coolant temp.

< 105℃-

HI 105℃ ≤ Coolant temp. -

ONLO

Coolant temp. < 105℃Refrigerant pressure <

18 bar

ON

HI 18 bar ≤ Refrigerant

pressure

HI 105℃ ≤ Coolant tem

p.

< 115℃-

HI115℃ ≤ Coolant temp. -

OFF (cut)

A/C compressor OFF conditions ▶

Coolant temperature: below -20℃ or over

115℃

Approx. 4 seconds after starting the engine

Engine rpm: below 650 rpm or over 4500 rpm

When abrupt acceleration

Refrigerant pressure:

* OFF below 2.0 kg/㎠, then ON over 2.4 kg/㎠

* OFF over 30 kg/㎠, then ON below 21.4 kg/㎠ -

-

-

-

-

The output voltage from refrigerant pressure sensor is 1.7 V to 3.5 V when the refrigerant pressure

is 10 to 24 kgf/㎠ with A/C "ON".Output voltage according to refrigerant pressure ▶

Cooling fan controls according to ATF ▶

ATF temperature Fan condition Remark

Over 110˚CHigh speed -

Page 358 of 828

01-8

Front View ▶

NO. FUNCTION NO. FUNCTION

1 HFM Sensor 12 Intake Manifold

2 Intake Air Duct 13 Cylinder Head

3 Cylinder Head Cover 14 Exhaust Manifold

4 Ignition Coi 15 Dipstick Guide Tube and Gauge

5 Spark Plug Connector 16 Connecting Rod

6 Fuel Distributor 17 Crankshaft

7 Injector 18 Engine Mounting Bracket

8 Exhaust Camshaft 19 Starter

9 Intake Camshaft 20 Crankcase

10 Valve Tappet 21 Oil Pump Sprocket

11 Intake Valve 22 Oil Pan

NO. FUNCTION NO. FUNCTION

23 Camshaft Adjuster 29 Oil Pump Drive Chain

24 Oil Filler Cap 30 Oil Strainer

25 Engine Hanger Bracket 31 Oil Pump

26 Cooling Fan and Viscous Clutch 32 Ring Gear and Flywheel of Drive Plate

27 Oil Filter 33 Piston

28 Timing Chain

Side View ▶

Page 382 of 828

04-6

2. DESCRIPTION AND OPERATION

1) General Description

The cooling system maintains the engine temperature at an efficient level during all engine

operating conditions.

When the engine is cold, the cooling system cools the engine slowly or not at all. This slow

cooling of the engine allows the engine to warm up quickly.

The cooling system includes a radiator and recovery subsystem, cooling fans, a thermostat and

housing, a water pump, and a water pump drive belt. The timing belt drives the water pump.

All components must function properly for the cooling system to operation. The water pump

draws the coolant from the radiator. The coolant then circulates through water jackets in the

engine block, the intake manifold, and the cylinder head. When the coolant reaches the operating

temperature of the thermostat, the thermostat opens. The coolant then goes back to the radiator

where it cools.

This system directs some coolant through the hoses to the heat core. This provides for heating

and defrosting.

The coolant reservoir is connected to the radiator to recover the coolant displaced by expansion

from the high temperatures. The coolant reservoir maintains the correct coolant level.

The cooling system for this vehicle has no radiator cap or filler neck. The coolant is added to the

cooling system through the coolant reservoir.

2) Radiator

This vehicle has a lightweight tube-and-fin aluminum radiator. Plastic tanks are mounted on the

upper and the lower sides of the radiator core.

On vehicles equipped with automatic transaxles, the transaxle fluid cooler lines run through the

radiator tank.

A radiator drain plug is on this radiator.

To drain the cooling system, open the drain plug.

3) Coolant Reservoir

The coolant reservoir is a transparent plastic reservoir, similar to the windshield washer reservoir.

The coolant reservoir is connected to the radiator by a hose and to the engine cooling system by

another hose.

As the vehicle is driven, the engine coolant heats and expands. The portion of the engine coolant

displaced by this expansion flows from the radiator and the engine into the coolant reservoir. The

air trapped in the radiator and the engine is degassed into the coolant reservoir.

When the engine stops, the engine coolant cools and contracts. The displaced engine coolant is

then drawn back into the radiator and the engine. This keeps the radiator filled with the coolant to

the desired level at all times and increases the cooling efficiency.

Maintain the coolant level between the MIN and MAX marks on the coolant reservoir when the

system is cold.

Page 383 of 828

04-72112-01

4) Water Pump

The belt-driven centrifugal water pump consists of an impeller, a drive shaft, and a belt pulley.

The impeller is supported by a completely sealed bearing.

The water pump is serviced as an assembly and, therefore, cannot be disassembled.

5) Thermostat

A wax pellet-type thermostat controls the flow of the engine coolant through the engine cooling

system. The thermostat is mounted in the thermostat housing to the front of the cylinder head.

The thermostat stops the flow of the engine coolant from the engine to the radiator to provide

faster warm-up, and to regulate the coolant temperature. The thermostat remains closed while the

engine coolant is cold, preventing circulation of the engine coolant through the radiator. At this

point, the engine coolant is allowed to circulate only throughout the heater core to warm it quickly

and evenly.

As the engine warms, the thermostat opens. This allows the engine coolant to flow through the

radiator wherethe heat is dissipated. This opening and closing of the thermostat permits enough

engine coolant to enter the radiator to keep the engine within proper engine temperature operating

limits.

The wax pellet in the thermostat is hermetically sealed in a metal case. The wax element of the

thermostat expands when it is heated and contracts when it is cooled.

As the vehicle is driven and the engine warms, the engine coolant temperature increases. When

the engine coolant reaches a specified temperature, the wax pellet element in the thermostat

expands and exerts pressure against the metal case, forcing the valve open. This allows the

engine coolant to flow through the engine cooling system and cool the engine.

As the wax pellet cools, the contraction allows a spring to close the valve.

The thermostat begins to open at 82°C(180 °F) and is fully open at 95°C(203°F). The thermostat

closes at 80°C (176°F).

6) Electric Cooling Fan

Keep hands, tools, and clothing away from the engine cooling fans to help prevent personal

injury.

This fan is electric and can turn on even when the engine is not running. -

If a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse

the damaged part. A bent or damaged fan assembly should always be replaced with a new

one to prevent possible injury. -

Page 384 of 828

04-8

The cooling fans are mounted behind the radiator in the engine compartment. The electric cooling

fans increase the flow of air across the radiator fins and across the condenser on air conditioned

(A/C)-equipped vehicles.

This helps to speed cooling when the vehicle is at idle or moving at low speeds.

All models have two fans. The main fan is 320 mm (12. 6 inches) in diameter with seven blades to

aid the airflow through the radiator and the condenser. An electric motor attached to the radiator

support drives the fan.

The auxiliary fan is 320 mm (12.6 inches) in diameter.

A/C Off or Non-AC Model ▶

The cooling fans are actuated by the engine control module (ECM) using a low-speed

cooling fan relay, a high-speed cooling fan relay and a cooling fan motor relay.

The ECM will turn the cooling fans on at low speed when the coolant temperature reaches

95°C(203°F) and at high speed when the coolant temperature reaches 105°C(221°F).

The ECM will change the cooling fans from high peed to low speed at 100°C(212°F) and

will turn the cooling fans off at 90°C (194°F). -

-

-

A/C On ▶

The ECM will turn the cooling fans on at low speed when the A/C system is on. The ECM

will change to high speed when the high side A/C pressure reaches 1860 kPa (269.8 psi).

The cooling fans will return to low speed when the high side A/C pressure reaches 1378

kPa (199.8 psi). -

-

7) Engine Coolant Temperature Sensor

The Engine Coolant Temperature (ECT) sensor uses a temperature to control the signal voltage to

the Engine Control Module (ECM).

8) Coolant Temperature Gauge

The coolant temperature gauge controls the instrument panel temperature indicator. The coolant

temperature gauge is located with ECT sensor.

Page 386 of 828

04-10

3) PWM Electric Fan

(1) Advantages and Disadvantages of the PWM Electric Fan

Advantages ▶

Enhanced A/C performance: at low speed,

at idling, driving in city

Reduction of vibration/noise: fan activated

by PWM only when necessary

Reduction of engine consuming power

(V/Fan driving force) by 4 Hp - Cost

saving -

-

-

Disadvantage ▶

Poor engine cooling perfomance at low

and high rpm -

4) PWM (Pulse Width Modulation) Unit

It controls the time of the output voltage to

control the fan motor speed independently.

Internal functions ▶

Motor power shutting-off function when

overcurrent is applied

Adverse voltage prevention function

Detection function for the motor lock

Temperature detecting function: The

electric fan operates at FULL speed to

cool down the PWM unit when the interior

temperature of PWM unit is over

120~150°C.

Communication function when failing: The

fail signal is transmitted to the ECU when

the PWM unit is malfunctioning.

Soft start function: The motor speed is

gradually increased when the motor is

initially operated. -

-

-

-

-

-

Page 511 of 828

04-20

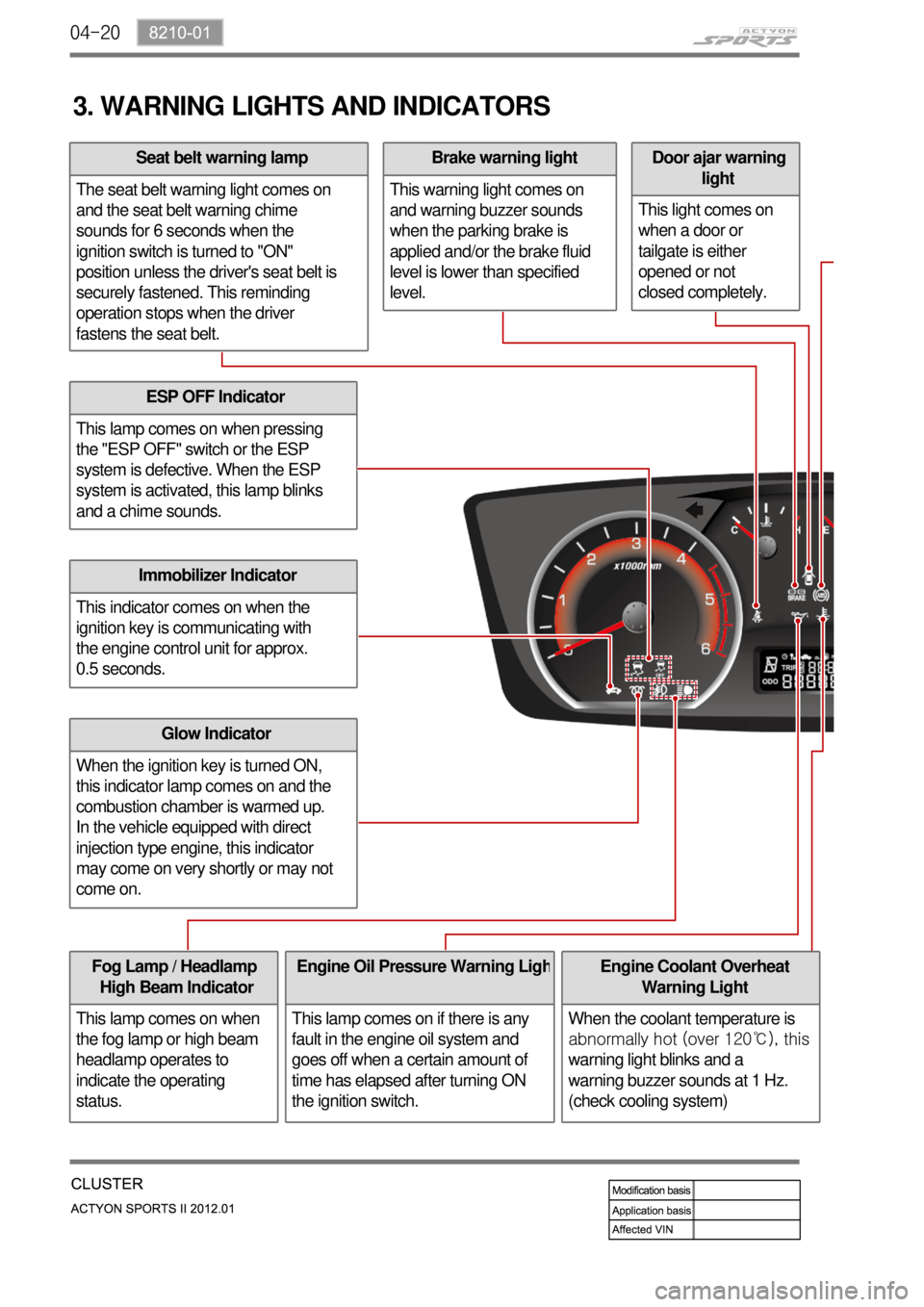

3. WARNING LIGHTS AND INDICATORS

ESP OFF Indicator

This lamp comes on when pressing

the "ESP OFF" switch or the ESP

system is defective. When the ESP

system is activated, this lamp blinks

and a chime sounds.

Immobilizer Indicator

This indicator comes on when the

ignition key is communicating with

the engine control unit for approx.

0.5 seconds.

Glow Indicator

When the ignition key is turned ON,

this indicator lamp comes on and the

combustion chamber is warmed up.

In the vehicle equipped with direct

injection type engine, this indicator

may come on very shortly or may not

come on.

Fog Lamp / Headlamp

High Beam Indicator

This lamp comes on when

the fog lamp or high beam

headlamp operates to

indicate the operating

status.Engine Oil Pressure Warning Ligh

This lamp comes on if there is any

fault in the engine oil system and

goes off when a certain amount of

time has elapsed after turning ON

the ignition switch.

Door ajar warning

light

This light comes on

when a door or

tailgate is either

opened or not

closed completely.Brake warning light

This warning light comes on

and warning buzzer sounds

when the parking brake is

applied and/or the brake fluid

level is lower than specified

level.Seat belt warning lamp

The seat belt warning light comes on

and the seat belt warning chime

sounds for 6 seconds when the

ignition switch is turned to "ON"

position unless the driver's seat belt is

securely fastened. This reminding

operation stops when the driver

fastens the seat belt.

Engine Coolant Overheat

Warning Light

When the coolant temperature is

abnormally hot (over 120℃), this

warning light blinks and a

warning buzzer sounds at 1 Hz.

(check cooling system)

Page 553 of 828

01-93680-01

3. TIGHTENING TORQUE

Description Size x Numbers Tightening torque

Transfer case housing M12 x 32 54 ~ 68

Etension housing M12 x 32 54 ~ 68

Oil pan M6 x 16 4 ~ 6

Valve body to transmission housing M6 x 26 8 ~ 13

Valve body to transmission housing M6 x 45 8 ~ 13

Center support to transmission housing M10 x 34 20 ~ 27

Output shaft locking nut M24 x 15 100 ~ 110

Pump cover to oil pump M8 x 55 24 ~ 27

Pump cover to transmission housing M8 x 40 24 ~ 34

Pump cover to transmission housing M8 x 58 24 ~ 34

Upper valve body to lower valve body M6 x 30 15 ~ 17

Detent spring M8 x 16 20 ~ 25

Variable bleed solenoid and speed sensor

M4 x 12 2.8 ~ 3.2

Transmission oil level plug 30 ~ 35

Front cooling lines to transmission cooler

25 ~ 35

Rear cooling lines to transmission cooler

25 ~ 35

Drive plate to torque converter

40 ~ 42

Gear select lever to shaft rod

14 ~ 20

Page 556 of 828

01-12

2. FEATURES

Early Downshifts with Hard Braking and Skip Shifts ▶

When heavy braking is detected, the transmission downshifts early and skips gears to provide

increased engine braking to provide gear selection for tip-in.

Gear Hold on Uphill/Downhill ▶

If the accelerator pedal is released when travelling uphill, upshifts are prevented to reduce

busyness on grades. If the accelerator pedal is released when travelling downhill, upshifts are

prevented to enhance engine braking.

Soft Engagement when Shifting to “D” and “R” Position ▶

A soft engagement feature avoids harsh take up of drive when selecting Drive or Reverse. This is

achieved by limiting engine speed and engine torque which results in a rapid, but progressive

engagement of either Drive or Reverse when moving from the Park or Neutral positions. There is

no drive engagement prevention strategy implemented on the transmission system as there is

sufficient engine strategy to protect the system. However, reverse gear engagement is prevented

until engine speed is less than 1400 rpm and the accelerator pedal position is less than 12% and

vehicle speed is less than 10 km/h.

Converter Clutch Lock-Up In All Gears ▶

The transmission features converter clutch lock-up in all gears. This feature provides improved

fuel economy and vehicle performance. It also improves transmission cooling efficiency when

towing heavy loads at low speeds, e.g. in city driving or hill terrain.

Embeded Memory Module (EMM) ▶

The embedded memory module (EMM) is

matched to the transmission's valve bodies

during transmission assembly to ensure

refined shift quality. The EMM is integrated

into the input speed sensor which is mounted

on the valve body in the transmission. The

EMM is used to store data such as valve body

calibration data and valve body serial number.

Upon installation, the TCU will download the

data from the EMM and utilise this data in the

operation of the transmission.

1) Features