engine SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 560 of 828

01-16

4. LIMP HOME MODE

In case of transmission malfunction ▶

If a serious fault occurs in the automatic transmission, the TCU enters the limp home

mode to secure safe driving and protect the automatic transmission.

As power is no longer supplied to the solenoid, the current basic function (P, R, N, D) is

maintained and the 4th gear can be maintained only by the operation of the hydraulic

system without electrical operation.

The ECU communicates with other electric modules with CAN. If a serious fault occurs, the

transmission automatically enters the limp home mode for service.

The TCU monitors all factors which can affect to the performance of the transmission and

diagnose the system according to OBD II regulation. 1.

2.

3.

4.

In case of overheated transmission ▶

The TCU enters the limp home mode when the batter voltage drops below 8 V.

If the transmission is overheated, the shift pattern is changed to the hot mode to cool the

transmission more efficiently.

While the transmission is overheated, the selector lever symbol and engine temperature

warning lamp on the instrument cluster blink until the transmission is cooled down to the

normal operation temperature. If the transmission is excessively overheated, the gear

cannot be shifted but remains in the neutral position. 1.

2.

3.

Towing the vehicle with A/T ▶

The best way to transport the vehicle is to load it to a truck and transport it, especially if the

vehicle is 4WD.

If towing the vehicle with the propeller shaft connected, the transmission or oil pump of

transfer case may malfunction, resulting in internal damage due to poor lubrication. -

Page 562 of 828

01-18

(2) CAN Input/Output

TCU receives and sends the data among the units through P-CAN communication.

CAN Input/Output Data between Engine ECU and TCU ▶

Page 564 of 828

01-20

3) Transmission Control Monitoring System

TCU monitors all input and output signals to identify possible failures. If a fault is detected, TCU

<0088008a009b0090009d0088009b008c009a0047009b008f008c0047009a0088008d008c009b00a0004700940096008b008c0047009b009600470092008c008c00970047009b008f008c0047008b00990090009d008c009902c5009a0047009a0088008d00

8c009b00a0004700880095008b0047009b008f008c00470093>ife span of transmission.

Monitoring the Supply Voltage ▶

Monitoring the Supply Voltage to Solenoid ▶

Monitoring the Gear Ratio ▶

Monitoring the Torque Converter ▶ If the battery voltage is too high or too low, the TCU sets the DTC.

TCU monitors the circuits for open or short to ground or supply. The monitoring function

evaluates the voltage characteristics while the switch is ON.

TCU monitors the gear is engaged properly in the allowed time.

TCU checks if the torque converter can be locked up properly. If it is failed, TCU releases the

torque converter clutch to activate the fail-safe operation.

4) Shift Energy Management

This function involves reducing or increasing the engine output torque during shifting. This

reduces the energy which is dissipated in the friction elements of the transmission during up-

shift. This is done by reducing the engine torque during the gear ratio change without interrupting

the tractive drive.

This function is used for:

Increasing the life span of transmission by shortening the slipping time

Improving the shift comfort by reducing the step changes due to gearshift

Transferring a higher engine power -

-

-

Real-time control of engine torque is required to maintain the proper shift operations and the

durability of transmission. TCU controls the engine torque during the gearshift by synchronizing

the operation of transmission clutches.

Page 565 of 828

01-213680-01

Pressure Modulation ▶

To provide a higher level of shift comfort and durability, the hydraulic pressure in the shift related

friction elements of the transmission must be matched accurately to the input torque to

transmission. This hydraulic pressure is composed of a hydraulically pre-set basic pressure and a

control pressure which is set by one of the variable bleed solenoids.

The transmission input torque can be directly calculated from the following operating parameters:

engine torque signals

engine speed or any signal transmitted from ECU through CAN lines

converter slip -

-

-

Separate pressure characteristics for each gear change make it possible to adapt precisely to the

particular shift operation.

5) Shift Mode Selection by TCU

The driver can select Standard (S) or Winter mode (W) with the mode switch. TCU automatically

changes the shift mode according to the transmission oil temperature, uphill or downhill gradient,

and altitude to keep the good driving conditions.

Standard Mode (S) ▶

Uphii and Downhill Mode ▶

Altitude Mode ▶ Standard Mode is selected when setting the mode switch in Standard (S) position with the gear

<009a008c0093008c008a009b00470093008c009d008c0099004700900095004702c8006b02c9004700880095008b0047009b008f008c0047009b009900880095009a00940090009a009a00900096009500470096009000930047009b008c00940097008c00

990088009b009c0099008c0047009000950047009500960099>mal operating range. Proper shift

timing provides the optimized fuel economy and good driving conditions.

In this mode, the operating points of torque converter lock-up clutch and the shifting points are

adjusted according to the vehicle weight.

In this mode, the shifting points are automatically adjusted according to the altitude to compensate

the engine torque changes due to barometric pressure and temperature.

Page 566 of 828

01-22

Winter Mode (W) ▶

Low Range Driving Mode ▶

Warm Up Mode ▶ When the Winter mode is selected, the second gear is engaged to start off the vehicle easily to

prevent wheel spin on slippery surfaces and WINTER mode indicator comes ON. The first gear is

not available in this mode.

When the vehicle is in 4L driving mode, the transmission uses a different shift mode to optimize

the low range driving. Similar to Winter mode, the first gear is not available.

This mode is normally used when the transmission oil temperature is below 20°C.

<007b008f008c0047009b009600990098009c008c0047008a00960095009d008c0099009b008c00990047008a0088009500950096009b00470089008c004700930096008a0092008c008b0054009c009700470089008c00930096009e00470059005700b600

6a0047009b00960047009700990096009d0090008b008c0047>the warming up process of

transmission.

Hot Mode ▶

<0070008d0047009b008f008c0047009b009900880095009a00940090009a009a00900096009500470096009000930047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c009b009e008c008c0095004700580058005700

b6006a004700880095008b00470058005b005c00b6006a0053> the system provides the cooling

and reduces the load to the transmission. This is called Hot Mode.

Above 110°C:

Above 130°C:

Above 145°C: -

-

-

In Hot Mode, any of shift mode is not available.

Cruise Control ▶

When the cruise control is activated, the engine ECU requests the downshift to increase the

engine brake effect.PWM fan ON

the engine torque is reduced and WINTER indicator is blinking

the transmission is held in Neutral (N) gear until the oil temperature falls

below 120°C (Final protection)

Page 569 of 828

01-253680-01

1) Power Flow - Manual (M Position)

Functioning elements ▶

Control ▶C2 applied, FSG (Forward Sun Gear)

driven

B2 applied to hold Rear Planet Carrier

stationary

Provides engine breake effect -

-

-

S1 ON, C1 shift valve moved to the left end, C1 clutch not engaged

S1 ON, B2 shift valve moved to the left end, B2 band operated (S7 should be ON)

C2 shift valve open (S2 OFF), C2 clutch engaged by drive oil

Drive oil (for C2 clutch engagement) is regulated by VBS S6 -

-

-

-

Connecting Components ▶

Gear

ratioON / OFF solenoids Variable pressure sol. valve-VBS

S1 S2 S3 S4 S5(A) S6(A) S7(A) S8(A) S9(A) S10(A)

3.53 ON 1 0 1 0-1

Gear

ratioEngaged element

C1 C2 C3 B1 B2 OWC Lock-up

clutch

AO AI R AO AI

3.53 ON ON ON

Power Flow Diagram ▶

Manual 1st gear is not engaged even when

moving the manual valve to a certain position.

This gear state is obtained electronically by

solenoids S1 and S7.

Page 615 of 828

03-73170-01

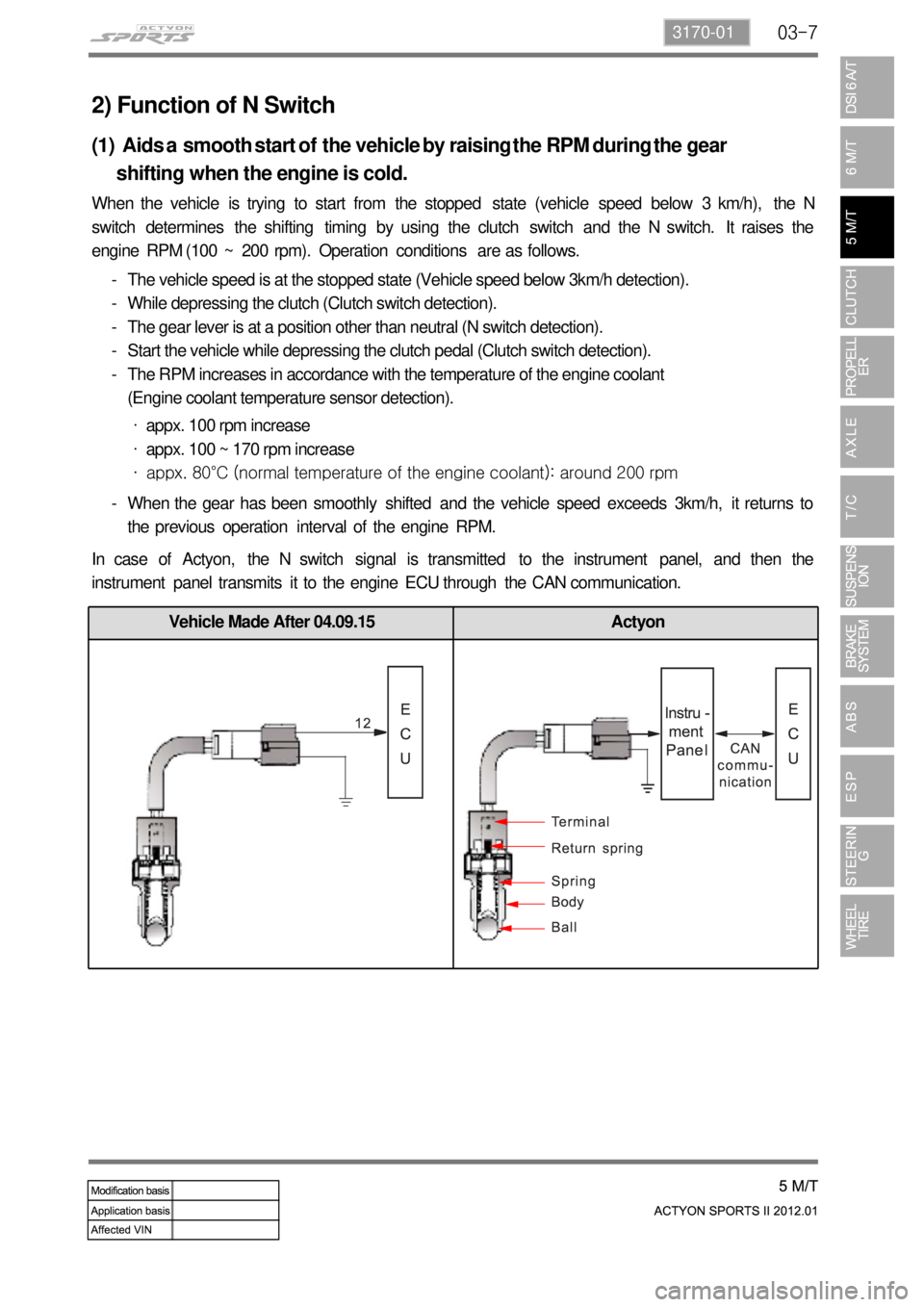

2) Function of N Switch

(1) Aids a smooth start of the vehicle by raising the RPM during the gear

shifting when the engine is cold.

When the vehicle is trying to start from the stopped state (vehicle speed below 3 km/h), the N

switch determines the shifting timing by using the clutch switch and the N switch. It raises the

engine RPM (100 ~ 200 rpm). Operation conditions are as follows.

The vehicle speed is at the stopped state (Vehicle speed below 3km/h detection).

While depressing the clutch (Clutch switch detection).

The gear lever is at a position other than neutral (N switch detection).

Start the vehicle while depressing the clutch pedal (Clutch switch detection).

The RPM increases in accordance with the temperature of the engine coolant

(Engine coolant temperature sensor detection). -

-

-

-

-

appx. 100 rpm increase

appx. 100 ~ 170 rpm increase

<008800970097009f00550047005f005700b6006a0047004f0095009600990094008800930047009b008c00940097008c00990088009b009c0099008c00470096008d0047009b008f008c0047008c0095008e00900095008c0047008a009600960093008800

95009b005000610047008800990096009c0095008b00470059>00 rpm ·

·

·

When the gear has been smoothly shifted and the vehicle speed exceeds 3km/h, it returns to

the previous operation interval of the engine RPM. -

In case of Actyon, the N switch signal is transmitted to the instrument panel, and then the

instrument panel transmits it to the engine ECU through the CAN communication.

Vehicle Made After 04.09.15 Actyon

Page 616 of 828

03-8

Variant Coding Options

(2) Detects the position of the shifting lever for the HDC operation

among ABS functions.

The HDC function operates only if the M/T shift lever is in forward or reverse position. Please refer

to the ABS section for the specific information related to the HDC.

Variant Coding Related to N Switch ▶

The N switch transmits information to the ECU through the CAN communication while New Rexton

is connected to the ECU through wires. Thus, if you set the variant coding in the engine ECU, you

must do it differently, and you must set the variant coding differently according to the vehicle

category and specification as below.

Neutral Signal Input None / Wire / CANWire /

Actyon & Kyron models with

manual transmission

New Rexton model with manual

transmission Manufactured

after 04.09.15

BODY IN: after 154600

Automatic transmission & Rodius

model with automatic

transmission before 2006

Page 619 of 828

04-4

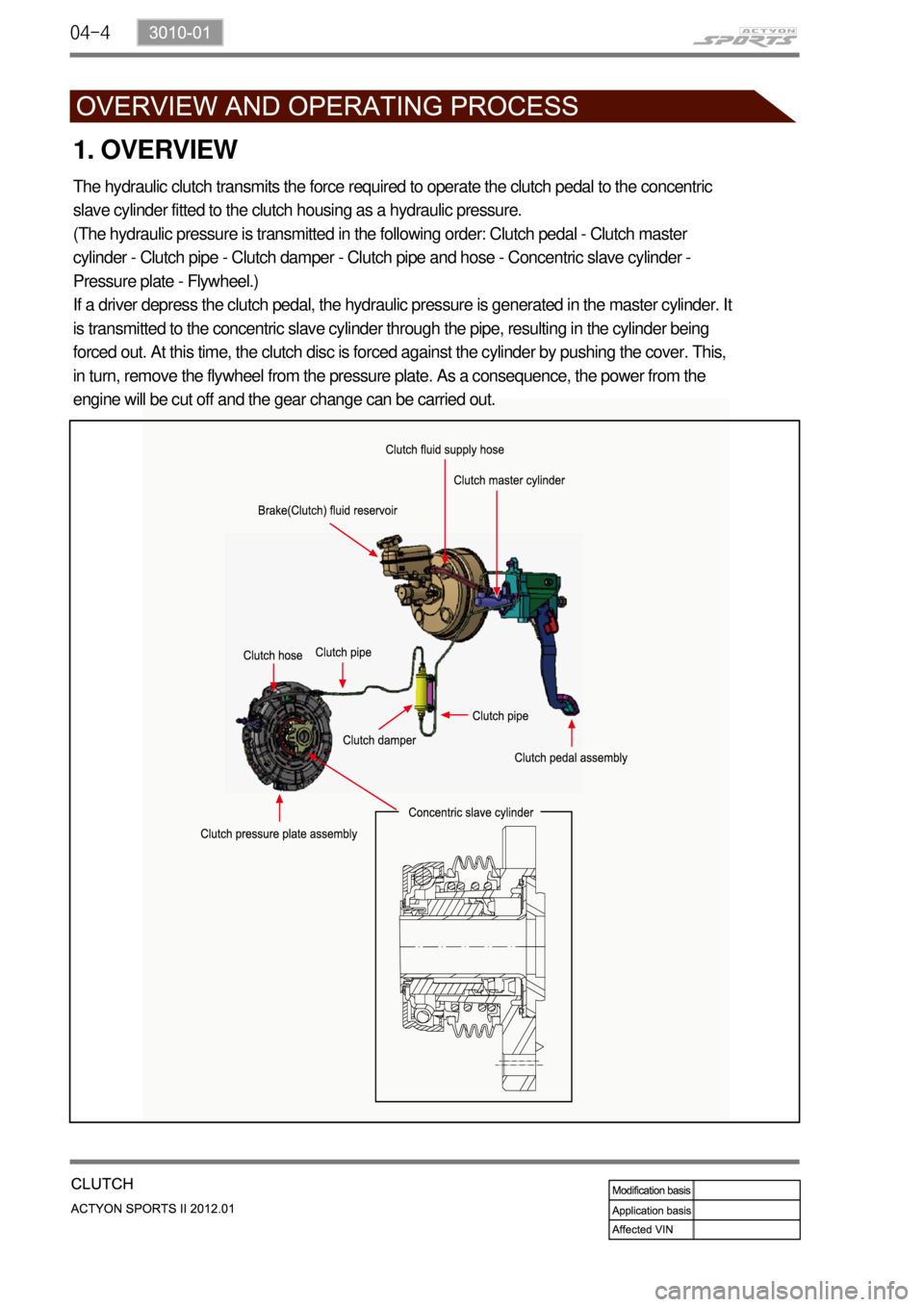

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric

slave cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master

cylinder - Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder -

Pressure plate - Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It

is transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being

forced out. At this time, the clutch disc is forced against the cylinder by pushing the cover. This,

in turn, remove the flywheel from the pressure plate. As a consequence, the power from the

engine will be cut off and the gear change can be carried out.

Page 621 of 828

04-6

2) Overview

Driving elements ▶

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The

clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements ▶

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the

splines of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted by

a diaphragm spring in the clutch cover pressure plate assembly.

Operating Elements ▶

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch

system releases the clutch by using release lever and release fork. This system provides higher

efficiency than conventional clutch system, and its durability is superior.

Clutch master cylinder (mounted on clutch pedal)

Concentric slave cylinder pipe (mounted inside of transmission) -

-