engine SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 623 of 828

04-8

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of

inertia of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 646 of 828

08-10

2. FRONT SUSPENSION (DOUBLE WISHBONE)

Advantage ▶

The advantage of a double wishbone suspension is that it is fairly easy to work out the effect

of moving each joint, so the kinematics of the suspension can be tuned easily and wheel

motion can be optimized.

It is also easy to work out the loads that different parts will be subjected to which allows more

optimized lightweight parts to be designed.

They also provide increasing negative camber gain all the way to full jounce travel unlike the

MacPherson strut which provides negative camber gain only at the beginning of jounce travel

and then reverses into positive camber gain at high jounce amounts. 1.

2.

3.

Disadvantage ▶

The disadvantage is that it is slightly more complex than other systems like a MacPherson strut.

Due to the increased number of components within the suspension setup it takes much longer to

service and is heavier than an equivalent MacPherson design. 1.

2. Double wishbone suspension is an independent suspension design using two (occasionally parallel)

wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the

chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to

control vertical movement. Double wishbone designs allow the engineer to carefully control the

motion of the wheel throughout suspension travel, controlling such parameters as camber angle,

caster angle, toe pattern, roll center height, scrub radius, scuff and more.

Lower arm Upper arm Shock absorber Stabilizer

Page 657 of 828

09-94850-01

Problem Cause Action

Burning smell

around tireToo frequent braking in high driving speed Reduce the use of

foot brake/use

engine brake

properly Used only foot brake during downhill driving

Driving with foot on brake pedal Get off the foot

from pedal

Foreign materials such as dirt or sand in brake system Replace: caliper,

wheel cylinder,

master cylinder,

return spring

Broken return spring in shoe assembly Replace

Incorrectly adjusted parking brake cable Adjust

Incorrect wheel or wheel cover

(generating the heat)Replace

Page 658 of 828

09-10

This section describes the noise phenomena occurred possibly in the brake system operation.

Distinguish between the information given below and the actual problems and then, inspect the

vehicle and take appropriate measures.

Noise symptoms and Causes -

Symptom 1. If depressing the brake pedal when the engine is cold, "screeching" sound always

occurs and, after driving for a while, the sound disappears..

This usually occurs in the morning. When the temperature goes down, the dew condensation

phenomenon sets moisture on the brake disc as the window frost forms. Due to this moisture, the

iron within the brake disc and pad oxidizes, forming undetectable micro-rusts on the disc

surface. When starting the engine under this condition, noise may sound due to the friction of

micro-rusts. When operating the brake several times, the disc temperature goes up and the

micro-rusts come off and the noise goes away. Depending on the driving conditions, noise gets

louder when slightly depressing the brake pedal and oppositely, noise is smaller when deeply

depressing the brake pedal. This is simply a physical phenomenon, called "morning effect" in

professional terms, and does not imply any problems with the brake system.

Symptom 2. Slip or screech after the brake pad replacement.

This usually occurs when the bed-in is not made between the disc and the pad's friction material.

The bed-in is a state that the brake system normally works and gives no noise out, when, after

about 300 km city driving, the contact area of the pad friction material is enlarged and the disk is

in complete contact with the pad's friction material. Therefore, for some time after the brake

disk/pad replacement, the brake system poorly operates or noise (abnormal sound) occurs due

to the partial contact.

Symptom 3. "Groaning" sound occurs in the automatic transmission vehicle when slightly taking

the foot off the brake pedal to slowly start after waiting for the signal, or slightly depressing the

brake pedal.

This is the noise "Creep groan" that occurs when, in both the automatic and manual transmission,

slightly releasing the brake pedal in the neutral gear at downhill roads.

It frequently occurs at the low braking power and low speed, through the following process. When

operating the brake system at low speed and low pressure, adhesion and slip repeatedly take

place between the brake disk and the friction material, and this makes the braking power

inconstant, instantly increasing or decreasing, and gives out the brake noise.

It is also a physical phenomenon and has no relation with the brake performance.BRAKE OPERATION AND NOISE ▶

Page 661 of 828

09-134850-01

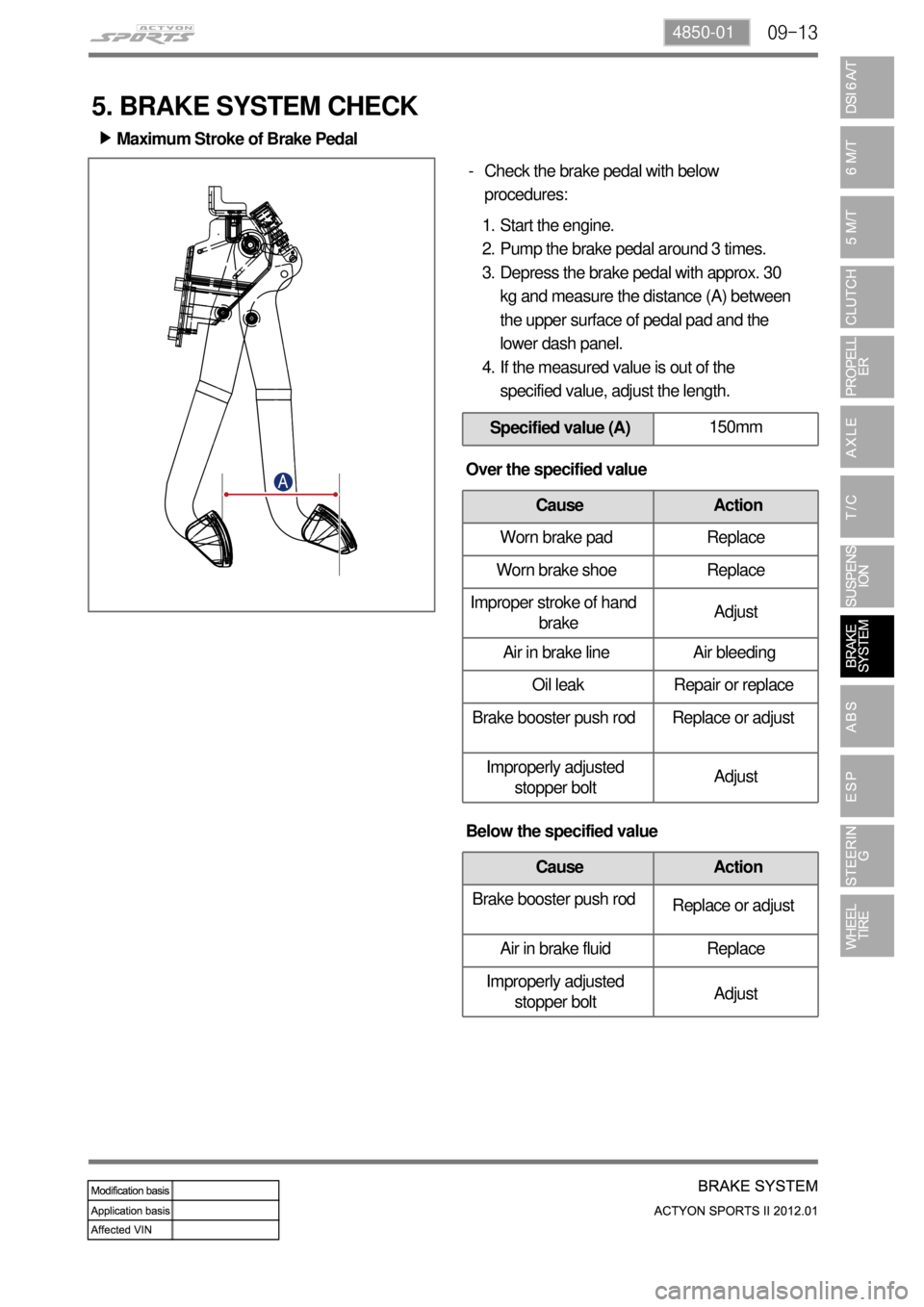

Maximum Stroke of Brake Pedal ▶

Check the brake pedal with below

procedures: -

Start the engine.

Pump the brake pedal around 3 times.

Depress the brake pedal with approx. 30

kg and measure the distance (A) between

the upper surface of pedal pad and the

lower dash panel.

If the measured value is out of the

specified value, adjust the length. 1.

2.

3.

4.

Specified value (A)150mm

5. BRAKE SYSTEM CHECK

Over the specified value

Cause Action

Worn brake pad Replace

Worn brake shoe Replace

Improper stroke of hand

brakeAdjust

Air in brake line Air bleeding

Oil leak Repair or replace

Brake booster push rod Replace or adjust

Improperly adjusted

stopper boltAdjust

Below the specified value

Cause Action

Brake booster push rod

Replace or adjust

Air in brake fluid Replace

Improperly adjusted

stopper boltAdjust

Page 662 of 828

09-14

Specified value (B)155mm

Push rod

Stop lamp

switch Pedal Height ▶

Check the pedal height with below

procedures: -

Start the engine and measure the length

(A) between floor mat and pedal.

If the measured value is out of the

specified value, adjust the length. 1.

2.

Adjust the pedal height with below

procedures: -

Disconnect the stop lamp switch connector.

Unscrew the lock nut and remove the stop

lamp switch assembly.

Loosen the lock nut on the pedal push rod.

Turn the pedal push rod to adjust the pedal

height.

Tighten the lock nut.

Install the stop lamp switch assembly.

Connect the stop lamp switch connector.

Check if the stop lamps come on when

pressing the brake pedal around 5 mm.

If the stop lamp dpes not come on, adjust

the stop lamp switch assembly again.

If the stop lamps come on, tighten the lock

nut and measure the pedal height again. 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Page 663 of 828

09-154850-01

Specified value (A)3 ~ 10mm

Connect the multimeter to stop lamp

switch connector and check if the

continuity exists when pushing in the

plunger. If the continuity doesn't exist, the

stop lamp switch is normal. - Pedal Free Play ▶

Stop Lamp Switch ▶Check the pedal free play with below

procedures: -

Stop the engine.

Depress the brake pedal several times to

discharge the vacuum pressure of the brake

booster.

Depress the brake pedal until you feel the

resistance, and measure the movement (A). 1.

2.

3.

Below the specified value: Check if the

distance between the outer case of stop

lamp switch and the brake pedal.

Over the specified value: It may be caused

by bigger clearance between the clevis pin

and the brake pedal arm. Replace the

components if necessary. -

-

Page 664 of 828

09-16

Let the engine run for 1 to 2 minutes and

stop it. If the brake pedal stroke is

shortened as pumping the brake pedal,

the system is normal. If not, the system is

defective.

Depress the brake pedal several times

with engine off. If the brake goes down

when starting engine with pedal

depressed, the system is normal. If not,

the system is defective.

Depress the brake pedal when the engine

is running. If the pedal height is not

changed for 30 seconds after stopping

the engine, the system is normal. If not,

the system is defective. 1.

2.

3.

If the above three checks are OK, the system

is normal. If any condition is not met, check

the valve, vacuum hose and brake booster. Brake Booster ▶

Page 688 of 828

10-94892-01

Front wheel speed sensor (4WD)

Located on the hub assembly.

Front discFront caliper assembly (2WD/4WD)

Located on the knuckle.

ABS hydraulic device and control unit

Located near the brake booster in engine compartment.

Page 708 of 828

11-74890-10

1. OVERVIEW

The ESP (Electronic Stability Program) has been developed to help a driver avoid danger of losing

control of the vehicle stability due to understeer or oversteer during cornering. The yaw rate

sensor, lateral sensor and longitudinal sensor in the sensor cluster and the steering wheel angle

sensor under the steering column detect the vehicle conditions when the inner or outer wheels are

spinning during oversteer, understeer or cornering. The ESP ECU controls against oversteer or

understeer during cornering by controlling the vehicle stability using input values from these

sensors and applying the braking force to the corresponding wheels independently. The system

also controls the engine power right before the wheel spin synchronized to decelerate the vehicle

automatically in order to maintain the vehicle stable during cornering.