fuel pump SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 32 of 828

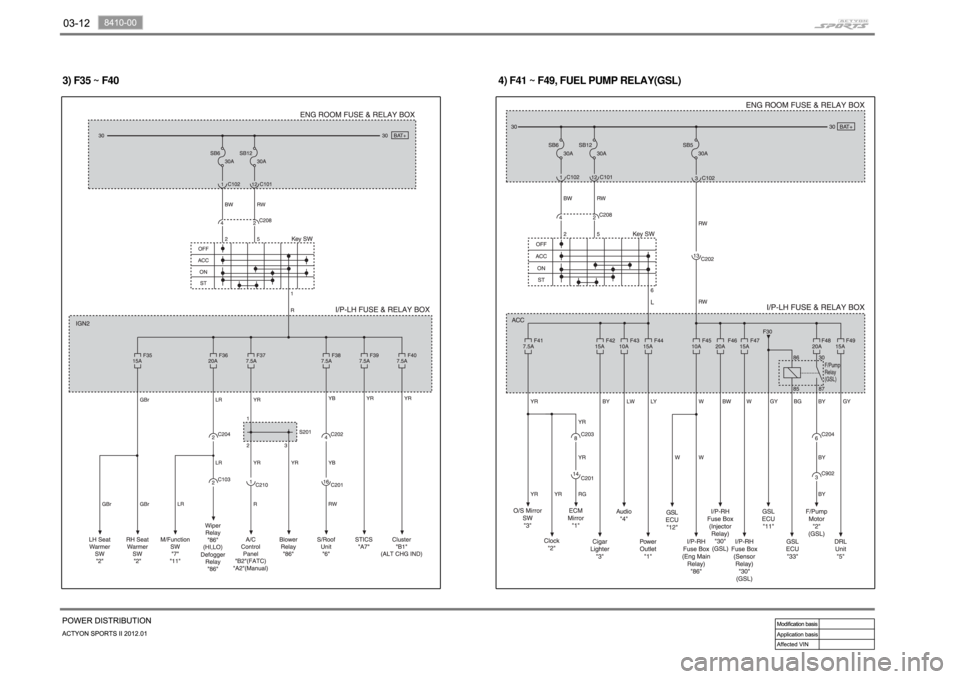

3) F35 ~ F404) F41 ~ F49, FUEL PUMP RELAY(GSL)

Page 47 of 828

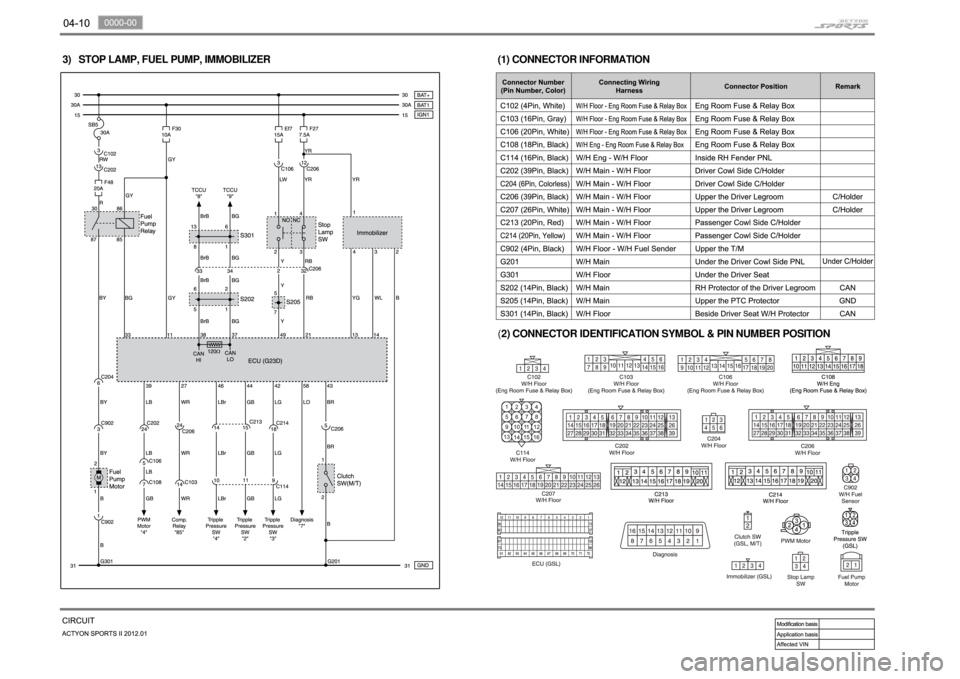

(1) CONNECTOR INFORMATION

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION STOP LAMP, FUEL PUMP, IMMOBILIZER 3)

Page 125 of 828

01-4

2. MAJOR COMPONENTS

Front view ▶

Vacuum pump

Oil filter assembly

Camshaft position sensor

Power steering pump pulley

Water pump pulley

Alternator pulley

Idler pulley No. 2

A/C compressor pulley

Auto tensioner

Idler pulley No. 1

Isolation damper

Rear view ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

IMV valve Crankshaft position sensor

Oil pressure switch

Page 130 of 828

01-90000-00

(3) Cautions before service

Prolonged exposure to the engine oil make cause a skin cancer or an irritation.

Used engine cotains the hazardous material that may cause the skin cancer. Do not allow the

used engine to make contact with your skin.

Make sure to wear the protection gloves and goggle when handling the engine oil. If contact

happens, rinse affected areas immediately with plenty of water. Do not wash it with gasoline or

solvent. If irritation persists, consult a doctor.

Improperly disposed engine oil can pollute the environment. Dispose used engine oil in

accordance with local environmental regulations. -

-

-

(5) Tightening the fastener

If fine dust or foreign material enters into DI engine's fuel system, there can be serious

damages between HP pump and injectors. So, be sure to cover removed fuel system

components with cap and protect removed parts not to be contaminated with dirt. (Refer to

cleanness in this manual while working on DI engine fuel system)

When working on the fuel line between priming pump and injector (including return line),

always plug the openings with caps to prevent foreign materials or dust from entering to the

openings and connections.

The HP fuel supply pipe (HP pump to fuel rail) and HP fuel pipe (Fuel rail to injector)

should be replaced with new ones when removed. 1.

2.

3. Scalding hot coolant and steam could be blown out under pressure, which could cause serious

injury. Never remove the coolant reservoir cap when the engine and radiator are hot.

(4) Lubrication system

3) Fuel and Oil System

If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified. -

-Clean the mating surfaces before tightening.

Place the marks with paint to tighten by angle if the angle wrench is not available. -

-

Page 143 of 828

02-6

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 4 20±2Nm -

Vacuum pumpM8×25 3 10±1Nm -

Timing gear case coverM12×55 3 85±8.5Nm -

M6×25 7 10±1Nm -

M6×45 1 10±1Nm -

M6×50 3 10±1Nm -

Cylinder head coverM6×35 21 10±1Nm -

Oil gauge tubeM6×16 1 10±1Nm -

Oil filter cap 1 25±2.5Nm -

Fuel railM8×35SOC 2 25±2.5Nm -

Injector clamp boltM6×60 2 10±1Nm,

120˚+10˚ -

High pressure pipe

(between HP pump and

fuel rail)M17 1 30±3Nm -

High pressure pipe

(between fuel rail and

injector)M17 4 30±3Nm -

Crank position sensorM5×14 1 8±0.4Nm -

Main wiringM6×16 5 10±1Nm -

Intake duct M8x25 4 25±2.5Nm -

Power steering pumpM8×100 3 25±2.5Nm -

Cylinder head front

coverM6×10 5 10±1Nm -

Ladder frameM8×16 5 30±3Nm -

Oil pumpM8×35 3 25±2.5Nm

-

Page 149 of 828

02-12

Electrical equipment ▶

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. there could be poor engine performance,

incomplete combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and each electrical equipment, be sure to disconnect battery negative

(-) terminal.

When replacing the electric device, use only genuine part and check the conditions of

connections and grounds. Loosened connection or ground make cause a fire and personal

injury. -

-Fuel and lubrication system ▶

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting

section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages

in HP pump and injectors. Thus, be sure to plug the inlets of removed fuel line components with

cap and protect removed parts not to be contaminated with dirt. (Refer to cleanness in this

manual while working on DI engine fuel system)

Page 186 of 828

03-32210-01

1. SPECIFICATION

Description Specification

Fuel Diesel

Fuel filterType Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Change interval every 50,000 km

Water separation interval every 15,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature-40 ~ 125˚C

Operating pressure 1800 bar

Operating temperature-30 ~ 120˚C

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tankCapacity 75 L

Material Steel

Fuel sender Single sender type

Page 187 of 828

03-4

2. MAINTENANCE AND INSPECTION

1) Maintenance Procedures for DI Engine Fuel System

Always keep the workshop and lift clean (especially, from dust).

Always keep the tools clean (from oil or foreign materials).

Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel

system. Wash your hands and do not wear working gloves. 1.

2.

3.

Follow the below procedures before starting service works for fuel system.

If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and

sealing caps to perform the diagnosis for DI engine fuel system in this manual. At this point,

thoroughly clean the related area in engine compartment. 4.

Clean the engine compartment before starting service works.

Tool kit for high pressure lineTook kit for low pressure line

Page 188 of 828

03-52210-01

Follow the job procedures. If you find a defective component, replace it with new one. 5.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each

injector should be replaced with new ones. The pipes should be tightened tospecified tightening

torques during installation. Over or under torques out of specified range may cause damages and

leaks at connections. Once installed, the pipes have been deformed according to the force

during installation, therefore they are not reusable. The copper washer on injector should be

replaced with new one. The injector holder bolt should be tightened to specified tightening torque

as well. If not, the injection point may be deviated from correct position, and it may cause engine

disorder.

Plug the removed components with clean and undamaged sealing caps and store it into the

box to keep the conditions when it was installed. 6.

To supply the fuel to transfer line of HP

pump press the priming pump until it

becomes hard. 7.

Priming pump

Priming pump cap

Fuel filter assembly

Check the installed components again and connect the negative battery cable. Start the

engine and check the operating status.

With Scan Tool, check if there are current faults and erase the history faults. 8.

9.

Page 191 of 828

03-8

(4) Loss of pump pressure/flow

Loss of HP pump pressure/flow ▶

Faulty fuel supply line, or damaged or worn pump causes the lack of flow pressure and flow

volume

Example: ▶

Air in fuel supply line

Excessive load on fuel supply line (←400 mBar)

Burned out and mechanical worn pump

High temperature of fuel supply (> 85℃) -

-

-

-