ABS SSANGYONG NEW ACTYON SPORTS 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 541 of 751

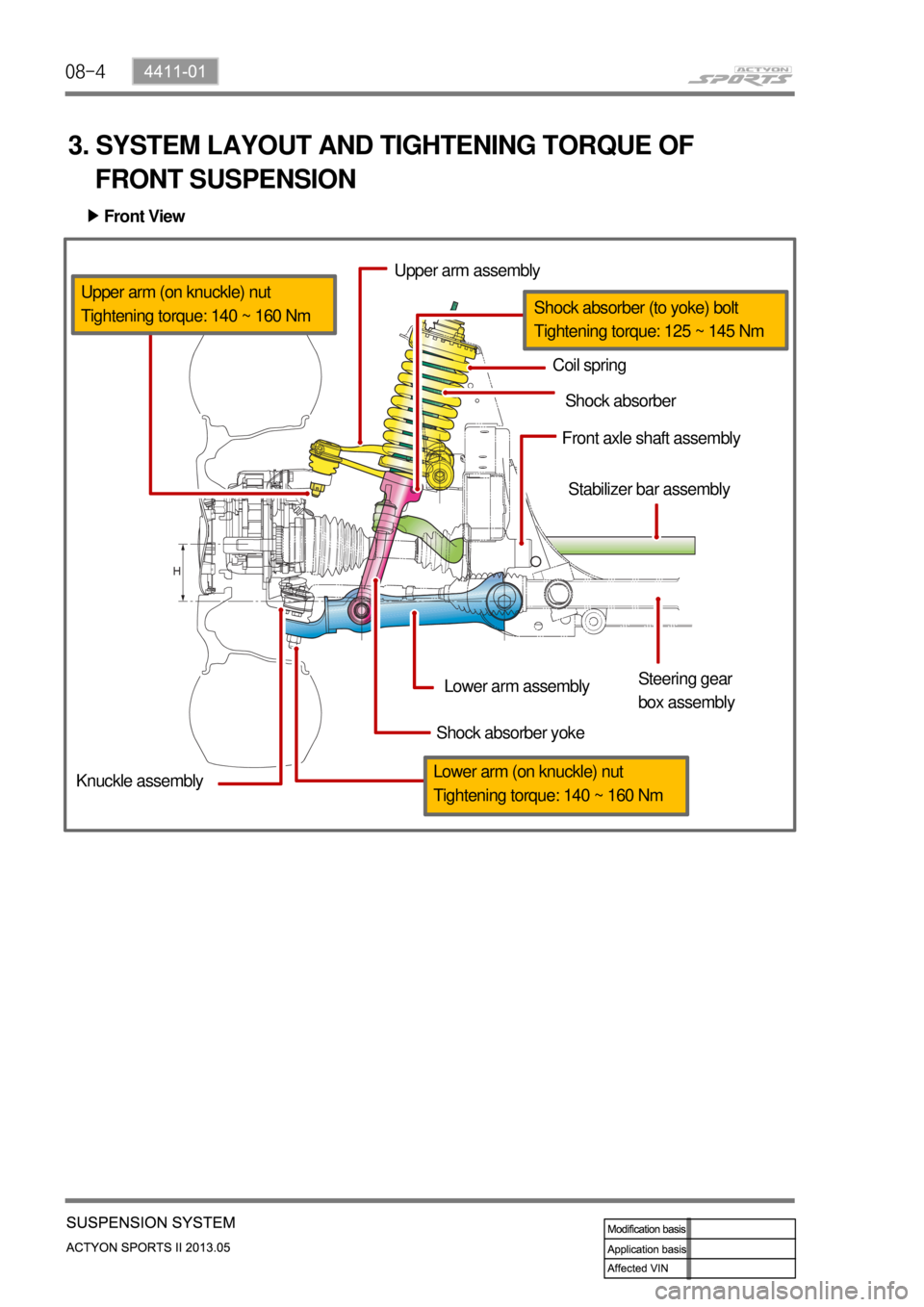

08-4

3. SYSTEM LAYOUT AND TIGHTENING TORQUE OF

FRONT SUSPENSION

Upper arm assembly

Coil spring

Shock absorber

Front axle shaft assembly

Steering gear

box assembly Lower arm assembly

Shock absorber yoke

Knuckle assembly

Stabilizer bar assembly

Front View ▶

Upper arm (on knuckle) nut

Tightening torque: 140 ~ 160 Nm

Lower arm (on knuckle) nut

Tightening torque: 140 ~ 160 Nm

Shock absorber (to yoke) bolt

Tightening torque: 125 ~ 145 Nm

Page 542 of 751

08-54411-01

Stabilizer bar link lower nut

Tightening torque: 110 ~ 130 Nm

Coil spring mounting nut

Tightening torque: 60 ~ 80 Nm

Stabilizer bar link upper nut

Tightening torque: 30 ~ 50 NmUpper arm (frame side) bolt/nut

Tightening torque: 110 ~ 130 Nm

Stabilizer bar clamp bolt

Tightening torque: 40 ~ 60 Nm

Lower arm (end yoke) bolt

Tightening torque: 70 ~ 80 Nm

Lower arm (shock absorber yoke side) nut

Tightening torque: 150 ~ 170 Nm

Lower arm (frame side) bolt/nut

Tightening torque: 210 ~ 230 Nm Top View ▶

Page 543 of 751

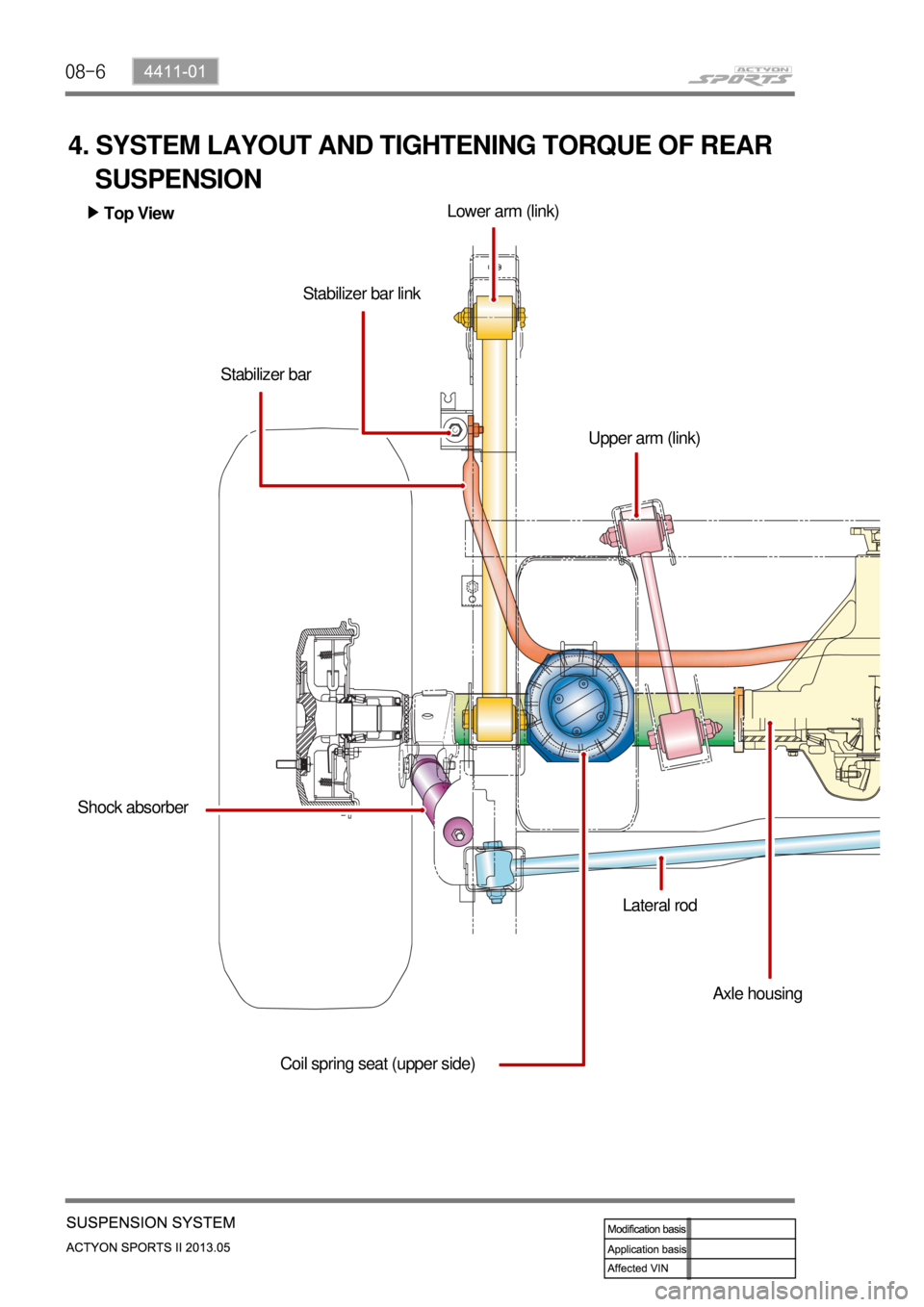

08-6

4. SYSTEM LAYOUT AND TIGHTENING TORQUE OF REAR

SUSPENSION

Lower arm (link)

Stabilizer bar link

Stabilizer bar

Shock absorber

Coil spring seat (upper side)Lateral rod

Axle housing Upper arm (link)Top View ▶

Page 544 of 751

08-74411-01

Lateral rod

Tightening torque: 150 ~ 180 Nm

Shock absorber upper bolt/nut

Tightening torque: 30 ~ 45 Nm

Shock absorber lower bolt/nut

Tightening torque: 80 ~ 100 Nm

Upper arm bolt/nut

Tightening torque:150~180 Nm

Lower arm bolt/nut

Tightening torque: 150 ~ 180 NmStabilizer bar link lower

Tightening torque: 60 ~ 80 Nm

Stabilizer bar mounting bracket

Tightening torque: 40 ~ 60 Nm

Stabilizer bar link upper

Tightening torque: 30 ~ 45 Nm

Page 545 of 751

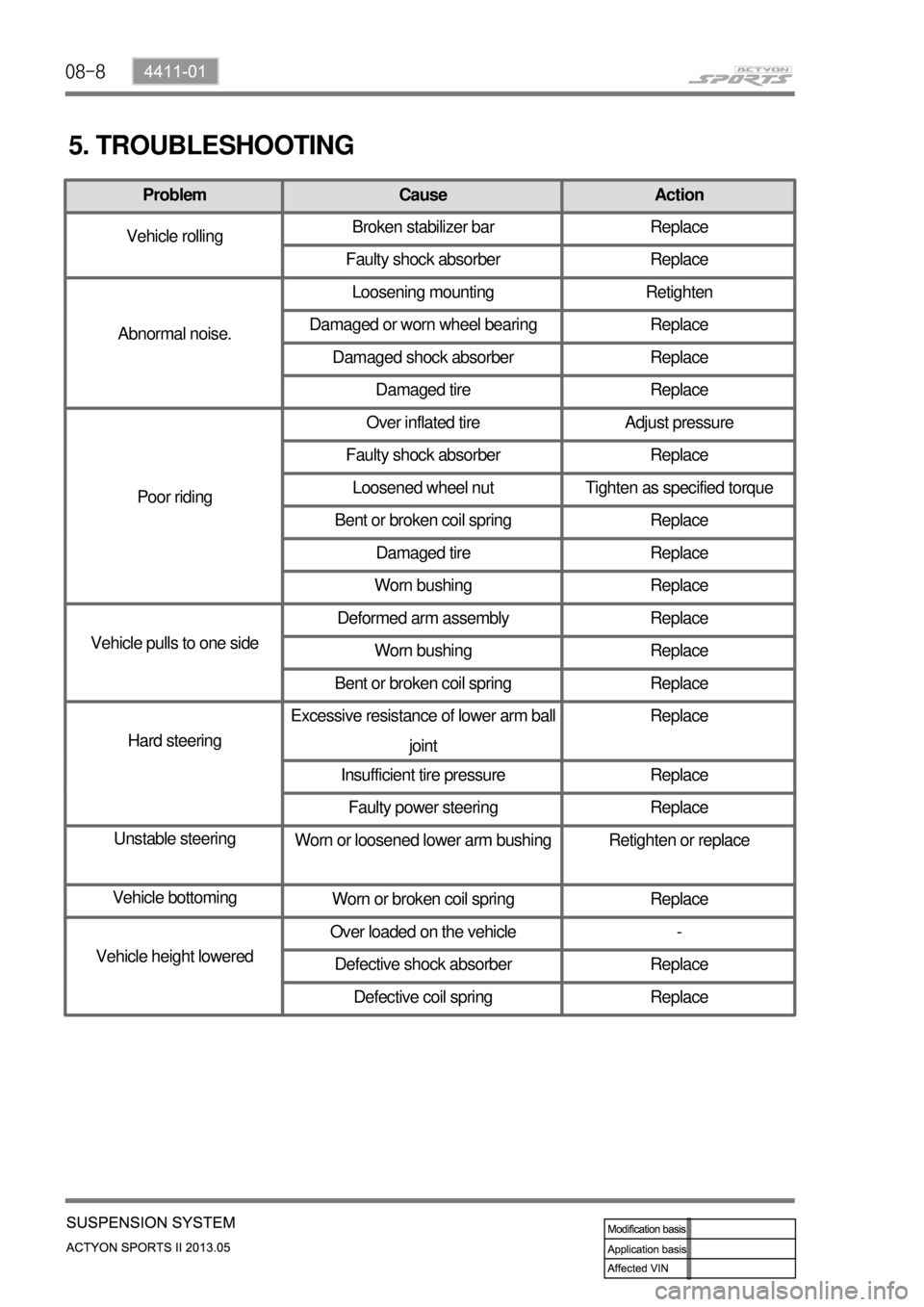

08-8

5. TROUBLESHOOTING

Problem Cause Action

Vehicle rollingBroken stabilizer bar Replace

Faulty shock absorber Replace

Abnormal noise.Loosening mounting Retighten

Damaged or worn wheel bearing Replace

Damaged shock absorber Replace

Damaged tire Replace

Poor ridingOver inflated tire Adjust pressure

Faulty shock absorber Replace

Loosened wheel nut Tighten as specified torque

Bent or broken coil spring Replace

Damaged tire Replace

Worn bushing Replace

Vehicle pulls to one sideDeformed arm assembly Replace

Worn bushing Replace

Bent or broken coil spring Replace

Hard steeringExcessive resistance of lower arm ball

jointReplace

Insufficient tire pressure Replace

Faulty power steering Replace

Unstable steering

Worn or loosened lower arm bushing Retighten or replace

Vehicle bottoming

Worn or broken coil spring Replace

Vehicle height loweredOver loaded on the vehicle -

Defective shock absorber Replace

Defective coil spring Replace

Page 546 of 751

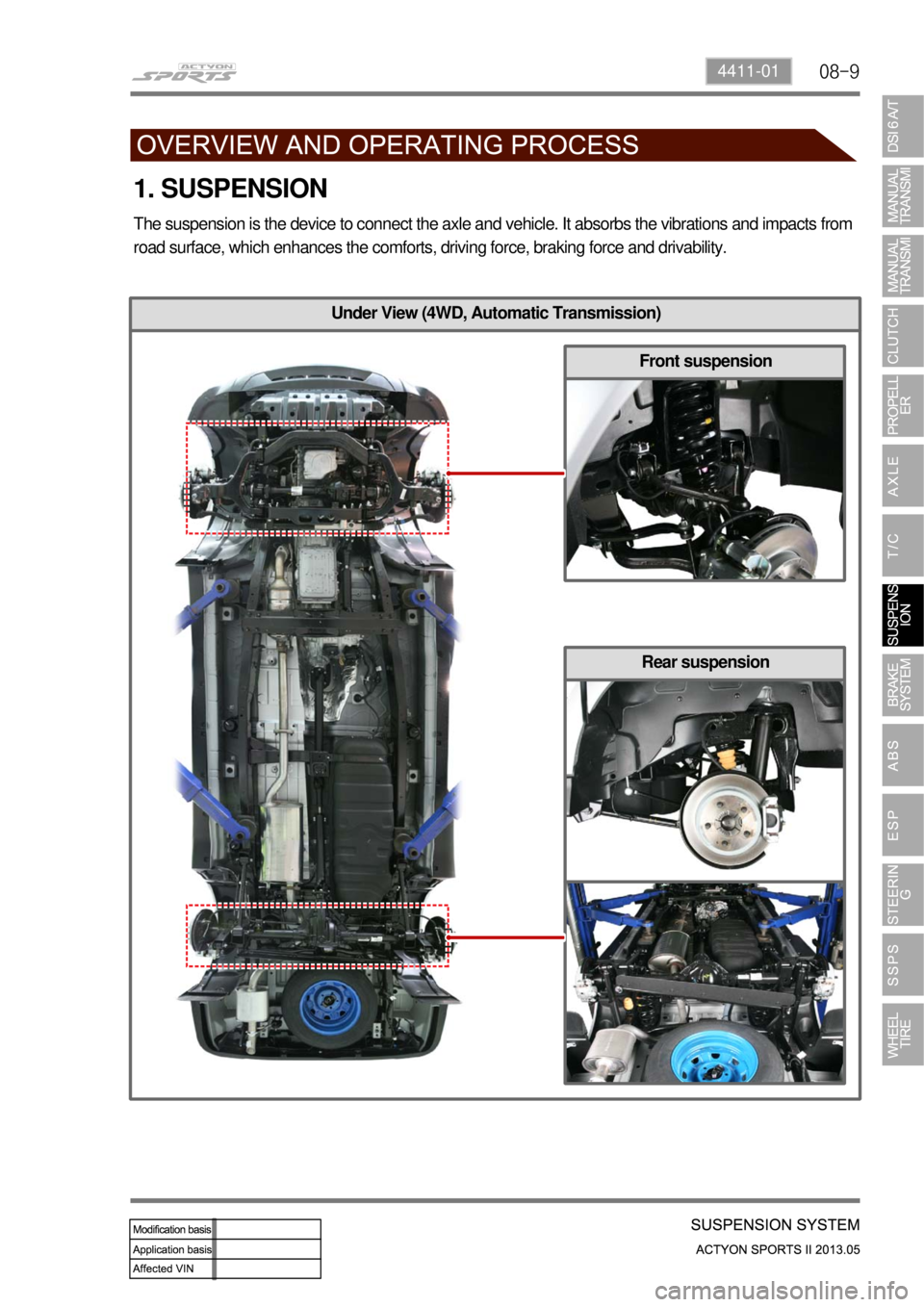

08-94411-01

Under View (4WD, Automatic Transmission)

Rear suspension

1. SUSPENSION

The suspension is the device to connect the axle and vehicle. It absorbs the vibrations and impacts from

road surface, which enhances the comforts, driving force, braking force and drivability.

Front suspension

Page 547 of 751

08-10

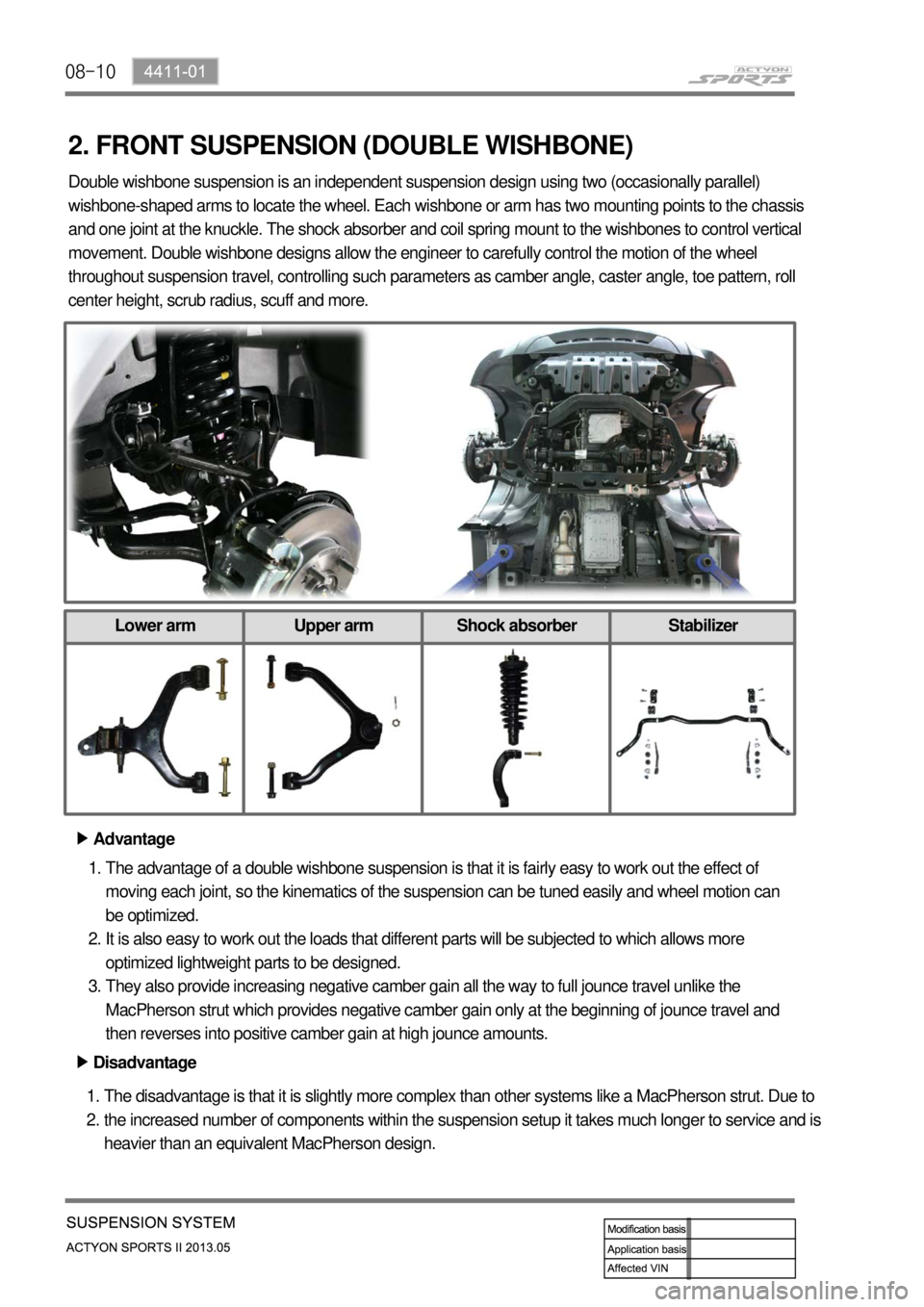

2. FRONT SUSPENSION (DOUBLE WISHBONE)

Advantage ▶

The advantage of a double wishbone suspension is that it is fairly easy to work out the effect of

moving each joint, so the kinematics of the suspension can be tuned easily and wheel motion can

be optimized.

It is also easy to work out the loads that different parts will be subjected to which allows more

optimized lightweight parts to be designed.

They also provide increasing negative camber gain all the way to full jounce travel unlike the

MacPherson strut which provides negative camber gain only at the beginning of jounce travel and

then reverses into positive camber gain at high jounce amounts. 1.

2.

3.

Disadvantage ▶

The disadvantage is that it is slightly more complex than other systems like a MacPherson strut. Due to

the increased number of components within the suspension setup it takes much longer to service and is

heavier than an equivalent MacPherson design. 1.

2. Double wishbone suspension is an independent suspension design using two (occasionally parallel)

wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis

and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical

movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel

throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll

center height, scrub radius, scuff and more.

Lower arm Upper arm Shock absorber Stabilizer

Page 548 of 751

08-114411-01

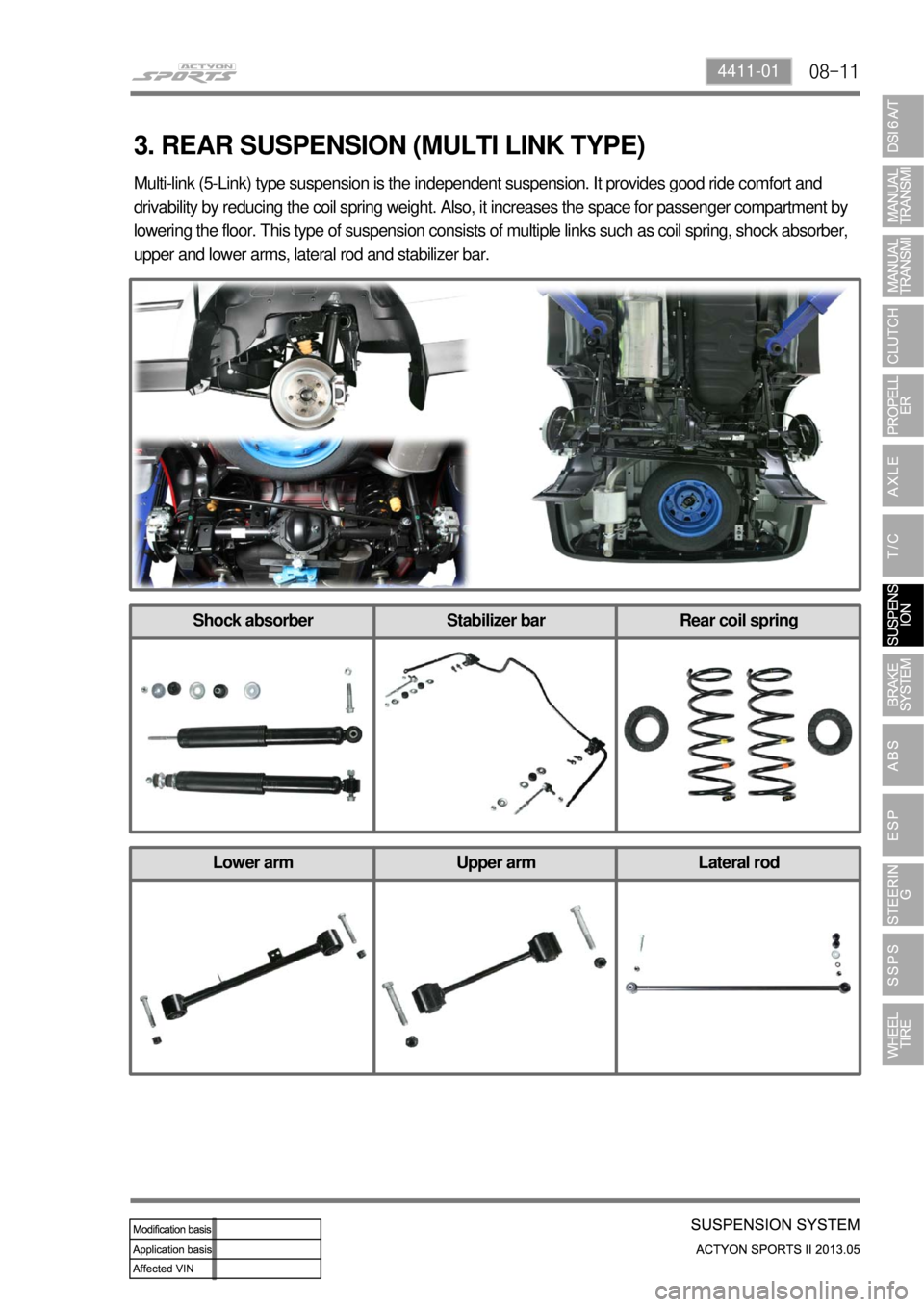

3. REAR SUSPENSION (MULTI LINK TYPE)

Multi-link (5-Link) type suspension is the independent suspension. It provides good ride comfort and

drivability by reducing the coil spring weight. Also, it increases the space for passenger compartment by

lowering the floor. This type of suspension consists of multiple links such as coil spring, shock absorber,

upper and lower arms, lateral rod and stabilizer bar.

Shock absorber Stabilizer bar Rear coil spring

Lower arm Upper arm Lateral rod

Page 550 of 751

08-134411-01

2) Camber

The angle between the center line of the tire and the vertical line when viewed from the front of the

vehicle

Positive camber: Top of the tire is tilted outward ▶

Advantages: The axle is not bent when it is loaded.

The force required to operate the steering wheel is reduced due to smaller

contact area (or load area) of the tire.

Restoring force of the steering wheel is gained (when turning the steering

wheel, the tire circles and the force to lift the frame is applied. In this case,

the shock absorber contracts and the restoration force is applied to the

steering wheel.) -

-

-

Disadvantages:Cornering force decreases as the positive camber increases when the

vehicle makes turn.

The hub bearing is worn unevenly if camber is excessive. -

-

Zero camber: When the tire center line is perpendicular to the ground level ▶

Negative camber ▶

Advantages:

Better traction force due to wide load area (applicable for off-road vehicle)

Better corner driving when the vehicle makes turn as the cornering force

increases (applicable for high-speed F1 vehicle) -

-

Disadvantages:

he axle is easy to be bent or deviated in the negative camber than in the

positive camber when load is applied on the axle.

Difficult to control due to wide load area. -

-

Camber

-0.5 ± 0.25°

Page 553 of 751

09-4

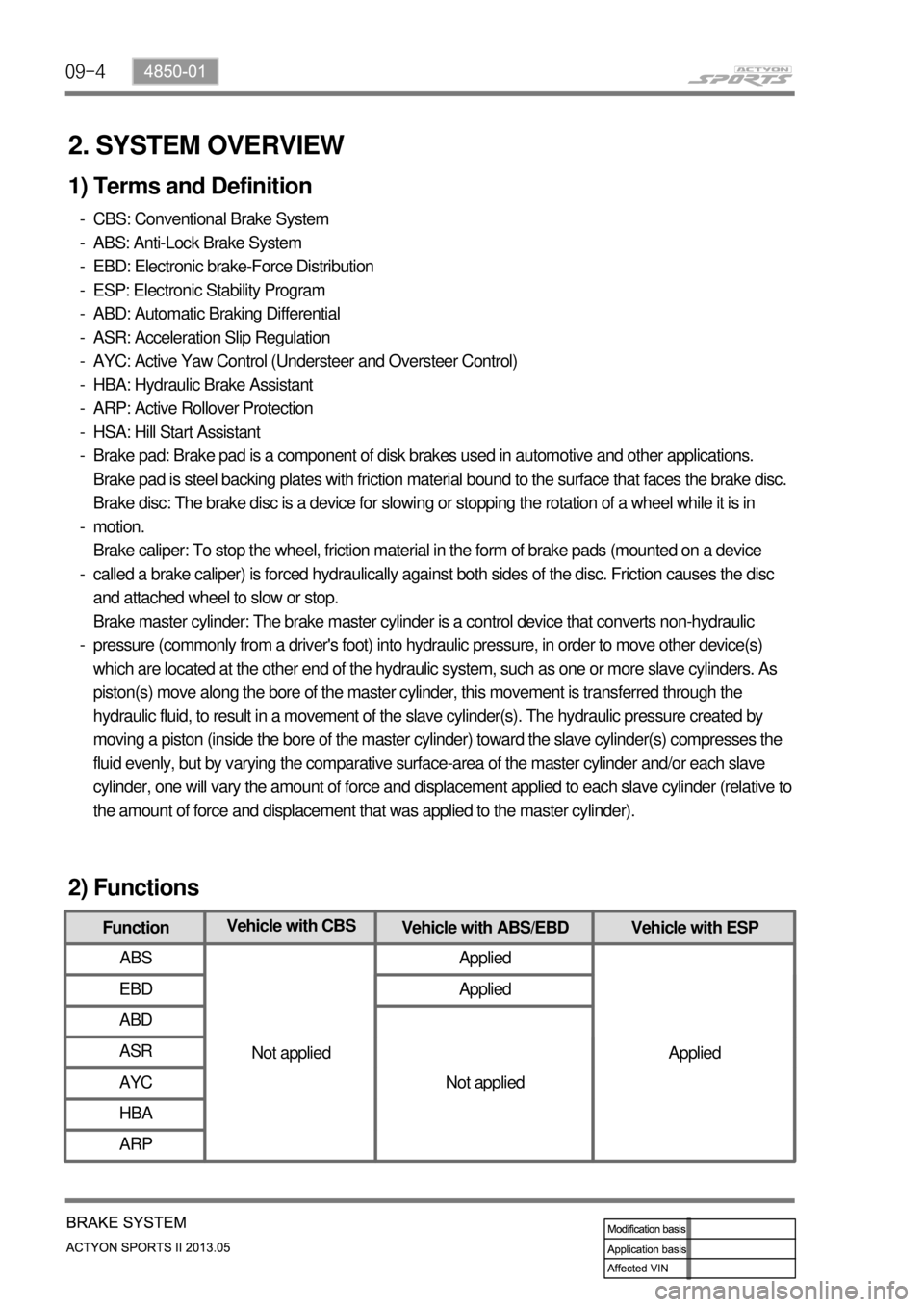

2. SYSTEM OVERVIEW

1) Terms and Definition

CBS: Conventional Brake System

ABS: Anti-Lock Brake System

EBD: Electronic brake-Force Distribution

ESP: Electronic Stability Program

ABD: Automatic Braking Differential

ASR: Acceleration Slip Regulation

AYC: Active Yaw Control (Understeer and Oversteer Control)

HBA: Hydraulic Brake Assistant

ARP: Active Rollover Protection

HSA: Hill Start Assistant

Brake pad: Brake pad is a component of disk brakes used in automotive and other applications.

Brake pad is steel backing plates with friction material bound to the surface that faces the brake disc.

Brake disc: The brake disc is a device for slowing or stopping the rotation of a wheel while it is in

motion.

Brake caliper: To stop the wheel, friction material in the form of brake pads (mounted on a device

called a brake caliper) is forced hydraulically against both sides of the disc. Friction causes the disc

and attached wheel to slow or stop.

Brake master cylinder: The brake master cylinder is a control device that converts non-hydraulic

pressure (commonly from a driver's foot) into hydraulic pressure, in order to move other device(s)

which are located at the other end of the hydraulic system, such as one or more slave cylinders. As

piston(s) move along the bore of the master cylinder, this movement is transferred through the

hydraulic fluid, to result in a movement of the slave cylinder(s). The hydraulic pressure created by

moving a piston (inside the bore of the master cylinder) toward the slave cylinder(s) compresses the

fluid evenly, but by varying the comparative surface-area of the master cylinder and/or each slave

cylinder, one will vary the amount of force and displacement applied to each slave cylinder (relative to

the amount of force and displacement that was applied to the master cylinder). -

-

-

-

-

-

-

-

-

-

-

-

-

-

FunctionVehicle with CBS

Vehicle with ABS/EBD Vehicle with ESP

ABS

Not appliedApplied

Applied EBD Applied

ABD

Not applied ASR

AYC

HBA

ARP

2) Functions