SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

NEW ACTYON SPORTS 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57512/w960_57512-0.png

SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

Page 38 of 751

02-70000-00

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping away

from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

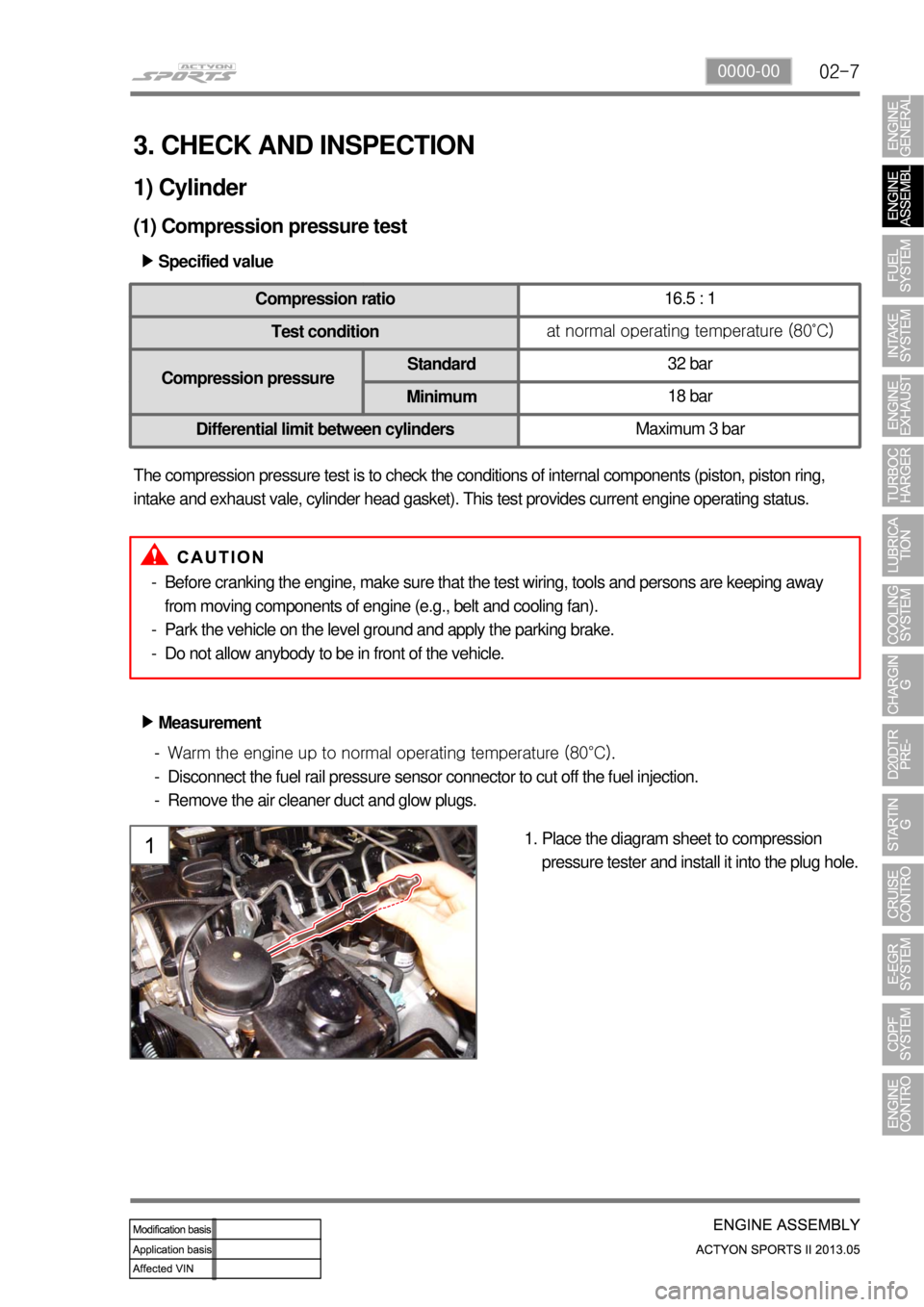

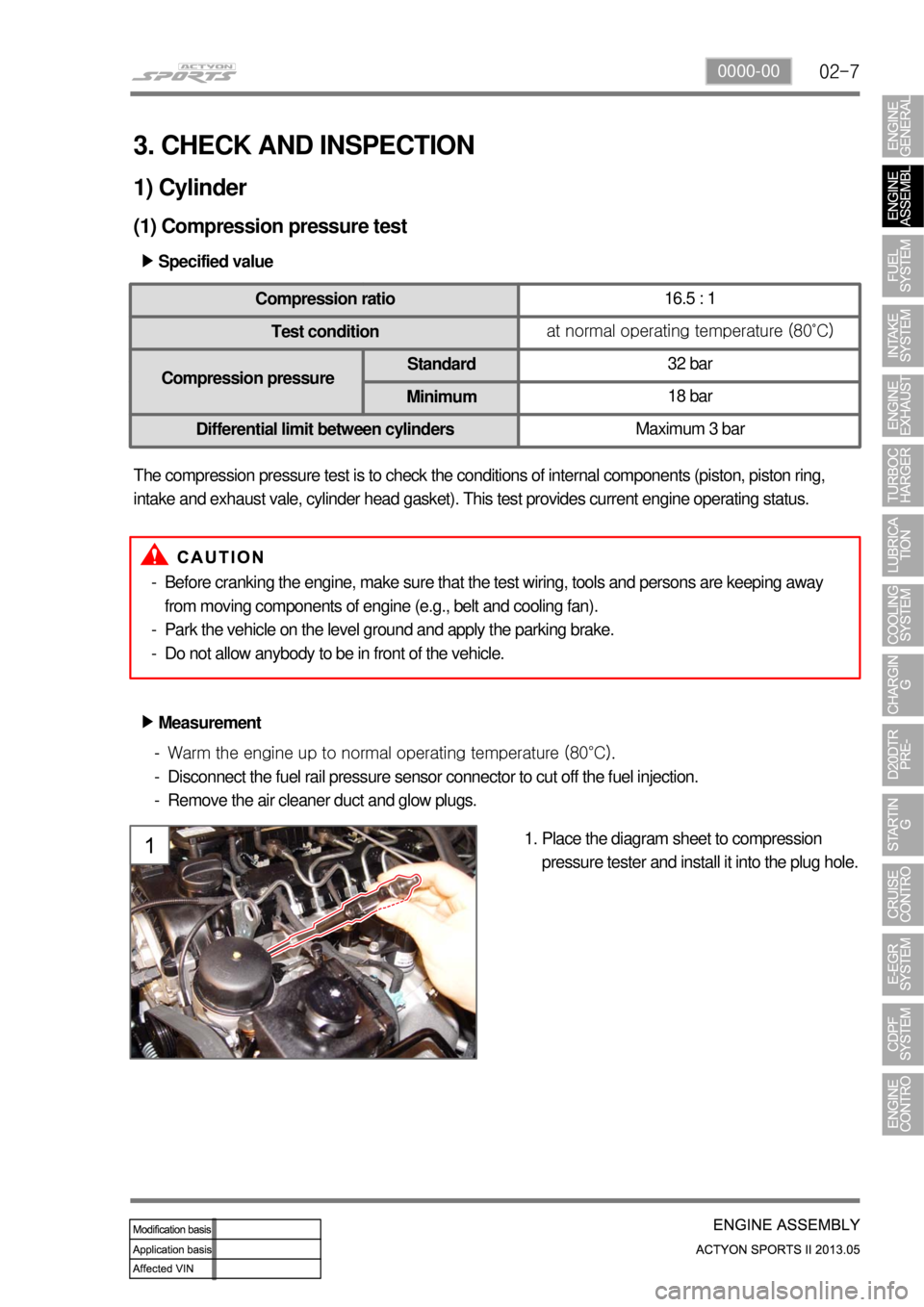

Measurement ▶

<007e0088009900940047009b008f008c0047008c0095008e00900095008c0047009c00970047009b00960047009500960099009400880093004700960097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c00

47004f005f005700b6006a00500055>

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug hole. 1.

Page 98 of 751

03-212210-01

1. OVERVIEW

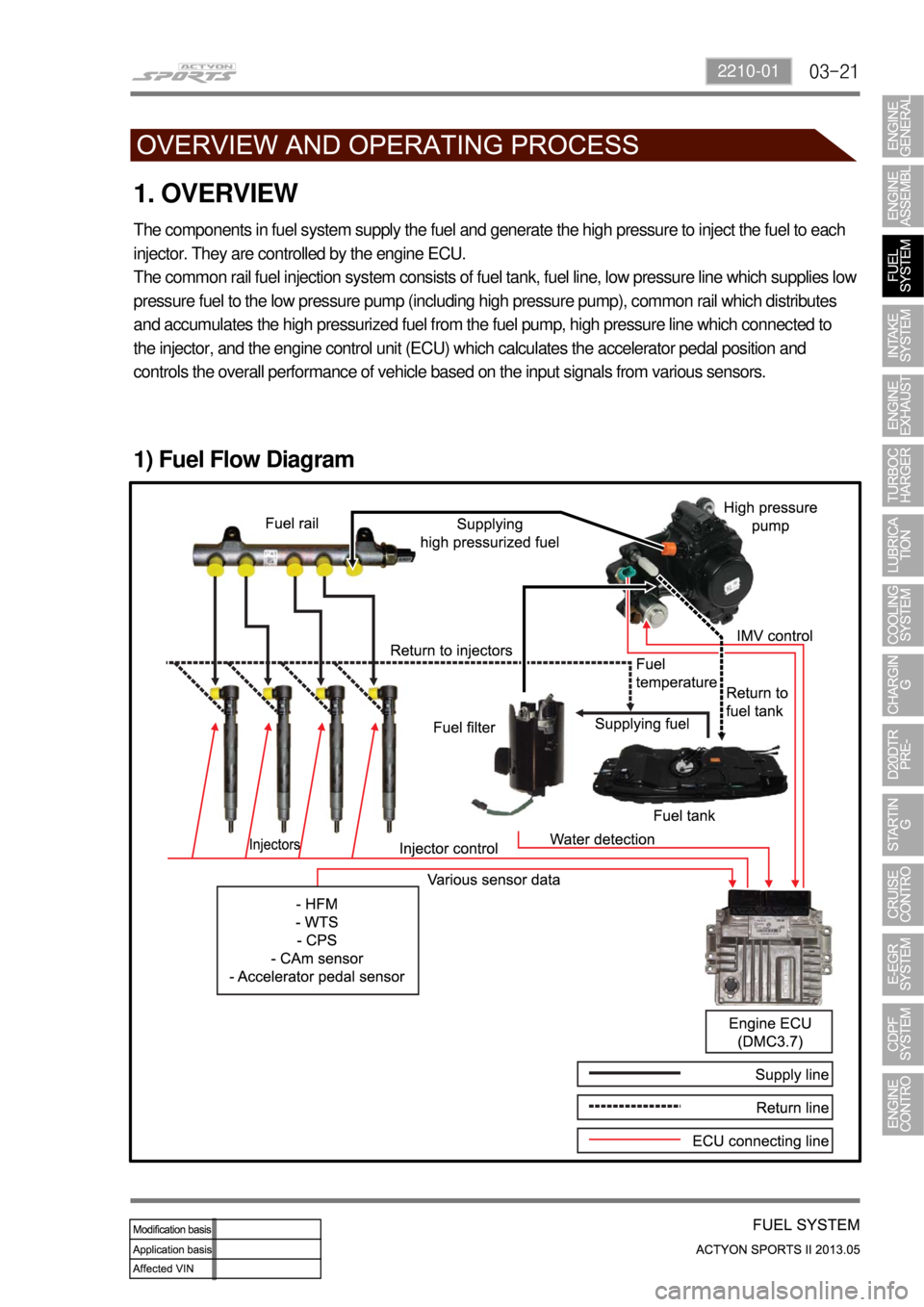

The components in fuel system supply the fuel and generate the high pressure to inject the fuel to each

injector. They are controlled by the engine ECU.

The common rail fuel injection system consists of fuel tank, fuel line, low pressure line which supplies lo

w

pressure fuel to the low pressure pump (including high pressure pump), common rail which distributes

and accumulates the high pressurized fuel from the fuel pump, high pressure line which connected to

the injector, and the engine control unit (ECU) which calculates the accelerator pedal position and

controls the overall performance of vehicle based on the input signals from various sensors.

1) Fuel Flow Diagram

Page 101 of 751

03-24

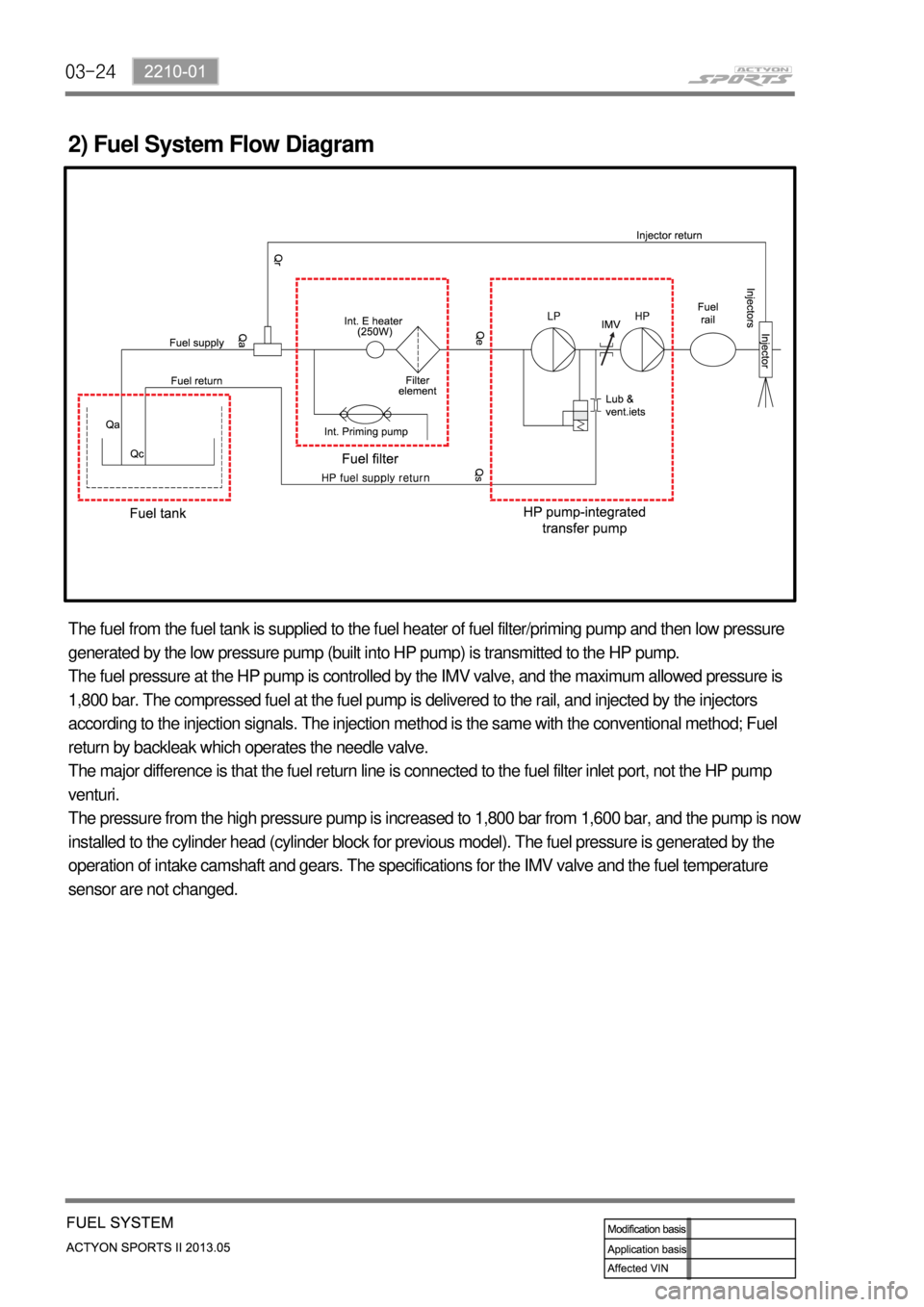

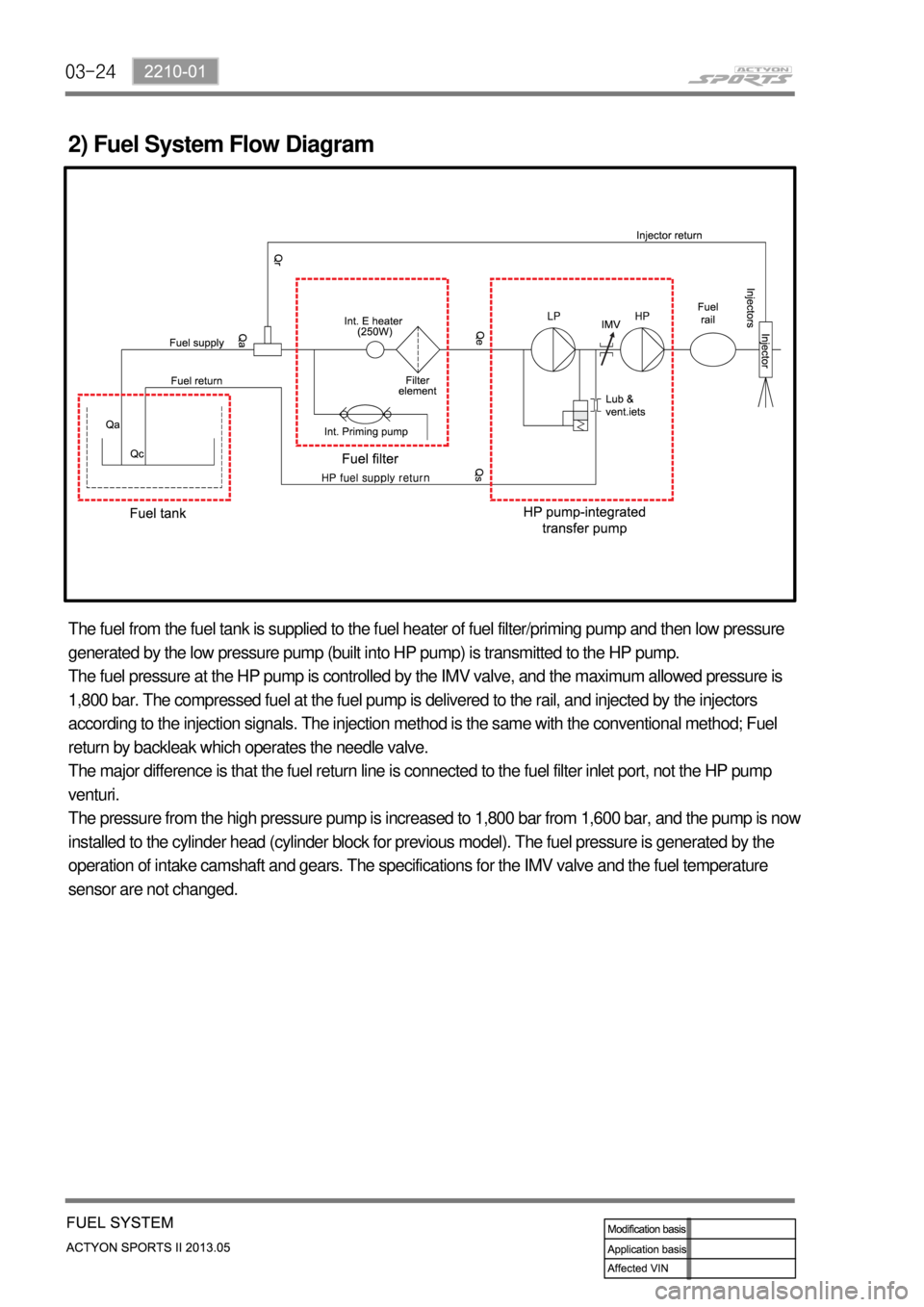

2) Fuel System Flow Diagram

The fuel from the fuel tank is supplied to the fuel heater of fuel filter/priming pump and then low pressure

generated by the low pressure pump (built into HP pump) is transmitted to the HP pump.

The fuel pressure at the HP pump is controlled by the IMV valve, and the maximum allowed pressure is

1,800 bar. The compressed fuel at the fuel pump is delivered to the rail, and injected by the injectors

according to the injection signals. The injection method is the same with the conventional method; Fuel

return by backleak which operates the needle valve.

The major difference is that the fuel return line is connected to the fuel filter inlet port, not the HP pump

venturi.

The pressure from the high pressure pump is increased to 1,800 bar from 1,600 bar, and the pump is now

installed to the cylinder head (cylinder block for previous model). The fuel pressure is generated by the

operation of intake camshaft and gears. The specifications for the IMV valve and the fuel temperature

sensor are not changed.

Page 158 of 751

09-131451-01

3. CIRCUIT DIAGRAM

Page 161 of 751

10-51413-00

2. SYSTEM OPERATION

1) Input/Output Diagram of Glow Plug Control Unit

2) System Diagram

Page 162 of 751

Page 170 of 751

Page 173 of 751

12-58510-23

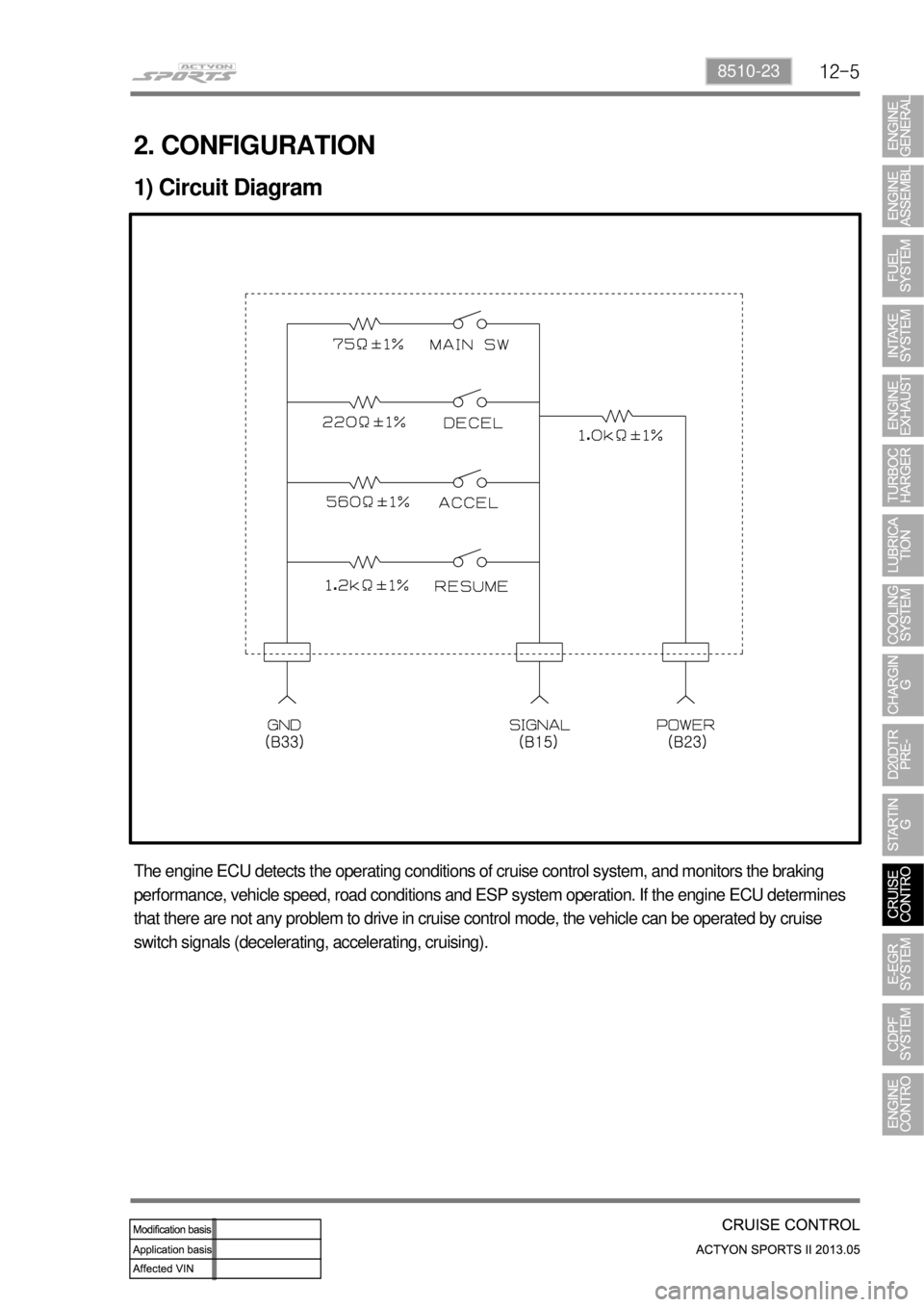

2. CONFIGURATION

1) Circuit Diagram

The engine ECU detects the operating conditions of cruise control system, and monitors the braking

performance, vehicle speed, road conditions and ESP system operation. If the engine ECU determines

that there are not any problem to drive in cruise control mode, the vehicle can be operated by cruise

switch signals (decelerating, accelerating, cruising).

Page 184 of 751

13-6

2. OPERATING PROCESS

1) Schematic Diagram

Page 202 of 751

14-18

6. ELECTRIC CIRCUIT DIAGRAM