ABS SSANGYONG NEW ACTYON SPORTS 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 600 of 751

10-20

6. HYDRAULIC CIRCUIT OF ABS

1) Normal Brake Operation (ABS is not working) Mode

If the driver depress the brake pedal so that the ABS does not operate, the hydraulic pressure in the

master cylinder increases through the vacuum booster and it is delivered to the wheel via the normal

open inlet valve. At this moment, the normally-closed outlet valve is closed The speed of the wheel that

hydraulic pressure is delivered reduces gradually.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Open

OFF

Outlet valve - Normal close (NC) valve Close

Page 601 of 751

10-214892-01

2) DUMP (ABS is working) Mode

Even when the hydraulic pressure on each circuit is constant, the wheel can be locked as the wheel

speed decreases. This is when the ABS HECU detects the wheel speed and the vehicle speed and

gives the optimized braking without locking the wheels. In order to prevent the hydraulic pressure from

increasing, the inlet valve will be closed, the outlet valve will be opened and the oil will flow into the low

pressure chamber. In addition, the ABS HECU operates the pump to circulate the oil in the low pressure

chamber to the master cylinder. This may make the driver to feel the brake pedal vibration and some

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Close

ON

Outlet valve - Normal close (NC) valve Open

Page 602 of 751

10-22

3) HOLD (ABS is working) Mode

As hydraulic pressure on each wheel increases, the wheel tends to lock. In order to prevent the wheel

from locking, the hydraulic valve modulator operates the inlet valve control solenoid to stop increasing

the hydraulic pressure by closing the inlet valve. At this moment, the outlet valve is closed. This

procedure helps the wheel to maintain a constant hydraulic pressure.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Close

OFF

Outlet valve - Normal close (NC) valve Close

Page 603 of 751

10-234892-01

4) RISE (ABS is working) Mode

As the wheel speed increases, the inlet valve opens and the wheel's pressure increases due to the

master cylinder pressure. In addition, the pump circulates the oil in the low pressure chamber to the

wheel. As the hydraulic pressure to the wheel increases, the wheel speed will reduce. This operation

continues repetitively until there are no signs that the ABS HECU tends to lock the wheels. Since the

ABS hydraulic pressure control process takes place repeatedly for a short time, there may be some

vibration and noises at the brake pedal.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Open

ON

Outlet valve - Normal close (NC) valve Close

Page 605 of 751

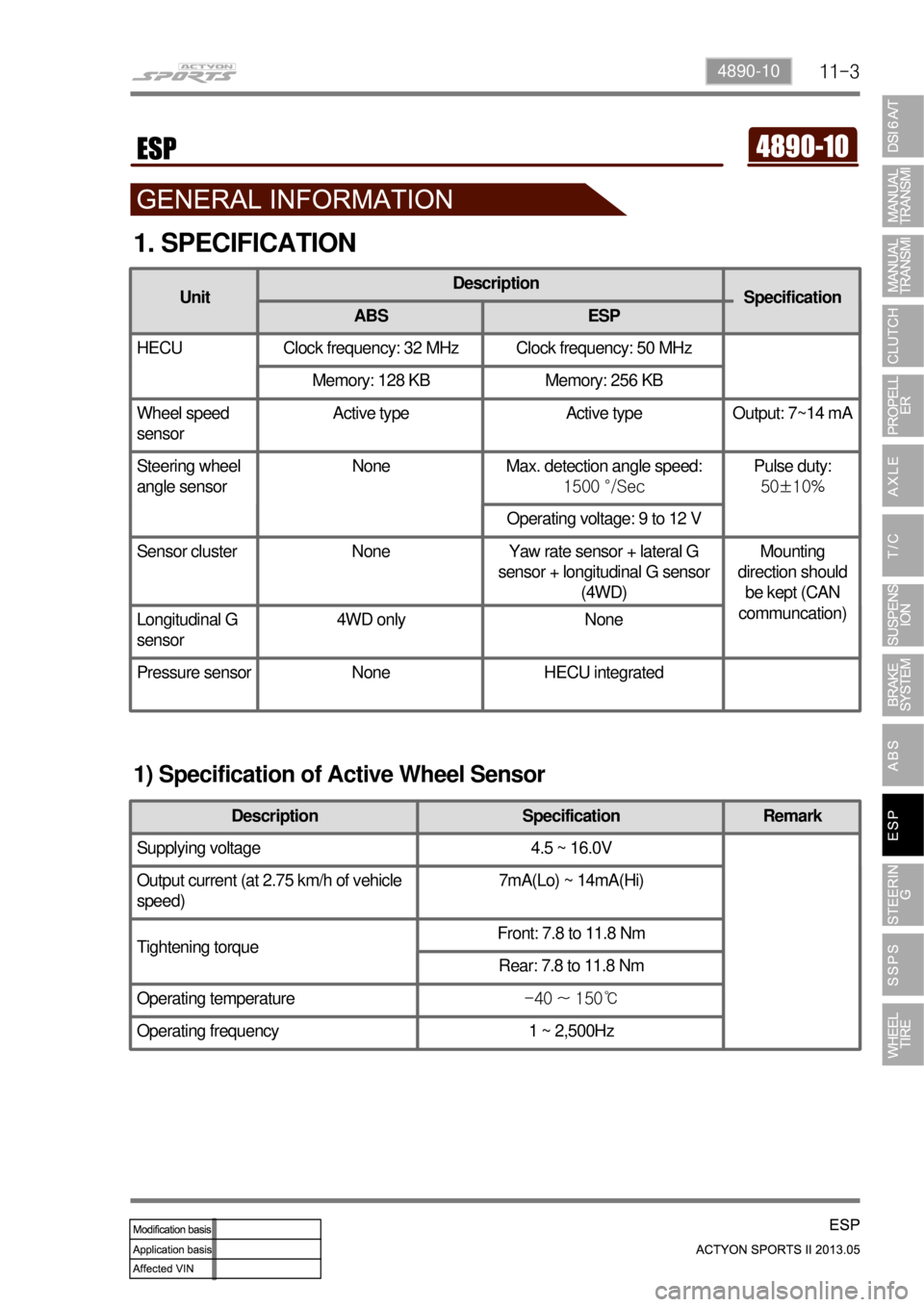

11-34890-10

1. SPECIFICATION

1) Specification of Active Wheel Sensor

Description Specification Remark

Supplying voltage 4.5 ~ 16.0V

Output current (at 2.75 km/h of vehicle

speed)7mA(Lo) ~ 14mA(Hi)

Tightening torqueFront: 7.8 to 11.8 Nm

Rear: 7.8 to 11.8 Nm

Operating temperature-40 ~ 150℃

Operating frequency 1 ~ 2,500Hz

UnitDescription

Specification

ABS ESP

HECU Clock frequency: 32 MHz Clock frequency: 50 MHz

Memory: 128 KB Memory: 256 KB

Wheel speed

sensorActive type Active type Output: 7~14 mA

Steering wheel

angle sensorNone Max. detection angle speed:

1500 °/SecPulse duty:

50±10%

Operating voltage: 9 to 12 V

Sensor cluster None Yaw rate sensor + lateral G

sensor + longitudinal G sensor

(4WD)Mounting

direction should

be kept (CAN

communcation)

Longitudinal G

sensor4WD only None

Pressure sensor None HECU integrated

Page 612 of 751

11-10

3. FUNCTION

1) Term Definition

ABS: Anti-Lock Brake System ▶

When the brake pedal is abruptly depressed, the HECU calculates the slip ratio of each wheel based on

information received from the wheel speed sensors and controls the hydraulic module data quickly and

precisely in order to maintain the friction between the road surface and tire optimal (static friction).

Therefore, by keeping the friction between the road surface and tire optimal, it is possible to obtain

following effects: Enhanced steering stability, improved direction stability, reduced stopping distance and

etc.

EBD: Electronic brake-Force Distribution ▶

This is to detect the tire speed from the wheel speed sensor in order to supply the braking pressure to

the rear tires individually. In other words, the HECU measures the tire deceleration speed continuously

and controls the rear inlet valve on the hydraulic modulator to obtain optimal braking force as much as

possible. Thereby, stopping distance, braking effect and straight stability are improved.

ESP: Electronic Stability Program ▶

This is used to make the vehicle stabilized to recognize the emergency driving conditions, and to control

the brake for each wheels and the engine power when the brake system or acceleration will not work

any more in dangerous circumstances.

TCS: Traction Control System ▶

When the wheel is slipping due to an excessive engine torque while starting off or driving, this controls

the driving force (braking force + engine torque) in order to prevent the wheel from slipping through the

engine or brake control.

AYC: Active Yaw Control ▶

This has been developed to help a driver avoid danger of losing control of the vehicle stability due to

understeer or oversteer during cornering, which is a part of the ESP function.

HBA: Hydraulic Brake Assistant ▶

Developed based on the fact that elderly drivers depress the brake pedal too soft even when hard

braking is necessary, this an assist system to operate the HECU drive motor immediately and apply high

braking force to the wheels when the brake pedal is depressed softly and the vehicle should be braked

in emergency.

ARP: Active Rollover Protection ▶

This is a supplementary device for safety in ESP system and can help minimize the rollover accidents by

detecting a potential rollover situation through the brake and engine control when making sudden lane

change or turning sharply by adding only the software, without any separate device or switch.

Page 613 of 751

11-114890-10

2) Component Overview By System

3) Part Overview By System

Part Vehicle with ABS Vehicle with ESP

HECU

Yes Yes Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator lamp

G sensor (integrated in HECU) 4WD: Yes, 2WD: No No

Sensor cluster (Yaw rate sensor +

lateral sensor+ G sensor)

No Yes ESP operation indicator lamp and

warning lamp

ESP OFF switch and indicator

Steering wheel angle sensor

Function Vehicle with ABS Vehicle with ESP

ABS Yes

Yes EBD Yes

HBA

No

ARP

Page 614 of 751

11-12

4. PRECAUTIONS

The warning lamp flashes and warning beep sounds when the ESP is operating

When the ESP operates during vehicle movement, the ESP warning lamp on the instrument panel

flashes and beep comes on every 0.1 second. The ESP system is only a supplementary device for

comfortable driving. When the vehicle exceeds its physical limits, it cannot be controlled.

Do not rely on the system. Keep on the safe driving.

Feeling when ESP is working

When the ESP system activates, the feeling can be different depending on vehicle driving

conditions.

For example, you will feel differently when the ESP system is activated during the ABS is operating

with the brakes applied and when the brakes are not applied on a curve.

If the ESP system operates when the brake is applied, the brake pressure will be increased on the

corresponding wheel which already has braking pressure for the ESP controls.

ARP Operation

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus,

stronger engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the driver

must take caution for the vehicle may drift away from the lane.

Noise and vibration that driver feels when ESP system is operating

The ESP system may transfer noise and vibration to the driver due to the pressure changes caused

by the motor and valve operations in a very short period of time. And, keep in mind that the output

and vehicle speed could be decreased without rpm increase due to the ASR function that controls

the engine power.

Page 615 of 751

11-134890-10

5. WARNING LAMPS

1) ABS Warning Lamp

ABS warning lamp module indicates the self diagnosis and malfunction.

ABS warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp comes on for 3 seconds for

self diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When disengaging the connector, the warning lamp comes on.

ABS is not available during lamp ON. In this condition, Only normal brake system without ABS

function is available.

When the communication between warning lamp CAN module in meter cluster, the warning

lamp comes on. 1.

2.

3.

4.

5.ABS warning lamp

Brake warning lamp

ESP OFF indicator

ESP warning lamp/indicator

EBD warning lamp 1.

2.

3.

4.

5.

Page 616 of 751

11-14

2) EBD (Electronic Brake-force Distribution) Warning Lamp (Brake

Warning Lamp)

EBD warning lamp when the system perform the self diagnosis and when it detects the malfunction of

EBD system. However, the brake warning lamp comes on regardless of EBD when the parking brake is

applied.

EBD warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp and the brake warning lamp

comes on for 3 seconds for self diagnosis and goes off if the system is OK (initialization mode).

When applying the parking brake, the brake warning lamp comes on.

When the brake fluid is not sufficient, the brake warning lamp comes on.

When disengaging the connector, the warning lamp comes on.

When the system is defective, ABS warning lamp and the brake warning lamp come on

simultaneously. 1.

2.

3.

4.

5.

When the solenoid valve is defective

When one or more wheel sensors are defective

When ABS HECU is defective

When the voltage is abnormal

When valve relay is defective a.

b.

c.

d.

e.

When the communication between warning lamp CAN module in meter cluster, the warning

lamp comes on. 6.

3) ESP OFF Indicator

ESP OFF indicator ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for self

diagnosis and goes off if the system is OK (initialization mode).

When the ESP OFF switch is pressed to turn off ESP function, ESP OFF indicator comes on. 1.

2.

4) ESP Warning Lamp

ESP warning lamp ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for

self diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When the ESP function is activated, ESP warning lamp blinks with the interval of 2 Hz.

When the communication between warning lamp CAN module in meter cluster, the warning lamp

comes on. 1.

2.

3.

4.

5.

5) ESP OFF Switch

If ESP OFF switch is pressed, ESP function is deactivated and the ESP OFF indicator in the instrument

cluster comes on.

To resume the ESP function, press the switch again. At this time, ESP OFF indicator goes out.